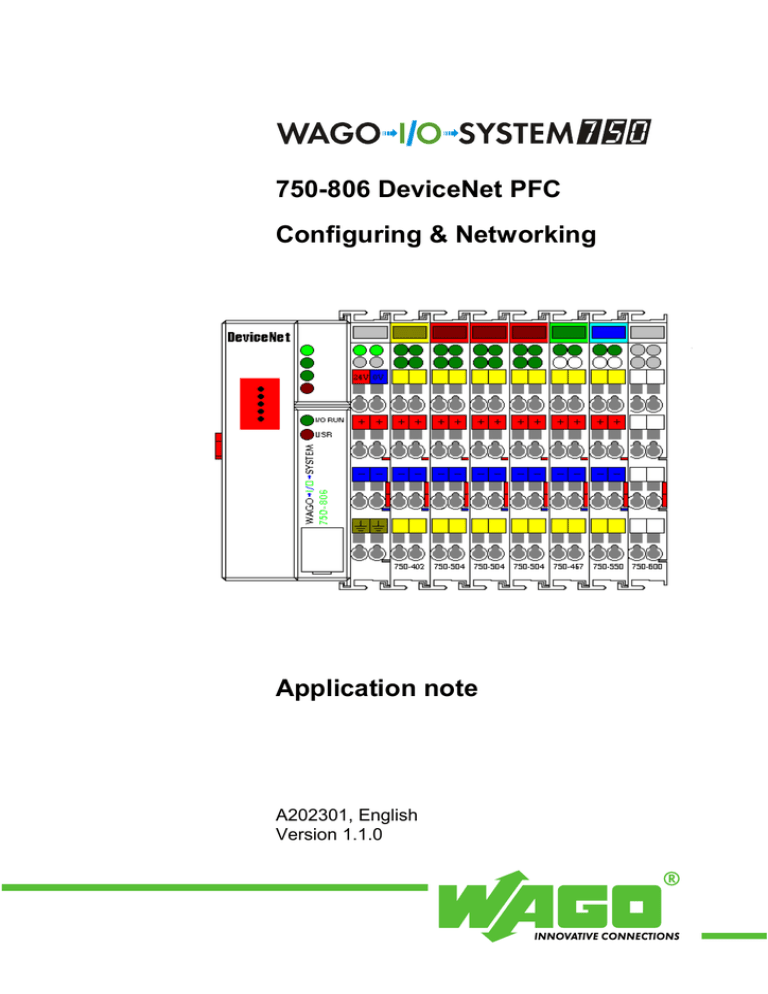

750-806 DeviceNet PFC

Configuring & Networking

Application note

A202301, English

Version 1.1.0

2 • General

Copyright ã 2003 by WAGO Kontakttechnik GmbH

All rights reserved.

WAGO Kontakttechnik GmbH

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax:

+49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web:

http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax:

+49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time.

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

Application note

A202301

Table of Contents

•3

TABLE OF CONTENTS

1 Important comments.................................................................................. 5

1.1 Legal principles............................................................................................ 5

1.1.1

Copyright .......................................................................................... 5

1.1.2

Personnel qualification ..................................................................... 5

1.1.3

Intended use ...................................................................................... 5

1.2 Range of validity.......................................................................................... 6

2

Description.................................................................................................. 7

3 Reference Material..................................................................................... 8

3.1 Setup RS Networx ....................................................................................... 8

3.2 Configure RX/ TX Settings ....................................................................... 12

3.2.1

Configure for RX............................................................................ 13

3.2.2

Configure for TX ............................................................................ 14

3.2.3

Configure PLC_Inputs and PLC_Outputs ...................................... 15

3.2.4

Using a Class,Instance,Attribute Editor.......................................... 17

3.3 Adding Nodes and Configuration .............................................................. 18

3.3.1

Mapped Inputs ................................................................................ 20

3.3.2

Mapped Outputs.............................................................................. 21

3.4 The PFC and Module Addressing.............................................................. 22

3.4.1

Internal Variables............................................................................ 24

3.5 PFC Example Program .............................................................................. 24

3.6 Advanced Programming for Node Status .................................................. 27

3.7 Advanced RSNetworx I/O Mapping.......................................................... 28

3.8 Advanced Dynamic Assembly I/O Mapping ............................................. 39

3.9 Configure RX/ TX Settings ....................................................................... 39

3.9.1

Configure for RX............................................................................ 40

3.9.2

Configure for TX ............................................................................ 40

3.9.3

Configure PLC_Inputs and PLC_Outputs ...................................... 41

3.10 Adding Nodes and Configuration ........................................................ 44

3.10.1

Mapped Inputs ................................................................................ 46

3.10.2

Mapped Outputs.............................................................................. 47

3.11 Dynamic Assemblies............................................................................ 48

3.11.1

New Class, Instance Variables........................................................ 48

3.11.2

Write Class Values Byte Format .................................................... 49

3.11.3

Write Class Values Word Format................................................... 49

3.11.4

Write Class Values Double Word................................................... 50

3.11.5

Read Only Class Values Byte Format............................................. 50

3.11.6

Read Only Class Values Word Format........................................... 51

3.11.7

Read Only Class Values Double Word Format .............................. 51

3.11.8

Understanding Mapping Dynamic Assemblies .............................. 52

3.12 Creating a Dynamic Assembly in the PFC .......................................... 54

3.13 Re-Direct I/O Map Pointer................................................................... 60

3.14 The PFC and Module Addressing........................................................ 63

Application note

A202301

4 • Table of Contents

Application note

A202301

Important comments

1

•5

Important comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanation is

carefully read and adhered to.

1.1 Legal principles

1.1.1

Copyright

This manual is copyrighted, together with all figures and illustrations contained therein. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and photo-technical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH. Non-observance will entail the right of claims

for damages.

1.1.2

Personnel qualification

The use of the product detailed in this manual is exclusively geared to specialists having qualifications in PLC programming, electrical specialists or

persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH declines all liability resulting from

improper action and damage to WAGO products and third party products due

to non-observance of the information contained in this manual.

1.1.3

Intended use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only admitted within the framework of the possibilities documented in the manuals. All

other changes to the hardware and/or software and the non-conforming use of

the components entail the exclusion of liability on part of WAGO Kontakttechnik GmbH.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH.

Application note

A202301

6•

Important comments

1.2 Range of validity

This application note is based on the stated hardware and software of the specific manufacturer as well as the correspondent documentation. This application note is therefore only valid for the described installation.

New hardware and software versions may need to be handled differently.

Please note the detailed description in the specific manuals.

Application note

A202301

Description

2

Description

This document is to be used with the example node from the document PFC

101 Get Started Quick. The following describes Configiuration and

Networking a Devicenet PFC to a Devicenet network.

This document was written using:

RSNetworx 3.00.00 from Allen-Bradley

SLC500

1747-SDN Scanner module

750806_2.EDS

When using DeviceNet a EDS file is needed for configuration. Use WAGO

750806_2.EDS for the 750-806 PFC. This file can be downloaded from the

web site www.wago.com

WAGO modules used in the example:

750-806 1

DeviceNet PFC Buscoupler Firmware Rev:2.1

750-402 2

4 Point 24Vdc Input module

750-504 3

4 point output modules

750-550 1

2 Channel Analog 0-10Vdc Output module

750-467 1

2 Channel Analog 0-10Vdc Input module

750-600 1

End module

For other details about WAGO DeviceNet & 750- 806 please refer to the

WAGO Devicenet Users Manual 750-135

Application note

A202301

•7

8•

Reference Material

3

Reference Material

3.1 Setup RS Networx

The modules are placed in the node as follows:

Start RSNetworx Configuration software.

Load ESD file into RSNetworx.

·

Click on Tools

·

Click on EDS Wizard Follow the wizard to load the EDS.

·

Use 750806_2.EDS for the install

Application note

A202301

Reference Material

•9

Figure: RS Networx Main Configuration Window

After the 750-806_2 EDS file has been loaded on the RSNetworx the software

is ready to build a network.

Figure: Add a Scanner to the Network

Click on the Communication Adapter Folder, Other folders may be displayed.

Cursor down and select the scanner to be used for the network.

Application note

A202301

10 •

Reference Material

Double Click or Drag and Drop on the right screen.

Next cursor down in the Communications Adapters.

Select Devicenet Controller 806 Major Rev:2 and double click to add to the

network.

Figure: Add the 750-806 to Network

Application note

A202301

Reference Material

• 11

Figure: Set Correct Node Address

Double click on the 750-806 DeviceNet Node.

The DeviceNet-Controller-806 Parameters window will pop up.

Click into the Address box and change the address to the DIP Switch settings

of the Node.

The Baud Rate is set by the last 3 DIP Switches of the Node Address.

SEE WAGO Devicenet Manual for DIP switch settings.

Application note

A202301

12 •

Reference Material

3.2 Configure RX/ TX Settings

The DeviceNet configuration is as follows.

750-806 DeviceNet PFC

1 Byte Input Status

750-402 4-Point Input

4 Bits Input

750-402 4-Point Input

4 Bits Input

750-516 4-Point Output

4 Bits Output

750-516 4-Point Output

4 Bits Output

750-516 4-Point Output

4 Bits Output

750-467 2CH Analog In

4 Bytes Input

750-550 2CH Analog Out

750-600 End Module

4 Bytes Output

------------

PLC fieldbus Variables Input

------------4 Bytes Input

PLC fieldbus Variables output 4 Bytes Output

----------------------------------------------------------------------------------------------RX/TX Calculations

RX= 17 Bytes

TX= 20 Bytes

In a normal DeviceNet configuration all Input Bits/Bytes must be added together for the RX parameter and the Output Bits/Bytes must be added together

for the TX parameter. If the RX/TX software configuration does not match

the node configuration there will be an error. The configuration must be correct before DeviceNet will run.

In this example the Inputs and Outputs are to be passed through the PLC

Fieldbus Variables. By configuring the 750-806 using PFC Fieldbus parameters the Master controller does not see the I/O modules in the configuration.

The scanner would be configured as follows:

RX: 4 Bytes (PLC Fieldbus Variables Output)

TX: 4 Bytes (PLC Fieldbus Variables Input)

Application note

A202301

Reference Material

3.2.1

Configure for RX

Cursor down to Parameter 16 and Click on the selection arrow.

Select Fieldbus output variables

The PFC will use %QX256-511 to output data to the SLC500.

Application note

A202301

• 13

14 •

3.2.2

Reference Material

Configure for TX

Cursor down to Parameter 17 and Click on the selection arrow.

Select Fieldbus input variables

The PFC will use %IX256-511 to output data to the SLC500.

Application note

A202301

Reference Material

3.2.3

Configure PLC_Inputs and PLC_Outputs

Cursor down to Parameter 40.

Enter the number of Bytes to be received from the Master to the PFC.

This example will receive 4 Bytes from the Master.

Configure the TX of the Scanner for 4 Bytes.

Cursor down to Parameter 42.

Enter the number of Bytes to be sent from the PFC to the Master.

This example will send 4 Bytes to the Master.

Configure the RX of the Scanner for 4 Bytes.

Download the parameter changes to the network.

Application note

A202301

• 15

16 •

Reference Material

PLC fieldbus Input Variables: 255 PLC_Input Variables are available for

the Master to download data to be used by the PFC Program.

This is how data is sent to the PFC which will be used in the WAGO-PRO32

program.

The first PLC_Input Variable starts at Register %IW256 in the PFC.

The last PLC_Input Variable ends at Register %IW511 in the PFC.

PLC fieldbus Variable output: 255 PLC_Output Variables are available for

the PFC to write data to the Master. The PFC program will place data into the

PLC_Output registers for the Master to receive.

This is how data is sent to the SLC from the WAGO-PRO32 program.

The first PFC_Output Variable starts at Register %QW256 in the PFC.

The last PFC Output Variable ends at Register %QW511 in the PFC.

Note:

PLC_Inputs receive data from the Master to be written into PFC memory.

PLC_Outputs write data from the PFC to the Master.

Application note

A202301

Reference Material

3.2.4

• 17

Using a Class,Instance,Attribute Editor

RSNetworx makes changing parameters easy because it has a nice text display

about the parameter and values. Most software does not have this type of display so a Class,Instance,Attribute Editor must be used. There are many types

of editors used so it is not possible to display them.

The following are the Class,Instance,Attribute and Attribute Values to be entered into the editor to make the changes as needed configure the Fieldbus Network Variables.

Parameter 16

Class 64, Inst 1,Attrib 0C

Default Attrib Value = 04 Analog&Digital input Plus Status

Change to Attrib Value= 0A Fieldbus Output Variables

Parameter 17

Class 64, Inst 1, Attrib 0D

Default Attrib Value =01 Analog&Digital output data

Change to Attrib Value= 0B Fieldbus Input Variables

Parameter 40

Class 64,Inst 1, Attrib 66

Set Attrib Value = Number of Fieldbus Input Variables (4=4Bytes or 2 Words)

Parameter 42

Class 64, Inst 1, Attrib 68

Set Attrib Value = Number of Fieldbus Output Variables (4=4Bytes or 2 Words)

Application note

A202301

18 •

Reference Material

3.3 Adding Nodes and Configuration

Figure: Add Node to the Scan List

Double Click on the Scanner Icon to start the configuration.

Click on the Scan List tab to display the above window.

Click on the

the Scanlist.

>

upper arrow to move the node from the Available Devices to

Click on Edit I/O Parameters to enter the RX/TX Data.

Application note

A202301

Reference Material

• 19

Figure: Enter RX/TX Parameters

From the PLC_input/PLC_output parameters these will be entered into the

scanner.

Click on Polled so the box has the check mark

Click into RX Size and enter 4 Bytes from PLC_outputs.

Click into TX Size and enter 4 Bytes for the PLC_Input.

Click OK when the parameters are entered.

If this window is displayed click YES.

All the I/O will be mapped automatically to the digital I/O at this time. The

I/O can be remapped if needed.

Note: If the I/O is mapped automatically it will place all modules and PLC

Network variables to the Digital I/O.

Application note

A202301

20 •

3.3.1

Reference Material

Mapped Inputs

Figure: Mapped Inputs

Next Click On Input. All the inputs are mapped as digital.

Input Map:

I:1.0

| 1 Word Reserved for Scanner Module |

I:1.1

| 1 Word PLC_Input

|

I:1.2

| 1 Word PLC Input

|

Application note

A202301

Reference Material

3.3.2

Mapped Outputs

Figure: Mapped Outputs

Next Click On Outputs. All the outputs are mapped as digital.

Output Map:

O:1.0 | 1 Word Reserved for Scanner Module |

Application note

A202301

O:1.1 | 1 Word PLC_Outputs

|

O:1.2 | 1 Word PLC_Outputs

|

• 21

22 •

Reference Material

3.4 The PFC and Module Addressing

1: Analogs and Specialty modules are always addressed first in the PFC

2: Digital modules follow next address after the Analog & Specialty modules

3: PFC Addressing is sequential

4: PFC Addressing starts at word 0

750-806 PFC I/O Addressing is as follows:

Inputs

Addrs

Variables

Control

750-467 %IW0

AICHAN1

PFC Controlled

%IW1

AICHAN2

PFC Controlled

750-402 %IX2.0 INPUT0

PFC Controlled

%IX2.1 INPUT1

PFC Controlled

%IX2.2 INPUT2

PFC Controlled

%IX2.3 INPUT3

PFC Controlled

750-402 %IX2.0 INPUT4

PFC Controlled

%IX2.1 INPUT5

PFC Controlled

%IX2.1 INPUT6

PFC Controlled

%IX2.1 INPUT7

PFC Controlled

PLC_Input1

%IW256 INPUT256

PFC Controlled

PLC_Input2

%IW257 INPUT257

PFC Controlled

Application note

A202301

Reference Material

Output

Addrs

Variables

Control

750-550 %QW0

AOCHAN1

PFC Only Control

%QW1

AOCHAN2

PFC Only Control

750-516 %QX2.0 OUTPUT0

PFC Only Control

%QX2.1 OUTPUT1

PFC Only Control

%QX2.2 OUTPUT2

PFC Only Control

%QX2.3 OUTPUT3

PFC Only Control

750-516 %QX2.4 OUTPUT4

PFC Only Control

%QX2.5 OUTPUT5

PFC Only Control

%QX2.6 OUTPUT6

PFC Only Control

%QX2.7 OUTPUT7

PFC Only Control

750-516 %QX2.8 OUTPUT8

PFC Only Control

%QX2.9 OUTPUT9

PFC Only Control

%QX2.10 OUTPUT10

PFC Only Control

%QX2.11 OUTPUT11

PFC Only Control

PLC_Output1 %QW256 OUTPUT256 PFC Only Control

PLC_Output2 %QW257 OUTPUT257 PFC Only Control

750-600 End Module (No Memory Allocation needed)

Application note

A202301

• 23

24 •

3.4.1

Reference Material

Internal Variables

Input256

First Word Memory location the DeviceNet Master places

data into the PFC is Input address %IW256.

Input257

Is the Second Word Memory Location the DeviceNet Master

can place data into the PFC

Output256

First Word Memory location to place data for the PFC to

send to the DeviceNet Master is %QW256.

Output257

Is the Second Word Memory Location for the PFC to place

data to send back to the PFC

Input256 and Input 257 = 4 Bytes of PLC_Input

Output 256 and Output257 = 4 Bytes of PLC_Output

3.5 PFC Example Program

A 750-806 test program was developed to verify that the Devicenet configuration is correct and data can pass between the Devicenet master and the 750806 PFC with out conflicts between the two processors.

Enter the following program into the PFC.

Create the PFC program.

Go On Line and Download the Program.

Flash the program into memory.

Run the program.

RSNetworx should be configured and downloaded to the scanner from the

steps above.

Start RSLogix to monitor data in the SLC for correct communications and

memory locations.

Application note

A202301

Reference Material

• 25

Figure: 806 test program

The I/O data can be monitored by WAGO-Pro32 online.

Rung 1:

INPUT0 is the first Input from the digital input modules (%IX2.0).

OUTPUT0 is the first Output from the first digital output module (%QX2.0).

When INPUT0 = True, OUTPUT0 = True.

The PFC has control of the output.

If the PFC and Scanner has been configured correctly this output will be on

continuously and not flash while the PFC is running.

Application note

A202301

26 •

Reference Material

Rung 2:

INPUT256 (%IW256) is the first 2-byte PLC_Input. The SLC places 2 bytes

of Network data into INPUT256.

Using the ADD operator to add 0 to INPUT256, transfers the data from

INPUT256 to AOCHAN1 (%QW0) which is channel 1 of the analog output

module.

If channel 1 of the analog output module is wired to channel 1 of the analog

input module, the data from the analog input will closely follow the data that

was placed into INPUT256.

The Analog Output Channel 1 will send a signal to the Analog Input Channel

1.

Changing the value in RSLogix to INPUT256 will change the value in the

Analog Output which sends a signal to the Analog Input.

Change this value and watch the analog input module change:

Rung3:

This rung is a free running timer. When the timer times out the output = True

which resets the timer to start over.

This rung used to clock the up counter in rung 4. Every time the output =

True the counter will count up 1.

Rung4:

As the counter is counting up the counter value is sent to the first PLC_Output

OUTPUT256 (%QW256).

Compare the data of OUTPUT256 with RSLogix and the data should count

up with the PFC.

The PFC program and Devicenet configuration is a small example to demonstrate how to configure the Devicenet scanner and the PFC to pass data between the two devices.

If one of these steps is not working correctly, check the configuration of

RSNetworx and the addressing in the PFC.

Application note

A202301

Reference Material

• 27

3.6 Advanced Programming for Node Status

Configuring the 750-806 this way the status byte will not be configured in the

scanner. Since the status byte is not configured no status data will be received

from the node. WAGO-PRO32 has a function block called

K_BUSS_ERROR that can be added to the program to monitor the K-Bus.

The function block will set a bit when there is an error, Tell you the error type,

and display the module that caused the fault. This data can be placed into the

PLC_fieldbus Output Network variables for the master to receive and take action. This also provides more data to be placed into HMI software for diagnostics.

Another function block that can be used is the F_BUS_ERROR. If there is a

Devicenet network error a bit will be set. This bit can be used in the PFC program to take action on loss of the network.

Application note

A202301

28 •

Reference Material

3.7 Advanced RSNetworx I/O Mapping

The following are examples of using offsets and mapping Word wide Registers and Analog Modules to M0/M1 data type used in the SLC500. These

Methods are for Reference only.

Figure: Advanced Input Mapping

Click on 1 under MAP to highlight.

Cursor over to Message and select Polled.

Next check Memory and be sure it has Discrete in the box.

Word =1 (Word 0 is reserved in RSNetworx)

Bit = 0

Bit Length = 16

When finished Click Apply Mapping

Click Close

Application note

A202301

Reference Material

• 29

Figure: Digital Input Map

The Digital input map should appear as the above picture.

I:1.0 = Reserved for Scanner

I:1.1 = Bits 3-0 are the 4 bits for the 750-402 module.

I:1.1 = Bits 7-4 Not used ( IF another 4 point module were added these

bits would be used).

I:1.1 Bits15- 8 are the Buscoupler Status Byte. Bit 8 is the only bit used in

the status byte.

Next Click on Advanced to map the analogs and PLC Variables

Application note

A202301

30 •

Reference Material

Figure: Map 2 Analog Input Registers

Cursor down to #2 in the Map box and click to highlight Map 2

Message = Polled

Memory = M File (Click on down arrow to make selection)

Word = 0

Bit = 0

Bit Length = 32 (2 channels of 16 bits for Analog Module)

Click on Apply Mapping, makes sure the parameter window appears as the

Above Picture.

Application note

A202301

Reference Material

• 31

Figure: Map 4 bytes for PLC Output Variable

Cursor down to #3 in the Map box and click to highlight Map 3

Message = Polled

Memory = M File (Click on down arrow to make selection)

Word = 2

Bit = 0

Bit Length = 32 (4 Bytes for PLC Output Variable)

Click on Apply Mapping, makes sure the parameter window appears as the

above Picture.

Application note

A202301

32 •

Reference Material

Figure: M File Map for Inputs

Application note

A202301

Reference Material

Figure: Map Outputs

Next click on Output to start mapping the outputs.

Click on Advanced to enter the output parameters.

Application note

A202301

• 33

34 •

Reference Material

Figure: Map Digital Outputs

Cursor down to #1 in the Map box and click to highlight Map 1

Message = Polled

Memory = Discrete (Click on down arrow to make selection)

Word = 1

Bit = 0

Bit Length = 16

Click on Apply Mapping, makes sure the parameter window appears as the

above Picture.

Application note

A202301

Reference Material

• 35

Figure: Map Analog Outputs

Cursor down to #2 in the Map box and click to highlight Map 2

Message = Polled

Memory = M File (Click on down arrow to make selection)

Word = 0

Bit = 0

Bit Length = 32

Click on Apply Mapping, makes sure the parameter window appears as the

above Picture.

Application note

A202301

36 •

Reference Material

Figure: Map PLC Output Variables

Cursor down to #3 in the Map box and click to highlight Map 3

Message = Polled

Memory = M File (Click on down arrow to make selection)

Word = 2

Bit = 0

Bit Length = 32

Click on Apply Mapping, makes sure the parameter window appears as the

above Picture.

Application note

A202301

Reference Material

Figure: Check Digital Output Map

Figure: Check M File & PLC Input Map

Application note

A202301

• 37

38 •

Reference Material

Figure: Network Summary

Click on Summary to check the Network Mapping

Node 01 RX should equal 10, TX should equal 10

Click on Apply

Click on OK

This window will close and the main window will be displayed.

Go Online to the DeviceNet Network.

Application note

A202301

Reference Material

• 39

3.8 Advanced Dynamic Assembly I/O Mapping

The following is an example of Dynamic Assembly mapping the 750-806.

Dynamic Assembly can be used to map I/O modules that some modules are

controlled by the Master and others are controlled by the 750-806 Wago-Pro

program. The following example is for advanced Devicenet users using

RSNetworx.

3.9 Configure RX/ TX Settings

The DeviceNet configuration is as follows.

750-806 DeviceNet PFC

1 Byte Input Status

750-402 4-Point Input

4 Bits Input

750-402 4-Point Input

4 Bits Input

750-516 4-Point Output

4 Bits Output

750-516 4-Point Output

4 Bits Output

750-516 4-Point Output

4 Bits Output

750-467 2CH Analog In

4 Bytes Input

750-550 2CH Analog Out

750-600 End Module

4 Bytes Output

------------

PLC fieldbus Variables Input

------------0 Bytes Input

PLC fieldbus Variables output 4 Bytes Output

RX/TX Calculations

RX= 10 Bytes

TX= 6 Bytes

In DeviceNet all Input Bits/Bytes must be added together and Output

Bits/Bytes must be added together to be entered into the RX / TX of RSNetworx. If the RX/TX software configuration does not match the node configuration there will be an error. The configuration must be correct before DeviceNet will run.

Application note

A202301

40 •

Reference Material

Note 1:

If the number of bits does not add up to a full byte, round up to the next

byte.

In this example the last 4 bits of Digital Outputs are unused so it is rounded up to the next byte.

Note 2:

Inputs are not controlled by the PFC or SLC but both processors can

read Inputs. There isn’t any need to configure for Inputs.

Note 3:

If the 750-806 is the only processor to control outputs and no output modules will be controlled by the SLC, then TX is configured with only the

number of PLC_Output bytes not the TX from the calculation above.

3.9.1

Configure for RX

The SLC will receive all bits from the input modules and the 4 bytes allocated

in ID#38.

The calculation from the list above:

RX = 10 Bytes

This includes all Real Inputs and PLC_Outputs

3.9.2

Configure for TX

The SLC will not have control of any output modules in this example, but the

SLC will have control of the PLC_Input registers.

ID# 37 is set to 0.

In this example 4 bytes of data will be sent to the SLC from the PFC.

Since the SLC will not control any outputs, but 4 bytes of PLC_Inputs are

needed to send to the PFC.

TX=4 bytes

No Real Outputs, 4 bytes of PLC_Inputs.

Application note

A202301

Reference Material

3.9.3

• 41

Configure PLC_Inputs and PLC_Outputs

Figure: Configure PLC Network Variables

Click into the Group box.

Click on the down arrow to display more parameters.

Cursor down to PLC fieldbus variables and Click to Highlight.

Another way is to move the mouse over to the right hand sliding bar and pull

down to ID number 37 & 38 PLC Input and Output Variables.

Application note

A202301

42 •

Reference Material

Figure: Configure Network Variables

Leave ID# 37 Number of PLC fieldbus Input variables at 0.

The PFC will read the data as inputs.

(A value of 4 could be entered to prevent confusion, but not necessary)

ID# 37: Is the number of PLC_Input bytes the 750-806 receives from the Master (SLC).

The PLC_Input Registers and are located at Address %IW256 - %IW511

of the 750-806 PFC.

ID# 38: Is the number of PLC_Output bytes the 750-806 PFC sends to the

Master (SLC).

The PLC_Output Registers and are located at Address %QW256-%QW511

of the 750-806 PFC.

Application note

A202301

Reference Material

• 43

PLC fieldbus Input Variables: 255 PLC_Input Variables are available for the

Master to download data to be used by the PFC Program.

This is how data is sent to the PFC which will be used in the WAGO-PRO32

program.

The first PLC_Input Variable starts at Register %IW256 in the PFC.

The last PLC_Input Variable ends at Register %IW511 in the PFC.

In this example ID# 37= 0 Bytes reserved, because the PFC reads the data as

inputs. Inputs are not controlled, they are only monitored.

PLC fieldbus Variable output: 255 PLC_Output Variables are available for

the PFC to write data to the Master. The PFC program will place data into the

PLC_Output registers for the Master to receive.

This is how data is sent to the SLC from the WAGO-PRO32 program.

The first PFC_Output Variable starts at Register %QW256 in the PFC.

The last PFC Output Variable ends at Register %QW511 in the PFC.

In this example ID# 38 = 4 Bytes reserved. This allocates 4 Bytes of Variable

data in the Scanner other than I/O.

Note:

PLC_Inputs receive data from the Master to be written into PFC memory.

PLC_Outputs write data from the PFC to the Master.

Application note

A202301

44 •

Reference Material

3.10 Adding Nodes and Configuration

Figure: Add Node to the Scan List

Double Click on the Scanner Icon to start the configuration.

Click on the Scan List tab to display the above window.

Click on the

the Scanlist.

>

upper arrow to move the node from the Available Devices to

Click on Edit I/O Parameters to enter the RX/TX Data.

Application note

A202301

Reference Material

• 45

Figure: Enter RX/TX Parameters

From the RX/TX calculations enter in the correct parameters.

Click on Polled so the box has the check mark

Click into RX Size and enter 10 Bytes. This is Received bytes for inputs.

Click into TX Size and enter 4 Bytes for the PLC_Input, No Outputs are allocated.

Click OK when the parameters are entered.

If this window is displayed click YES.

All the I/O will be mapped automatically to the digital I/O at this time. The

I/O can be remapped if needed.

Note: If the I/O is mapped automatically it will place all modules and PLC

Network variables to the Digital I/O.

Application note

A202301

46 •

Reference Material

3.10.1

Mapped Inputs

Figure: Mapped Inputs

Next Click On Input. All the inputs are mapped as digital.

Input Map:

I:1.0

| 1 Word Reserved for Scanner Module |

I:1.1

| 1 Word Analog Input Channel 1

|

I:1.2

| 1 Word Analog Input Channel 2

|

I:1.3

| 1 Byte Status

I:1.4

| 1 Word PLC_Inputs 1

|

I:1.5

| 1 Word PLC_Inputs 2

|

| 1 Byte Digital Inputs |

Application note

A202301

Reference Material

3.10.2

Mapped Outputs

Figure: Mapped Outputs

Next Click On Outputs. All the outputs are mapped as digital.

Output Map:

O:1.0 | 1 Word Reserved for Scanner Module |

Application note

A202301

O:1.1 | 1 Word PLC_Outputs 1

|

O:1.2 | 1 Word PLC_Outputs 2

|

• 47

48 •

Reference Material

3.11 Dynamic Assemblies

Dynamic assemblies are created in memory so I/O maps can be configured and

stored in DeviceNet as Class, Instance, Attributes.

Once the Dynamic Assembly has been created a map has to be configured and

loaded into the Dynamic Assembly memory. Pointer parameters need to be

changed in the PFC to re-direct the pointer to the Dynamic Assembly map.

If the Dynamic Assembly and Map is not created and left open the SLC will

have control of all I/O.

The Dynamic Assembly and Map configure the PFC to make it possible for

the SLC to control only mapped modules.

In this example only the PLC_Inputs are mapped so the SLC will only control

the PLC_Inputs INPUT256 and INPUT257 and not control any of the output

modules.

3.11.1

New Class, Instance Variables

The New Class variable are used to Read/Write directly to the PLC I/O Network variable memory locations.

Example:

Class 166, Instance 1 will send 1word of data to %IW256

Class 166, Instance 2 will send 1word of data to %IW256

Class 160 sends 1 byte of data that includes bytes 1-255

Instance 1 is the 1st byte to send data.

Instance 2 is the 2nd byte to send data.

Instance 1-255 the data can be written or read.

Note:

Do not change the Attribute Value. Default is 1 and must remain 1

The following is a list PFC_Input Variables of Class, Instance data. These

memory locations are Write to PFC_Input memory area.

The PFC_Input memory location starts at %IW256 and ends at %IW511.

Application note

A202301

Reference Material

3.11.2

Write Class Values Byte Format

Class 160 (0xA0) Input Fieldbus Variable USINT

Instance 1-255 (Bytes 1-255)

Max. Instance = 255

Class 161 (0xA1) Input Fieldbus Variable USINT

Instance 1-255 (Bytes 256-510)

Max. Instance = 255

Class 162 (0xA2) Input Fieldbus Variable USINT

Instance 1-2 (Bytes 511-512)

Max. Instance = 2

3.11.3

Write Class Values Word Format

Class 166 (0xA6) Input Fieldbus Variable UINT

Instance 1-255 (Bytes 1-255)

Max. Instance = 255

Class 167 (0xA7) Input Fieldbus Variable UNIT

Instance 256

Max Instance = 1

Application note

A202301

• 49

50 •

Reference Material

3.11.4

Write Class Values Double Word

Class 170 (0xAA) Input Fieldbus Variable UDINT

Instance 1-128

Max. Instance =128

Class 171 (0xAB) Input Fieldbus Variable UDINT

Instance 1-128

Max. Instance 128

Note: Starts with 2 bytes offset (the 2nd and 3rd UINT(Class 166,Instace 2 and

3) = First UDINT (Class 171, Instance 1) ect.)

The following is a list PFC_Output Variables of Class, Instance data. These

memory locations are Read the PFC_output memory area.

The PFC_Output memory location starts at %QW256 and ends at %QW511.

3.11.5

Read Only Class Values Byte Format

Class 163 (0xA3) output Fieldbus Variable USINT

Instance 1-255 (Bytes 1-255)

Max. Instance = 255

Class 164 (0xA4) output Fieldbus Variable USINT

Instance 1-255 (Bytes 256-510)

Max. Instance = 255

Class 165 (0xA5) output Fieldbus Variable USINT

Instance 1-2 (Bytes 511-512)

Max. Instance = 2

Application note

A202301

Reference Material

3.11.6

• 51

Read Only Class Values Word Format

Class 168 (0xA8) output Fieldbus Variable UINT

Instance 1-255 (Bytes 1-255)

Max. Instance = 255

Class 169 (0xA9) output Fieldbus Variable UNIT Instance 256

Max Instance = 1

3.11.7

Read Only Class Values Double Word Format

Class 172 (0xAC) output Fieldbus Variable UDINT

Instance 1-128

Max. Instance =128

Class 173 (0xAD) output Fieldbus Variable UDINT

Instance 1-128

Max. Instance 128

Note: Starts with 2 bytes offset (the 2nd and 3rd UINT(Class 168,Instace 2 and

3) = First UDINT (Class 173, Instance 1) ect.)

Application note

A202301

52 •

Reference Material

3.11.8

Understanding Mapping Dynamic Assemblies

Since Real Outputs Modules are not going to be mapped, the PLC_Inputs do

need to be mapped so the SLC has control of these two registers to send data

to the PFC.

First the map must be generated. The following example will be used in this

Application Note. Below breaks the numbers down to understand Dynamic

Mapping.

Example:

10 00 06 00 20 A6 24 01 30 01

10 00 06 00 20 A6 24 02 30 01

10 = Number of Bits to be Allocated

10hex=16bits

Low Byte

00 = Number of Bits to be Allocated

High Byte

06 = Path numberPath=6 or 0

Low Byte

00 = Path number

High Byte

20 = Class Marker tells Dnet next is Class Data

A6 = Class Data Type

24 = Instance Marker tells Dnet next is Instance Data

01 = Instance Data

30 = Attribute Marker tells Dnet next is Attribute Data

01 = Attribute data

Application note

A202301

Reference Material

What does this mean:

10hex = 16 bits of data is to be Allocated in Memory

06hex =Next 6 Bytes will be the Class, Instance, Attribute data to be used.

20hex = Class Marker

A6hex = 1 word of PLC_Input Variable type Integer.

See above New Class, Instance Variables for definition.

24hex = Instance Marker

01hex = Position 1 In Memory for the next 16 bits

30hex = Attribute Marker

01hex = Default value leave at 1

The map in Bold numbers configures to write data to %IW256.

See the above example Un-Bold numbers.

The Instance data was changed from 01 to 02 to map the next 16 bits for

%IW257.

Application note

A202301

• 53

54 •

Reference Material

3.12 Creating a Dynamic Assembly in the PFC

A Dynamic Assembly has to be created in the PFC memory. This memory location is where the Map will be placed.

The following will create the Dynamic Assembly position in memory to place

the map.

Click on the 750-806 to highlight the Icon in RSNetworx.

Next Cursor to Device and click to display the pull down menu.

Cursor down to Class Instance Editor and Click.

Application note

A202301

Reference Material

• 55

The following Warning window will be displayed.

Note: This Editor changes parameters in the buscoupler and caution

should be taken.

Make sure all data is entered in ALL HEX or ALL DECIMAL

(Examples are in Hex). If an address was entered in Decimal and data

entered in Hex, the data will go to the wrong location and change that position. The original Value will be lost.

Things can be changed inside which can make the PFC stop working.

Click yes to continue.

The Class Instance Editor window will be displayed.

Application note

A202301

56 •

Reference Material

Figure: Class Instance Editor Window

Click in Description and pull down to Create.

Enter in the following:

Class = 4

Instance = 0

Attribute = 1

Note: Do not press the Enter key, this will close the window and you will

have to start over.

Application note

A202301

Reference Material

Click on Execute to create a Dynamic Assembly position.

If the Dynamic Memory location was successfully created,

Data Received from the device = 100 0

If an error is displayed in the Data Received window the Dynamic Memory

Location was not created.

Check Class, Instance, Attribute Values

Check Dnet Connection

Check Dnet Configuration

Application note

A202301

• 57

58 •

Reference Material

Map data to Class 4 Instance 64 Attribute 2

Next Click in Description and cursor to Set Single Attribute.

Enter in the Following:

Class = 4

Instance = 64

(64hex = 100decimal)

Attribute = 2

Click into Data Sent to the device window to enter the following data.

Enter all the following data at once with space between numbers.

All numbers are in hex.

10 00 06 00 20 A6 24 01 30 01 10 00 06 00 20 A6 24 02 30 01

Once the data is verified and correct

click on Execute.

Application note

A202301

Reference Material

If all has worked correctly a message should be displayed in Data received

from the device:

“ The command completed”

If the map was not sent successfully then

Communication error or response error will be displayed.

Check Dnet connection.

Make sure Dynamic Assembly was created

.

Application note

A202301

• 59

60 •

Reference Material

3.13 Re-Direct I/O Map Pointer

Double Click on the 750-806 Icon to bring up the EDS Parameters.

Cursor down to ID#13 and ID# 14.

ID#13: is the pointer for Inputs (Default = 4)

If Inputs were mapped for the SLC then this parameter would be changed.

Leave at the default value.

There isn’t any need to map inputs because the SLC and PFC can

monitor inputs. The SLC and PFC do not control inputs they only read them.

ID#14: is the pointer for Outputs (Default = 1)

Outputs have been mapped into the Dynamic Assembly memory area 100dec.

(0x64hex).

The pointer has to be changed to point to the Dynamic Assembly Output map.

Double click on the 1 in ID#14 and enter 25604 decimal to redirect the pointer

to the Dynamic Assembly Output Map.

Download to device

Why 25604 In ID#14: In Hex format this equals (0x6404)

04 = Class type

(Low byte)

64 = 100 Decimal (High Byte)

From the note in an earlier step:

Dynamic Assembly 100 was created.

Dynamic Output Map data was entered into position 100.

ID#14 tells the pointer to do a Class 4 structure and look in Dynamic position

100 for the Output Map.

Application note

A202301

Reference Material

• 61

In the step above, 2 16 bit registers of Dynamic Integer were mapped for

PLC_OUT1 (PFC Address %IW256)

PLC_OUT2 (PFC Address %IW257)

No Real Outputs were mapped because the SLC will not have control the outputs.

Why is the Dynamic Assembly Map Needed:

The SLC is a processor that is trying to control the outputs through the scanner.

The PFC is a processor that is trying to control the outputs locally at the same

time.

Example:

If the SLC Output address = 0 and the PFC Output address = 1 the two processors are fighting to turn the output on and then off. The same thing will happen

if the logic is reversed between the two processors. The Output logic happens

very quickly. The outputs should be controlled by only one processor and

should be on continuously when controlled. The same applies to Analog outputs.

Symptoms:

While monitoring WAGO-I/O-PRO32 it is possible to see the output change

state at random and very quickly. Analog Outputs will be controlled by the

PFC, but for a brief moment. The output will change to the SLC output data

then back to the PFC control.

If this happens, look at the configuration steps above in Dynamic Assembly.

Application note

A202301

62 •

Reference Material

Figure: Save the Dynamic Assembly Map

Once the Dynamic Assembly Map has been created and the map data entered

the data needs to be saved in memory before cycling power.

Cursor down to ID#39 Save Dynamic Assembly Instances

Click on the down arrow to pull the menu down

Select the lower choice

“Dynamic created instances are stored in Non-volatile memory”

Download to Device

The Dynamic Assembly and Dynamic data Map will be save in memory

Resetting Dynamic Memory:

If the 750-806 Dynamic memory is to be reset

Select the Upper choice of ID#39

“Dynamic created instances are not stored in memory”

Cycle Power to the PFC

This deletes Dynamic assembly 100 and all the map data.

A new Dynamic configuration can be entered into the PFC from the above

steps.

Application note

A202301

Reference Material

• 63

3.14 The PFC and Module Addressing

1: Analogs and Specialty modules are always addressed first in the PFC

2: Digital modules follow next address after the Analog & Specialty modules

3: PFC Addressing is sequential

4: PFC Addressing starts at word 0

750-806 PFC I/O Addressing is as follows:

Inputs

Application note

A202301

Addrs

Variables

Control

750-467 %IW0

AICHAN1

SLC500/PFC Controlled

%IW1

AICHAN2

SLC500/PFC Controlled

750-402 %IX2.0 INPUT0

SLC500/ PFC Controlled

%IX2.1 INPUT1

SLC500/ PFC Controlled

%IX2.2 INPUT2

SLC500/ PFC Controlled

%IX2.3 INPUT3

SLC500/ PFC Controlled

750-402 %IX2.0 INPUT4

SLC500/ PFC Controlled

%IX2.1 INPUT5

SLC500/ PFC Controlled

%IX2.1 INPUT6

SLC500/ PFC Controlled

%IX2.1 INPUT7

SLC500/ PFC Controlled

PLC_Input1

%IW256 INPUT256

SLC500/ PFC Controlled

PLC_Input2

%IW257 INPUT257

SLC500/ PFC Controlled

64 •

Reference Material

Output

Addrs

Variables

Control

750-550 %QW0

AOCHAN1

PFC Only Control

%QW1

AOCHAN2

PFC Only Control

750-516 %QX2.0 OUTPUT0

PFC Only Control

%QX2.1 OUTPUT1

PFC Only Control

%QX2.2 OUTPUT2

PFC Only Control

%QX2.3 OUTPUT3

PFC Only Control

750-516 %QX2.4 OUTPUT4

PFC Only Control

%QX2.5 OUTPUT5

PFC Only Control

%QX2.6 OUTPUT6

PFC Only Control

%QX2.7 OUTPUT7

PFC Only Control

750-516 %QX2.8 OUTPUT8

PFC Only Control

%QX2.9 OUTPUT9

PFC Only Control

%QX2.10 OUTPUT10

PFC Only Control

%QX2.11 OUTPUT11

PFC Only Control

PLC_Output1 %QW256 OUTPUT256 PFC Only Control

PLC_Output2 %QW257 OUTPUT257 PFC Only Control

750-600 End Module (No Memory Allocation needed)

Application note

A202301

Reference Material

Application note

A202301

• 65

WAGO Kontakttechnik GmbH

Postfach 2880 • D-32385 Minden

Hansastraße 27 • D-32423 Minden

Phone:

05 71/8 87 – 0

Telefax: 05 71/8 87 – 1 69

E-Mail:

info@wago.com

WAGO Corporation USA

N120W19129 Freistadt Road

PO Box 1015

Germantown, Wi 53022

Phone: 1-262-255-6333

Fax: 1-262-255-3232

Internet:

http://www.wago.com

Call Toll Free: 1-800-DIN-RAIL

(346-7245)

Internet:

http://www.wago.com