Power Systems Modernization ª Trip Unit Solutions

The Evolution of Trip Units

A Look at the Numbers

The basic elements of Low Voltage Power Breakers (LVPBs)

are: the mechanism, current-carrying parts, the arc interruption structure, the insulation structure and the tripping

system. One of the major problems with the vast installed

base of LVPBs is the reliability of the tripping system. Why

replace a complete breaker if the problem is in the tripping

system? Between 1940 and 1970, breaker manufacturers used

electromechanical trip units, which lost calibration, required

a great deal of preventative maintenance, and are no longer

supported. Next came the first solid-state trip units. These

were peak-sensing devices that provided greater reliability

and accuracy but were unable to adapt to the changing

world of electrical noise and harmonics.

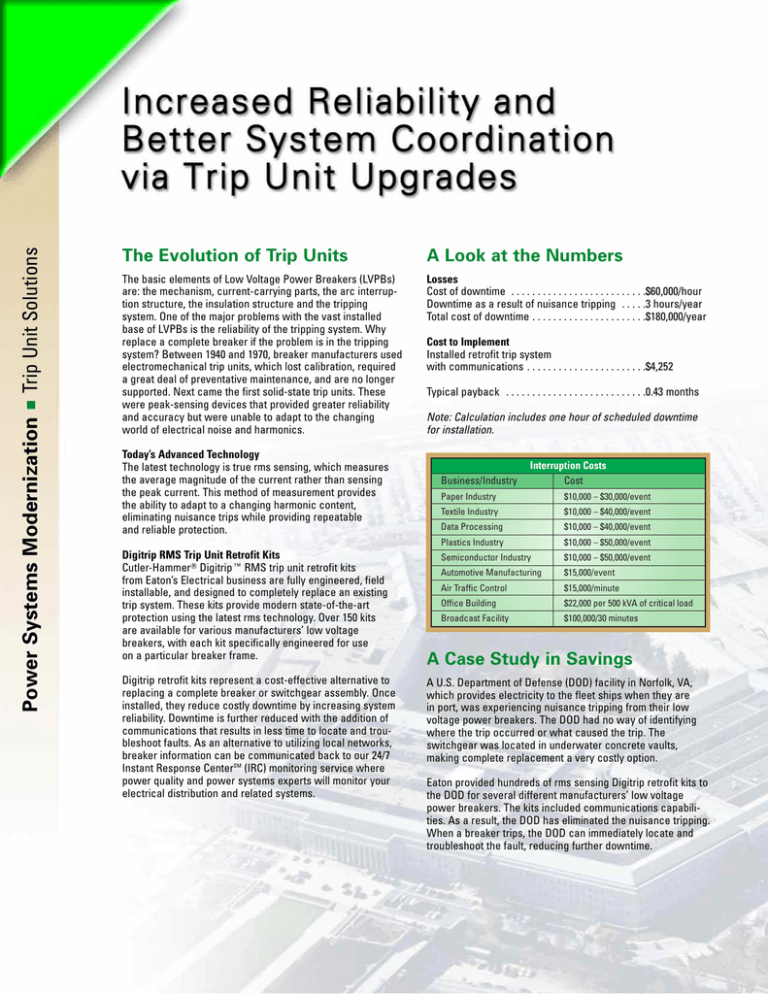

Losses

Cost of downtime . . . . . . . . . . . . . . . . . . . . . . . . . .$60,000/hour

Downtime as a result of nuisance tripping . . . . .3 hours/year

Total cost of downtime . . . . . . . . . . . . . . . . . . . . . .$180,000/year

Today’s Advanced Technology

The latest technology is true rms sensing, which measures

the average magnitude of the current rather than sensing

the peak current. This method of measurement provides

the ability to adapt to a changing harmonic content,

eliminating nuisance trips while providing repeatable

and reliable protection.

Digitrip RMS Trip Unit Retrofit Kits

Cutler-HammerT DigitripE RMS trip unit retrofit kits

from Eaton’s Electrical business are fully engineered, field

installable, and designed to completely replace an existing

trip system. These kits provide modern state-of-the-art

protection using the latest rms technology. Over 150 kits

are available for various manufacturers’ low voltage

breakers, with each kit specifically engineered for use

on a particular breaker frame.

Digitrip retrofit kits represent a cost-effective alternative to

replacing a complete breaker or switchgear assembly. Once

installed, they reduce costly downtime by increasing system

reliability. Downtime is further reduced with the addition of

communications that results in less time to locate and troubleshoot faults. As an alternative to utilizing local networks,

breaker information can be communicated back to our 24/7

Instant Response CenterSM (IRC) monitoring service where

power quality and power systems experts will monitor your

electrical distribution and related systems.

Cost to Implement

Installed retrofit trip system

with communications . . . . . . . . . . . . . . . . . . . . . . .$4,252

Typical payback . . . . . . . . . . . . . . . . . . . . . . . . . . .0.43 months

Note: Calculation includes one hour of scheduled downtime

for installation.

Business/Industry

Interruption Costs

Cost

Paper Industry

$10,000 – $30,000/event

Textile Industry

$10,000 – $40,000/event

Data Processing

$10,000 – $40,000/event

Plastics Industry

$10,000 – $50,000/event

Semiconductor Industry

$10,000 – $50,000/event

Automotive Manufacturing

$15,000/event

Air Traffic Control

$15,000/minute

Office Building

$22,000 per 500 kVA of critical load

Broadcast Facility

$100,000/30 minutes

A Case Study in Savings

A U.S. Department of Defense (DOD) facility in Norfolk, VA,

which provides electricity to the fleet ships when they are

in port, was experiencing nuisance tripping from their low

voltage power breakers. The DOD had no way of identifying

where the trip occurred or what caused the trip. The

switchgear was located in underwater concrete vaults,

making complete replacement a very costly option.

Eaton provided hundreds of rms sensing Digitrip retrofit kits to

the DOD for several different manufacturers’ low voltage

power breakers. The kits included communications capabilities. As a result, the DOD has eliminated the nuisance tripping.

When a breaker trips, the DOD can immediately locate and

troubleshoot the fault, reducing further downtime.

Integrated Solutions Summary

Our engineering professionals have the expertise and experience

to correctly apply Digitrip retrofit kits to a variety of low voltage

power breakers, thereby increasing reliability and offering

improved system coordination.

ª Asset Optimization: Outsource the responsibility for the

electrical distribution system and associated equipment to

Eaton - Electrical Services & Systems. Offerings involve cost

savings and performance guarantees for greater focus on

the core business. Asset Optimization uses all the tools and

capabilities within the other service platforms, resulting in

improved reliability, life expectancy and overall cost.

ª Knowledge Management: Collect and transform your system

data to useful knowledge; allow for proactive planning, energy

management, optimized decision making, failure prediction and

ultimately, cost savings.

ª Integrated Project Solutions: Engineering, design, procurement,

installation and commissioning of power systems equipment; a

total turnkey approach.

ª Power Systems Engineering Solutions: Power systems automation, design engineering, training, predictive diagnostics, power

quality and power systems studies/analysis to decrease costs

and increase productivity.

ª Power Systems Modernization: Keep systems operating at peak

efficiency, reliability and safety; extend the life of the electrical

asset through equipment life extension and upgrade solutions

utilizing new technologies.

For further information, please visit our Web site at:

www.EatonElectrical.com and click on Support, then Services &

Systems, or contact your nearest Eaton - Electrical Services &

Systems office.

For emergency service, call 1-800-498-2678 and ask for the office

nearest you.

Cutler-Hammer is a federally registered trademark of Eaton Corporation.

ª New Equipment Services: Installation, testing and commissioning of virtually any electrical equipment.

ª Field Services: Power system and equipment service, maintenance programs, testing, upgrades and Aftermarket solutions;

24/7 emergency service; crisis response and disaster recovery.

Eaton Electrical Inc.

1000 Cherrington Parkway

Moon Township, PA 15108

United States

tel: 1-800-525-2000

www.EatonElectrical.com

© 2004 Eaton Corporation

All Rights Reserved

Printed in USA

Publication No. SA02727003E / Z2790

August 2004