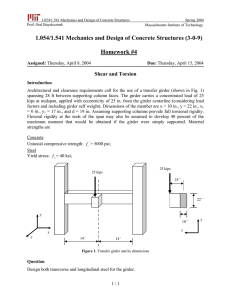

Steel Structures

advertisement