Maxwell Technologies, Inc.

3888 Calle Fortunada

San Diego, CA 92123

January 20 th , 2016

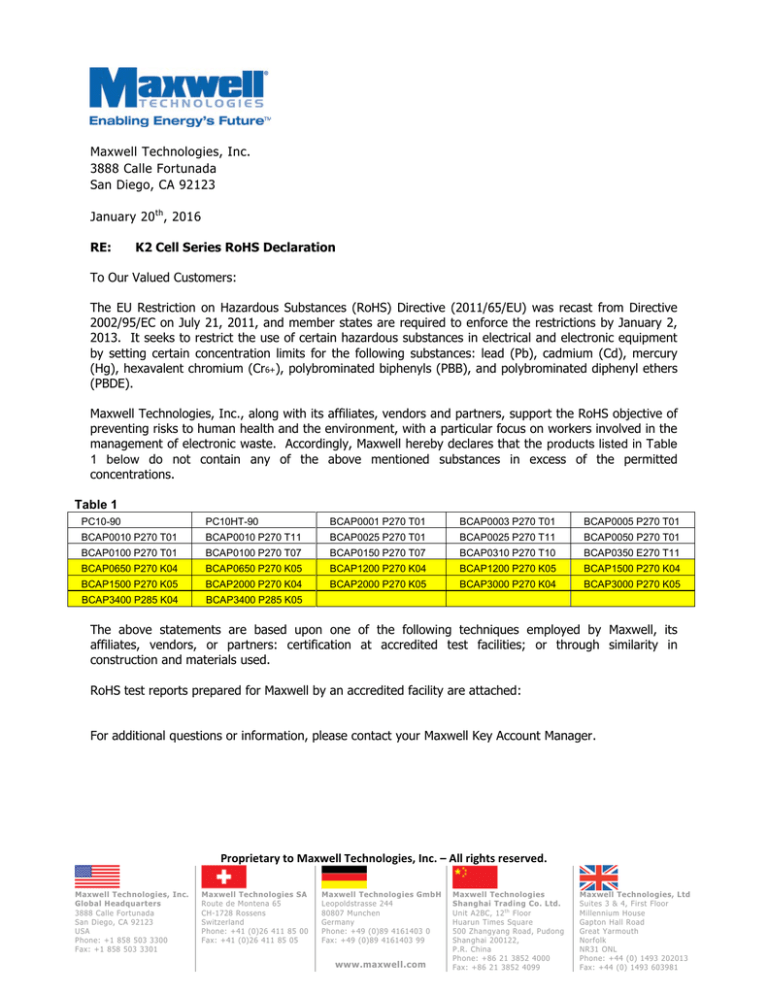

RE:

K2 Cell Series RoHS Declaration

To Our Valued Customers:

The EU Restriction on Hazardous Substances (RoHS) Directive (2011/65/EU) was recast from Directive

2002/95/EC on July 21, 2011, and member states are required to enforce the restrictions by January 2,

2013. It seeks to restrict the use of certain hazardous substances in electrical and electronic equipment

by setting certain concentration limits for the following substances: lead (Pb), cadmium (Cd), mercury

(Hg), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), and polybrominated diphenyl ethers

(PBDE).

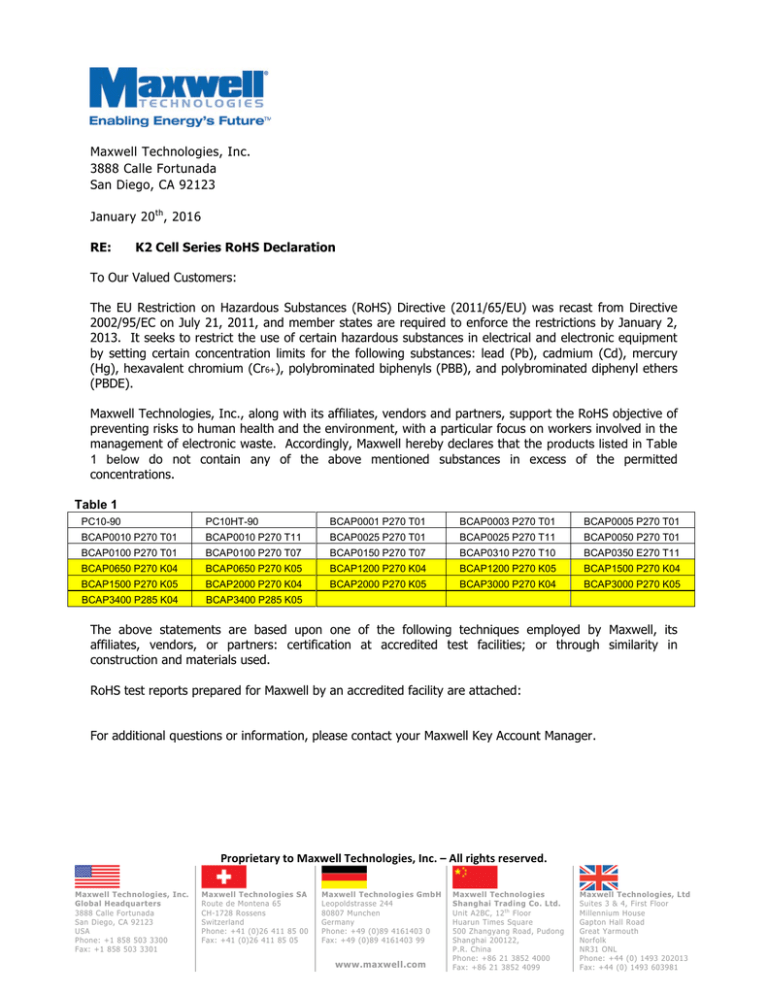

Maxwell Technologies, Inc., along with its affiliates, vendors and partners, support the RoHS objective of

preventing risks to human health and the environment, with a particular focus on workers involved in the

management of electronic waste. Accordingly, Maxwell hereby declares that the products listed in Table

1 below do not contain any of the above mentioned substances in excess of the permitted

concentrations.

Table 1

PC10-90

PC10HT-90

BCAP0001 P270 T01

BCAP0003 P270 T01

BCAP0005 P270 T01

BCAP0010 P270 T01

BCAP0010 P270 T11

BCAP0025 P270 T01

BCAP0025 P270 T11

BCAP0050 P270 T01

BCAP0100 P270 T01

BCAP0100 P270 T07

BCAP0150 P270 T07

BCAP0310 P270 T10

BCAP0350 E270 T11

BCAP0650 P270 K04

BCAP0650 P270 K05

BCAP1200 P270 K04

BCAP1200 P270 K05

BCAP1500 P270 K04

BCAP1500 P270 K05

BCAP2000 P270 K04

BCAP2000 P270 K05

BCAP3000 P270 K04

BCAP3000 P270 K05

BCAP3400 P285 K04

BCAP3400 P285 K05

The above statements are based upon one of the following techniques employed by Maxwell, its

affiliates, vendors, or partners: certification at accredited test facilities; or through similarity in

construction and materials used.

RoHS test reports prepared for Maxwell by an accredited facility are attached:

For additional questions or information, please contact your Maxwell Key Account Manager.

Proprietary to Maxwell Technologies, Inc. – All rights reserved.

Maxwell Technologies, Inc.

Global Headquarters

3888 Calle Fortunada

San Diego, CA 92123

USA

Phone: +1 858 503 3300

Fax: +1 858 503 3301

Maxwell Technologies SA

Route de Montena 65

CH-1728 Rossens

Switzerland

Phone: +41 (0)26 411 85 00

Fax: +41 (0)26 411 85 05

Maxwell Technologies GmbH

Leopoldstrasse 244

80807 Munchen

Germany

Phone: +49 (0)89 4161403 0

Fax: +49 (0)89 4161403 99

www.maxwell.com

Maxwell Technologies

Shanghai Trading Co. Ltd.

Unit A2BC, 12 th Floor

Huarun Times Square

500 Zhangyang Road, Pudong

Shanghai 200122,

P.R. China

Phone: +86 21 3852 4000

Fax: +86 21 3852 4099

Maxwell Technologies, Ltd

Suites 3 & 4, First Floor

Millennium House

Gapton Hall Road

Great Yarmouth

Norfolk

NR31 ONL

Phone: +44 (0) 1493 202013

Fax: +44 (0) 1493 603981

Environmental Services

Test Report No.:

Page 1 of 8

31272032.002

Client:

Maxwell Technologies

9244 Balboa Ave San Diego, CA 92123 US

Test Item:

Material samples for analysis

See material list

Identification:

Models 650F - 3400F

Delivery Condition:

apparent good

Testing Location:

TÜV Rheinland of North America

2709 SE Otis Corley Dr, Suite 11 Bentonville, AR 72712 USA

Test Specification:

Directive 2011/65/EU on the restriction of the use of certain hazardous

substances in electrical and electronic equipment (RoHS)

Date of Receipt:

7/16/2012

Following the guidelines for Analysis IEC 62321

Test Result:

The above described test object was tested and passed to the abovementioned test specification.

Tested by:

Checked by:

Drew Dumas

Laboratory Technician

7/23/2012

Date

Name

Signature

Mark Smith

Laboratory Manager

3/10/2014

Date

Name

Signature

Other Aspects:

Test Method: IEC 62321:2008

Components were evaluated using one or more of the following methods:

XOS XRF Screening, Wet chemical analysis, or Manufacturer RoHS compliance mark/documentation.

This test report relates to the a. m. test sample. Without permission of the test center this test report is not

permitted to be duplicated in extracts. This test report does not entitle to carry any safety mark on this or similar

products.

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

Page 2 of 8

31272032.002

1. Testing Date(s):

7/18/2012 - 7/23/2012

2. Test Results – Models 1200F & 3000F

Material List

1200F Model

Material Number

Material Description

10

45

Electrode, carbon/foil

Paper Separator

25,50,65

Metal Lid/collector negative and positive

35

Can

30

Rubber gasket o-ring

20

70

Insulation Ring

Tape, Polyimide, partially glued, width

15mm

Plug, Aluminum, Fill-Port

80

Barcode Label

40

Heat Shrink

75

EPDM Plug

15

3000F Model

Material Number

Material Description

90

Label, K2 Plastic

10

45

Electrode, carbon/foil

Tape, Polyimide, partially glued, width

15mm

Paper Separator

30

Rubber gasket o-ring

20

Insulation Ring

35

Can

25,50,65

Metal Lid/collector negative and positive

80

Barcode Label

70

Plug, Aluminum, Fill-Port

75

EPDM Plug

15

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

Page 3 of 8

31272032.002

Report matrix for XRF Screening

1200F Model

Material No.

ppm [mg/kg]

Cd

Cr^

Pb

Hg

Br^

10a

ND

ND

ND

ND

ND

10b

ND

ND

10

ND

ND

45

ND

ND

ND

ND

ND

25,50,60

ND

ND

10

ND

ND

35

ND

ND

17

ND

ND

30

ND

41

22

ND

ND

20

ND

ND

ND

ND

ND

15

ND

ND

ND

ND

ND

75

ND

31

14

ND

ND

70

ND

ND

ND

ND

ND

40

ND

ND

ND

ND

ND

80

ND

ND

7.1

ND

ND

3000F Model

Material No.

ppm [mg/kg]

Cd

Cr^

Pb

Hg

Br^

90

ND

ND

ND

ND

ND

10

ND

ND

ND

ND

ND

15

ND

ND

ND

ND

ND

45

ND

ND

ND

ND

ND

30

ND

ND

ND

ND

ND

20

ND

ND

ND

ND

ND

35

ND

ND

ND

ND

ND

25,50,65

ND

23

15

ND

ND

75

ND

ND

ND

ND

ND

70

ND

ND

ND

ND

6.1

80

ND

ND

ND

ND

ND

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

Page 4 of 8

31272032.002

Remark:

1.

RED TEXT: These items are inconclusive by XRF-Screening and should be retested by chemical testing.

2.

NT = Not Tested (Bromine in Alloys)

3.

ND = Not Detected (less than limits of XRF detection)

4.

(WC) = See Wet Chemistry Results

Limits of Detection

(mg/kg)

Cr

Br

Cd

Hg

Pb

15

5

5

4

5

XRF Screening limits for different matrices

Materials

Metallic

Polymeric

Electronic

Components

Cr

PX

PX

Br

-PX

Unit(ppm)

Cd

Hg

Pb

PX F PXF PXF

PX F PXF PXF

PX

PX

PX F PXF PXF

Instrument

Supplier/Vendor

Model /

Type

X-ray Fluorescence Spectrometry

XOS

HD Prime

ICP-MS

Agilent Technologies Inc.

7700

GC-MS

Agilent Technologies Inc.

6890/5975

3. Sample Photos

See attachment

4. Exemptions

Annex III: Applications exempted from the restriction in Article 4(1)

1.

Mercury in single capped (compact) fluorescent lamps not exceeding (per burner):

a) For general lighting purposes < 30 W: 5 mg

Expires on 31 December 2011; 3,5 mg may be used per burner after 31 December 2011 until 31 December 2012; 2,5 mg

shall be used per burner after 31 December 2012

b) For general lighting purposes ≥ 30 W and < 50 W: 5 mg

Expires on 31 December 2011; 3,5 mg may be used per burner after 31 December 2011

c) For general lighting purposes ≥ 50 W and < 150 W: 5 mg

d) For general lighting purposes ≥ 150 W: 15 mg

e) For general lighting purposes with circular or square structural shape and tube diameter ≤ 17 mm

No limitation of use until 31 December 2011; 7 mg may be used per burner after 31 December 2011

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

31272032.002

Page 5 of 8

f)

g)

2.

3.

For special purposes: 5 mg

For general lighting purposes < 30 W with a lifetime equal or above 20 000 h: 3,5 mg

Expires on 31 December 2017

Mercury in double-capped linear fluorescent lamps for general lighting purposes not exceeding (per lamp):

a) Tri-band phosphor lamps

1. Tri-band phosphor with normal lifetime and a tube diameter < 9 mm (e.g. T2): 5 mg

Expires on 31 December 2011; 4 mg may be used per lamp after 31 December 2011

2. Tri-band phosphor with normal lifetime and a tube diameter ≥ 9 mm and ≤ 17 mm (e.g. T5): 5 mg

Expires on 31 December 2011; 3 mg may be used per lamp after 31 December 2011

3. Tri-band phosphor with normal lifetime and a tube diameter > 17 mm and ≤ 28 mm (e.g. T8): 5 mg

Expires on 31 December 2011; 3,5 mg may be used per lamp after 31 December 2011

4. Tri-band phosphor with normal lifetime and a tube diameter > 28 mm (e.g. T12): 5 mg

Expires on 31 December 2012; 3,5 mg may be used per lamp after 31 December 2012

5. Tri-band phosphor with long lifetime (≥ 25 000 h): 8 mg

Expires on 31 December 2011; 5 mg may be used per lamp after 31 December 2011

b) Mercury in other fluorescent lamps not exceeding (per lamp):

1. Linear halophosphate lamps with tube > 28 mm (e.g. T10 and T12): 10 mg

Expires on 13 April 2012

2. Non-linear halophosphate lamps (all diameters): 15 mg

Expires on 13 April 2016

3. Non-linear tri-band phosphor lamps with tube diameter > 17 mm (e.g. T9)

No limitation of use until 31 December 2011; 15 mg may be used per lamp after 31 December 2011

4. Lamps for other general lighting and special purposes (e.g. induction lamps)

No limitation of use until 31 December 2011; 15 mg may be used per lamp after 31 December 2011

Mercury in cold cathode fluorescent lamps and external electrode fluorescent lamps (CCFL and EEFL) for special purposes

not exceeding (per lamp):

a) Short length (≤ 500 mm)

No limitation of use until 31 December 2011; 3,5 mg may be used per lamp after 31 December 2011

b) Medium length (> 500 mm and ≤ 1500 mm)

No limitation of use until 31 December 2011; 5 mg may be used per lamp after 31 December 2011

c) Long length (> 1500 mm)

No limitation of use until 31 December 2011; 13 mg may be used per lamp after 31 December 2011

4.

a)

b)

c)

d)

e)

f)

Mercury in other low pressure discharge lamps (per lamp)

No limitation of use until 31 December 2011; 15 mg may be used per lamp after 31 December 2011

Mercury in High Pressure Sodium (vapor) lamps for general lighting purposes not exceeding (per burner) in lamps with

improved color rendering index Ra > 60:

I. P ≤ 155 W

No limitation of use until 31 December 2011; 30 mg may be used per burner after 31 December 2011

II. 155 W < P ≤ 405 W

No limitation of use until 31 December 2011; 40 mg may be used per burner after 31 December 2011

III. P > 405 W

No limitation of use until 31 December 2011; 40 mg may be used per burner after 31 December 2011

Mercury in other High Pressure Sodium (vapor) lamps for general lighting purposes not exceeding (per burner):

i. P ≤ 155 W

No limitation of use until 31 December 2011; 25 mg may be used per burner after 31 December 2011

ii. 155 W < P ≤ 405 W

No limitation of use until 31 December 2011; 30 mg may be used per burner after 31 December 2011

iii. P > 405 W

No limitation of use until 31 December 2011; 40 mg may be used per burner after 31 December 2011

Mercury in High Pressure Mercury (vapor) lamps (HPMV)

Expires on 13 April 2015

Mercury in metal halide lamps (MH)

Mercury in other discharge lamps for special purposes not specifically mentioned in this Annex

5.

a)

b)

Lead in glass of cathode ray tubes

Lead in glass of fluorescent tubes not exceeding 0,2 % by weight

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

31272032.002

Page 6 of 8

6.

a)

b)

c)

Lead as an alloying element in steel for machining purposes and in galvanized steel containing up to 0,35 % lead by

weight

Lead as an alloying element in aluminum containing up to 0,4 % lead by weight

Copper alloy containing up to 4 % lead by weight

7.

a)

b)

Lead in high melting temperature type solders (i.e. lead- based alloys containing 85 % by weight or more lead)

Lead in solders for servers, storage and storage array systems, network infrastructure equipment for switching, signaling,

transmission, and network management for telecommunications

c)

I.

II.

III.

IV.

Electrical and electronic components containing lead in a glass or ceramic other than dielectric ceramic in

capacitors, e.g. piezoelectric devices, or in a glass or ceramic matrix compound

Lead in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

Lead in dielectric ceramic in capacitors for a rated voltage of less than 125 V AC or 250 V DC

Expires on 1 January 2013 and after that date may be used in spare parts for EEE placed on the market before 1

January 2013

Lead in PZT based dielectric ceramic materials for capacitors which are part of integrated circuits or discrete

semiconductors

Expires on 21 July 2016

8.

a)

b)

Cadmium and its compounds in one shot pellet type thermal cut-offs

Expires on 1 January 2012 and after that date may be used in spare parts for EEE placed on the market before 1 January

2012

Cadmium and its compounds in electrical contacts

9.

a)

b)

Hexavalent chromium as an anticorrosion agent of the carbon steel cooling system in absorption refrigerators up to 0,75

% by weight in the cooling solution

Lead in bearing shells and bushes for refrigerant-containing compressors for heating, ventilation, air conditioning and

refrigeration (HVACR) applications

11.

a)

Lead used in C-press compliant pin connector systems

May be used in spare parts for EEE placed on the market before 24 September 2010

b) Lead used in other than C-press compliant pin connector systems

Expires on 1 January 2013 and after that date may be used in spare parts for EEE placed on the market before 1 January

2013

12. Lead as a coating material for the thermal conduction module C-ring

May be used in spare parts for EEE placed on the market before 24 September 2010

13.

a) Lead in white glasses used for optical applications

b) Cadmium and lead in filter glasses and glasses used for reflectance standards

14. Lead in solders consisting of more than two elements for the connection between the pins and the package of microprocessors

with a lead content of more than 80 % and less than 85 % by weight

Expired on 1 January 2011 and after that date may be used in spare parts for EEE placed on the market before 1 January

2011

15. Lead in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit flip

chip packages

16. Lead in linear incandescent lamps with silicate coated tubes

Expires on 1 September 2013

17. Lead halide as radiant agent in high intensity discharge (HID) lamps used for professional reprography applications

18.

a) Lead as activator in the fluorescent powder (1 % lead by weight or less) of discharge lamps when used as specialty

lamps for diazoprinting reprography, lithography, insect traps, photochemical and curing processes containing phosphors

such as SMS ((Sr,Ba) 2 MgSi 2 O 7 :Pb)

Expired on 1 January 2011

b) Lead as activator in the fluorescent powder (1 % lead by weight or less) of discharge lamps when used as sun tanning

lamps containing phosphors such as BSP (BaSi 2 O 5 :Pb)

19. Lead with PbBiSn-Hg and PbInSn-Hg in specific compositions as main amalgam and with PbSn-Hg as auxiliary amalgam in

very compact energy saving lamps (ESL)

Expires on 1 June 2011

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

31272032.002

Page 7 of 8

20. Lead oxide in glass used for bonding front and rear substrates of flat fluorescent lamps used for Liquid Crystal Displays (LCDs)

Expires on 1 June 2011

21. Lead and cadmium in printing inks for the application of enamels on glasses, such as borosilicate and soda lime glasses

23. Lead in finishes of fine pitch components other than connectors with a pitch of 0,65 mm and less

May be used in spare parts for EEE placed on the market before 24 September 2010

24. Lead in solders for the soldering to machine through hole discoidal and planar array ceramic multilayer capacitors

25. Lead oxide in surface conduction electron emitter displays (SED) used in structural elements, notably in the seal frit and frit

ring

26. Lead oxide in the glass envelope of black light blue lamps

Expires on 1 June 2011

27. Lead alloys as solder for transducers used in high-powered (designated to operate for several hours at acoustic power levels

of 125 dB SPL and above) loudspeakers

Expired on 24 September 2010

29. Lead bound in crystal glass as defined in Annex I (Categories 1, 2, 3 and 4) of Council Directive 69/493/EEC ( 1 )

30. Cadmium alloys as electrical/mechanical solder joints to electrical conductors located directly on the voice coil in transducers

used in high-powered loudspeakers with sound pressure levels of 100 dB (A) and more

31. Lead in soldering materials in mercury free flat fluorescent lamps (which, e.g. are used for liquid crystal displays, design or

industrial lighting)

32. Lead oxide in seal frit used for making window assemblies for Argon and Krypton laser tubes

33. Lead in solders for the soldering of thin copper wires of 100 μm diameter and less in power transformers

34. Lead in cermet-based trimmer potentiometer elements

36. Mercury used as a cathode sputtering inhibitor in DC plasma displays with a content up to 30 mg per display

Expired on 1 July 2010

37. Lead in the plating layer of high voltage diodes on the basis of a zinc borate glass body

38. Cadmium and cadmium oxide in thick film pastes used on aluminum bonded beryllium oxide

39. Cadmium in color converting II-VI LEDs (< 10 μg Cd per mm 2 of light-emitting area) for use in solid state illumination or

display systems

Expires on 1 July 2014

40. Cadmium in photoresistors for analogue optocouplers applied in professional audio equipment

Expires on 31 December 2013

Annex IV: restrictions specific to medical devices and monitoring and control instruments

Equipment utilizing or detecting ionizing radiation

1. Lead, cadmium and mercury in detectors for ionizing radiation.

2. Lead bearings in X-ray tubes.

3. Lead in electromagnetic radiation amplification devices: micro-channel plate and capillary plate.

4. Lead in glass frit of X-ray tubes and image intensifiers and lead in glass frit binder for assembly of gas lasers and for vacuum

tubes that convert electromagnetic radiation into electrons.

5. Lead in shielding for ionizing radiation.

6. Lead in X-ray test objects.

7. Lead stearate X-ray diffraction crystals.

8. Radioactive cadmium isotope source for portable X-ray fluorescence spectrometers.

Sensors, detectors and electrodes

1a.

1b.

1c.

1d.

Others

9.

10.

11.

12.

Lead and cadmium in ion selective electrodes including glass of pH electrodes.

Lead anodes in electrochemical oxygen sensors.

Lead, cadmium and mercury in infra-red light detectors.

Mercury in reference electrodes: low chloride mercury chloride, mercury sulphate and mercury oxide.

Cadmium in helium-cadmium lasers.

Lead and cadmium in atomic absorption spectroscopy lamps.

Lead in alloys as a superconductor and thermal conductor in MRI.

Lead and cadmium in metallic bonds creating superconducting magnetic circuits in MRI, SQUID, NMR (Nuclear Magnetic

Resonance) or FTMS (Fourier Transform Mass Spectrometer) detectors. Expires on 30 June 2021.

13. Lead in counterweights.

14. Lead in single crystal piezoelectric materials for ultrasonic transducers.

15. Lead in solders for bonding to ultrasonic transducers.

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

Environmental Services

Test Report No.:

Page 8 of 8

31272032.002

16. Mercury in very high accuracy capacitance and loss measurement bridges and in high frequency RF switches and relays in

monitoring and control instruments not exceeding 20 mg of mercury per switch or relay.

17. Lead in solders in portable emergency defibrillators.

18. Lead in solders of high performance infrared imaging modules to detect in the range 8-14 μm.

19. Lead in Liquid crystal on silicon (LCoS) displays.

20. Cadmium in X-ray measurement filters.

21. Cadmium in phosphor coatings in image intensifiers for X-ray images until 31 December 2019 and in spare parts for X-ray

systems placed on the EU market before 1 January 2020.

22. Lead acetate marker for use in stereotactic head frames for use with CT and MRI and in positioning systems for gamma beam

and particle therapy equipment. Expires on 30 June 2021.

23. Lead as an alloying element for bearings and wear surfaces in medical equipment exposed to ionizing radiation. Expires on 30

June 2021.

24. Lead enabling vacuum tight connections between aluminum and steel in X-ray image intensifiers. Expires on 31 December

2019.

25. Lead in the surface coatings of pin connector systems requiring nonmagnetic connectors which are used durably at a

temperature below – 20 °C under normal operating and storage conditions. Expires on 30 June 2021.

26. Lead in

solders on printed circuit boards,

termination coatings of electrical and electronic components and coatings of printed circuit boards,

solders for connecting wires and cables,

solders connecting transducers and sensors,

that are used durably at a temperature below – 20 °C under normal operating and storage conditions.

Expires on 30 June 2021.

27. Lead in

solders,

termination coatings of electrical and electronic components and printed circuit boards,

connections of electrical wires, shields and enclosed connectors,

which are used in

a) magnetic fields within the sphere of 1 m radius around the isocentre of the magnet in medical magnetic resonance

imaging equipment, including patient monitors designed to be used within this sphere, or

b) magnetic fields within 1 m distance from the external surfaces of cyclotron magnets, magnets for beam transport and

beam direction control applied for particle therapy.

Expires on 30 June 2020.

28. Lead in solders for mounting cadmium telluride and cadmium zinc telluride digital array detectors to printed circuit boards.

Expires on 31 December 2017.

29. Lead in alloys, as a superconductor or thermal conductor, used in cryo-cooler cold heads and/or in cryo-cooled cold probes

and/or in cryo-cooled equipotential bonding systems, in medical devices (category 8) and/or in industrial monitoring and control

instruments. Expires on 30 June 2021.

30. Hexavalent chromium in alkali dispensers used to create photocathodes in X-ray image intensifiers until 31 December 2019

and in spare parts for X-ray systems placed on the EU market before 1 January 2020.

31. Lead, cadmium and hexavalent chromium in reused spare parts, recovered from medical devices placed on the market before

22 July 2014 and used in category 8 equipment placed on the market before 22 July 2021, provided that reuse takes place in

auditable closed-loop business-to-business return systems, and that the reuse of parts is notified to the consumer. Expires on

21 July 2021.

32. Lead in solders on printed circuit boards of detectors and data acquisition units for Positron Emission Tomographs which are

integrated into Magnetic Resonance Imaging equipment. Expires on 31 December 2019.

33. Lead in solders on populated printed circuit boards used in Directive 93/42/EEC class IIa and IIb mobile medical devices other

than portable emergency defibrillators. Expires on 30 June 2016 for class IIa and on 31 December 2020 for class IIb.

34. Lead as an activator in the fluorescent powder of discharge lamps when used for extracorporeal photopheresis lamps

containing BSP (BaSi 2 O 5 :Pb) phosphors. Expires on 22 July 2021.

-End of Report-

TÜV Rheinland of North America Bentonville, AR Office 2709 SE Otis Corley Dr U.S.A.

Tel.: 479-250-0060 Fax: 479-254-0821 Mail: msmith@us.tuv.com Web: www.us.tuv.com

File: 31272032.002

10b

RoHS Testing Points

10a

45

Model 1200F

Model 1200F

25,50,65

Model 1200F

35

Model 1200F

20

30

Model 1200F

15

Model 1200F

75

Model 1200F

70

Model 1200F

40

Model 1200F

80

Model 1200F

File: 31272032.002

RoHS Testing Points

Front side of wrap

90b

90a

Model 3000F

Model 3000F

Back side of wrap

90c

Model 3000F

10b

10a

Model 3000F

15

45

Model 3000F

20

30

Model 3000F

35

Model 3000F

25,50,65

Model 3000F

75

Model 3000F

70

Model 3000F

80

Model 3000F