Industrial Applications of Ultrasound

advertisement

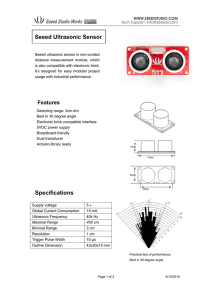

IEEE TRANSACTIONS ON SONICS AND ULTRASONICS, VOL.SU-22, NO. 2, MARCH 60 1975 Industrial Applications of Ultrasound -A Review I. Hish-Power Ultrasound Abstract-The estimated worldwide sales of ultrasonic power equipment for industrial uses total nearly $100 million a year. The industry had its beginnings shortly after WorldWar II and grew steadily over the next two and a half decades. Lower cost of ultrasonic power made possible by advancesin electromechanical power conversion materials and power semiconductors has greatly contributed to the practicality of ultrasonic equipment. Yet the main reason behind the growth of power ultrasound is the ability to perform some unique jobs that save money and have become indispensable in modern manufacturing. Not all attempts to implement ultrasonic power devices have been successful, butcommercial success is a function of technological state of the art and the need for the process. Since both change with time, surprises are likely. Who would have guessed the potential of ultrasonic plastic welding, letalone that of ultrasonic “sewing”? ’ While stressing the more established applications, this article takes a broaderlookat the uses of high frequency mechanical vibratory energy, outlining the advantages and the limitations of each process. I. GENERAL I N CONTRASTto ultrasonic nondestructivetesting, theobject of a macrosonicapplication is to expose the workpiece to enough vibratory energy to bring about some permanent physicalchange. This involves a flow of mechanical power from the source to the workpiece, which,dependingontheapplication,mayrangefrom a few wattspersquareinch to tens of thousands of watts per square inch. Vibratory input, during the time of exposure, is normally of thecontinuousRavetype. Macrosonicphenomenaextend well intothemegahertz range, butmost practicalworkisdone at frequencies of between 20 and 60 kHz, somewhat above the range human hearing. A basic macrosonic systemconsists of an electromechanicaltransducerandahighfrequencyelectric power supply. The power supply converts the available elect’riclinepower intohighfrequency electricpower which is used to drive the electromechanical transducer. The transducers are typically of a compound design, but at theirheart use electrostrictiveor magnetostrictive elements which changephysicaldimensions inresponse to an electric or a magnetic field. Mostmoderntransducers use piezoelectric ceramicsof lead zirconate titanate due to its superior electromechanical conversionefficiency, typically in the orderof 95% or better. Manuscript received November 8, 1974. The author is with Branson Ultrasonics Corporation, Subsidiary of Smith Kline Corporation, Eagle Rd., Danbury, Conn. 06810. Just what are the limits of practical ultrasonic power today? If the application allows stacking of sonic power sources, no particular limit to the maximum t,otal power exists. The poweravailablefrom a single half-wave transducer, however, is limited bythe volume of the electromechanicalconversionmaterial that canbe accommodated and varies inversely uit’h the square of the frequency. As transducer design dependson the use, exact power limits are not possible to pin down, but,4 kW a t 20 kHz could serve as a rough reference. Bydefinition, the mechanical power transferred from the sonic source to the load is the product of sonic source velocity at the loadinterface and the mechanical force resisting the sourcevelocity [l]. The force is produced by the medium on.which the sonic source is acting. Transducer output velocity and frequency can be used as primarysourceparameters. The product of velocity andfrequency defines acceleration, andtheratio of velocity andfrequency defines t’he transduceroutput displacement. See Table I. As a point of interest,practicalultrasonicpower sources are by nature velocity or displacement generating devices, where due to high mechanical Q the motion is sinusoidal, andthereareno practicalways of directly generating ultrasonic forces. The most commonly used transducers are of extensional type where the output face of the transducer is a circular piston area vibrating sinusoidally in the direction of t’he transducer axis. Thetransduceroutput facecan be applied directly to the load, or coupled to intermediate sonic resonators (Fig. 1). Extensionaltransducersimpart compressional waves to the load. Transducers can also be designed to produceshear,torsional or flexural vibration, or to focus vibrational intensity in fluid media. Contrarytothepopularmyth, ultrasonic treatment isnormallynotdoneby focusing soundwaveson the work through the air. In most cases a direct contact with the vibratory tool is needed, or liquid is used as a vehicle. Neither is therea commonmechanismresponsiblefor all sonic effects: ultrasonic metal welding is unrelated to ultrasonic aerosol production, and plastic welding is unrelated to ultrasonic cleaning. Yet there are some peculiarities about the basic ultrasonic parameters, as shown in the following example. A 20 kHztransduceroperating a t apeakoutput velocity of 26 ft./sec. will havepeak-to-peak displacementamplitude of 0.005 inches andpeak acceleration of 10 X l@g. To load t8he transducer to 1 kW the load 61 SHOE: INDUSTRIAL APPLICATIONS OF ULTRASOUND TABLE I EFFECT OF FREQUENCY ON TRANSDUCER PARAMETERS PARAMETER FREQUENCY FREQUENCY x 2 Length L L/2 Width W w/2 Weight K W8 Sonics and Liquids and Sonics and Solids give an overview of macrosonicapplications and highlightsome of the more intriguing developments. 11. FIVE MAJOR APPLICATIONS A . Cleaning Ultrasoniccleaning is the oldest industrial applicaPower density P P tion of power ultrasound. Present-day uses span a wide D D/Z Displacement variety of industries ranging from castings to semiAcceleration A ZA conductors. Ultrasonic cleaning is often combined with V V Output velocity other pre- and post-cleaningoperationssuch as presoaking or vapor rinsing and makes use of a variety of detergentsand cleaningsolutions.Descaling and degreasing are also done. Themainadvantage of ultrasoniccleaning lies in “brushlessscrubbing”due to cavitation, which ina well-designed cleaner is evenly distributed throughout the volume of the liquid and is capable of reaching normally inaccessible places.Ballbearings, carburetorparts,and vessels with complex internal cavities can be effectively cleaned. works best, on relatively hard Ultrasonic cleaning materialssuchas metals, glass,, ceramics, and plastics, which reflect rather than absorb sound. Cleaning equipment normally operates in the range of 20-50 kHz. The phenomenon responsible for ultrasonic cleaning is cavitation.Highfrequencyalternating pressure in a liquidforms microscopic voids whichgrow t o a certain size, then collapse, causing very high instantaneous temperatures and pressures. This implosion of cavitaFig. 1. Sonicandultrasonicpowertransducers: S kW, 10 kHz; 1 kW, 20 kHz; and 40W, 40 kHz. Transducers are of piezoelectric tionalbubbles does therough work of loosening dirt type. and grease stuck to the workpiece. Oscillation of stable cavitational bubbles. andtheresult’antmicrostreaming must exert onthetransducerapeak force of 57 lbs. also contribute to cleaning [ S ] . (excluding any reactive loading).Theworkperformed Cavitationcanbeproducedbyothermethodsthan by this transducer in one second is equivalent t o lifting ultrasonics and is commonwith underwater propeller a 740 lb. load to a height of one foot. What is so unusual blades and steam turbines. Ultrasonically induced cavitaabout these values? tion, however, can be produced as a far field effect,, away is characterized by very high from the source, andwithoutany First,powerultrasound gross movement of repetition rates, small displacements, moderate point the liquid. Far field effect. is achieved by resonating the velocities, and very high accelerations. Second, large amounts total volume of the liquid in the cleaner. ,4t frequencies of work can be done without application of high forces and of interest, the layers of maximum cavitational intensity large displacements. The transducer in the example, repeat every 0.5 to 1.5 inches producing fairly uniform incidentally, would weigh about 2 lbs. cleaning throughoutthe volume. For moreuniformity Another useful characteristic is the ability to propagat e the parts may be moved duringexposure. Power density of ultrasonic cleaners is relatively through solids, liquids, and gasses and form a resonant low, pattern. This allows work to be done at areas away from usually below 10 watts per square inch of driving area. results in a loss of the source and makes it possible to treat a large volume An attempt to “overdrive” t8he tank the far field effect and causes pronounced cavitation and of material. Most uses of macrosound depend on compound vibrawear at the driving surface. tion-induced phenomena occurring in matter. These are The choice of cleanerfrequencyisnormallydet’er1) cavitation and microstreaming in liquids [ 2 ] , [3] mined by the application. Since cavitational shock 2 ) surfaceinstability occurring at liquid-liquid and intensity is higher at, lower frequencies, a 2.5 kHz cleaner liquid-gas interfaces [4], will havemorebrute cleaningability thana 40 kHz 3) heating and fatiguing in solids.. cleaner.However lower frequencies havebeenfound Major uses of macrosound are discussed next in order damaging to somedelicate parts,and for cleaning of of commercial significance. Since hardfactsarenot semiconductors, for instance, 40 kHz may be preferable. available, the ranking is by necessity subjective. Sections 40 kHz cleaning is also quieter. Output surface S W 4 Power P P/4 62 IEEE TRANSACTIONS ON SOMCS AND ULTRASONICS, MARCH 1975 choice of optimum cleaning paramet.erscanbe and further advances in this area are likely. tricky B . Plastic Welding Fig. 2. Monorail automated ultrasonic cleaning system for cleaning, rinsing, and drying automotive ring andpinion gears. Fig. 3. with power Buppliea mounted in the base. Smallultrasoniccleaners Standard industrial cleaners typically range inpower fromone hundredtoacouple of thousandwattswith corresponding tank capacities of 1-44 gallons.Multikilowatt special syst,ems with tank capacities of several 2 ) . In recent hundred gallons arenotuncommon(Fig. years, low power, low cost(below $100) cleaners have becomeavailable,which hasmade ultrasoniccleaning accessible to m a l l shops and laboratories (Fig. 3). Modernultrasoniccleanersemploysolid-state electronic power supplies with automatic tuning and do not require operatorattention. A commonproblem to all ultrasoniccleaners is gradualdeterioration of the tank due to cavitational erosion. This depends largely on the application, and well-designed systems can give years of satisfactory service. It is hard to envision any dramatic breakthroughs in ultrasonic cleaning. Tank materials and design can probably be further improved to extend life and enhance for cleaning. Since cavitationalbehavior is different different,solvents, and alsochangeswithtemperature, Probablywithout knowing it, most, people in the United States come in daily contact with ultmsonically m-elded plastic parts. The processwasdeveloped in tho was quickly accepted in asscmbly of last ten years and toys, appliances, and indust,rial thermoplastic parts. The big break came with discovery of far field welding, which made welding of rigid thermoplastics possible and extendedthetechniquebeyond welding of plastic films practiced earlier. Ultrasonic welding hasan idealcombination of ingredients sought in modern manufacturing. The process is fastand clean,requiresnoconsumables, does not need a skilled operator, and lends itself readily t,o automation. It is used extensively in the automotive industry for assembly of taillights, dashboards, heater duct,s, and other components where plastics have replaced thc traditional use of glass and metal. How does the process work? Essentially, highfrc?qut*ncy vibrationproducesheat whichmelts the plastic. Yct ultrasonically induced heat can be generated sclr:c:tivc~ly, precisely at the interface of the parts being joined without indiscriminate heating of the surrounding material. Less weld energy is used, resulting in less dist,ortion and material degradat’ion. Sinco tha heat is gctneratcd within the plastic and not conducted from the t,oo1, welding can be a.ccomplished in completely inaccessible placps. Mostthermoplasticshavecharacteristicssuitablefor ultrasonic welding [S]. This includes theabilityto transmit and to absorb vibration, as ~vell as low thermal conductivity to facilitatelocal build-upof heat,. Heatingin plasticis a function of ultrasonicstress and varies roughly as the square of stress amplitmud(;.To maximize the stress in the weld region, the cwntact’ area between the parts being joined is rcduced. Static: clamping force is used t o keep the parts together during wclding. A “holdtime” of a fraction of a second is added after ultrasonic exposure to allow the plastic t80solidify before unclamping. Typical welds arc don(. in less than a second. Compared to cleaning, ultrasonic plastic wdding requires much higher power densities, typically hundrcds of watts per square inch at’ the weld, and at t8he contact of the toolwith the workpiecc. To deliversuch power densities plastic welding horns operate at amplit,udcs of 0.001 to 0.005 inches (over ten times higher than cleaning), and due t o high energy storage exhibit very sha,rp mechanicalresonances.Additionally,dependingon the application,theymustaccomrnodatc a wide variety of loads, andduringthe welding mechanicalloadingmay vary. To satisfy these requirementjs a new breed of rquipmenthadtobedeveloped, raisingultrasonicpower technology to a new level. Modern ultrasonic plastic welders operate prodominantlyaround 20 kHz at power outputss below 1000 63 SHOH: INDUSTRIAL APPLICATIONS OF ULTRASOUND Fig. 6. Ultrasonic man welder for assembly of large plastic panels, such as used in plastic furniture. Fig. 4. 700 W, 20 kHz ultrasonic pl&ic welder. Fig. 5. Two ormore horns areoften usedforweldinglargerparts. Horns are slotted to produce uniform vibration. watts, lock automatically on the hornresonance, and holdvibrationalamplitudeconstantforvarying mechanical loads. Another useful innovation has been the use of mechanical amplitude transformers to facilitate matchis ing of equipment t’o the load.Ultrasonicexposure controlled by accurate electronic timers (Fig. 4). The mostvisibleprogressover the yearshasbeen made in thesize of plastic parts t’han can be ultrasonically welded, primarily helped byhigher power equipment andadvancesin ultrasonic horndevelopment(Figs. 5 Fig. 7. Spot welding ribsontoplastic boat. and 6 ) . Improvementsinjoint design havecxtendcd ultrasonic welding to more difficult plastics and shapes. Ramifications of ultrasonic welding processinclude ultrasonic staking, spot welding, and inscrting of metal parts into plastic [7] (Fig. 7 ) . An areadeservingspecialconsiderationisultrasonic welding of woven and nonwoven fibers [S], [S]. Thermoplastic textiles with up to 35% natural fiber content can be ultrasonically “sewn”. Thc advantages include absence of thread and its color-matching problems, simultaneous 64 IEEE TRANSACTIONS ON SONICS AND ULTRSSONICS, MARCH 1975 Fig. 10. 1200 W, 20 kHz ultrasonicmetalwelder.Lapweldsare produced by ultrasonic shear at the interface. v. Fi 8 Ultrsllonic“sewingmachine” for joiningthermoplastic abrlcs withoutneedle or thread. U p t o35% natural fibre content is acceptable. Fig. 9. Stitch patterns possible with ultrasonic sewing. execution of several stitches, and numerous variations of simultaneous cut and seal operations (Figs. 8 and 9). Further developments in ultrasonic plastic welding are likely to be in the area of horn improvement to expand the size andwear. Shift to lower frequenciesis a possibilitysince many welding operat’ions areautomated and the noise can be conveniently shielded. C . Metal W e l d i n g Commercialcquipment for ultrasonic metal welding was introduced in t,he late 1950’s. Originally the process found acceptance in the semiconductorindustry for welding of miniature conductors,known asmicrobonding [lo]. lieccnt advances in equipment design and the need for better ways of joining high conductivity metals haverevivedtheinterestin ultrasonic metal welding on furtherimprovement of tho process. andspurred Standard cquipment is available to weld parts up to 1/8” thickand larger,dependingon thematerialandpart configuration (Fig. 10). Fig. 11. Automotive starter motor armature with armature windings ultrasonically welded t o commutator segments; both metals are copper (Courtesy of Ford Motor Co.). The uniqueness of ultrasonic metal welding resides in the fact t,hat theprocess is relat,ively “cold”. While some heating occurs, the welding dependsmoreoncleaning than on material melting. Ultrasonic shear causes mutual abrasion of the surfacesbeingjoined,breaking up and dispersing oxides and other contamination. The exposed, plast’icized, metal surfaces arebroughttogetherunder pressure and solid-statebonding takes place [lo]. In this respect ultrasonic welding resembles spin welding, or pressure welding, with the noted difference that there is no gross movement of parts or largedisplacement of material. Ultrasonic metal welds are thus characterized by low heat and relatively low distortion. Welding temperatures are typically below the meltingtemperatures of the metals, whichhelps to avoid embrittlement and formation of highresistance intermetalliccompounds in dissimiiar metal welds. Since electricalconductivity plays1x0 rolc in theprocess, with applications that are difficult, or impossible, 65 SHOE: INDUSTRIAL APPLICATIONS OF ULTRASOUND Fig. 13. Large'ultrasonic tank for immersion soldering. Fig. 12. Low heat of ultrasonic metal welding allows sealing liquidfilled copper tubing. Typically no pre-cleaning is needed on high conductivity mehls. resistance welding can be done ultrasonically. This includes melding of high conductivitymetals,suchas electric grade aluminum and copper (Fig. l l ) , also combinations of metals of differentresistivitieslikecopper and steel. Welding of parts widely differing inheatcapacity, such as foil to thicksections, is difficult withheat-dependent methods but can be done with ultrasound. Other uses include sealing of liquid-filled containers(Fig. 12) and packaging of heat-damageable contentsand explosives. Ultrasonic metal welding as an industrial process has the desirable characterist,ics of ultrasonic plastic welding but also has more competition from other metal-joining methods. Besides microbonding, its applications are mainlyin electric and electronicindustries in assembly of electric motors,transformers, switches, and relays. Current trend t o replace copper by aluminum is helped by ultrasonic welding since there are not many reliable alternatives for joining aluminum conductors. Since metal welding requiresshearultrasonicmotion parallel to the plane of the weld, far field welding is not practical. The method is essentially suitable for producing spot, welds and line welds. Continuous seaming of metal foil and sheet is also possible. Ultrasonic power densit'ies atthecontact with the welding tip are very high, in the order of 10,000 watts per square inch. This causes tip wear and atpresent makes ultrasonic welding impractical for hard metals. hnother limitation is compatibility of materials which dueto requirementformutualabrading ab2it.y mustnotbe too far apart inhardness. The equipmentforultrasonicmetal welding ranges 40 from low power microbonders operating between and 60 kHzto machines of severalkilowatt output capacity operating between 10 and 20 kHz, for welding of larger parts.It, should benotedthat, onhigh con- Fig. 14. Ultrasonicallysolderedaluminum was used. radiator ducts. No flux duct'ivitymaterialsultrasonic welding canbe over 20 timesmore efficient compared to resistance welding. Thus a 5 k W ultrasonic welder may be equivalent to a 100 kVA resistance welder. Automatic tuning and constant amplitude control are a must on larger ultrasonic welders. Furtheracceptance of ultrasonicmetal welding d l largelydepend on effective solutions t o properjoint design and dissemination of this knowledge to potential users. Totake full advant,age of ultrasonic welding thepartsmustbe designed for the process. Improvementsin welding tip materialsand design are also probable. D. Soldering Ultrasonicsolderingcan tin without fluxes and improves wettability under most conditions. The process is fundament'ally similar t'o ultrasonic cleaning and has been triedwith various degrees of success since the early 1930's. Growing need for fluxless soldering of aluminum and a general striving for quality have given ultrasonic soldering a new significance. Applications of ultrasonic soldering [1l] include electric and electronic components where nickel, Kovar, and other hard-to-tin metals are often used. Tinning of transformer leads, both copper and aluminum, is also effect'ive. 66 Continuoussoldering of printedcircuits C121 and continuous wire tinning is another area of interest. Recent activity in aluminum heat exchangers with the inherent problem of trapped flux has created an opportunity for ultrasonics in the air conditioning industry and inspired development of large ultrasonic soldering tanks (Figs. 13 and 14). Overall processing times with ultrasonic soldering can be improved because pre-cleaning and post-cleaning operations are usually eliminated. Also, the actual soldering is faster. Tinning is more uniform. The principle of operation is simultaneous cleaning and tinning. Cavitation in molten solder erodes surface oxides and exposes clean metal to solder. Design of ultrasonic solderingequipment, however, ismoreinvolved dueto highoperatingtemperat'ures.Presentultrasonic soldering tanks operate a t temperatures up to850°F. Both far field and near field soldering are done, ranging in power densities from a few watts t o several hundred watts per square inch. Resistance t o cavitat,ional erosion is an important consideration in the design of equipment and is compounded by the requirement for metallurgical compat,ibility. Future developments are likely t o bring more efficient ways of couplingultrasonicenergy to the workpiece as well as improvements in ultrasonic tank materials. Operatingtemperaturelimits will probably be raised, which may make volume treatment of high temperature metals practical. IEEE TRANSACTIONS ON SONICS -4ND ULTRASONICS, MARCH Fig. 15. Ultrasonic rotary machine threading. Axial ultrasonic vibration motion of the drill. 1975 for drilling, milling, and is added t o rotational small-diameter,deep,intersecting holes i n quartzfor lasers, machining nuclear react,or matcrinls, plasma E. Machining sprayedcoatings and ferrite con1putc.r parts. Drilling, of possible. Tho toolsaro To date, ultrasonic machining has proved most effec- milling, andthreadingarc various shapes and sizes, from 0.02 to 1.5 inches in diamtive on hard, brittle materials, like alumina, other ceramics, and glass. Two methods are currently in use. eter. 20 kHz frequency is used (Figs. 16 and 17). Drilling of boron-epoxy composites laminatcdwith The older method, knownas ultrasonic impact grinding, steel and t>itaniumsheetrepresents an int,erestingcase makesuse of abrasiveslurry(usuallyboroncarbide, silicon carbide, or aluminum oxide) fed between the non- and has beenresearched to someextent [15]. Convcntional tools that cut, boron fibres do not work on metal, rotatingvibrating tool andthe workpiece. Oddthreedimensional shapes can be reproduced, wherethe resulting and vice versa. Ultrasonic drilling promises a compromise. Ultrasonic rotary machining is a useful and, insome impression is negative a of the t,ool. Simultaneous machining of clusters of holes is also possible. The method cases, indispensable process of somewhat 1imit)ed comis inherently slow and therefore has limited possibilities mercial potential due to the exotic nature of its applications. in the industry. In the more recent development, known as ultrasonic 111. SONICS AND LIQUIIIS: is superrotary machining,axialult'rasonicvibration OTHER APPLICATIONS imposedupon the rotary motion of the drill. Diamond An extensive list o f applications is given in Tablc 11. impregnated or plated core drills, water-cooled through It is intcrosting to not'c that tl1c majority o f macrosonic the center, are used. The tools operate typically around wit,ll fen- cixcept,ions 5 000 rpm,andtheoperationis essentially high speed applicationsinvolveliquids,and depend either on cavitation, or, like aerosol production, abrasion (Fig. 15). on surfacc instability. It is also intercsting that to date Ultrasonic rotary machining subst'antially increases cutting rates, extends tool life, and due to the lower tool no other liquid-related sonic appliration has had anypressures used allows better dimensionalcontrol and thing vaguely resembling the commcwial succcss of ultrareduccs chipping. A simple explanation of the process is sonic cleaning. continuous cleaning of the tool by cavitation of the coolant,furtheraidedbyultrasonic acceleration of the A . Extractim ?\lost popular here is thc us(: o f high intensity cavitatool. The tool loads less and cuts more efficiently. and low Uses for ultrasonic rotary machining [13], C141 include tion for biological cell disruptioninresearch machining of precision ceramic components, drilling volume processing. 07 SHOH: INDUSTRIAL APPLICATIONS OF ULTRASOUND Fig. 16. Glass, aluminum oxide, and ferrite parts drilled and machined with ultrasound. Rotary method waa used. Fig. 17. Diamond impregnated and plated tools used in rotary ultrasonic machining, Most areliquidcooledthrough the center. TABLE I1 MACROSONIC APPLICATIONS-LIQUIDS APPLICATIONS PROCESS RANKING ALSJANTAGES CLEANING Cleaning, degreasing, descaling industrial parts. Cleaning hospital equipment. Saves time and manual labor. Cleans hard-to-reach areas. A SOLDERING Fluxless aluminum soldering. Soldering and tinning electric and electronic components. Eliminates flux, pre- and postcleaning. reduces rejects. B EXTRACTION Blological cell breakage for research. Antigen extraction. Simple to use. Reduces damage to contents. B Extracting perfume, juices, chemicals from flowers, fruits, plants. Speeds up extraction. Increases yields. Allows lower temperatures. Emulsifying cosmetic toilet preparations, essential and mineral oils. Waste treatment. Emulsifies without pre-mixing. Reduces or eliminates surfactants. Dye pigment and dye dispersion. Insecticide preparation. Fine, uniform dispersion. No flocculation. Medical inhalatlon, nebulizing. Small particles, controlled slze. No gas used. Small particles, controlled size. More efficient burning. HOMOGENIZING ATOMIZATION Fuel atomization, Metal powder production. B B C DRYING Drying heat sensitive powders, food stuff, pharmaceuticals, defoaming. Lower temperatures. Prevents damage to perishables. C DEGASSING Beer and carbonated drink "fobbing".Photographic solutlon agltatlon. Better control, safe for glass containers. C Degassing glass. Reduces molten metals and CHEMICAL PROCESS Electroplatlng. ENHANCEMENT Increases platlng rates. Denser, more uniform deposit. Aging alcoholic beverages. PZIROUS MEDIA porosity. FLOW Filtering; Impregnation ENHANCEMENT C Speeds up process. Increases flow rates. Better penetration. C EROSION Cavitation eroslon testlng. Deburring, stripplng. Convenient to use. Saves labor. C CRYSTALLIZATION Metal treatment durrngcasting and weldlng. Refines grain, reduces stresses. X TtD2FUG.L TPANSPORT Uistlllation processes. DEPOLYMERIZATION Extruding plastics. Plastic flbre manufacturing. A B - and other chemical Speeds up heat exchange. Lowers viscoslty. Established large-scale process Established small-scale process C X - Some industrial use Experimental X X 68 IEEE TRANSACTIOKS ON SONICS AND ULTRASONICS, MARCH 1975 of residualstresseshave also Near field cavit'ation breaks downcell walls and releases Degassing andremoval cell contents into the surrounding liquid. The method is been reported. In spite of a large volume of reference material on this used to extract active antigens for making vaccines and subject [19], there is no evidence of commercial impleas a general tool for studying cell structure. Lltrasonic some installationsineastern extraction is simple and, if cooling is used, causes minimal mentation.Theremaybe Europe [5 3. degradation of contents. The obvious difficulties here are the severe environment The equipment is normally in the range of 100 to 500 for the ultrasonicequipmentandtherequirement for watts,operatingaround 20 kHz.Highamplitudehorns are used, producing power densities in the order of 500 treating a large volume. These, again, may be helped by watts per square inch. Batch and continuous processing current research in ultrasonic soldering. are done. Other extractionuses include extractionof perfume from C . Emulsification The main advantage of ultrasonic emulsification is in flowers, essential oils from hops, juices from fruits, and the ability bo mix some immiscible liquids wit'hout addichemicalsfrom plants [S], [16]. Thepotentialhere tives (surfactants). Recent publicity has called attention seems great,but'application progress, atleastinthe United States, has been slow. A review of high intensitm y to the emulsification of water in heating oil for bet'ter liquid processing is neededin view of the powerful 10 kHz fuel economy and less pollution [20]. Fuel saving seems uncertain, but there may besome substance to cleaner equipment and other equipment improvernents available burning, and it is an interesting development to watch. today. B . Atomization D. Heat Transfer [all Ultrasonicatomizerscanproducesmalldroplets of predictable size. Foragivenliquid,droplet size isa function of atomizerfrequencyandgetssmalleras the frequency is increased [4]. 1. Ultrasonicnebulizers for medicalinhalationhave shown best commercial progress. Medical nebulizers operate bet,ween 1 and 3 megahertz and produce droplets between l and 5 microns. Mainadvantagesare small particle size, tight distribut,ion, and the absence of gas, which makes ultrasonic nebulizers suitable for anesthetic systems [17]. 2. Fuelatomization by ult,rasound [l71 hasbeer researched to a considerable extent t o improve combustion efficiency and reduce pollution. Several types of devices, both electronic andpneumatic,arein use, operating between 20 and 300 kHz. Use in oil burners as well as carburetorshas beenconsidered but due to marginal economics has never caught on in a big way. 3. Dispersion of molten metals for production of powders and metal spraying has been demonstrat)ed. Spraying of molten lead, tin, zinc, bismuth, aluminum, and cadmium has been reported, but cost justification is questionable ~ 1 7 1[W. , There is apat,terntotheseapplications:Greatest success has beenachievedwhere the requirement for quality supersedescost, andthethroughput needcdis low. As theproductgetscheaperand t.hP processing rates increase, ultrasonicatomizat,ionbecomes less desirable. Some of t.his is likely t,o change.Fuel, for instance, costs more today, and ultrasonic atomizers can be built for less. 3hltenmetal dispersion withits formidable equipment prob1c:nls may become practical as a result of the progress in ultrasonic soldering. Cavitation-induced microst'irring can decreasethe thermal boundary layer and improve heat transfer in a variety of systems.References datebacktotheearly 1960Js, and uses indistillationandother chemicalprocessing have been suggested. Present concern with efficiency has made the topiconce more popular. B. Crystallization Finer grain has been prod~lctdin aluminum and other nletalsbyinsonationduringthc solidification stage. E. Flow Enhancement Liquid flow ratesthrough porousmediacan be increased byultrasound. Uses in filtering [22], [a31 and is impregnation have been suggested. The subject intriguing because low amounts of vibratory power can be effective. IV. SONICSANDSOLIDS: OTHER APPLICATIONS An ext'ensive list of applications is given in Table 111. A . MetalForming Over the years there has been a considerable interest by the controversies about the in this area, heightened mechanism of the process. The benefits o f vibration-asxistcd formingtypically include lower forming forces, larger percentage deformation without t,earing, and improvements in surface finish. Dueto highpowerrequirementsthe successful work performed to date has beenlimited to objectssmall in size or cases where the area to be affected is small. 1. Tube clra?uing withultrasound C241 has beenused in manufact,uringfor about, ten years and is most effective on thin wall tubing having an initial diameter of about 4 inch or less. TJsually the plug is vibrated in the direction of drawing. The advantages are faster drawing rates, better size control, and ability to producedifficult shapes, such as rectangular tubing with sharp corners, or tubes 500: 1 ) . with large diameter-to-wall ratios (up to Aluminum, copper, iron,and nickel based alloy, have been drawn. 69 SHOE: INDUSTRIALAPPLICATIONS OF ULTRASOUND TABLE 111 MACROSONIC APPLICATIONS~OLIDS PROCESS WELDING APPLICATIONS RANKING PLASTICS - Welding rigidt h e m plastics. Seam welding film and fabric. Metal-in-plastic insertlon. Staklng. ADVANTAGES Fast, clean, economical, good weld integrity. Welds inaccessible areas. A B METALS - Mlcrobonding. Lap welding Low heat, no pre-cleaning. high electrical conductivity and dis-Insensitive to electrical similar metals. Seam welding sheet. resistivity and heat capacrty mismatch. MACHINING DENTAL - Prophylaxis teeth treatment. ~ a s yto use, less discomfort compared to hand scrubbing. - HARD, BRITTLE MATERIALS Vlbratlonasslsted rotary machining. B Faster rates, longer tool life. B better dimensional control. Impact grinding using abrasive slurry. Makes multiple hole patterns, odd, three-dimenslonal shapes. METALS - Vlbration-assisted drilling, Faster rates, longer tooll l f e . tapping, turning. better finish. C METALS - Drawing thlnwall tubing of large diameter to wall ratios. Higher drawlnq rates. Allows drawing difficult shapes. C Drawing small diameter wire from difficult-to-form metals. Faster drawlng, less breakage, better surface. CUlTING Vlbration-assisted cuttingof fibrous and spongy materials. Better cuttingdue to blade acceleration, or melting. C FATIGUING Destructive testing and quallty control. Saves testing time. hidden flaws. C CLEAVAGE Cleaving crystals and laminated objects. High Impact, high rate. C FRICTION WDUCTION Vibrating sieves and hoppers. Speeds up material flow. C Torquing Tighter joints X Compactrng powders, sintering. Improves uniformity in complex X molds. Increases density. FORMING DENSIFICATION A B - Established large Established small scale process scale process C X - Finds Some industrial use Experimental 2. Ultrasonic wire drawing allows faster drawing rates, [as]. To duplicate the effect on a 3 inch diameter slug, andreduces surfaceimperfections. Many investigations close to one million watts of sonic power would be needed. The use of macrosoundfordeformation of a large were reported in theearly 1 9 6 0 ’ ~with ~ particular mention wire from hard- volume of metalmaynotbejustaroundthe of advantages for drawing small diameter corner. to-form materials like tungsten and molybdenum. There But small-scaleapplications are practical. Simultaneous has been little commercial activity. Improved equipment metal welding and crimping, for instance, is being done. is now available and may rejuvenate the interest in the B . Metal Drilling process 3. Ultrasonic riveting hasbeen of interesttoaircraft Rotary ultrasonic drilling tried with conventional manufacturers. Experiments on aluminum and titanium twist drills produced interesting but uneven results. Axial rivets showed a possibility of a substantial reduction in ultrasonic vibration was added to rotary motion of the formingforce,andinsome cases a largerdeformation drill. without cracking. Another set of experiments concerned Faster driiling rates and longer drill life were aluminum leak-tightriveting. The important question h e reobtained on titanium using small-diameter cobalt drills, is the effect of vibratory forming on fatigue life of the but nosignificantimprovement was noticedonseveral rivet and is largely unanswered. other metals [26]. A number of portable drills are in use As asoberingthoughton sonic metalforming,it is for titanium drilling intheaircraftindustry. A special interestingtomentionanexperimentontitaniumand short ultrasonic drill adapter was developed to make the severalgrades of stainlesssteel,designed to show the process practical (Fig. 18). effect of sonics on volume deformation obscured in drawing C . Dental Treatment operations by high surface friction. An interesting success story, not quite fitting into the Cylindrical slugs& of an inchin diameter were flattened 400-600% reductions in static industrial world,concernsanultrasonic“machinetool” with and without sound. force were possible for equivalent deformation, but sonic designedfor use inprophylaxistreat8ment, periodontia, power densities were over 100 000 watts per square inch and other areas of operative dentistry (Fig. 19). [%I. 70 Fig. 18. PortableQuackenbush drill, usedin aircraftmanufacturing, equipped with ultrasonic drill adapter. Faster drilling rates and better drill life were demonstrated on titanium. IEEE TRANSACTIONS ON SONICS AND ULTRASONICS, MdRCH 1975 Fig. 19.Ultrasonicdentalequipment fordescaling teeth(prophylaxis), and other uses in operative dentistry. (Courtesy of Cavitron Ultrasonics, Inc.). This equipment is becoming popular and is apparent,ly of types of things power ultrasound can do that would be liked by dentists and patients, who prefer it over the old representative of the present state of the art and inspire manual scrubbing. Descaling of teeth is accomplished by further thought’ on the subject. a linear, or elliptical, reciprocating scrubbing a t 25 kHz, ACKNOWLEDGMENTS aided by cavitation of the water spray.A variety of interTheauthor wishes to thank Cavitron Ultrasonics changeableinsertsareavailable for variousscrubbing CorporationandFord l\/lot,or Companyforthe use of operations. photographs and B. L. Mims for reading the manuscript. B. Crystal Cleavage C271 The illustrations are courtesy of Branson Ultrasonics Crystal cleavage by ultrasound proved to be a valuable Corporation unless otherwise noted. method of maintaining particle balance in a continuous REFERENCES chemicalprocessing installation.Ultrasonicallydisinte[l] Hueter, T. F., and R. H. Bolt,“Sonics”, p. 41,Wiley, New grated crystals are split along cleavage planes in contrast York (1955). to random breakage produced by mechanical means. While[2] Noltingk, B . E., and E. A. Neppiras,Proc.Phys. Soc., 63B, No. 9, 674-685 (1950). ultrasonic disintegration takes place in a super-saturated [3] Elder, Kolb and Nyborg, Phys. Rev., 93, 364(A) (1954). liquid,studiesshowed that cleavageresultsfrom direct [4] Doyle, A. W., B. V. Mokler, and R. R. Perron, API Research Conf. Paper CP62-1‘$1962). collision of particles with ult’rasonic horn and with one [5] Neppiras, E. A., Macrosonics in industry”, Ultrasonics, another [28]. It is likely that the principle would also Januarv (1972). [6] “Guide tb Ultrasonic Welding of Plastics”, Appliance Manuwork in a gas medium. V. T H E F U T U R E Unheralded by scientific publications, ultrasonic plastic welding has become a large-scale industrial process while the considerably researched metallurgical and metal working areas have resulted in relatively little. Equally disappointinghavebeen“catalytic”uses of ultrasound inchemistry.Theattentionpaidtoa givenultrasonic area is largely influenced by the topic of the day, as evidencedby currentinkrestinult’rasonic fuel treatment [ Z O ] , wastetreatment [as], oilwell rejuvenation, et’c., and is not always related to the true worth of the process. Thus taught by experience, the author will refrain from any specific predictions save for pointing out two general factors. The cost of an acoustic watt has been declining and following t8he general technologicaltrend will continue to do so in the future. This will make ultrasonic power more competitive with convent’ional processes. The second factor is thatmore ultrasonic equipment is now in use and more people are working with it. This increased exposure will undoubtedly lead t’o new uses. Rather than compiling an all-inclusive list of ultrasonic applications, the author has tried to show a cross section facturer, April (1974). [7] Sherry, J. R., “Assembling Plastic Parts”, Automation,November (1973). [8] Creegan,H. K., “TheThermal JoiningMachine”,Modern Textiles, June (1073). [9] “SonicStitching inColor”,Apparel Manufacturer,August (1973). [lo] Hulst, A. P., “Ultrasonic welding of metals”,Ultrasonics, November (1972). [l11 LeGrand,Rupert,“Ultrasonicsgets 3 new jobs”, American Machinist, Februarz 8, 1971. [l21 Gootbier, E. A., Ultrasonics in masssoldering”,Western Electric Engineer, January 1969, Vol. XIII, No. 1. [l31 Dallas,Daniel B., “The new look of ultrasonicmachining”, Manufacturing Engineering and Management, February (1970). [l41 “Tiny holes with a tliameter/length ratio of 1:300 successfully drilled in glas“,, Industrial Diamond Review, March (1973). [l51 Grauer, W . , Ultrasonic Machining”, Grumman Aerospace Corp. Technical Report AFML-TR-73-86, April (1973). 1161 Skauen, D. M,, J. Pharm. Sci., 56, No. 11, November (1967). 117) Topp, M. N., and Eisenklam, P., “Industrial and medical uses of ultrasonicatomizers”,Ultrasonics, Vol. 10, 127-133, May (1972). [l81 Pohlman, R., Conf. Proc. Ultrasonics Int. (1973) sponsored by J. Ultrasonics. [l91 Rosenberg, L. D.,“PhysicalPrinciples of UltrasonicTechnology”, Vol. 2, 145-273. [20] “Oil and Water Alchemy”, Time, February 11, 1974, p. 3. [21] Rosenberg, L. D., “PhysicalPrinciples of UltrasonlcTechnology”, Vol. 2, 3?;-409. [22] Semmelink, A., Ultrasonically enhanced liquid filtering”, Conf. Proc. Ultrasonics Int. (1967) sponsored by J. Ultrasonics. [23] Ibid., “Use of ultrasound to increase filtration rate”, Fairbanks, H. V., p. 11. [24] Jones, J. B., “Ultrasonic metal deformation processes”,Proc. IEEE TRANSACTIONS ox SONICS AND ULTRASONICS, VOL. su-22, NO. 2, MARCH 1975 71 Int. Conf. Manufacturing Technology, September (1967), 1972, Shoh, A. [27] Midler, United M.,States Patent number 3,510,266 (May 6, Am. Soc. Tool and Mfg. Engineers. [25] Langenecker, B., Illiewich, S., and Vodep, O., “Basic and 1970). ap lied research on metal deformation in macrosonic fields at (281 Klink A., Midler M., and Allegretti J., “A Study of Crystal P\ PL-Austria”. Conf. Proc. Ultrasonics Int. (1973) Cleavage bv SonifierAction”,ChemicalEngineeringProgress . .~ sDonsored .~ . by J. Ultrasonics. Sympoiium”Series, No. 109, 1971, Vol. 67. (261 “New Developments In Metal Working Procmes”, paper, 83rd (291 “The Silent Treatment”, Time Magazine, February 11, 1974, Meeting Acous. SOC. Am., Bu5al0, New York, 18-21 April pp. 74-75. Industrial Applications of Ultrasound-A Review II. Measurements, Tests, and Process Control Using Low-Intensity Ultrasound LAWRENCE C. LYNNWORTH Abstract-Thefollowingapplications are reviewed:ultrasonic measurement of flow, temperature,density, porosity, pressure, viscosity andothertransportproperties,level, position, phase, thickness,composition,anisotropy andtexture, grain size, stress andstrain,elasticproperties,bubble, particle andleakdetection, nondestructive testing, acoustic emission, imaging and holography, and combinations of these. Principles, techniques, equipment, and application data are summarizedfortheseareas.Most of the measurements utilize approaches designed to respond primarily to sound speed, but some depend on attenuation effects. Most equipment in use involves intrusive probes, but noninvasive, externallyBoth mountedtransducersarebeing promoted in severalareas. are widelyused.Limitations due pulse and resonance techniques to the influence of unwanted variables are identified in some cases. A bibliography andlist of vendors providesources for further information. INTRODUCTION T HE MAIX purpose of this review is to identify the breadth,depth,pract,icality,andlimitations of industrialapplications of small-signal ultrasound.Additionally, we will attempt to identify patterns of emerging ultrasonic technology. In general, the scope of this review will be limited toindustrialapplications wherein the transductionor propagation of low-intensity ultrasound responds to t,he properties, state, or quality of the medium or prrt in question. By restrictingt’he scope to “indust.ria1” applications we choose to omitnumerousinteresting and important applications in research, and in medical, dental, and biological areas. “Low-intensity” avoids macrosonic and nonlinear acoustic areas such as ultrasonic Manuscript received November 8, 1974. The author is with Panametrics, U‘altham, MW. 02154. cleaning,machining, wire drawing, welding, atomizing cavit’ating, emulsifying, influencing of chemical reactions shock-wave measurements, and therapy. By limiting the scope to cases where the objective is measuring uItrasound transduction or propagation to indicate the value of some variable parameter, we intend to detour around devices such as quartz clocks, ultrasonic garage door openers, TV channel selectors, delay lines, filters, and signal processors despite the obvious industrial significance of such devices. I n view of all these omissions, the reader may rightfully ask, “What’s left’?” For the answer see Table I. This review generally makes no attempt t’o identifythe earliest demonstration of the entries in Table I, nor to compare with competing technologies. Readers interested in the origins of acoustical measurements of sound speed, attenuation, polarization, or related quantities arereferred elsewhere.’ Standard commercial equipment,particularizedfor a specific application, is available for almost every iten1 on the list. Additionally, since virtually any ultrasonic measurement can be analyzed in terms of observations related to transit t,ime or wave amplitude, general-purpose electronic measuringequipmentsuch as digital processing oscilloscopes, computingcounters,timeintervalometers, peakdetect’ors, etc.,may also be used to perform the industrialmeasurement,s or tests to be discussed below. The items in TableI could be categorized into two major groups in terms of instrument response being associated primarilywithsoundspeed c or attenuation coefficient R. B. Lindsay,ed., Acoustics-lfislorical and Philosophicul Deuelopment (1973); Physical Acoustics (1973), Dowden,Hutchinson and Ross Inc.,Stroudsberg, Pa. See also: D. M. Considine,ed., Encyclopedia of Znstrumentation and Control, McGraw-Hill, New York (1971).