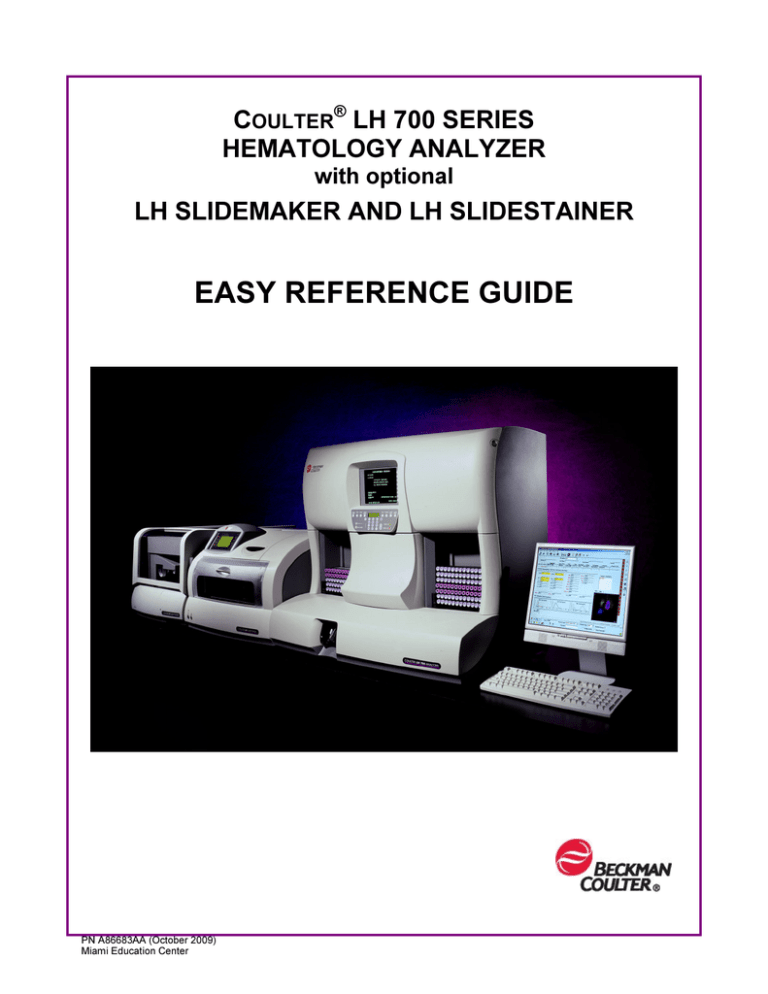

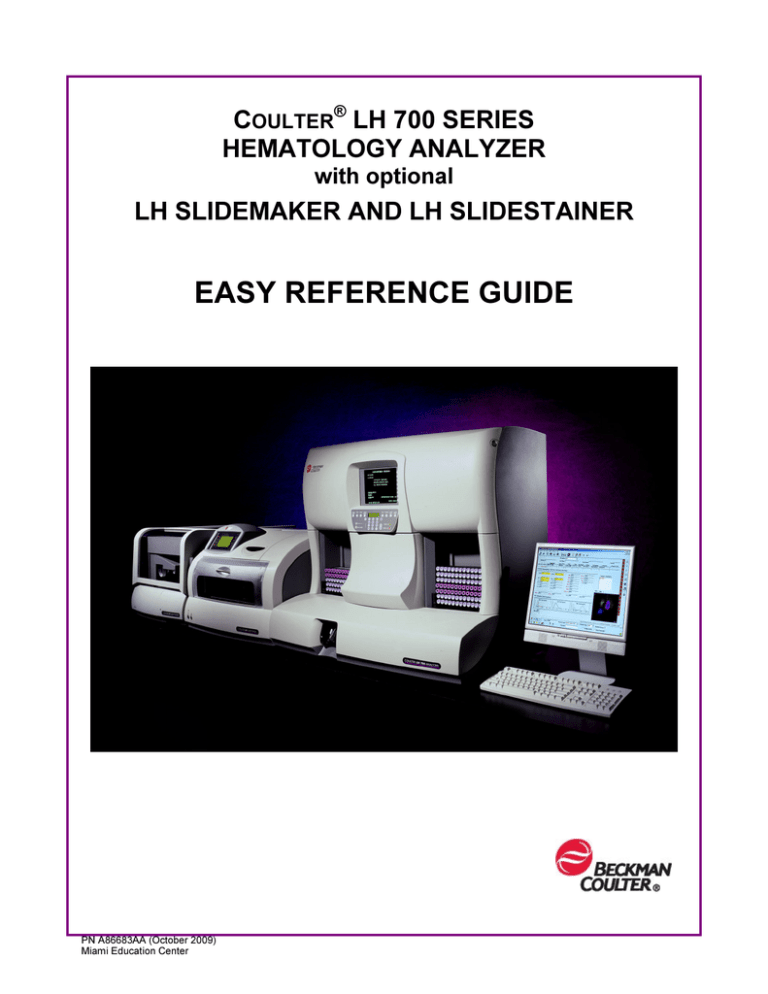

COULTER® LH 700 SERIES

HEMATOLOGY ANALYZER

with optional

LH SLIDEMAKER AND LH SLIDESTAINER

EASY REFERENCE GUIDE

PN A86683AA (October 2009)

Miami Education Center

Safety Notice

Read all product manuals and consult with Beckman Coulter-trained personnel before attempting to operate

instrument. Do not attempt to perform any procedure before carefully reading all instructions. Always follow

product labeling and manufacturer’s recommendations. If in doubt as to how to proceed in any situation,

contact your Beckman Coulter representative. Beckman Coulter, Inc. urges its customers to comply with all

national health and safety standards such as the use of barrier protection. This may include, but is not limited

to, protective eyewear, gloves, and suitable laboratory attire when operating or maintaining this or any other

automated laboratory analyzer.

Alerts for Warning and Caution

Throughout this manual, you will see the appearance of these alerts for Warning and Caution conditions:

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, could result in death or serious

injury. May be used to indicate the possibility of erroneous data that could result in an incorrect diagnosis.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices. May be used to indicate the possibility of

erroneous data that could result in an incorrect diagnosis.

Safety Precautions

WARNING

Risk of operator injury if:

All doors covers and panels are not closed and secured in place prior to and during instrument

operation.

The integrity of safety interlocks and sensors is compromised.

Instrument alarms and error messages are not acknowledged and acted upon.

You contact moving parts.

You mishandle broken parts.

Doors, covers and panels are not opened, closed, removed and/or replaced with care.

Improper tools are used for troubleshooting.

To avoid injury:

Keep doors, covers and panels closed and secured in place while the instrument is in use.

Take full advantage of the safety features of the instrument.

Acknowledge and act upon instrument alarms and error messages.

Keep away from moving parts.

Report any broken parts to your Beckman Coulter Representative.

Open/remove and close/replace doors, covers and panels with care.

Use the proper tools when troubleshooting.

CAUTION

System integrity could be compromised and operational failures could occur if:

This equipment is used in a manner other than specified. Operate the instrument as instructed in

the product manuals.

You introduce software that is not authorized by Beckman Coulter into your computer. Only

operate your system’s software with software authorized by Beckman Coulter.

You install software that is not an original copyrighted version. Only use software that is an

original copyrighted version to prevent virus contamination.

CAUTION

If you purchased this product from anyone other than Beckman Coulter or an authorized Beckman

Coulter distributor, and, it is not presently under a Beckman Coulter service maintenance agreement,

Beckman Coulter cannot guarantee that the product is fitted with the most current mandatory

engineering revisions or that you will receive the most current information bulletins concerning the

product. If you purchased this product from a third party and would like further information

concerning this topic, call your Beckman Coulter Representative.

This document is not intended to replace the information in your instrument Instructions for

Use manual. Information in the Instructions for Use manual supersedes information in any

other manual.

PN A86683AA (October 2009)

Miami Education Center

ii of xii

TRADEMARKS

5C, COULTER, COULTER COUNTER, FACULTY, ISOTON, LIN-C, LYSE S, and S-CAL are

trademarks of Beckman Coulter, Inc.

All other trademarks, service marks, products or services are trademarks or registered trademarks

of their respective holders.

Copyright © Beckman Coulter, Inc. 2007

All Rights Reserved

PN A86683AA (October 2009)

Miami Education Center

iii of xii

REVISION STATUS

Revision AA

Initial Issue (October 2009)

Combine the LH 750 PNA48907and LH 780 PNA36293

Easy Reference Guides.

Software 2D1/2B1 or higher

© 2009 Beckman Coulter, Inc.

PN A86683AA (October 2009)

Miami Education Center

iv of xii

TABLE OF CONTENTS

Hematopoiesis: The Original Family Tree

Normal Histograms – LH 780 and LH 750

Normal Data Plots (2D and 3D)

Workstation

Log Off/Log On LH Workstation

The Command Center

The Eight LH Application Buttons

Special Help Icons

LH SlideStainer Icons

LH Workstation (computer) Shutdown

Daily Functions

LH 700 Series

Analyzer CRT and Numeric Keypad

Shutdown Cycle Summary

Startup Cycle Summary

Running Latron Summary

Running COULTER® 5C® and Retic-C™ Cell Controls Summary

LH SlideMaker

SM Keypad Display Map

Suggested Daily Setup for LH SlideMaker

LH SlideStainer

Suggested Daily Setup for LH SlideMaker with LH SlideStainer

Calibration

Reproducibility and Carryover

Host/LIS Down

Setting Up the LH Workstation

Creating the ToDo List

IQAP/eIQAP Information

General Information

IQAP Download Procedure

How to Register and Enroll in eIQAP

PN A86683AA (October 2009)

Miami Education Center

v of xii

How to Access eIQAP

Upload File Messages

Parts Diagrams

LH 700 Series

Diluter Front Panels

Diluter Front Cover (top view)

LH SlideMaker

Sample Access and Reservoir Module

Dispense Module

Dispense Probe Mechanism and Rinse Block

Slide Transport Module

Common Troubleshooting Fixes

Common Orderable Parts

LH 700 Series

Instrument Power Off/On

Low Vacuum Low Message

Low Vacuum Drifted Message

Fluid Leaks

Level Sense Message

Backwash Tank Not Full Message

Probe Messages

Rocker Bed Messages

Aspiration Messages

No Diff Results

No Retic Results

LH SlideMaker

Dispense Probe Messages

Low Vacuum 1 or 2 Messages

Shuttle or Truck Vacuum Messages

LH SlideStainer

Bath Not Draining Messages

Bath Not Filling Messages

As Needed Cleaning Procedures

LH 700 Series

LH SlideMaker

LH SlideStainer

Optimizing Stain Protocols

PN A86683AA (October 2009)

Miami Education Center

vi of xii

Hematopoiesis: The Original Family Tree

Courtesy Johns Hopkins University Press,

The Johns Hopkins Atlas of Human Functional Anatomy,

Leon Schlossberg, illustrator

PN A86683AA (October 2009)

Miami Education Center

vii of xii

Normal Histograms – LH 780

RBC Histogram

Range Indicators

Upper and lower limits

defined by the lab or

can be turned off.

Platelet Histogram

Normally has two curves.

Green curve is the smooth

or raw data. Black curve is

the fitted data.

WBC Histogram

Black line indicates the

35 fL lower threshold.

Area checked for

presence of interference.

PN A86683AA (October 2009)

Miami Education Center

viii of xii

Normal Histograms – LH 750

RBC Histogram

Platelet Histogram

Normally has two curves.

Green curve is the smooth

or raw data. Black curve is

the fitted data.

WBC Histogram

Black line indicates the

35 fL lower threshold.

Area checked for

presence of interference.

PN A86683AA (October 2009)

Miami Education Center

ix of xii

Normal Data Plots

2D Data Plot (WBC Differential)

Eosinophils

Monocytes

Lymphocytes

Neutrophils

Non-white cells

Basophils

2D Data Plot (WBC Differential) (Lymphs removed)

Basophils

PN A86683AA (October 2009)

Miami Education Center

x of xii

3D Data Plots (WBC Differential)

3D Data Plot (WBC Differential) (default view)

y-axis

Volume

z-axis

Conductivity

x-axis

Light Scatter

Point of origin

(0, 0, 0) xyz

coordinate

3D Data Plot (WBC Differential) (rotated 90 degrees)

Point of origin

(0, 0, 0) xyz

coordinate

PN A86683AA (October 2009)

Miami Education Center

xi of xii

2D and 3D Data Plots (Reticulocytes)

2D Data Plot (Reticulocytes)

WBCs

Mature RBCs

Reticulocytes

Platelets/

Non-red cells

3D Data Plot (Reticulocytes)

Point of origin

(0, 0, 0) xyz

coordinate

PN A86683AA (October 2009)

Miami Education Center

xii of xii

Log Off/Log On LH Workstation

To Log Off the LH Workstation

Step

1

Action

Select

appears.

from the Command Center. The Log Off the System window

The default selection is Log Off Current User.

2

Select

to confirm that you want to log off the current user name.

To Log On to the LH Workstation

Step

Action

Type your user name or verify the current name displayed.

1

■

User names are defined by those with Lab Admin (Level 3) access.

Type your password.

2

Remember that passwords are case-sensitive.

If you forget your password, the Lab Admin access can reset it for you.

3

Select

at the bottom of the logon screen. The Workstation checks your

password and starts the LH Workstation.

PN A86683AA (October 2009)

Miami Education Center

1 of 59

The Command Center

The Command Center is the green bar located across the bottom

of the desktop area.

The user currently

logged on.

Eight LH

Application buttons

Default Type

Selects the sample test

mode if no barcode or

Random Access

Process Type

Usually has Auto

Analysis selected.

Status Indicators

for Analyzer or

SlideMaker and

PC

Barcode entry

Scanned or Typed

Enable/Disable

Random Access

Traffic-light icon

Instrument Status

Body Fluid Option

Predilute Option

with

dilution factor entry

When you want to change the area you are viewing, just select a

new button from the Command Center. The program automatically

closes what was open and then opens the new selection.

There are three exceptions:

If the Run Configuration

screen is open, you exit by selecting

either

(OK, save and close) or the red

you made.

to cancel any changes

If the Help screen is open, you exit by selecting the small x in the upper

right corner of the Help screen.

If the History Logs are open, exit by selecting the small x in the upper

right corner of the History Logs screen.

PN A86683AA (October 2009)

Miami Education Center

2 of 59

The Eight LH Application Buttons

Run Configuration

Takes you to the screen to view/change Print, LIS and LH

SlideMaker run choices. Also access to AutoStop choices.

Patient Results

Takes you to the screen to view patient results from either the

Results/Graphics view or the Database/ToDo view.

Quality Assurance

Takes you to the screens associated with various QA data:

Daily Checks, Quality Control, Extended QC, XB, XM,

Reproducibility, Carryover, Calibration.

Help

Provides access to an extensive multimedia help system built

into the software.

History Logs Viewer

Provides access to the various electronic logs for review, to

add comments, print or archive.

System Status

View current details about the system , such as software

revision.

System Setup

Provides access to the various setup functions to customize

your workflow: General Settings, Quality Assurance, Patient

etc.

Log Off (Exit) the System

Choose between Log off current (default) or Shutdown the

Workstation.

PN A86683AA (October 2009)

Miami Education Center

3 of 59

Special HELP Icons

These icons are found within the HELP system on the Workstation.

Help button on Main Command Center

or a screen’s tool bar.

Help Mode (Context Sensitive Help)

button.

In a HELP topic, shows that the topic

was changed in the current revision of

the software and HELP.

Shows that you can find a list of topics

related to the current HELP topic on the

screen.

Indicates that you can find a subprocedure with a graphic by clicking on

the Picture icon.

Indicates that you can go to a video clip

of maintenance or other procedure by

clicking on the Projector icon.

PN A86683AA (October 2009)

Miami Education Center

4 of 59

COULTER® LH SlideStainer Icons

From System Set Up,

go to

. Select

tab.

Save Protocol

Saves newly created or modified staining protocol.

Delete Protocol

Deletes selected protocol. You cannot delete a protocol

while it is in use.

Download SlideStainer Protocol (LabAdmin only)

Downloads a saved or modifiedstain protocol to the

SlideStainer. The icon will only be available when the

SlideStainer is in Standby mode.

New Protocol

Provides blank Staining Protocol data fields to prepare

to set up a new protocol or to modify an existing

protocol.

Open SlideStainer Arm Dialog Box (LabAdmin only)

Arm is aligned in response to error situations.

SlideStainer Status

Provides information about Serial # and cycle count

among others. Buttons to open and close gripper and

reinitialize arm.

SlideStainer Input Queue Status (LabAdmin only)

Displays SlideStainer input/output queue configuration

for configuring the “parking lot” / empty basket areas.

Drain SlideStainer Reagent Lines

In preparation for shutting down SlideStainer or

preventing spillage during maintenance procedures.

Monitor Sensor Status

To troubleshoot error messages. Also monitor values

for temperatures, pressure sensors, and battery VDC

information.

Download SlideStainer Software (LabAdmin only)

To upgrade software or respond to error situations

PN A86683AA (October 2009)

Miami Education Center

5 of 59

LH Workstation (computer) Shutdown

The LH Workstation (computer) should go through this procedure at least once per week.

You may have to shut down and restart the Workstation in response to certain error

situations or if the computer doesn’t respond. Be sure to read any Help message for error

recovery carefully for this indication.

In the event of a communication problem between the Workstation and the LH 780

Analyzer, you may need to reset the Analyzer using the RESET button on the upper right

corner of the Analyzer cover as well as selecting to shut down and restart the Workstation.

Step

1

2

Action

Select

from the Command Center.

Select Shutdown the Workstation, then Select OK

The Workstation will save any unsaved data, close all

applications and display a window notifying you it is shutting

down the workstation. This may take a minute.

Next, a window is displayed that states you may now power

off the workstation.

3

Turn off the computer workstation power using the power

button on the front of the computer tower.

Always verify that the power actually went off. Sometimes,

you need to hold in the button until all power is off.

4

After one minute, turn the power back on.

5

Log on to the workstation when the Log On window

reappears.

PN A86683AA (October 2009)

Miami Education Center

6 of 59

Analyzer CRT and Numeric Keypad

LH 780

Always return to this

screen to run the

instrument.

Use this button to

access the Main Menu

LCD Display

Numeric Keypad

PN A86683AA (October 2009)

Miami Education Center

7 of 59

Analyzer CRT and Numeric Keypad

LH 750

Always return to this

screen to run the

instrument.

Use this button to

access the Main Menu

LCD Display

Numeric Keypad

PN A86683AA (October 2009)

Miami Education Center

8 of 59

Shutdown Cycle Summary

Shutdown (Cleaning Cycle)

Step

1

2a

2b

Action

Verify pneumatics are On. (Look at the Power Supply

display. If off, press the

key on the Analyzer Numeric

Keypad.)

If you have an LH SlideMaker, select Shutdown from the

SlideMaker keypad menu. Wait until cycle completes

before proceeding to next step.

When the Analyzer CRT and the LCD display both

indicate “Ready”, press the

key on the Analyzer

Numeric Keypad. This pulls the enzymatic cleaning agent

into the Diluter.

Shutdown must be performed once every 24 hours

that the instrument is in use.

The cleaning agent must remain in the Diluter for a

Note

3

minimum of 30 minutes.

Cleaning agent removal cycles are performed

automatically at the end of the programmed cleaning

time. (30 minutes to 24 hours)

No Background Checks or Electronic Tests are

performed at this time.

Proceed to Startup Summary

PN A86683AA (October 2009)

Miami Education Center

9 of 59

Startup Cycle Summary

Startup (Daily Checks)

Step

1

Action

Press the

key on the Analyzer Numeric Keypad.

After the cleaning agent removal cycles, this is the

only key you can use.

The instrument automatically performs the following

checks:

Background counts (CBC, DIFF, RETIC)

Ramp & Precision electronic checks

Various voltage, pressure and temperature checks

Note If you have an LH SlideMaker, it will startup automatically

if it was in Shutdown. If not, run Startup from the SM

keypad.

Review the Daily Checks results:

Look at the Workstation Daily Checks screen (click

on the Command Center, then click

from the

common toolbar) or look at the automatic printout of

results.

If any background or main system checks show FAIL

2

then repeat the required test from the Analyzer CRT

screen:

Select Main Menu, Analyzer Functions, Startup

Tests.

As required select Background or Ramp or

Precision.

PN A86683AA (October 2009)

Miami Education Center

10 of 59

Running Latron Summary

COULTER® LATRON™ Primer and Control

Run this check once every 24 hours.

LATRON Primer and Control - always run as a pair.

Always run the Patron Primer first to clean the pathway through the

flowcell.

Follow with the Latron Control to check and verify the VCS gains, CVs

and laser alignment.

Step

Action

At the Workstation:

1

Choose Auto Analysis in the Process Type field on

the Command Center.

Open the LATRON folder on the QC screen.

2

At the Analyzer Numeric Keypad, press

Retic) or

(Diff). Then press

.

(Diff &

Press the

key on the Analyzer Numeric Keypad to run

the Primer.

3

Present the Primer vial to the manual aspiration tip

and remove when you hear the beep.

If the results are ≤ 500, continue with the Control.

If the results are > 500, repeat the Primer.

Press

to continue (do not press the

key again)

Very gently, invert the Control vial 5-8 times, being

4

careful to avoid bubbles or foam.

Present the Control vial to the manual aspiration tip

and remove when you hear the beep.

If any results are out of range, repeat the Primer, then

repeat the Control.

Press the

5

key twice to return to READY at the

Analyzer Numeric Keypad.

PN A86683AA (October 2009)

Miami Education Center

11 of 59

Running 5C and Retic-C Cell Controls Summary

COULTER® 5C® Cell Control and RETIC-C™ Cell Control

The frequency of running these controls depends upon

regulatory and laboratory policy for quality assurance

programs.

Step

1

2

Action

Allow vials to equilibrate at room temperature for 10-15

minutes.

Mix each vial individually, by hand, using the 8 x 8 x 8

mixing method as described in the control package insert:

Begin with the vial upright between the palms of your

a) hands and roll the full length, forward and backwards

eight times. (first eight)

Next turn vial upside down between the palms of your

b) hands and roll the full length, forward and backwards

eight times. (second eight)

c)

Next hold vial in one hand and invert eight times. (third

eight)

Note Perform the above steps twice for 5C Cell Control vials.

1

For RETIC-C Cell Control vials perform the above steps

once.

3

Visually check each vial after mixing to ensure cells are

suspended. If cells are not suspended, then repeat one

more set.

4

Place the control vials, barcode face up, into a regular

cassette and place the cassette into the loading bay.

5

When analysis is complete, remove control vials from the

cassette and store them in the refrigerator.

Note The entire process, steps 1-5 must be completed within 30

minutes to preserve control stability.

2

6

Review control results according to your laboratory’s

policy.

PN A86683AA (October 2009)

Miami Education Center

12 of 59

COULTER® LH SlideMaker Keypad Display Map

MAIN MENU

ROUTINE FUNCTIONS*

SPECIAL FUNCTIONS

SERVICE FUNCTIONS

RUN MODE

SPECIAL CYCLES

MAIN MENU – ROUTINE FUNCTIONS*

PNEUMATIC/POWER

SUPPLIES

PRINTER LABEL

FUNCTIONS

Displays Pressures, Vacuums,

Voltages

Save Printer Label Intensity

Increment Intensity

Decrement Intensity

SYSTEM SETTINGS

ADVANCE BASKET

Manually advance basket one

position

UNLOCK CASSETTE

Manually unlocks slide cassette

LOCK CASSETTE

Manually locks slide cassette

Displays Software/Hardware Rev

ROUTINE FLUIDICS*

Backwash Tubing

Prime Reagent

Reservoirs

Drain Vac

Accumulator

Drain

Run STARTUP*

Run SHUTDOWN*

MAIN MENU – SERVICE FUNCTIONS

Service Use Only – needs Service Password

MAIN MENU – SPECIAL FUNCTIONS

REBOOT PRINTER

SENSOR STATUS

DEFINE SMEAR SPEED

DRYER TEMP

KEYPAD TEST

DISPLAY TEST

DRYER FUNCTION TEST

MAIN MENU – RUN MODE

VIEW ERROR

MAIN MENU – SPECIAL CYCLES

PRINT LABEL

Prints test “Dummy” label after replacing Labels or Ribbon

BLEACH SYSTEM

•

The choices in green are your daily functions.

PN A86683AA (October 2009)

Miami Education Center

13 of 59

LH SlideMaker Suggested Daily Setup

These checks/setups may be done during the Shutdown

cycle, or at any time appropriate for your lab.

LH SlideMaker - only

Verify that the Slide Cassette is full.

Check Label and Ribbon supply, replace if

necessary. (refer to Help)

Place up to twelve empty slide baskets in the

front and rear tracks. (if no LH SlideStainer)

Inspect dispense probe and rinse cup and clean

if any traces of blood are seen. (refer to Help)

Once the system is operating automatically, do not grab

slides prematurely, this can cause jams and resets. Let

the SlideMaker do its job.

PN A86683AA (October 2009)

Miami Education Center

14 of 59

LH SlideMaker With LH SlideStainer

Suggested Daily Setup

These checks/setups may be done during the Shutdown cycle, or

at any time appropriate for your lab. Depending on workload,

SlideStainer baths may need attention more than once a day.

LH SlideMaker

Verify that the Slide Cassette is full.

Check Label and Ribbon supply, replace if necessary.

Verify there are no more than six slide baskets in the

SlideMaker and locate them in the rear track. There

should be no baskets in the front track.

Inspect dispense probe and rinse cup and clean if any

traces of blood are seen. (refer to Help)

LH SlideStainer

Place the SlideStainer in Standby state.

Place six slide baskets in the Empty Basket area.

Verify bath reagent container levels. Replace/Refill as

necessary.

Drain all baths.

Check Waste Containers. Empty if necessary.

(Waste 1 = Aqueous, Waste 2 = Methanol)

Check the “stain” baths for excess sediment and clean

with methanol if necessary.

Fill all baths (according to your lab’s protocol)

Place the SlideStainer in Auto state. Once the major

workload finishes, empty baskets are stained if left in

Auto. You may change between Standby and Auto state.

Once the system is operating automatically, do not grab

slides prematurely, this can cause jams and resets. Let the

SlideMaker and SlideStainer do their jobs.

Note: Your Applications Specialist may help you to revise

these setups to better suit your lab’s protocols and needs.

PN A86683AA (October 2009)

Miami Education Center

15 of 59

Calibration Summary

Note: to be used by Beckman Coulter trained personnel only

1

Shutdown for 30 minutes to ensure apertures are clean.

Check Reagent Levels:

2

Diluent (1/2 to 2/3 full)

CBC Lytic Reagent (¼ full – 1L or 5L)

3

Run Startup and verify Daily Checks results.

4

Analyze COULTER®5C® Cell Controls.

5

Disable Automatic Print on the Run Configuration screen.

6

Prepare one S-CAL® Calibrator tube according to the package

insert directions.

Run S-CAL Calibrator:

Set up Workstation screen as described in HELP and

delete previous results from the Calibration table.

7

Set up S-CAL Calibrator reference values required for

your reagent system.

Remember to choose the correct S-CAL Calibrator lot #

from the box on the left of the Calibration screen.

At the Analyzer CRT screen, turn Blood Detector ON, set

the # of aspirations/tube to 11, verify Default Type is C.

After calibration runs are complete, review the calibration data

and transmit new cal factors if necessary:

Prepare Analyzer to RECEIVE new values:

8

From the Analyzer CRT screen, select the following:

Main Menu, Analyzer Functions, Calibration,

Receive Average Cal Factors.

Select Adjust Calibration button on the specific toolbar

from the Workstation calibration run screen.

9

10

When finished, be sure to return the Workstation and Analyzer

CRT screen to your lab’s default settings.

If any calibration factor changes were made, rerun 5C Cell controls to

verify the calibration.

PN A86683AA (October 2009)

Miami Education Center

16 of 59

Reproducibility and Carryover Summary

Note: to be used by Beckman Coulter trained personnel only

Disable Automatic Print on the Run Configuration screen.

1

Run Reproducibility (Default Type set to C or CD) with the selected normal

whole blood specimen. Refer to HELP for sample requirements.

a

Set up the Workstation screen as described in HELP and delete

previous results from the table.

b

Set the # aspirations/tube to 1 and cycle a separate sample collected

in a salt of EDTA.

c

Using 2-6 tubes from the same donor (5 mL EDTA), pool, mix and

aliquot the sample into 2-6 clean EDTA tubes.

d

Set the # of aspirations/tube to 5 on the Analyzer CRT screen.

e

Place 2 of the tubes in the same cassette in the right loading bay.

f

After the samples are analyzed, review the results.

The procedure begins with an N=10. If all parameters pass, you may

stop processing. Otherwise, you may need more data. See Note 2

below.

Note 1

g

Note 2

Verify that the %CV (Coefficient of Variation) does not exceed the

established limits.

Reproducibility Limits for CBC

Parameter

%CV

WBC

≤ 1.7

RBC

≤ 0.8

Hgb

≤ 0.8

MCV

≤ 0.8

Plt

≤ 3.3

MPV

≤ 2.2

If any limit is exceeded, repeat with two more tubes of the prepared sample

blood, until at least 11 but not more than 31 whole blood samples have

been analyzed. You may stop the analysis at any point between 11 and 31

runs if the reproducibility established limits have been met. You may not

pick and choose which runs are included. Runs included for the

assessment need to be consecutive runs.

If any instrument results exceed these limits, repeat with another donor

sample. If you still have a failure, an instrument problem may exist. Call

your Beckman Coulter Representative. (Note: the above limits are also

available in HELP)

PN A86683AA (October 2009)

Miami Education Center

17 of 59

2

Run Carryover study (Default Type set to C) with the selected blood

samples and 3 separate diluent tubes.

a

Set up Workstation screen as described in HELP and delete

previous results from the table.

b

Set # aspirations/tube to 1 and turn the Blood Detector OFF at

the Analyzer CRT screen.

c

Run the samples and diluent tubes.

d

Check results.

PN A86683AA (October 2009)

Miami Education Center

18 of 59

What To Do If Your Host/LIS Goes Down

Setting up the LH Workstation

At the LH Workstation, from the Command Center, go to:

(System Set Up)

(General Settings)

1

2

Select Cass/Pos or Sample ID as applicable to your situation:

a

Select Cass/Pos as the only Positive Identifier if you do not have

bar code labels.

b

Select Sample ID as the only Positive Identifier if you are using bar

code labels.

3

Click on

(OK) to save.

4

Go to

5

On the Common Toolbar, select

(Patient Results) (Database / ToDo List)

(Add Sample Requests)

Before adding entries on the ToDo List, do you want to set up the

Cass/Pos # to Autosequence? This makes preassigning more efficient.

NOTE

If YES, go to step 6.

If NO, go to Processing Preassigned Samples.

6

NOTE

On the Add Sample Requests window, select

(AutoSequence)

Select HELP from the Setting Up AutoSequencing window to learn more

about available options.

7

Set AutoSequence Control At Test Level.

8

Select to autosequence only Cass/Pos for the test modes you are running.

9

Enter the starting Cass/Pos number for each test mode.

10

Select

PN A86683AA (October 2009)

Miami Education Center

(OK) to continue.

19 of 59

What To Do If Your Host/LIS Goes Down

Creating the ToDo List

1

2

3

4

5

On the Add Sample Request window, select Diff (for CBC/Diff), CBC

(for CBC only), for example.

Tubes without bar code labels

Tubes with bar code labels

If you said Yes to

Place the cursor in the Sample ID

Autosequencing of Cass/Pos #,

field.

you should see the first

2

Cass/Pos # in the Cass/Pos

field.

If you said No to

Use the hand-held bar code

Autosequencing of Cass/Pos#,

scanner to scan the Sample ID

3

type the first Cass/Pos# into the

in the Sample ID field. Verify ID

Cass/Pos field.

scanned.

Use the <Tab> key to move the cursor to the Patient ID field.

Patient ID is the unique identifier for each sample. You must assign a

Patient ID when you create a ToDo List. This can be any number that is

unique to the patient, e.g., accession #, Medical Records #, Social Security

#.

[Optional] You may enter additional demographic information, including

Patient name, Age, Gender, Physician and/or Location.

6

Select

to save an entry and make additional entries on the ToDo List.

7

After making your final entry, select

8

Select

again.

(Close) to exit the Add Sample Request window.

Go to the ToDo List CBC/Diff (or other Test Mode) to verify that your

entries are correct.

If the entries are not immediately visible, you may need to double click on

NOTE

the folder for the appropriate Test Mode to refresh the screen.

10

Remember to check the following!

In

(Run Configuration)

9

Select

options according to your lab protocol

While the Host/LIS is down, you may want to disable it. Remember

to change your settings when the Host/LIS comes back on-line.

Select

(SlideMaker) options, if necessary.

Select (OK) to save.

It is also possible to print two sample reports during a down time, one

Chartable and one Laboratory. Go to System Setup>>General>>Reporting

NOTE

Options>>Printout Options. Save.

Then go to Run Configuration and set print to All Samples. Save.

PN A86683AA (October 2009)

Miami Education Center

20 of 59

IQAP/eIQAP General Information

Important Points to Remember When Setting Up eIQAP

Make note of the following:

Instrument

IQAP Participant #

Serial Number

System ID

Number to Call for Help: 800-526-7694 (USA and Canada)

PN A86683AA (October 2009)

Miami Education Center

21 of 59

IQAP Download Procedure

Step

Action

1

Select

on the Command Center.

2

Select

to display the CONTROLS window.

3

Select

. An IQAP Disk Storage window appears.

4

Ensure the removable media (formatted CD, flash drive, or floppy disk) is

inserted in the appropriate drive or connected to the computer.

5

Select the lot numbers you want copied to the removable media.

6

Select

7

The "Save as" window appears.

8

Specify the location of your removable media and select "Save".

9

After the download process is complete, retrieve the removable media from the

appropriate drive or USB location

10

Use the files downloaded to submit the data through the eIQAP website. Files

may also be submitted via e-mail or as a last resort mailed to IQAP.

PN A86683AA (October 2009)

Miami Education Center

to begin copying the control information.

22 of 59

How to Register and Enroll in eIQAP

You must be registered on the Beckman Coulter website to gain access to the Electronic

Quality Assurance Programs. In order to access the Hematology eIQAP program, you

need to set up your account (i.e. obtain your instrument’s IQAP number).

Step

Action

1

Go to www.beckmancoulter.com

2

Hover over the words “Customer Support” on the menu bar.

3

From the drop down box choose “QA & Service Programs”

4

Select the link “Enroll in IQAP” near the middle of the page

5

On the Quality Assurance Programs window there are links to register and

enroll.

Note

If you already have a login ID and password, proceed to "Enroll in eIQAP".

Skip the registration.

How to Access eIQAP

Step

Action

1

Go to www.beckmancoulter.com .

2

Hover over the words “Customer Support” on the menu bar.

3

From the drop-down box choose “QA & Service Programs”.

4

Select the link “Go to eIQAP” near the middle of the page.

5

On the Quality Assurance Programs window, select the link “Go to

Hematology eIQAP”..

6

On the next window enter your Beckman Coulter username and password.

7

On the following page look for Hematology Resources and select “eIQAP

Help”. This begins a breeze presentation designed to walk you through the

functionality provided in the Hematology eIQAP application.

PN A86683AA (October 2009)

Miami Education Center

23 of 59

Upload File Messages

Message

Interpretation

Upload successful

The files have been successfully uploaded.

ID on diskette

doesn’t match

instrument’s ID

The IQAP ID on the diskette, obtained from the instrument setup,

does not match the IQAP ID displayed for the selected instrument.

1. Ensure the data on the diskette is from the selected

instrument.

2. Ensure the IQAP ID is entered correctly in the instrument

setup.

Not matching serial

number on diskette

The diskette serial number, obtained from the instrument setup,

does not match the serial number displayed for the selected

instrument.

1. Ensure the data is from the selected instrument.

2. Ensure the serial number is entered correctly in the

instrument setup.

3. Ensure there are no spaces or symbols within the serial

number.

Drive not ready or

unreadable diskette

The drive cannot access or read the diskette.

1. Ensure the diskette is inserted into drive A.

2. Repeat download and upload process with a new diskette.

3. Ensure diskette drive is functional.

Windows temporary

folder missing

The Windows operating system temporary folder is missing.

Invalid data

collection software

Coulter STKS, MAXM, or HMX data was collected with an

unacceptable software version.

1. Reconfigure diskette at the Resources page.

2. Repeat download and upload process with newly

configured diskette.

Not an IQAP

diskette or

incomplete

download

Diskette is not configured as an IQAP diskette.

1. Ensure diskette is from IQAP download.

2. Ensure instrument provided a successful download

message.

3. Repeat download and upload process with a new diskette.

PN A86683AA (October 2009)

Miami Education Center

24 of 59

Message

Interpretation

Incomplete control

data file

The diskette does not contain a complete control file.

1. Ensure instrument provided a successful download

message.

2. Repeat download and upload process with a new diskette.

Failed to upload

IQAP files

An interruption occurred during the transfer of data through the

internet.

1. Repeat upload process at a later time using the same

diskette.

Data on the diskette cannot be accessed as the applet certificate

that is required to upload the IQAP files from a diskette was not

Insufficient privilege accepted.

to access file

1. Logout of eIQAP and out of the Beckman Coulter website.

system

Reenter eIQAP and accept the certificate at the Upload

Files page by selecting either Yes or Always.

2. If unable to accept the certificate, enter data manually.

Drive write

protected

Couldn’t create files

in the floppy, please

check it’s writable

and has xxxx bytes

or more free in the

floppy

Corrupted IQAP file

on MAXM, STKS, or

HmX

diskette

PN A86683AA (October 2009)

Miami Education Center

Data on the diskette cannot be accessed as the diskette is write

protected.

1. Ensure the window in the lower left corner of the diskette is

closed.

The diskette does not have sufficient space to create the

IQAPUPLOAD file.

1. Repeat download and upload process with a new diskette.

The file has been corrupted.

1. Repeat download and upload process with a new diskette.

25 of 59

PN A86683AA (October 2009)

Miami Education Center

COULTER® LH 700 Series

Diluter Front Panel

26 of 59

PN A86683AA (October 2009)

Miami Education Center

Needle Vent Chamber

Manual Aspiration Tip

Aspiration Pump (PM 9)

Probe Wipe Assembly

5

6

7

8

COULTER® LH 700 Series

Diluter Front Cover (top view)

Stain Pump (PM 5)

Stained Blood Shear Valve (CVL 93/128)

Retic Mixing Chamber (VC 17)

Stain Mixing Chamber (VC 24)

Blood/Stain Aspiration Pump (PM 11)

15

(behind)

10 Retic Shear Valve (CVL 87/127)

Blood Sampling Valve

3

11

12

13

14

4

9

RANDOM ACCESS MODULE (B)

Rear Blood Detector (under and behind)

Diff Shear Valve (CVL 85/126)

SAMPLING STATION (A)

1 Needle Assembly

2 Front Blood Detector

27 of 59

DIFF MODULE (C)

16 Flow Cell

17 Triple Transducer

Diff Mixing Chamber

18

(VC 25)

PN A86683AA (October 2009)

Miami Education Center

Sample Access and Reservoir Module

(under the Diluter front cover on the left)

COULTER® LH SLIDEMAKER

28 of 59

PN A86683AA (October 2009)

Miami Education Center

SOL10

SOL9

SOL8

SOL7

SOL6

SOL5

SOL4

SOL3

SOL2

SOL1

Dispense 2

Manifold

card

FD5

VL4B

FD3

VL3B

VL10

(in the LH SlideMaker on the front right)

Dispense Module

VL20

VL19

VL18

VL17

VL16

VL15

VL14

DP2 VL7 VL6

COULTER® LH SLIDEMAKER

SOL23

SOL22

SOL21

SOL20

SOL19

SOL18

SOL17

SOL16

Dispense 1

Manifold

card

SOL14

SOL15

FD6 VL8 FD8 DP1

DP1

29 of 59

6985076D

New Configuration

VL8

PN A86683AA (October 2009)

Miami Education Center

Dispense Probe Mechanism and Rinse Block

COULTER® LH SLIDEMAKER

30 of 59

PN A86683AA (October 2009)

Miami Education Center

Slide Transport Module

COULTER® LH SLIDEMAKER

31 of 59

Common Troubleshooting Fixes

Common Orderable Parts

Fluidics

Low Vacuum Low Message

Low Vacuum Drifted Message

Fluid Leaks

Level Sense Message

Backwash Tank Not Full Errors

Mechanical

Probe Errors

Aspiration Errors

Rockerbed Errors

Results

No Diff Results

No Retic Results

LH SlideMaker

Dispense Probe Errors

Vacuum Errors

LH SlideStainer

Bath Not Draining Errors

Bath Not Filling Errors

PN A86683AA (October 2009)

Miami Education Center

32 of 59

Common Orderable Parts

Part Number

Part Description

Quantity

P.O.

6807145

3203015

Needle Pierce Cartridge Assembly

Tubing, silicone, round, 0.062 id., black stripe

1 Ea

10 Ft.

Y

N

3213135

3213163

3203016

3213137

3213176

6706295

Tubing, silicone, I-beam, 0.062 id., black stripe

Tubing, silicone, round, 0.062 id x .047W, brown

Tubing, silicone, round, 0.079 id, blue stripe

Tubing, silicone, I-beam, 0.079 id, blue stripe

Tubing, silicone, round, 0.079 id x .039W, yellow

Pick-up tubing, universal, 10-20L, Clenz

10 Ft.

10 Ft.

10 Ft.

10 Ft.

10 Ft.

1 Ea

N

N

N

N

N

Y

6706296

6706297

6805636

178453

5120248

1022450

Pick-up tubing, for 5L Lyse S-III

Pick-up tubing, 0.5-1.9L for 1L Lyse S-III and Pak

Waste line tubing

Diluent pick-up tube with float sensor, 20L

Tubing, Waste Level Sensor Assembly

Air Filer (under Power Supply)

1 Ea

1 Ea

1 Ea

1 Ea

1 Ea

1 Ea

Y

Y

Y

Y

Y

Y

1022868

2517119

2523574

6232263

6232259

3202036

Air Filter (rear cover Analyzer)

Screw cap for large pick-up tubes

Screw cap for small pick-up tubes

“Y” connector, .050 id x .130 od

Fitting, hose barb, “Y”, .093 id x .093 od

Tubing, polyurethane, .082 id x .144 od

1 Ea

1 Ea

1 Ea

2 Ea

2 Ea

14 Ft

Y

N

N

N

N

N

6855763

5415206

6605505

2016733

2016732

6806470

Pull apart std. pinch valve, single

Pinch valve removal tool

Glass slides, 1 gross=2 packages

Slide Labels, 1500/roll

SM Printer Ribbon

Slide Cassette

SM

SM

SM

SM

2 Ea

1 Ea

5-10 Gr

1 Roll

1 Roll

1 Ea

N

Y

Y

Y

Y

Y

6806894

2603047

1024888

6807094

Slide Basket

Air filter

Bath, Liquid

Reagent Rack, round opening (1 gal.)

Reagent Rack, 2 rectangular openings

(2L)

Tray, bath, plastic (holds five baths)

Tray, divider

Tubing, pickup assembly, reagent

SM

SM

ST

ST

1 Ea

1 Ea

1 Ea

1 Ea

Y

Y

Y

Y

ST

1 Ea

Y

ST

ST

ST

1 Ea

1 Ea

1 Ea

Y

Y

Y

Filter, Liquid, Waste / Reagent, w/tubing

Pickup tubing, Di water, level sense

assy.

Accuvette (200/bx)

ST

1 Ea

Y

ST

1 Ea

Y

1 Bx

Y

6807093

1024889

1024915

6706296

6806976

5120249

A35473

PN A86683AA (October 2009)

Miami Education Center

33 of 59

Instrument Power Off/On

Power Off

Step

Action

1

Press

Turn off the main breaker switch on the left side of the Power Supply.

2

WARNING

3

on the Analyzer Control keypad.

Risk of personal injury. A shock hazard exists if the power cord is

connected. Unplug the primary power cord before performing these

procedures.

Disconnect the primary power cord at the source (not at the power

supply).

Power On

Step

Action

1

Reconnect primary power cord.

2

Turn on the main breaker switch on the left side of the Power Supply

3

Press

on the Analyzer Control keypad.

LH SlideMaker

There is a power button on the front of the LH SlideMaker to turn power

off and on. If required by a procedure, there is a Main Power switch on

the rear of the SlideMaker.

LH SlideStainer

There is a power button on the left side of the LH SlideStainer to turn

power on and off. If required by a procedure, there is a Main Power

switch on the rear of the SlideStainer.

PN A86683AA (October 2009)

Miami Education Center

34 of 59

Low Vacuum Low Message

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Low

Vacuum

Low?

Start

Yes

Verify Low Vacuum

reading is 6.000 ± .010

using F92.

Adjust if necessary.

Able to

adjust?

Yes

No

Verify.

Run a

specimen

Resolved?

No

Yes

Done

Is Vac Trap

Full?

Yes

1. Empty/Clean jar**.

2. Ensure float is down.

3. Reattach jar without

cross-threading.

No

Verify Low Vacuum

reading is 6.000 ± .010

using F92.

Adjust if necessary.

Able to

adjust?

Yes

No

Look at your

Vacuum Isolator

Chambers (VICs)

Yes

Drain the VICs.

Press F05, then

16,

then Enter

Did VICs

drain?

Yes

Press Stop

three times.

No

Are one or both

of the VICs full

of liquid?

Verify Low Vacuum

reading is 6.000 ± .010

using F92.

Adjust if necessary.

Call BCI

Flush Low Vac Line

(see attached

procedure)

No

Yes

Are one or both

VICs cracked?

No

Able to

adjust?

No

Yes

Call BCI

Done

No

Are all lines

connected to top

of VICs?

Yes

Are there

holes in any of

the lines?

Yes

Replace the

tubing.

No

Reconnect

PN A86683AA (October 2009)

Miami Education Center

Verify Low Vacuum

reading is 6.000 ± .010

using F92.

Adjust if necessary.

**Power Off instrument

before performing

procedure.

Follow HELP.

35 of 59

Flush Low Vacuum Line

Check the Vacuum Overflow Tank (VC22). If

over half full stop and call BCI. If empty or less

than half full, proceed to next step.

Remove the right side panel.

Open the lower door.

Remove the clear plastic shield.

Locate the low vacuum tubing connected to the

area labeled COUNT VACUUM on the right rear

panel. Disconnect the smaller tubing from the

front of the fitting.

Dip the disconnected end of the tubing into a

container with no more than 20 mL of DI water

until it is all aspirated.

Leave the tubing disconnected for ten (10)

minutes while it draws air to dry the vacuum line.

Reconnect the tubing, replace the plastic shield,

close the door and replace the right side panel.

Locate the Vacuum Overflow Tank (VC22) and

disconnect the float sensor connector, P-13/J13.

Press STOP on the keypad and allow VC22 to

drain.

Once VC22 is empty, reconnect P-13/J-13. (If

alarm is triggered, “VACUUM OVERFLOW

TANK STILL FULL” press ALARM RESET on

the keypad and disregard error message.)

Return to

Low Vac Low

flowchart

PN A86683AA (October 2009)

Miami Education Center

36 of 59

Low Vacuum Drifted Message

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Start

Verify Low Vacuum

reading is 6.000 ± .010

Yes

using F92.

Adjust if necessary.

Low

Vacuum

Drifted?

Won’t adjust?

Sluggish adjustment?

Drifting?

Yes

Flush Low Vac Line

(see attached

procedure)

No

Run

Specimen

No

Message

reoccurs?

Perform

Reset

Yes

All Pass &

Message gone?

Perform

Startup

Able to

adjust?

Yes

Perform F92.

Verify low vac

reading 6.000 ± .010

Yes

No

No

Call BCI

Done

Check all count tubings. Verify

tubing not cut through pinch

valves. Verify RBC sweepflow

tubings secure.

Yes

Yes

Repair and

replace tubing.

Verify Low Vacuum

reading is 6.000 ± .010

using F92.

Adjust if necessary.

Able to adjust?

Found issue with

tubing?

No

PN A86683AA (October 2009)

Miami Education Center

Call BCI

No

37 of 59

Flush Low Vacuum Line

Check the Vacuum Overflow Tank (VC22). If

over half full stop and call BCI. If empty or less

than half full, proceed to next step.

Remove the right side panel.

Open the lower door.

Remove the clear plastic shield.

Locate the low vacuum tubing connected to the

area labeled COUNT VACUUM on the right rear

panel. Disconnect the smaller tubing from the

front of the fitting.

Dip the disconnected end of the tubing into a

container with no more than 20 mL of DI water

until it is all aspirated.

Leave the tubing disconnected for ten (10)

minutes while it draws air to dry the vacuum line.

Reconnect the tubing, replace the plastic shield,

close the door and replace the right side panel.

Locate the Vacuum Overflow Tank (VC22) and

disconnect the float sensor connector, P-13/J13.

Press STOP on the keypad and allow VC22 to

drain.

Once VC22 is empty, reconnect P-13/J-13. (If

alarm is triggered, “VACUUM OVERFLOW

TANK STILL FULL” press ALARM RESET on

the keypad and disregard error message.)

Return to

Low Vac Drifted

flowchart

PN A86683AA (October 2009)

Miami Education Center

38 of 59

Fluid Leaks

Review information in HELP and in the TS3-Replacing Components Module.

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Start

I-beam

tubing leak?

Yes

**Find correct

replacement

I-beam tubing with

same color stripe.

Cut new piece

of tubing to

same length as

original.

Carefully

reconnect the

two ends.

Done

No

Other

tubing leak?

Yes

**Find correct

replacement

tubing with same color

stripe or part number.

Cut new piece

of tubing to

same length as

original.

Done

No

Disconnect leaky

tubing* and pull

out of pinch valve.

Thread new piece

of tubing carefully

through tracks in

pinch valve.

Disconnect leaky

tubing*.

Carefully connect

new tubing

No

Round, red stripe

silicon in Random

Access Module?

Yes

**Find correct

replacement

tubing with same

color stripe.

Done

Cut new piece

of tubing to

same length as

original.

Carefully connect

new tubing

**Power Off instrument

before performing

procedure.

Follow HELP.

Disconnect leaky

tubing*.

Carefully thread

new tubing

through blue

spacer sleeve

(Fig. 1)

*Be sure to mark

the exact places

where tubing is

removed.

Fig. 1

PN A86683AA (October 2009)

Miami Education Center

39 of 59

Level Sense Message

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Start

Reagent/

Level out

message

Is

container

empty?

No

Yes

Verify all tubing

connections from

reagent to

instrument.

If diluent, check float

sensor in container

and sensor

connection (Fig. 1).

Did system

prime diluent?

Perform F16 to

Prime Diluent.

No

Yes

No

Change container

and update

reagent log.

Verify.

Run a

specimen.

Done

Replace

Diluent pickup

tube.

Level out

message?

Yes

Yes

Any tubing

disconnected/

pinched?

Fig.Fig.

2 1

Reconnect/

straighten

tubing

Press Startup

and observe.

Sensor Connector

Level out

message?

No

Yes

No

Replace Ibeam tubing**

Yes

**Look at reservoirs

in back of unit.

(Open door on right

side, back)

Check the I-beam

tubing from

reservoir thru

pinch valve. (Fig. 2)

Is I-beam

tubing

crimped?

No

Any bubbles

or leaks?

Press Startup

and observe.

Call BCI

Yes

No

Yes

Reconnect or

replace leaky

tubing

Problem

continues?

No

Fig. 2

Done

**Power Off instrument

before performing

procedure.

Follow HELP.

CBC

Lyse

PN A86683AA (October 2009)

Miami Education Center

Retic

Clear

Retic

Stain

Pack

Prsrv

Pack

Lyse

Cleaner

40 of 59

Backwash Tank Not Full Message

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

41 of 59

Flush Backwash Tank Vacuum Supply Line

Ensure all materials are on hand including a 20 mL

syringe with a piece of yellow-striped tubing (5-inch)

attached to the tip and some distilled water.

Remove the left diluter panel by lifting up and out on

the panel.

Locate VL-107A, the white pinch valve located

above the Backwash Tank. The top fitting above VL107A is a feed-through fitting marked FF-5.

Disconnect the I-beam tubing from FF-5.

Fill the syringe with distilled water and attach the

syringe tubing to FF-5.

Vacuum draws the water out of the syringe. If

needed, you may push on the plunger if the water

does not pull on its own.

The water fills the Vacuum Overflow Tank (VC 22)

Use enough water so that VC 22 is half full.

Disconnect the syringe tubing and reconnect the Ibeam tubing to FF-5.

Press the Reset button on the Analyzer. VC 22

drains.

Perform Diluter Function F-30 to activate the

Backwash Tank Check to confirm resolution.

Run a blood sample to verify Instrument

performance.

Return to

Backwash Tank

Not Full flowchart

PN A86683AA (October 2009)

Miami Education Center

42 of 59

Probe Messages

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

43 of 59

Rocker Bed Messages

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Start

Message:

Bed not Forward

Bed not Backward

Bed not Level

Manually rock

the bed to see

if there is any

physical

obstruction.

F95 – release

all solenoids

Any physical

obstruction?

Yes

No

Fig. 1 – Top view

Fig. 2 – Side view

Bed Not

Forward

Bed Not

Level

Locate the

sensors at the

right side of the

rocker bed (see

Fig. 1 & 2)

Remove it/

Fix it

Clean

sensors with

canned air.

Message

gone?

No

Flag in

sensor

Yes

Call BCI

Bed Not

Backward

Done

Start

Place a sample

cassette with tubes

on the bed and

slide under tube

detector.

Message:

Bed Not

Advanced

Any

obstruction?

Yes

Call BCI

No

Perform the As-needed

Rocker Belt Procedure

Done

Yes

Movement

OK?

No

Use F96 to

verify belt

movement.

Wipe belt with moist

gauze (DI water) top and

bottom. Pull belt from right

to left to clean all.

Dry thoroughly, top and

bottom.

Call BCI

PN A86683AA (October 2009)

Miami Education Center

44 of 59

Aspiration Messages

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

Check the Help

information for the

particular aspiration

message (N, B, P, C)

received

Aspiration

message and

alarm received

Start

Is the message

occurring on more

than one sample?

Yes

Clean and

exercise shear

valve 85/126

No

Check the

sample tube

for clots.

Clots found?

Proper amount

of blood?

Yes

Yes

No

Check the sample tube

for correct blood

volume (at least 1mL of

properly collected

blood)

No

Perform the as needed Clean Shear

Valves Procedure

1. Locate shear valve 85/126.

Redraw

sample

Check if Hgb

result <4 g/dL.

2. While watching the ceramic in the left

side, activate Sol 126. Observe the space

created between the ceramic and the

metal.

Done

Hgb < 4 g/dL?

Yes

4. Press Stop three times to exit the

solenoid function.

No

No

Rerun in

Automatic

aspiration

mode

3. Clean this space with DI water and dry

with lint-free tissues.

Rerun in

Manual

aspiration

mode

Still aspiration

messages?

No

5. Rerun sample(s).

Still aspiration

messages?

Yes

Replace

needle

Yes

Perform Flush

Needle/

Aspirate Pump

Pathway

(see attached

procedure)

Yes

Call BCI

Yes

PN A86683AA (October 2009)

Miami Education Center

Still aspiration

messages?

Done

45 of 59

Flush Aspiration Pathway Between the Needle and Aspirate Pump

Read all the instructions before beginning the procedure.

Needed:

• COULTER® cleaning agent

• 10-mL syringe (PN 2523145)

• 5” (12.7 cm) yellow-striped tubing (PN 3213176)

• Cassette

• Three (3) previously analyzed samples

1. Ensure that all safety precautions are followed while servicing BCI equipment. This

includes (but is not limited to) using proper lab protocol, identifying potential blood borne

pathogen exposure, using personal protective equipment, and properly disposing of parts.

2. Power off the instrument and power supply.

3. Push the aspiration tip for the manual mode all the way back in.

4. Fill syringe with 4 mL COULTER® cleaning agent (more than 4 mL will result in spillage).

5. Connect 5” (12.7 cm) yellow-striped tubing to syringe.

6. Remove tubing at fitting FF160 (refer to FIGURE 1). FF160 is located approximately five

inches (12.7 cm) to the left of the blood sampling valve and five inches (12.7 cm) from the

front of the diluter.

7. Connect yellow-striped tubing from syringe to fitting FF160.

8. Inject the COULTER® cleaning agent into FF160. The fluid will fill needle bellows (rubber

sleeve surrounding the needle) – pressure should be minimal.

9. Exercise the syringe (push plunger back and forth) to ensure that pathway is clean.

10. Remove yellow-striped tubing from FF160 and reattach brown-striped tubing from VL-9B

to fitting FF160.

11. Power up system.

12. Perform Start-up.

13. Run bloods to verify problem resolution.

Fig. 1

Return to Aspiration

Messages Flowchart

PN A86683AA (October 2009)

Miami Education Center

46 of 59

No Diff Results

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

47 of 59

No Retic Results

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

48 of 59

Dispense Probe Messages

On LH SlideMaker

Use the diagrams for Dispense Probe Mechanism and Slide Transport Mechanism

on pages 34 and 35 of this guide to help locate the sensors.

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

49 of 59

Low Vacuum 1 or 2

Messages on LH SlideMaker

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

50 of 59

Shuttle or Truck Vacuum

Messages on LH SlideMaker

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

51 of 59

Bath Not Draining Messages

On LH SlideStainer

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

52 of 59

Bath Not Filling Messages

On LH SlideStainer

Whenever performing any troubleshooting procedures, always wear all required personal protective

equipment.

PN A86683AA (October 2009)

Miami Education Center

53 of 59

As Needed Cleaning Procedures

LH 700 Series

Air Filters

Aspiration Probe Wipe

BSV Drip Plate

BSV Outside

Clogged Flow Cell

Needle Assembly

Rocker Bed Belt

Stripper Plate

Shear Valves

LH SlideMaker

Air filter

Blood Spills and Broken Slides

Catch Tray

Dispense Probe and Rinse Cup

Priming/Backwashing

Flushing the SlideMaker

LH SlideStainer

Basket Holders

Basket Tray (s)

Bath Liquid Level Sensor

Bath Tray

Bath Tray Overflow Sensor

Drain and Fill Tubes

Dryer and Adjacent Plate

Holding Position Tray

Plastic Baths

Tubing Tray

Flushing Stain Baths and Tubing

PN A86683AA (October 2009)

Miami Education Center

54 of 59

LH 700 Series

As Needed Cleaning Procedures

See Cleaning Overview in HELP to determine if certain cleaning procedures are

necessary.

In HELP, go to the Index tab. Type in the word Cleaning. Select overview-diluter.

Other cleaning procedures found here include the following:

PROCEDURE TITLE

COMPONENT

air filter

Cleaning and Replacing Air Filters

aspiration probe wipe

Cleaning Manual Aspiration Probe Wipe

BSV drip plate

Cleaning Blood Sampling Valve Drip Plate

BSV outside

Cleaning Blood Sampling Valve (Outside Sections)

clogged flow cell

Clearing Clogged Flow Cell

needle assembly

Clean Needle Assembly Area

rocker bed

Rocker Bed

stripper plate

Stripper Plate

Shear Valve (from search tab)

Cleaning the Shear Valve

PN A86683AA (October 2009)

Miami Education Center

55 of 59

LH SlideMaker

As Needed Cleaning Procedures

To access the following cleaning procedures in HELP:

select Contents>LH SlideMaker>Cleaning Procedures

COMPONENT

PROCEDURE TITLE

Air filter

Cleaning and Replacing Air Filter (SlideMaker)

Blood Spills and Broken Slides

Cleaning Blood Spills and Broken Slides

Catch Tray

Dispense Probe and Rinse Cup

Cleaning a Catch Tray

Cleaning the Dispense Probe and Rinse Cup

Priming/Backwashing

Flushing the SlideMaker

Priming/Backwashing SlideMaker

Flushing the SlideMaker (Bleach System)

PN A86683AA (October 2009)

Miami Education Center

56 of 59

LH SlideStainer

As Needed Cleaning Procedures

To access the following cleaning procedures in HELP:

select Contents>LH SlideStainer>Cleaning Procedures.

PROCEDURE TITLE

COMPONENT

Basket Holders

Basket Holders

Basket Tray

Basket Tray

Bath Liquid Level Sensor

Bath Liquid Level Sensor

Bath Tray

Bath Tray

Bath Tray Overflow Sensor

Bath Tray Overflow Sensor

Drain and Fill Tubes

Drain and Fill Tubes

Dryer and Adjacent Plate

Dryer and Adjacent Plate

Holding Position Tray

Holding Position Tray

Plastic Baths

Plastic Baths

Tubing Tray

Tubing Tray

Flushing Stain Baths and Tubing

Flushing Stain Baths and Tubing

PN A86683AA (October 2009)

Miami Education Center

57 of 59

Stain – 30 seconds

Buffer – 1 minute

Shorten buffer time until you achieve the desired color.

a) Adjust with acid solution until you achieve the desired color.

b) Try a buffer with a lower pH.

Lengthen rinse time until you achieve the desired color.

Decrease stain time until you achieve the desired color.

Lengthen buffer time until you achieve the desired color.

Shorten stain time until you achieve the desired color.

Buffer time too long

Too light

Stain time too short

Buffer time too short

Poor quality rinse water

Buffer time too long

Rinse time too long

Too dark

Shorten buffer time until you achieve the desired color.

Decrease rinse time until you achieve the desired color.

a) Change water.

b) Verify water meets specifications of Type II NCCLS water

Increase stain time until you achieve the desired color

Increase buffer time until you achieve the desired color

Prolong staining time until you achieve the desired color.

Stain time too short

Buffer too alkaline

Drain and fill all baths.

a) Adjust with alkaline solution until you achieve the desired color.

b) Try a buffer with a higher pH.

a) Shorten rinse time (Bath 5) until you achieve the desired color.

b) Adjust frequency of Bath 5 drain and fill until you achieve the desired color.

Action

All reagents too old

Excessive washing

Buffer too acidic

Cause

Insufficient washing

Stain time too long

Buffer time too short

Stain time too long

Too blue

Too red

Symptom

the length of staining times (longer = more intense)

decreasing the buffer strength

concentration of stain in buffer (more stain = darker, more intense)

PN A86683AA (October 2009)

Miami Education Center

•

•

•

Coloration (red / blue) is primarily controlled by the pH of the buffer.

Stain intensity and differential staining characteristics can are controlled by:

•

•

Typical time adjustments increments

58 of 59

Beckman Coulter has developed BCI TruColor™ reagents and default protocols for use on the LH SlideStainer. The Beckman Coulter default

protocols are to a predefined coloration specification (See tables on next page). Since coloration is subjective, optimization of the protocols and/or

reagents may be necessary to meet your individual coloration criteria. Ensure that both the methanol and water you use meet the specifications

detailed in your system’s online Help.

Overall Stain Quality

Optimizing Stain Protocols

Add quick rinse step to protocol (primarily for WG and MGG). See help topic Quick Rinse

Method.

Drain/Fill all baths.

Excess stain left on slide

Stain or Stain/buffer too

old

Rinse (Bath 5) dirty

Background

staining (overall

slide shows

color)

Precipitate

(clumps or fine

particles on

whole slide)

Make new blood smear.

Purple

Red blood cells

Red blood cells

Red blood cells

Red blood cells

Red blood cells

WBC

WBC

Small spots

Inclusions

Medium sized spot

Threadlike filaments

Small granules

Coarse Granules

Spots

Purple/blue

Purple

Purple

Purple

Dark Purple

Sky-Blue

Pink

Color

Human Blood Cell Inclusions

Description

Cell

Spicule-like formation

Myeloblast

Granules

Cytoplasm

Erythrocyte

Lymphocyte

Monocyte

Neutrophil

Metamyelocyte

Myelocyte

Promyelocyte

Basophil

PN A86683AA (October 2009)

Miami Education Center

59 of 59

Pink

Blue

Gray blue

Pink

Pink

Pink

Blue

Purple,

black

Orange

Purple

Purple

Coloring of Romanowsky Stains

Structure

Cell

Color

Nuclei

All

Purple

Eosinophil

Reference

Neutrophil

:

Wintrobe’s Clinical Hematology, 9th edition, Vol. 1, page 23.

Platelet

NCCLS Document H20 A, Volume 12, Number 1. Reference Leukocyte Differential Count (Proportional) and Evaluation of

Instrumental methods.

Color Atlas and Instruction Manual of Peripheral Cell Morphology, O’Connor, Barbara H., 1984, page 16 – 18.Copied from: PN 4276448D (November 2003)

Inclusion

Auer rods

Pappenheimer

bodies

Malaria parasites

Howell-Jolly bodies

Cabot rings

Basophilic stippling

Toxic Granulation

Dohle bodies

The tables below represent the stain characteristics against which the Beckman Coulter

TruColor™ reagents and BCI default protocols were evaluated.

Overall pale blue

staining

Drain/fill Stain and Stain/Buffer baths.

Stain too old

RBC centers

appear punched

out (cookie

cutter effect in

center of cells)

Stain baths dirty (Stain

and Stain/Buffer)

Blood smear more than

2 hours old prior to fixing

a) Drain/Fill the methanol bath.

b) Dip empty basket in methanol prior to re-entry into system.

Water has contaminated

the methanol

a) Drain/Fill Bath 5.

b) Increase frequency of Bath 5 drain/fill.

c) Add Quick Rinse step to protocol (primarily for WG or MGG). See help topic Quick Rinse

Method.

Perform the Bath Flushing Procedure.

Action

Cause

Dilute buffer solution with deionized or distilled water until you achieve the desired color

Symptom

Buffer too concentrated