A New Calculation Method for Bode and Nyquist Diagrams of Rotor

advertisement

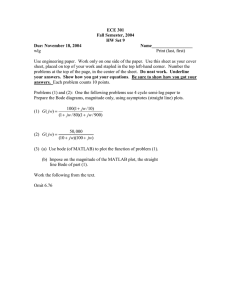

A New Calculation Method for Bode and Nyquist Diagrams of Rotor Startup or Shutdown and Its Application * First A. Xining Zhang, Second B. Jili Wu , Third C. Jinliang Guo , and Fourth D. Jinjie Xu Abstract—In order to prepare well for drawing Bode and Nyquist diagrams of vibration signals collected from rotor startup or shutdown process, a new Hilbert transform based calculation method is proposed. Experiment results show that the proposed method can smooth Bode and Nyquist diagrams, has more accuracy in amplitude and phase calculation, and also can not be affected by harmonic components of rotor vibration. Verifying tests on dynamic balancing experiment reveal that vibration values of rotor greatly reduce after balancing by using the information extracted form Bode and Nyquist diagrams. The vibration signal collected contains multiple frequency components,only fundamental frequency can reflect rotor balance, and its harmonic components mainly refelt the other fault of rotor,such as misalignment and crack. so the Bode and Nyqusit diagrams mentioned in the paper are just computed from fundamental component.Theoretically, we assume that the unbalanced mass will not change during startup and shutdown process, so the vibration response of fundamental component is continuous, then Bode and Nyqusit diagrams will be smooth curves. I. INTRODUCTION Generally to draw Bode and Nyquist diagrams, the vibration signals collected from startup or shutdown process could be preprocessed through tracking filters to keep fundamental frequency component and phase-lock-loop multiplier circuit to collect certain samples in each circle of rotor. In above processing, key phase signal is adopted in determining the rotor revolving frequency. Because the tracking filter and data sampling of current circle mainly depend on the period of previous circle, these hardware based methods work very well when the rotor speed changes smoothly[4-6]. But when the rotor speed changes sharply, such as the rotor getting through critical speed area, the performance could be less effective. And these methods which are highly hardware dependent are comparatively expensive. In the process of startup or shutdown, rotating machines experience a non-steady operating condition. Due to the variational speed , it is difficult to extract unbalancing features during this process. Only a few imbalance features can be obtained from stationary vibration signals. In fact, vibration signals corresponding to startup or shutdown process contain richer imbalance information, which can be extracted and utilized for dynamic balance[1]. Bode and Nyquist diagrams are significant monitoring and diagnosis methods used in rotating machinery[2-3].The analysis of Bode and Nyquist diagrams is particularly important for startup or shutdown of rotating machinery. In the non-stationary startup or shutdown process, the speed of rotating machinery experiences a increasing or inverse changing process, meanwhile the frequency of the centrifugal force produced by imbalance mass also experiences the same process.The fundamental component of vibration in startup or shutdown process is exactly corresponding to the vibration excited by centrifugal force. So Bode and Nyquist diagrams can well describe the vibration feature excited by centrifugal force. Therefore, balancing condition of machine can be monitored and analyzed by Bode and Nyquist diagrams analysis. This is particularly important for the machine that can not startup after shutdown. *Resrach supported by ABC Foundation. F. A. Xining Zhang is with Mechanical Engineering Department, Xi’an Jiaotong University, No.28, Xianning West Road, Xi’an, Shaanxi, 710049, P.R. China ( corresponding author to provide phone: 029-82669053; e-mail: zhangxining@ mail.xjtu.edu.cn). S. B. Jili Wu is with Mechanical Engineering Department, Xi ’an Jiaotong University, No.28, Xianning West Road, Xi’an, Shaanxi, 710049, P.R. China ( e-mail: wujili@stu.xjtu.edu.cn). T. C. Jinliang Guo is with Mechanical Engineering Department, Xi’an Jiaotong University, No.28, Xianning West Road, Xi’an, Shaanxi, 710049, P.R. China ( e-mail: 871196789@qq.com). F. D. Jinjie Xu is with Mechanical Engineering Department, Xi’an Jiaotong University, No.28, Xianning West Road, Xi’an, Shaanxi, 710049, P.R. China ( e-mail: 362948602@qq.com). In order to solve those problems, two traditional methods are introduced, which give priority to software processing instead of hardware. In the first traditional method, vibration signals are collected only at a number of predetermined speeds during rotor startup or shutdown process. Then Bode and Nyquist diagrams are drawn after amplitude and phase information of fundamental frequency of each vibration signal record are extracted with Fourier transform. The Bode and Nyquist diagrams drawn by this method not only suffer from low quality of smoothness of amplitude curve and phase curve, but also suffer from the influence of harmonic frequency components. In the second traditional method, vibration signals collected from startup or shutdown process are acquired continuously. Bode and Nyquist diagrams are drawn after frequency, amplitude and phase information of vibration signals corresponding to each rotor revolution are extracted directly in time domain. Though more smoother Bode and Nyquist diagrams can be obtained by this method than the former one, but the huge calculation volume and harmonic components influence make it infeasible in practice. In order to eliminate the harmonic components influence, Empirical Mode Decomposition(EMD) is introduced to extract the fundamental frequency component from the vibration signal to draw hologram Bode diagram [7-8]. The method is only effective for small accelerate range rotating machinery. In case of large accelerate range, for example, the fundamental frequency component of startup vibration is often broken into many small segments distributed in different intrinsic modes. Complete fundamental frequency component of startup process still can’t be obtained. A new approach for complete fundamental frequency component extracting from vibration signals collected from startup or shutdown process is presented in the paper. The application of Bode and Nyquist diagrams drawn by the proposed method in rotor dynamic balancing is given. Satisfactory balancing result is achieved, and rotor vibrations are greatly decreased. x1 (t ) Ae nt sin( n2 n 2 t ). The particular solution x2 (t ) which reveals steady vibration can be written as (3). The forced steady vibration during Startup or shutdown process is mainly considered in the paper. x2 (t ) X sin( t ) . The amplitude of vibration response written as follows. X= II. THE VIBRATION RESPONSE OF UNBALANCED ROTOR STARTUP OR SHUTDOWN PROCESS Bode and Nyquist diagrams are originally proposed to describe the frequency response characteristics of the system in automatic control area. Rotor is a typical second-order vibration system. Once a rotor is under the imbalance state, forced vibration will be excited by imbalance mass. Therefore, the fundamental frequency component of forced vibration in startup or shutdown process is used to describe the balancing condition of a rotor. And in the forced vibration, the phase of vibration vector(vibration response) always lags behind the unbalanced vector(unbalanced mass), when a rotor is at the speed of critical speed, the lagging phase is up to 90o, according to this feature, it is very useful to confirm the unbalanced angle by vibration phase in the Bode diagram at critical speed. So only the output(vibration response) is considered, the input(unbalanced mass) is unknown and to be solved, the output caused by the input can be measured by sensors. Therefore some features of the output could be recognized. (2) X can be further Xo (1 r ) (2 r )2 Xo 2 2 F meo 2 = k k arctan (3) 2 / n 1 ( / n )2 (4) (5) (6) r / n is frequency ratio, c 2m is damping ratio, X o is the displacement due to the static force F . is the phase of vibration response. Where, Where, X and are the function of frequency ratio and damping ratio.When =0.1 and F / k =1 ,Fig.2 shows characteristics curves of amplitude-frequency and phase-frequency in Bode diagram. Fig.1 shows a rotor system[9]. If only the horizontal direction vibration is considered, vibration of the rotor system could be described as(1). Figure 2. Bode diagram of vibration response of rotating frequency. Figure 1. Schematic of imbalance rotor. m x c x k x me 2 sin( t ) (1) Where, the mass of rotor is m, e is eccentric distance , c is damping coefficient, k is rotor stiffness, F is static force. The solution of (1) includes two parts: x1 (t ) and x2 (t ) . A general solution x1 (t ) which reveals damped transient vibration can be written as III. THE PRINCIPLE OF HILBERT TRANSFORMATION BASED BODE AND NYQUIST DIAGRAM CALCULATION The key of drawing Bode and Nyquist diagrams is to calculate the amplitude and phase of fundamental vibration components at each speed in the Startup or shutdown process. As the amplitude and the corresponding phase of transient vibration signal vary with time in the process. So Hilbert transformation is introduced to acquire them. For the sake of convenience, the amplitude curve and the phase curve against time, which are calculated by Hilbert transformation, are named as Hilbert amplitude curve and Hilbert phase curve of original vibration signal.Averaging the upper and lower envelop curves could weaken the effects of harmonic frequency, a another better method to eliminate the effects of harmonic frequency is the fractional fourier transform and a narrowband filtering in the fractional fourier domain[10]. Then the average curve of the upper and lower envelope curves is adopted as corrected Hilbert amplitude curve. Hilbert phase curve of vibration signal changes as a function of time, While the phase in Bode and Nyquist diagram is relative to the phase of keyphasor signal. So where needs a keyphase signal to realize the phase conversion. Specifically, on Hilbert phase curve, Phase values extracted relative to the key pulse of keyphasor signal are used to get a corrected change curve of phases by curve interpolation, the phases on the curve is relative to initial phase value of keyphasor signal at each sampling time. So far, the calculation steps of Bode and Nyquist diagrams can be summarized as follows: and 2. Horizontal and vertical vibrations at section B are measured by current eddy sensors 3 and 4. Two plates on the rotor shaft which are used for balance discs are marked as C and D. There are 24 evenly distributed screwed holes on each plate, which are used for adding balancing weight. Keyphasor signal is collected by eddy current sensor 5. Sensors 1 and 3 are defined as the direction X, while direction of sensors 2 and 4 are defined as Y. Acc/Dec rate is controlled by speed controller according to the setting value. The vibration and key phase signals during Startup or shutdown process is collected by tape recorder of Sony PC208AX. 1) Collection of vibration signal and keyphasor signal during Startup or shutdown process of investigated rotor. 2) Determine the times of each phase pulse on keyphasor signal. 3) Performing Hilbert transform of the vibration signal x (t ) , and constructing analytic function z (t ) . z(t ) x(t ) jy(t ) a(t )e j(t ) . (7) 4) Calculation of Hilbert amplitude curve a (t ) and Hilbert phase curve (t ) . a(t ) x(t ) 2 y (t ) 2 . (t ) arctan y (t ) . x(t ) (8) (9) 5) Performing the correction of Hilbert amplitude curve by averaging the upper and lower envelope curves of Hilbert amplitude curve obtained in step 4. 6) Performing the correction of Hilbert phase curve by extracting the phase values on Hilbert phase curve corresponding to the times of key phase pulse on keyphasor signal, and phase interpolating at each sampling times. 7) Draw Bode and Nyquist diagrams with corrected Hilbert amplitude curve and Hilbert phase curve. IV. EXPERIMENTS AND DATA ANALYSIS The Startup or shutdown experiments are carried out on the rotor test rigs of RK4, which is manufactured by Bently Corporation. The structure of RK4 is shown in Fig.3. A measurement section A is at motor end of rotor, while measurement B is at free end of rotor. Horizontal and vertical vibrations of section A are measured by eddy current sensors 1 Figure 3. Structure of Bently RK4. In the experiment, the rotor speed-up range is set between 300(r/min) and 4500(r/min). The vibration signals and keyphase signal are collected during the speed-up process in experiment. Signal sampling frequency of each channel is 24000(Hz). The vibration signal and keyphase signal coming from sensors 1 and sensor 5 respectively are selected and analyzed with the purposed method. The Bode and Nyquist diagram of fundamental frequency component of vibration signal are shown in fig.4. For the convenience of comparison, fig.5 gives Bode and Nyquist diagrams drawn by the conventional method with signals collected discontinuously at certain predetermined speeds. It is easy to see that Bode and Nyquist diagram drawn by the proposed method is much smoother. Especially, the resolution gets much higher through the critical speed. Besides, Bode and Nyquist diagram calculated with the proposed method is free of amplitude error and phase error caused by the average effect of Fourier transform in computation process. (a) Bode diagram. (a) Bode diagram. (b) Nyquist diagram. Figure 4. Bode and Nyquist diagrams drawn by the proposed method. Another comparison of Bode and Nyquist diagrams drawn by the proposed method and traditional method is illustrated in fig.6 and fig.7. The Bode and Nyquist diagrams shown in fig.6 are drawn by the proposed method. Bode and Nyquist diagrams shown in figure 7 are drawn by the second traditional method. In fig.7(b), it is obvious that it exists a protruding point caused by the interference of second harmonic frequency component. The above interference does not appeared in fig.6(b). (b) Nyquist diagram. Figure 5. Bode and Nyquist diagrams drawn by the first traditional method with signals at certain speeds. Experimental analysis indicates that the proposed Hilbert based Bode and Nyquist diagrams calculation method is low in computation volume comparing with the traditional method, it can effectively extract the information from transient vibration signal, errors both from average effect of Fourier transform in computation and the interference of second harmonic frequency component are suppressed, and accurate Bode and Nyquist diagrams are obtained. (a) Bode diagram. V. APPLICATION OF BODE AND NYQUIST DIAGRAMS IN DYNAMIC BALANCING As Bode and Nyquist diagrams directly show the balancing condition of rotor, the information on Bode and Nyquist diagrams can be utilized for rotor balancing. The following experiments are carried out on RK4. Sensor installation and data acquisition system in the experiment are same as those in part 3 of the paper. (b) Nyquist diagram. Figure 6. Bode and Nyquist diagrams drawn by the proposed method. Unbalancing mass EC 1.2 g90() and ED 1.2 g90() are artificially introduced on disk C and disk D to simulate unbalance in experiment. Bode diagram of the Startup process is drawn with the proposed method. Low-speed balancing method for flexible rotor is employed, and the balancing weights calculated on disks C and D are EPC 1.63g271() and EPD 1.54 g273() respectively. Obviously, the calculated balancing weights is only a little bigger than the artificially introduced weights in magnitude. The angles of balancing weights are almost right in the opposite positions of the artificially introduced weights. Vibrations are collected after balancing added weights. Fig.8 is the comparison between original vibration and vibration after balancing. It is obvious that rotor vibration reduces greatly after balancing with weights calculated according to Bode and Nyquist diagrams. Figure 8. Comparison of vibration before and after balancing. VI. CONCLUSION (a) Bode diagram. The paper propose a Hilbert transform based Bode and Nyquist diagram calculating method, which is used to process vibration signals of rotor Startup or shutdown. The principle and the calculation steps of the method are presented in the paper. The performance of the method is verified by experiment. At last, one balancing example is given, in which Bode diagram calculated by the proposed method is employed in balancing weights calculation. Then main conclusions can be summarized as follows. 1) The proposed method can extract the amplitude curve and phase curve fundamental frequency component from vibration signals, and It can be used to calculate Bode and Nyquist diagrams with the vibrations in Startup or shutdown process. (b) Nyquist diagram. Figure 7. Bode and Nyquist diagrams drawn by the second traditional method. 2) The results of principle study and experiment analysis indicate that the proposed method is insusceptible to Errors both from average effect of Fourier transform in computation and the interference of second harmonic frequency component. So accurate Bode and Nyquist diagrams can be obtained. 3) The proposed method has the advantageous of low computation volume comparing with the traditional method. 4) Application of Bode and Nyquist diagrams in rotor balancing suggests that Bode and Nyquist diagrams calculated by the proposed method are correct and can be used in rotor dynamic balancing and balance monitoring. ACKNOWLEDGMENT The authors gratefully acknowledge the contribution of State Key Laboratory for Manufacturing Systems Engineering, the project of National Key Basic Research Program (2009CB724405), the project of National Natural Science Foundation of China(51275379) and reviewers’ comments. REFERENCES [1] Agnes Muszynska. Vibrational Diagnostics of Rotating Machinery Malfunctions. International Journal of Rotating Machinery, Vol. 1, No. 3-4, pp. 237-266, 1995. [2] Erik Swanson, Chris D. Powell, Sorin Weissman. A Practical Review of Rotating Machinery Critical Speeds and Modes. sound and vibration, pp. 10-17, May. 2005. [3] David P. Fleming. Unbalance Response Prediction for Accelerating Rotors With Load-Dependent Nonlinear Bearing Stiffness. NASA/TM—2005-213801. [4] Qu Liangsheng, Shi Dongfen. Ten years of holospectrum : Retrospect and prospect. Journal of vibration, Measurement & Diagnosis, Vol.18, No.4, pp. 235-242, Dec.1998. [5] Zheng Longxi. Computer aided testing and analysis system of rotor vibration bode diagram. Journal of Astronautic Metrology and Measurement, Vol.22, No.4, pp. 48-50, Aug. 2002. [6] Li Yuanyou. The vibration signal testing and analyzing system for great rotating machine. Master's thesis of Chongqing University, Nov. 2002. [7] Huang N E. Review of empirical mode decomposition. Proc. SPIE, No. 4391, pp. 71-79, 2001. [8] Gai Guanghong. The theory and application of Hilbert-Huang transformation for mechanical signal. PhD Thesis of Xi’an Jiaotong University, No. 10:45-50, 2005. [9] Kou Shengli. Vibrations and field balancing of steam turbine generator unit. China electric power press, vol.8, No. 1, pp. 20-25, 2007. [10] Zhang Xining, Guo Jinliang, Wu Jili. Extracting fundamental frequency during rotating machine startup and shut-down via fractional domain filtering . Journal of Xi’an Jiaotong University, vol.4, No. 11, pp. 92-96, 2013.