QNC1 Relay

advertisement

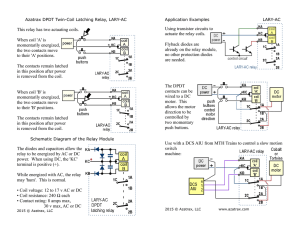

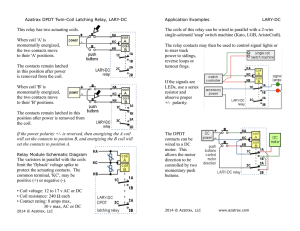

Relay Solutions BR 930 SERIES Siemens.com/mobility QNC1 Relay A dc neutral, tractive armature contactor General data Contact Arrangement: 2F(HD) 4B, 2F(HD) 2F 2B and 2F(HD) 5B Nominal Rated Voltage: 24 and 50V dc Approximate Weight: 1.35 kg Note: Refer to the following data sheets: • 7-1-1 for general information and contact ratings. • 7-2-1 for dimensions. • 8.2 for tools. • 8.3 for plugboard and connector details. Refer overleaf for speci c data. Description In addition to signalling contacts it is tted with two Heavy Duty HD front contacts with magnetic blow out. The relay is ac immune to 240 V ac rms 50 Hz. It is designed primarily for the control of point machine motors. HD Contacts and Wiring arrangement Each heavy duty contact terminal is connected to two plugboard connectors in parallel, each connector should be wired with two wires in parallel to handle the heavy currents involved. To ensure efficient operation of the magnetic blowouts the connection polarity shown below must be observed for d.c. operation. Note: The back contacts can be connected in series to give detection of a welded heavy duty front contact. Contact Layout viewed from rear A 1 2 3 4 5 B C D Supply + 1 Load - 3 B 8 B Supply - B R1 coil 7 coil R3 C D A B C D Supply + F Load - B Load - B Load + B Load + B 8 B Supply - B Supply - B R2 coil 4 Load + B F 2 B 6 A 5 6 7 Supply + coil coil coil R4 2F(HD) 4B 2F(HD) 2F 2B 2F(HD) 5B Packaging EMC Compliance Q-Relays are packed in a carton holding ten relays; the same container is used for quantities of four to nine relays. Quantities less than four are packed individually in cardboard boxes, as are all traincarried relays. Each container has a bar-coded label affixed to the outside, stating details of the packaged relay(s) and the quantity therein. Q-Relays comply with the relevant emission requirements of EN 55014. It is considered that these relays have inherent immunity to in-service electromagnetic disturbance. A Technical Certi cate for EU Directive on EMC (89/336/EEC) has been obtained. Technical data SIEMENS Part No. (PAD No.) CONTACT ARRANGEMENT RATED VOLTAGE (V dc) PIN CODE COIL RES (OHMS) WDG SPEC 1/108/- MAX FULL OP. (V dc) MIN REL (V dc) PLUGBOARD REQD No. OF CONNECTORS J4137/3 REMARKS B18550/1 (85/001545) 2F(HD) 4B 50 166 BCDJK 1800 85 40 14 J4138/250 18 BRB Spec. 966 F1 B18550/2 (85/001535) 2F(HD) 4B 24 167 BCEFK 270 90 19.2 8.5 J4138/261 18 B18550/3 2F(HD) 2F 2B 50 XBFJK 1800 85 40 14 J4138/284 18 ---- B18550/4 2F(HD) 5B 50 XDFGK 1800 85 40 7.5 J4138/346 20 ---- BRB Spec. 966 F1 Un-drilled plugboard Part No. E7218/1 Representation of Relay, Plugboard and Retaining clip (Clip Part No. J4136/1) Siemens Ltd Infrastructure & Cities Sector Mobility and Logistics Division Rail Automation PO Box 79 Pew Hill Chippenham Wiltshire SN15 1JD UK www.siemens.com/rail-automation Printed in the United Kingdom Data Sheet 7-2-51 X342/55/000070 Revision 04 The information within this document contains general descriptions of the technical options available, which do not always have to be present in individual cases. The required features should therefore be speci ed in each individual case at the time of closing the contract.