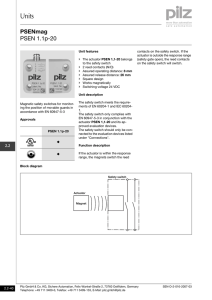

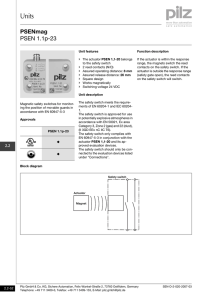

PSEN product range

advertisement