Safety Checks and Maintenance of Private

advertisement

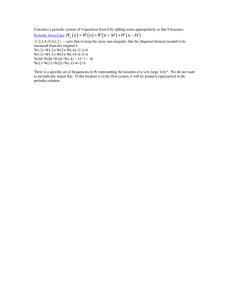

PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 PROCEDURE PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES Purpose The service line that connects private property to the networks distribution line is owned by the property owner. The property owner/consumer is legally responsible for the safety and maintenance of their electrical installation; this includes overhead or underground service lines, not just the wiring inside a building. This standard will provide the consumer and the consumer’s contractor with a clear process for the regulatory periodic safety check of private service lines to prevent serious harm to members of the public or significant damage to their property. Prepared By : K Tierney Approved For Issue By: G Lloyd NETWORK WAITAKI Revision 003: Feb 2013 Page 1 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Documentation Revision Control: Document Revision Description of Change Date Version 001 Initial Standard document Reviewed – No changes New definitions Added sections 6 to 6.8 General checks 24/11/2009 30/11/2011 17 /7/2012 1/02/2013 Version 002 Version 003 NETWORK WAITAKI Revision 003: Feb 2013 Page 2 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES Index: NP15/105 Feb 2013 Definitions 1 Introduction- Consumers Responsibility Safety Compliance Checks 2 Regulations 3 High Voltage Lines 4 Private HV Lines – Asset Management 5 ‘Electrically Safe’ & ‘Electrically Unsafe’ 6 General Checks 7 Certification of private lines 8 Electrically Unsafe Lines 9 Verification Dossier 10 Safety Checks – Periodic Assessment 11 Specific Earth Testing 12 Equipment Check for Private HV Line 13 Preventative Maintenance 14 Preventative Maintenance Tasks and Intervals 15 Access to Power Lines 16 Trees and Power Lines APPENDIX List of Authorised Contractors Certificate of Periodic Safety Check Record of Periodic Earth Tests. Safety Compliance Checks – Flow chart NETWORK WAITAKI Revision 003: Feb 2013 Page 3 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Definitions: Consumer: means any person who is supplied, or who applies to be supplied, with electricity. Contractor: means any competent person or organisation carrying out work for the consumer. Works: means all fittings that are used in conjunction with the generation, conversion, transformation or conveyance of electricity but, does not include any part of an electrical installation. Consumers Works: means the privately owned portion of service line between the Point of Connection (POC) to the network line and the Point of Supply (POS) at the end users property boundary. Point of Connection: (POC) means the point of demarcation where the private owned line connects to the network owned line. The POC is usually the location of the network owned isolation device which could be either LV or HV. Point of Supply: (POS) means the point at which the service line crosses the end users property boundary as defined in the Electricity Act 1992. The line then becomes part of the electrical installation. If the POC is within the end users property boundary, the POS is at the same location. Electrical Installation: means all fittings beyond the property boundary (POS) that form part of a system that is used to convey electricity to a point of consumption or used to generate or store electricity. Can include a private service line. Private HV Line: A private HV service line is an overhead or underground power line exclusively for use by the end user. The transformer is owned by NWL and power is consumed by LV appliances. The line may also be used jointly by other consumers. The supply transformer, the HV and LV service fuses are owned by NWL. Joint Service Line: Is a service line that supplies in part a third party for example, where the last length of line to a consumer’s property branches off a line owned by a neighbouring property. Safety Check: means a careful examination of the works or installation to confirm that it is within compliance with the Electrical Safety Regulation 2010, Reg. 41 to 46 and assessed whether or not it is ‘electrically unsafe’. Test: means a logical methodology with or without test instruments to ascertain whether an electrical installation meets required performance standards. NETWORK WAITAKI Revision 003: Feb 2013 Page 4 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Vegetation Safety Clearance: means the required clearance distance between trees and other vegetation and the electrical conductors. 1 INTRODUCTION – CONSUMERS RESPONSIBILITY. The enactment of the Electricity Act 1992 and the Electricity Safety Regulations 2010, requires owners of electrical installations Under Regulation 15 – “Using Works, Installations, Fitting and Appliances”, to ensure that installations are not used if found electrically unsafe. An electrical installation may also include a private service line that conveys electricity between the lines owned by the network company (the network) and a consumer’s premises. The point at which the network ends and the private service line begin is the point of connection/point of supply and is usually where network owned isolation fuses are located. A private service line may be connected at high voltage or low voltage and owned by the end user, either alone or in part by a third party (joint ownership). A private service line may be located on land owned by the end user and/or on land owned by a neighbouring property. The private service line owners’ responsibility extends to the operation, maintenance, safety and replacement of the power line. The only exceptions to the above are NWL owned meters, relays and the supply transformer associated with the installation. The owner may however, contract their responsibility for the operation and maintenance of the line to a competent person. The consumer is still obligated to ensure the periodic safety checks are done by a competent person so that the lines and the poles supporting them are not in an unsafe condition. This includes checking for close contact with trees etc. Keeping your power lines in a safe condition will help to ensure you, your family and the general public avoid serious injury or death. NETWORK WAITAKI Revision 003: Feb 2013 Page 5 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 2. Regulations: - Existing Installations Low Voltage Lines - the consumer shall employ their own electrical Contractor to perform the required periodic safety checks. The Electricity Safety Regulations outlines some basic conditions which will constitute an unsafe electric line if measures are not in place to: • Prevent accidental contact with exposed live conductors • The characteristics of poles and fittings are impaired, broken or badly damaged. • Conductors are not secure at terminations and supports. • Accessible non earthed exposed metal parts within 2.5m above ground. • Electric line conductors within the minimum ground clearance. • Construction, buildings, excavations or other works within the minimum safety distances (NZECP34) 3 High Voltage Lines – Installations & Works ESR,s 40 and 62 require every owner of private lines to establish and implement a periodic safety checking system on a regular basis that complies with the following: The safety checking system must ensure– • The HV lines be checked for compliance with regulations 41 to 46. • Provide periodic checking at reasonable intervals. (NWL inspects its own distribution lines on a rotational basis every 5 years). • That records to be kept of the results of every periodic check to demonstrate this responsibility has been met and what maintenance work has been done. Standard NP25/55 – Recording Periodic Safety Check provides a standard process to follow. 4 HV Service Lines – Asset Management: The Electricity Act requires high voltage assets to be managed by a body or person as defined in the Act as an Electricity Operator. NWL is an Electricity Operator and offers an asset management service to ensure high voltage lines are regularly checked and records kept. The service will only apply to outdoors high voltage service lines and will include: • Documentation that clearly identifies the assets owned by the consumer • Faults answering service. • High voltage operating of the service line. • NWL has offered each line owner to undertake the prescribed safety checks required by the Electricity Regulation every 5 years in line with this Network Standard NP15/105. • The consumer must in addition visually check over the line for anything that looks unsafe at least on a yearly basis. Record these checks. • NWL will test the transformer earths every 5 years to ensure electrical integrity in accordance with Network Standard NS10/15 Section 8 “Testing Earthing System Resistance” • NWL will maintain a data base of those installations and the dates when the next inspection and tests are due. NETWORK WAITAKI Revision 003: Feb 2013 Page 6 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 • NWL will notify the consumer of the results of the safety checks and earth tests, and what remedial action may be necessary. Consumers must notify NWL if they do not wish to avail themselves of this management service. The consumer must then engage their own Electricity Operator to manage and operate their private service line in accordance with the Act. 5. ‘Electrically safe’ and ‘electrically unsafe’ is defined in ESR 5 such as to create a spectrum that increases from the former to the latter. The state of being electrically unsafe is the point at which the risks of serious harm to persons or significant damage to property become intolerable in the view of a reasonable person. ‘Safe’ generally denotes compliance with current regulations, codes and Standards, but most of the works and installations now in existence and in use will have been designed and installed to older regulations, codes and Standards. They age and deteriorate over time. The current regulations permit these to still be used provided they are not ‘electrically unsafe’. The risks associated with their use may be higher than if they were ‘safe’ but they remain in the tolerable range of acceptance. 6 General Checks 6.1 General Means the visual examination of electrical equipment of an installation to provide a judgement on its condition with set criteria to ensure that it is not electrically unsafe. 6.2 When an installation is designed and installed the following measures are basic and are those which establish a safe installation. • • • Test to ensure polarity and phasing is correct Rating of protection device is correct Ensure that the installation is compatible with the supply system. Major safety features are provided for in the installations design: 1. Protection against direct contact. 2. Protection in case of indirect contact. 3. Protection for mechanical soundness of equipment 4. Protection when working on electrical installations. 5. Protection from dangers resulting from arc fault. 6 Protection against fire. Periodic safety checks for private high voltage service lines (ESR 40) require checks to be made to ensure the above mentioned safety features are not unduly compromised with regards to ESR 41 to 46: NETWORK WAITAKI Revision 003: Feb 2013 Page 7 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 6.3 Strength of Structures (ESR 41) The overhead line is designed, constructed and maintained so that it will readily withstand the stresses placed on it by extreme wind, rain, snow, and ice and such other events as earthquakes, floods, lahars, etc. that might be reasonably expected in the location in accordance with ESR 41. (The network company may advise the construction standards that it applies for the design, construction and maintenance of its own HV overhead lines in similar locations). 6.4 Effective Connection to Earth (ESR 42) The system of which the overhead line is part is provided with an effective connection to the general mass of earth in accordance with ESR 42. The connection to earth will normally be provided by the supplying network where the neutral is effectively earthed at the distribution transformer (MEN), in which case it may be assumed by the person carrying out the safety checks as being effective. 6.5 Isolation (ESR 43) Convenient means exist, in accordance with ESR 43, to isolate the HV electrical Installation from the supplying network by means of a HV switch, fuses or links provided either within the HV electrical installation or else by the supplying network. 6.6 Effective Electrical protection (ESR 44) The private overhead line is protected by fuses placed at the point of connection plus the protection of the supplying network (as permitted by ESR 44). In rare cases, the private overhead line is protected by a circuit breaker or recloser at the point of connection with protective relays provided to discriminate with the network protection. Equipment, other than fuses, that is provided to protect the overhead line has been checked for correct installation and operation by way of secondary injection and primary injection testing to check the correctness of CT ratio and polarity. Settings provide for full discrimination to lessen the risk of operation of network feeder protection acting as backup protection. 6.7 Notices (ESR 45) Wherever the overhead line is constructed of poles or supports that may be climbed without the use of equipment (such as a ladder), and the conductors of the line are un-insulated, conspicuous and durable notices reading “Danger Live Wires” or similar are present on the poles or supports as per ESR 45. 6.8 Records and Plans (ESR 46) Records as required by ESR 40 are kept, and are available to the network company or request, as to the dates and results of safety checks carried out on the overhead line. Records and plans as may be reasonably required by ESR 46 are kept, and may be accessed by any person reasonably requiring them, as to the ready location of the overhead line. NETWORK WAITAKI Revision 003: Feb 2013 Page 8 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 7 Certification of Private HV Lines From the moment a HV line is left connected, responsibility shifts to the owner to ensure that it remains in the state of not unsafe. Periodic safety checks mandated in ESR 40 provide the owner with a recognised means of ensuring this safety thereby removing owner liability. The duty of the safety check assessor is to report on the status of the works. If any deficiency is found which would not render it to be ‘electrically unsafe’ there is no requirement to have it rectified prior to the assessor issuing certification to the owner who requested it. 8 Electrically Unsafe Lines If any deficiency is found which would render the works electrically unsafe the assessor must notify the owner and NWL of the unsafe non-compliance. The owner has the responsibility under the regulations to have the non-compliance rectified within the prescribed time specified in the ESR 41. NWL has the final option of removing the unsafe connection from its network until it is rectified. NWL will follow up with the individual responsible to ensure the required work has been done. If the unsafe service line is shared, NWL make contact with all affected owners/consumers. It is still the owners/consumers obligation to keep an eye out for things that don’t look safe and be sure to deal to them before they get worse. Do not just rely on the safety check carried out every 5 years. The consumer must check more regularly. 9 Verification Dossier The owner of a private HV service line should hold documentation outlining the assets which they own and the subsequent periodic safety checks along with what maintenance work has been done.. It is vital that all documentation relating to the private line be recorded and filed in a Verification dossier or the like and be kept by the Installation owner to prove regulatory compliance. Verification dossiers are expected to include other relevant documents where applicable:* Certificate of Compliance number (or copy thereof, the Consumer would have received the certificate from the installing contractor for any new installation work). * Plans of the installation including location of earth mats and underground cables. * Details of equipment (manuals) * Equipment and Appliance Test Certificate commissioning tests and results of the periodic safety checks. * Records of maintenance work. NETWORK WAITAKI Revision 003: Feb 2013 Page 9 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Plus any other relevant information including, design calculations where appropriate. 10. SAFETY CHECKS - PERIODIC ASSESSMENT 10.1 A line owner who chooses to nominate NWL as the Electricity Operator to provide the asset management of their line can expect the safety compliance checks as shown in the Appendix - Flow Diagram for Service Lines. A line owner who chooses to nominate an alternative provider for asset management as their Electricity Operator must ensure the safety compliance checks are as shown in the Appendix – Flow Diagram for Service Lines. 10.2 The on-going safety of any High Voltage installation including a private service line is measured by periodic safety checks. NWL has a 5 yearly rotational safety check on its own network and will, as your chosen operator, check your private HV service line on the same basis. It’s the owner’s obligation to ensure that their installation is periodically checked to determine whether or not it is unsafe with regards to ESR 41 to 46. 10.3 A safety check does not imply that an installation will remain electrically unsafe. Rather it is a report on whether or not it was ‘unsafe’ at that space in time. Regulation 15 makes it the responsibility of the owner or operator to ensure the installation is not unsafe and the safety check provides proof (or otherwise) of meeting that responsibility. The periodic Safety Certification Report should be filed in the Installation’s verification dossier and held by the owner. When carrying out a safety check the inspector should check whether equipment is appropriately identified and labelled with respect to the diagrams and records. 11. Specific Earth Testing The integrity of the earthing system of transformers should be verified by appropriate periodic inspection and tests. NWL will visually check the earth conductors and connections when conducting the usual 5 yearly periodic safety checks on service lines. NWL will do resistant measurement tests to ensure electrical integrity of transformer earths associated with private service lines on a 5 year basis when testing other NWL transformer earths in the same area. Records of all resistance tests will be maintained by NWL and the private service line resistance tests will be notified to each consumer on the Consumer Earth Test report shown in the Appendix. NETWORK WAITAKI Revision 003: Feb 2013 Page 10 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 12. Equipment check for Private HV Line Where applicable, the following equipment should be included in the safety check: Overhead lines Cables - Clearances from ground, structures, trees etc., Electricity Regulations 17 and ECP34 Clearances from other lines, ECP34. Check for change of usage of ground under lines and its effect on clearances and hazard to supports. Line condition, warning notices, pole and crossarm state, insulator, braces. Earthing of metalwork including cable potheads, ABS’s etc. Point of entry, clearances, warning notices, building changes, or hazards to maintenance staff. Structures, e.g. transformer, pole state, insulation, earthing, conductors, clearances. Cables adequately supported and protected on poles including inspection of - cables, o/h terminations, earthing of potheads where appropriate, warning notices, radius of bends, cable entry to substations. Examine transformer and switchgear Cable terminations for leaks, heat, and noise. Check that cable armouring is securely terminated and earthed. Inspect cable insulation and continuity records. Cable route marking. Earthing - Check that earthing of substations, switchgear etc. is in accordance with ECP35-(6.5) (6.6) Check earthing of structures, buildings, ECP35 (6.6). Neutral point earthing or artificial earthing points. Fuses - That fuse sizes are appropriate for transformer protection. Fuse storage is adequate. Fuse Resistance tests Transformers (usually owned by NWL) - Check for oil leaks, tank distortion. Check oil level, colour, and oil temperature. Silica gel breather operation. Earthing conductors attached. Cable terminations sound, insulation intact, neutral earthed if appropriate. Check test records. Check case and radiators for damage and or corrosion. Test Equipment - Check test and measuring equipment records for appropriate test results. Inspect test equipment for serviceability NETWORK WAITAKI Revision 003: Feb 2013 Page 11 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES Earthing Attachments - NP15/105 Feb 2013 Check condition of flexible cables, appropriateness of cable cross section, terminations and insulating pieces. 13. Preventative Maintenance Maintenance is undertaken to maintain the value of the assets, maintain adequate levels of reliability and it should identify conditions of reduced safety. Safety checks are an important element of maintenance but their use must be controlled to improve reliability. Important elements to be considered are:* * * * * * * the frequency their scope what equipment is to be checked what is to be checked for standard “check lists” are necessary to ensure consistency record and report findings work schedule from findings 14. Preventable Maintenance Tasks & Intervals The owner of a private service line must ensure that the following are typical tasks carried out on private service lines and the maintenance period which should be followed:Overhead Lines Inspect condition of cross arms, insulators, conductors and poles every 4-5 years frequency, depending on pole type and age. Check clearances from ground using NZECP 34:2001 for electrical safe distances. Wood Poles All wood poles must be checked prior to climbing. Consumer owned poles must be subject to a rigorous pre-climb inspection including underground checks. Underground Cables Check they are adequately supported and Protected from damage. Transformers Check that oil leaks do not contaminate the ground- annually where applicable. Earths Tested every three to five years. NWL will carry out these tests on a regular basis. Trees Check for trees which could pose a hazard to power lines. NETWORK WAITAKI Revision 003: Feb 2013 Page 12 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 15. Access to power lines Where property owners do not own the power lines which cross their property they have rights and responsibilities in relation to those lines. For new lines, the line owner will have needed an easement or other contractual agreement to build the line. Under the easement or agreement, the line owner has the right to access the private property to maintain those lines. For older lines where there is no agreement in place, the line owner has the right under the Electricity Act 1992 to access the private land to inspect, maintain and replace the lines (so long as the line replacement does not injuriously affect the property). The land owner can set reasonable conditions for the line owner’s access but cannot include payment of money. 16. Trees and Power Lines The Electricity (Hazards from Trees) Regulations 2003, governs the control of trees around power lines. The property owner has obligation under the regulations reinforced by the consumer’s contract with their electricity retailer. The contract requires trees and other vegetation be kept away from all power lines and other electrical equipment on private property. NWL is not obliged to inspect the trees and vegetation around private lines, but may observe a problem in the course of its other tasks. If a tree problem is observed, NWL may issue a Cut & Trim notice. This does not in any way reduce the responsibility of the private service line owner for inspecting their own line on an annual basis for tree and other vegetation hazards. If you wish to cut or trim trees near you’re privately owned service line , we recommend that you engage a competent contractor who will have the essential skills and specialist equipment to conduct the work safely. Ring NWL on 0800 440 220 for a list of competent contractors. NETWORK WAITAKI Revision 003: Feb 2013 Page 13 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Safety Compliance Checks – Flow Diagram for Service Lines NP15/100 Guidelines for Management of Service Lines Owner & (NWL) (Owner) NWL Asset Management Data Base Owner notified of line NWL will be Owners ownership. Plan & Asset Electricity Operator Alternative Nominated report forwarded to owner Electricity Operator *Owner to ensure regular Faults maintenance & repairs done Service Manage Faults, operating, and regular safety check Repairs & maintenance and ensure Operating Periodic Safety Checks are done See NP15/105 NWL 5 yearly assessment check Periodic Safety Checks NP15/105 (Ensure it’s not electrically unsafe) Stability poles Tree Structures proximity X arms etc. Earthing Change in ground clearances (Ensure it’s not electrically unsafe) Owner UG pole Inspection Owner Regular/yearly Manage safety check yearly of lines, poles tree (electrically Inspections safe) Proximity to buildings Recording Periodic Safety Checks NP25/55 Devise system of recording Safety Checks Owner to Arrange repair & maintenance Inform Owner of results Owner to file Record of checks, Repairs & maintenance in owners dossier file to prove Regulation compliance NETWORK WAITAKI Revision 003: Feb 2013 Page 14 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 APPENDIX Approved Contractors for work on Private Overhead Lines: • Network Waitaki Contracting, Oamaru Manager: Derek McGee (03) 433 0591 or 027 491 6155. • Network Electrical Servicing, Invercargill Manager: Michael Fife (03) 218 8897 or 021 491 951. • Electricity Ashburton Manager: Wayne Watson (03) 307 9800 • Lemacon, Ashburton Manager: Tony Potts (03) 307 6622 or 021 784 641. NETWORK WAITAKI Revision 003: Feb 2013 Page 15 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 NETWORK WAITAKI LTD CERTIFICATE OF PERIODIC SAFETY CHECK Asset Condition Periodic Safety Check Record Name: ICP Number: Location: Postal Address: 5 February 2009 Asset Identification Diagram See Over Page NWL PVT POS HVDC - Network Waitaki Ownership Private Ownership Point of Supply – legal boundary where electricity enters the premises HV disconnection point – physical demarcation point of line ownership Asset Listing ID Description Line Segment L432-09-00, Pole 20419 Pole 20420 Pole 20421 Pole 20841 Transformer Site Transformer T836 Owner Inspection Date Result PVT PVT PVT PVT PVT NWL Mar 2008 Mar 2008 Mar 2008 Mar 2008 Mar 2008 Mar 2008 Pass Pass Pass Pass Pass Pass I certify that the results of the periodic safety check of the above private service line with Electricity (Safety) Regulation 40, are as stated on the attached Information and Safety Check Report: This certificate is subject to the condition that all reasonable care has been exercised in the inspection of the overhead line and no other mechanical or electrical defect was detected that will render the line unsafe. Signature NETWORK WAITAKI Date Revision 003: Feb 2013 Page 16 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 NETWORK WAITAKI LTD Form NF05/180 General information and Safety Check report for safety checking system compliant with ESRs 40-46 of Electricity (Safety) Regulations 2010. I certify that the identified overhead line has been safety checked and I consider that the line is: (strike out options that do not apply) a) not structurally, or electrically unsafe and may continue to remain in service with the application of routine maintenance for the next five years. b) structurally/electrically unsafe and the remedial work identified in the report needs to be done within the next……….months in order to remain in service, subject to a further safety recheck after that date. c) structurally/electrically unsafe and should be disconnected forthwith, to be reconnected only after completion of the remedial work in the report and a further safety recheck. Item Information required Information/comments Owner of Line Location Voltage of line Two wire, three wire 11kV Classification of line Consumer works, Installation Actual or assessed Line construction year Applicable regulatory safety period ESR 38: protection of line provided? ESs 1984, 1993, ECP 34 1193 Fuses, HV earth fault and overcurrent, etc? Protection provided by NWL or owner? Type of poles Wood, concrete, ESR 41: poles capable of withstanding likely structural loading? ESR 42: earthing system for protection provided? Is any pole structurally unsafe? Neutral earthed at supply transformer Earthing system provided by NWL/owner? ESR 43: line isolation? Means of isolation provided by NWL/owner? ESR 44: earth fault protection provided for HV conductors Fuses, links, hard wired? Earth fault protection provided on NWL HV feeder? Earth fault protection provided by NWL/owner? NETWORK WAITAKI Revision 003: Feb 2013 Page 17 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES ESR 44: protection setting or fuse rating appropriate? ESR 45: danger notices in place on all climbable poles carrying uninsulated conductors? ESR 46: documented safety checking system with full records in place held by the line owner? Location of the point of connection with the network? Location of the point of supply along line NP15/105 Feb 2013 Setting of fuse rating discriminates with NWL feeder protection for most faults? Copy held by NWL where default operator Pole number Nearest pole number General condition of cross-arms, fasteners & stays General condition of conductors Any buildings or other structures within safety distances of line Any trees along the line which encroach the growth limit zone? Are any poles marked with orange suspect tag? Are any poles marked with a red tag? What remedial work is needed to ensure public safety for at least 5 years? When should remedial work be carried out to ensure public safety? Signature……………………….. NETWORK WAITAKI ERs 1984, ECP 34 1993, ECP 34 2001? Within three months, six months, twelve months? Date……………… Revision 003: Feb 2013 Page 18 of 19 PERIODIC SAFETY CHECK OF PRIVATE SERVICE LINES NP15/105 Feb 2013 Appendix RECORD OF PERIODIC EARTH TESTS PRIVATE HV SERVICE LINE TRANSFORMER SITE NUMBER. T…………. Consumer……………………………………… Address……………………………………………. …………………………………………….. To be measured at intervals of not more than 5 years Equipment Transformer Air Break Switch Surge arrestor Other Mounting Single Pole □ Two Pole □ Ground Mount □ □ □ □ □ Test each electrode resistance, MEN system resistance and, ”Touch and Step” resistance. Earth No. Electrode 1 Voltage R1Ω RESISTANCES Electrode 2 M.E.N Step Resistance R2Ω R3Ω R4Ω Touch Resistance R5Ω Remarks…………………………….. ………………………………… Measured By…………………………….. NETWORK WAITAKI Revision 003: Feb 2013 Page 19 of 19