Crompton Instruments Current and Voltage Transformers

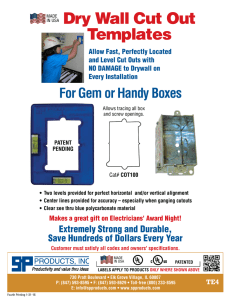

advertisement