8-1 DIVISION 8 PAINTING SPECIFICATIONS 8.1 General 8.1.1

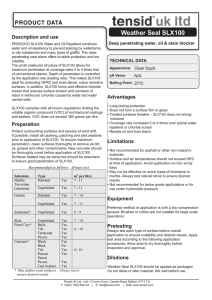

advertisement

DIVISION 8 PAINTING SPECIFICATIONS 8.1 General 8.1.1 Scope Contractor shall provide all labor, material, and equipment and perform all operations necessary for all painting work specified including the painting of concrete block walls, reinforced concrete walls, concrete slab floors, and exposed iron and steel work including pumping units, electrical switchgear, piping, valves, and miscellaneous metal. 8.1.2 Submittals Prior to beginning work, Contractor shall furnish to Owner the following: a. 8.2 A material list for all painting materials to be used. Said list shall include manufacturer's name, designation, description, color charts and related data. Materials 8.2.1 Contractor shall deliver all painting materials to the work site in original containers with seals and labels intact. Containers shall not be opened until after they have been inspected by Owner. 8.2.2 Painting materials for prime and finish coats shall be Koppers, Rust-Oleum, Frazee or FSC coatings, or approved equal. 8.2.3 Prepared material shall be used without cutting or diluting except as specified herein or as directed by manufacturer and approved by Owner. 8.3 Workmanship All work shall be done by thoroughly qualified painters in a neat and workmanlike manner. All work which shows carelessness or lack of skill in execution or is defective due to any other cause will be rejected. Said work shall be redone to satisfaction of Owner prior to acceptance of work. [4/08] 8-1 8.4 Application 8.4.1 Unless specified otherwise, paint shall be applied by brush or spray. Paint system shall have a dry film thickness of five (5) mils minimum, unless specified otherwise. 8.4.2 Paint shall be applied only on thoroughly clean and dry surfaces, unless specified otherwise. Paint shall not be applied in extreme heat, cold, damp or humid weather, or in dust- or smoke-laden air. 8.4.3 Paint materials shall be kept sealed or covered when not in use. Oily rags or waste shall be kept in covered containers and disposed of at frequent intervals. 8.4.4 If brushes are used, they shall have sufficient body and length of bristle to spread paint in a uniform coat. Paint shall be evenly spread and thoroughly brushed out and no residual brush marks shall remain. On surfaces which are inaccessible for brushing, paint shall be applied by spray, sheepskin daubers, or other means as approved by Owner. 8.4.5 If a spray method is used, the operator shall be thoroughly qualified in use of the equipment required. Air compressors employed in spray painting shall be equipped with suitable trapping devices to keep water, oil, and other impurities from entering air lines. Runs, sags, thin areas, or other imperfections in paint coat shall be considered as cause for rejection and Contractor shall be required to make all necessary corrections to satisfaction of Owner. 8.4.6 All exposed iron and steel work together with pumping units, electrical switchgear, piping, valves, and miscellaneous metal shall receive a prime coat(s), shop applied if possible, before installation. After installation, said materials shall be cleaned and all welds, tool marks, and other defects shall receive a touch-up prime coat. Said materials shall then receive two finish coats. 8.5 Paint Systems 8.5.1 Previously Uncoated Concrete Block Walls. [4/08] 8-2 8.5.1.1 All surface defects shall be repaired and surfaces shall be cured a minimum of seven (7) days thereafter. Surfaces shall then be cleaned with steam or with a commercial cleaner to remove all grease, oil, and chemical residues and then thoroughly rinsed with water. 8.5.1.2 The prime coat, Koppers Block Sealer, Rust-Oleum 5199 White Masonry Filler, FSC-Sealkreet, or Frazee Acrylic Block Filler #262, shall be applied according to manufacturer's recommendations. 8.5.1.3 The finish coat, Koppers 200 HB Epoxy, Rust-Oleum series 9300, or Frazee Duratec #202, shall be applied in the color specified and in sufficient quantity to achieve specified thickness. 8.5.1.4 Minimum drying time between prime coat and finish coat shall conform to the manufacturer's recommendations. 8.5.2 Previously Uncoated Reinforced Concrete Walls. 8.5.2.1 All surface defects shall be repaired and surfaces shall be cured a minimum of seven (7) days thereafter. Surfaces shall be cleaned with steam or with a commercial cleaner to remove all grease, oil, and chemical residues and then thoroughly rinsed with water. 8.5.2.2 The prime coat, Koppers Block Sealer, Rust-Oleum series 5199, FSC-Sealkreet, or Frazee Acrylic Block Filler #262, shall be applied according to manufacturer's recommendations. 8.5.2.3 The finish coat, Koppers 200 HB Epoxy, Rust-Oleum series 9300, or Frazee Duratec #202, shall be applied in the color specified and in sufficient quantity to achieve specified thickness. 8.5.2.4 Minimum drying time between prime coat and finish coat shall conform to the manufacturer's recommendations. [4/08] 8-3 8.5.3 Previously Coated Concrete or Masonry Walls. 8.5.3.1 Prior to any work, the existing paint shall be tested for compatibility by applying thinner, Koppers 10,000 or Rust-Oleum 160, to a small test portion of wall. If after 30 minutes the existing paint has begun to lift or wrinkle, manufacturer shall be consulted before performing any work. If the existing paint has not begun to lift or wrinkle, the paint system shall be applied as specified herein. 8.5.3.2 All surface defects shall be repaired and all surfaces shall be scraped to remove deteriorated coatings and other deleterious materials. Surfaces shall then be cleaned with steam or with a commercial cleaner to remove all grease, oil, and chemical residues. 8.5.3.3 The prime coat, Koppers Surfacer or Rust-Oleum 9391 Flat White, shall be applied to thoroughly dry surfaces. 8.5.3.4 The finish coat, Koppers 200 HB Epoxy or Rust-Oleum series 9300, shall be applied in the color specified and in sufficient quantity to achieve specified thickness. 8.5.3.5 Minimum drying time between prime coat and finish coat shall conform to manufacturer's recommendations. 8.5.4 Previously Uncoated Concrete Slab Floors. 8.5.4.1 All surface defects shall be repaired and surfaces shall be cured a minimum of 30 days. Floor shall be cleaned with etching solution, Rust-Oleum Surfa-Etch 108 (Rust-Oleum paint system only), and then thoroughly rinsed with water. 8.5.4.2 The prime coat, Koppers 200 HB Epoxy or Rust-Oleum series 9300, shall be applied to thoroughly dry surfaces (4 days minimum drying time) after it has been thinned approximately 25% with thinner, Koppers 10,000 or Rust-Oleum 160. [4/08] 8-4 8.5.4.3 The finish coat, Koppers 200 HB Epoxy or Rust-Oleum series 9300 with 1½ pounds pumice per gallon, shall be applied in the color specified and in sufficient quantity to achieve specified thickness. 8.5.4.4 Minimum drying time between prime coat and finish coat shall be 16 hours and minimum drying time before normal traffic shall be 24 hours. 8.5.5 Previously Coated Concrete Slab Floors. 8.5.5.1 Prior to any work, the existing paint shall be tested for compatibility by applying thinner, Koppers 10,000 or Rust-Oleum 160, to a small test portion of the floor. If after 30 minutes the existing paint has begun to lift or wrinkle, manufacturer shall be consulted before performing any work. If the existing paint has not begun to lift or wrinkle, the paint system shall be applied as specified herein. 8.5.5.2 All surface defects shall be repaired and allowed to dry thoroughly. Floor shall then be cleaned with commercial cleaner. 8.5.5.3 The prime coat, Koppers 200 HB Epoxy or Rust-Oleum series 9300, shall be applied to thoroughly dry surfaces. 8.5.5.4 The finish coat, Koppers 200 HB Epoxy or Rust-Oleum series 9300 with 1½ pounds pumice per gallon, shall be applied in the color specified and in sufficient quantity to achieve specified thickness. 8.5.5.5 Minimum drying time between prime coat and finish coat shall be 16 hours and minimum drying time before normal traffic shall be 24 hours. 8.5.6 Galvanized Metal [4/08] 8-5 8.5.6.1 Surfaces shall be cleaned with commercial cleaner and dried thoroughly. Prior to using Koppers Coating System, treat galvanized metal with Koppers 30 Metal Conditioner; and prior to using Frazee Coating System, treat galvanized metal with Frazee Prep Wash #117. 8.5.6.2 The prime coat, Koppers 622 HB Rust Penetrating Primer, Rust-Oleum 3202 Undercoat, FSC ZeroRust Primer, or Frazee Metal Prime #661, shall be applied in one very thin coat. 8.5.6.3 The second prime coat, Frazee Super Bond #381 (Frazee Paint System only), shall be applied to thoroughly dry surfaces. 8.5.6.4 The finish coat(s), Koppers Rustarmor 500 HB, Rust-Oleum New Color Horizons System, FSC-SA3 Silicone ALKYD (gloss enamel), or Frazee Duratec #202, shall be applied in the color specified in sufficient quantity to achieve specified thickness (two coats minimum). 8.5.6.5 The first finish coat shall be applied between 1 and 24 hours after application of the primer. Minimum drying time between the two finish coats shall be 24 hours. 8.5.7 Bare Steel 8.5.7.1 Mill scale and rust shall be removed. Surfaces shall be cleaned with commercial cleaner and dried thoroughly. 8.5.7.2 The first prime coat, Koppers 662 HB Rust Penetrating Primer, Rust-Oleum X-60 Red Bare Metal Primer, FCS Zero-Rust Primer, or Frazee Metal Prime #661, shall be applied to thoroughly dry surfaces. 8.5.7.3 The second prime coat, Rust-Oleum 960 Zinc Chromate Primer (Rust-Oleum paint system only), or Frazee Super-Bond or #381 (Frazee Paint System only), shall be applied to thoroughly dry surfaces. [4/08] 8-6 8.5.7.4 The finish coat, Koppers Rustarmor 500 HB, Rust-Oleum New Color Horizons System, FSC SA-3 Silicone ALKYD (gloss enamel), or Frazee Duratec #202, shall be applied in the color specified and in sufficient quantity to achieve specified thickness (two coats minimum). 8.5.7.5 Minimum drying time between each coat shall be 24 hours. 8.5.8 Previously Painted Steel 8.5.8.1 Surfaces shall be cleaned with commercial cleaner and dried thoroughly. 8.5.8.2 Prior to any work, the Contractor shall test the existing paint for compatibility with the proposed paint system. If the existing paint begins to lift or wrinkle during the testing, the proposed paint manufacturer shall be consulted before performing any work. If the existing paint has not begun to lift or wrinkle, the proposed paint system shall be applied as specified herein. 8.5.8.3 All welds, tool marks, and bare spots shall be primed with Koppers 622 HB Rust Penetrating Primer, FSC Zero-Rust Primer, Frazee Metal Prime #661, Rust-Oleum 960 Zinc Chromate Primer, or Tnemec Series V10 Versare Primer, Modified Alkyd Rust-Inhibitive Primer. 8.5.8.4 The finish coat, Koppers Rustarmor 500 HB, Rust-Oleum New Color Horizons System, FSC SA-3 Silicone ALKYD (gloss enamel), Frazee Duratec #202, or Tnemec Series 28 Tufcryl Acrylic Polymer-Gloss, shall be applied in the color specified and in sufficient quantity to achieve specified thickness (two coats minimum). 8.5.8.5 Minimum drying time between each coat shall be 24 hours. 8.5.9 Previously Epoxied Steel Surfaces 8.5.9.1 All epoxied steel surfaces shall be sandblasted to “commercial blast-cleaned” metal to remove any rust or flaking epoxy coating. [4/08] 8-7 8.5.9.2 Prior to any work, the Contractor shall test the existing epoxy for compatibility with the proposed epoxy system. If the existing epoxy begins to lift or wrinkle during the testing, the proposed epoxy manufacturer shall be consulted before performing any work. If the existing epoxy has not begun to lift or wrinkle, the proposed epoxy system shall be applied as specified herein. 8.5.9.3 After surface preparation of the surfaces, the surfaces shall receive two coats of Tnemec Series 66 Hi-Build Epoxoline, Epoxy-Polyamide coating, and shall be applied in the color specified and in sufficient quantity to achieve the specified thickness (two coats minimum). 8.5.9.4 Minimum drying time between each coat shall be 24 hours. 8.6 Protection 8.6.1 Contractor shall protect freshly painted or epoxied surfaces from accumulation of dust, dirt, water, or other foreign materials, whatever the cause or source. Any damaged surfaces shall be wiped clean, sanded, or stripped to a clean, dry condition and recoated to satisfaction of Owner. 8.6.2 Contractor shall protect all parts of the work site during his operation. Tarps and cloths shall be placed where required to protect floors and equipment from spatter and droppings. Electric switchplates, lighting fixtures, nameplates, hardware, glass, vehicles, and all other items not to be painted or epoxied shall be removed, covered, or otherwise protected during coating operations. Contractor shall clean or otherwise restore any surfaces which are painted or epoxied as a result of Contractor's failure to provide proper protection and said restoration shall be performed to satisfaction of Owner. [4/08] 8-8