PART 2 - Rites

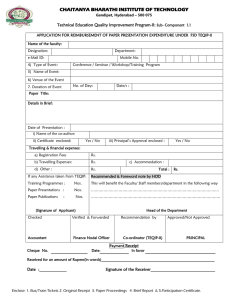

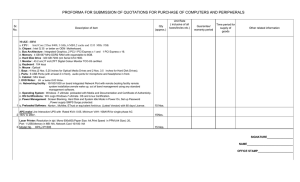

advertisement