An Active EMI Filtering Technique for Improving Passive Filter Low

advertisement

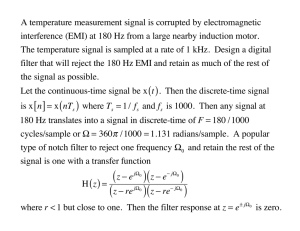

172 IEEE TRANSACTIONS ON ELECTROMAGNETIC COMPATIBILITY, VOL. 48, NO. 1, FEBRUARY 2006 An Active EMI Filtering Technique for Improving Passive Filter Low-Frequency Performance Wenjie Chen, Xu Yang, Member, IEEE, and Zhaoan Wang, Senior Member, IEEE Abstract—In recent years, there has been considerable interest in the development and applications of active electromagnetic interference (EMI) filters. An active EMI filter (AEF) for integrated power electronics module (IPEM) is proposed in this paper, where large passive EMI filter is replaced by small passive components and active op-amp circuit. The technique is appropriated when improved attenuation is required at relatively low frequencies and the high-frequency filtering requirements are easily met. The effectiveness of the proposed circuit has been verified by experimental results. It is demonstrated that the proposed approach is most effective in a case where it is desirable to minimize the amount of passive components in the filter. Index Terms—Active filters, current transformers, electromagnetic interference (EMI), passive filters. I. INTRODUCTION HE size and performance of electromagnetic interference (EMI) filter components are important considerations in integrated power electronics modules (IPEMs). Planar integrated passive EMI filters have been employed to achieve the necessary degree of ripple attenuation [1], [2]. However, in designing passive filters the compensating bandwidth is comparatively narrow. Only a certain part of noise can be eliminated. The size, weight, temperature, and reliability limitations of magnetic core can present a significant design constraint. Active ripple cancellations provide alternative approaches to the problem. Some practical forms of AEFs have been reported recently [3]–[11]. In this paper, a small passive filter is coupled with an active circuitry to attenuate the noise. The passive filter serves to limit the ripple to a certain degree. The active circuit cancels or suppresses the low-frequency ripple components that are most difficult to attenuate with a small size passive lowpass filter. The combination of these two schemes can lead to an improvement in the filter’s attenuation performance over a wide frequency range. At frequency greater than the bandwidth of the active circuit, the filter performs as a passive component, which permits a substantial reduction in the passive filter size, with potential benefits in IPEM size, weight, and cost. After a brief comparison between active power filter (APF) and active EMI filter (AEF), an active filter topology suitable for an IPEM application is introduced. Its characteristics are analyzed and the current sensor is discussed. Experimental results T are presented, demonstrating that good noise attenuation can be combined with high efficiency. II. COMPARISON BETWEEN APF AND AEF The basic idea of active filter has been known for some time [3]–[11]. Fig. 1 illustrates the principle and classification of AEF. According to the circuit configuration and connections, the AEFs are classified as parallel AEF and series AEF. To reduce the complexity of the AEF, there is also hybrid passive/active EMI filter. Their compensation principle is similar to that of the APF. On the other hand, there are great differences between the AEF and APF, which include the following. 1) Noise frequency. APF deals with the harmonic current or voltage that is below 9 kHz, and in most cases, the APF could filter only low order harmonic effectively. While the EMI noise spectrum of the AEF is from 150 kHz to 30 MHz according to the EMC standard—CISPR22, the bandwidth of AEF should be much wider than that of APF. 2) Power rating. According to [12], low power application of APF refers to the power lower than 100 KVA while the high power application of APF means that power is greater than 10 MVA. In short, the power rating of the APF is very high. As for AEF, the power is very small. Consider the CISPR22 class B, and assume that the attenuation on LISN is 60 dB µV. The power is only 0.2 µW. 3) Implementation of controlled voltage/current source. Since the power rating of APF is very high, the efficiency of the circuit should be higher enough; otherwise, the thermal management will be difficult to deal with. To achieve high efficiency, it is necessary to use the switching mode in the implementation of the controlled voltage or current source. On the contrary, the power rating of the AEF is very tiny, thus it does not need to use switching mode. The linear mode is enough. Therefore, it is entirely feasible to utilize the AEF in the design of the input EMI module of the IPEMs to restrain the EMI noise. III. IMPLEMENTATION OF THE AEF A. Active Circuit Realization Manuscript received December 11, 2004; revised September 22, 2005. This work was supported by the National Natural Science Foundation of China (NSFC) under Project 50237030. The authors are with the School of Electrical Engineering, Xi’an Jiaotong University, Xi’an, China (e-mail: cwj@mail.xjtu.edu.cn; yangxu@mail.xjtu.edu. cn). Digital Object Identifier 10.1109/TEMC.2006.870803 The active topology in this work is shown in Fig. 2(a). The noise current is sensed through current transformer and is amplified; compensation current is injected back to the power circuit through the RC branch connected to the op-amp’s output. Ideally, with infinite gain, the negative feedback would drive the input voltage and, hence, the noise current to zero. 0018-9375/$20.00 © 2006 IEEE Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply. CHEN et al.: AN ACTIVE EMI FILTERING TECHNIQUE FOR IMPROVING PASSIVE FILTER LOW-FREQUENCY PERFORMANCE Fig. 1. 173 Generalized block diagram and configuration for active EMI filter. (a) Basic concept. (b) Parallel configuration. (c) Series configuration. Fig. 2. Topology of active EMI filter and the equivalent circuit. (a) Proposed active EMI filter. (b) Equivalent two-port T network model. A two-port T network model will explain the operational principle more clearly, as shown in Fig. 2(b). In an ideal filter, the noise current iq at the quiet port would be zero. Thus, the unwanted noise current in at the noisy port would be moved down to the controlled current source leg of the T port and flow back to the noisy port. To achieve this, a cancellation current ic = in should be generated in the controlled current source. In reality ic does not equal to in exactly, so the quiet port current iq = in − ic is nonzero. The closed-loop current transfer function can be found as iq 1 . (1) = in 1+F For good noise attenuation the current gains of the feedback should be as large as possible. In practice, to avoid instability the loop gain must be restricted at high frequency, resulting in limited noise attenuation bandwidth. In this filter circuit, the injected current cannot be circulated within the closed loop without using the coupling capacitor C1 because the closed loop cannot be made. Thus, C1 is used to provide the low-impedance path of the high-frequency noise current for the internal circulation. In this analysis there is an as- Fig. 3. Closed loop system of Fig. 2. (a) Block diagram of feedback system. (b) Frequency response. sumption that coupling capacitor has sufficiently low impedance at the frequency band of interest. The transfer function according to the block diagram of the feedback as shown in Fig. 3(a) is s (s + ω ) + 1 1 ω2 iq = . (2) ω1 1 2 in s + 1+ +k k s+ω ω2 ω2 1 2 1 Fig. 3(b) shows the frequency response of the AEF without including the effect of coupling capacitor. B. Current Transformer The measurement of EMI noise currents makes necessary the use of current transformer with a very wide frequency bandwidth and without distortion. An elementary structure based on a toroidal current transformer, a winding, and a resistor load is used in this paper. A simplified equivalent circuit of the current transformer is shown in Fig. 4. Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply. 174 IEEE TRANSACTIONS ON ELECTROMAGNETIC COMPATIBILITY, VOL. 48, NO. 1, FEBRUARY 2006 Fig. 4. Description of the current transformer. (a) Toroidal transformer. (b) Low-frequency model. Fig. 6. High-frequency response of current transformer. Fig. 7. Configuration of experimental system. Fig. 8. No EMI filter installed. Fig. 5. High-frequency performance of current transformer. (a) Equivalent circuit. (b) Simplified model. The low cutoff frequency is expressed by fL = Rl . 2πn2 µ0 µr Ae (3) Ae is the area of the magnetic circuit, l is the effective length of the core, and µr is reversible permeability. To improve fL , it is necessary to increase n and to have large Ae , a short l, and a high-permeability magnetic material. Since the frequency of the EMI noise is as high as 30 MHz, it is necessary to discuss the high-frequency performance. Fig. 5(a) shows the high-frequency equivalent circuit of the current transformer [13]. L1 and L2 are the primary and secondary leakage inductance, C1 and C2 are the primary and secondary winding capacitance, Lµ is the magnetizing transformer inductance, and Cm1 and Cm2 are the primary and secondary interwinding capacitance. Although the interwinding capacitance has a great influence on the frequency response, the electrostatic shield will divide the capacitance into Cm1 and Cm2 . For an easier understanding of the current transformer’s behavior, we ignore Lµ , because for high frequencies, the current in L is greater than that in Lµ . The simplified equivalent model is shown in Fig. 5(b). The transfer function is shown in (4) at the bottom of the page, and the high cutoff frequency is fH = 2π 3 1 C1 C2 R (L1 + L2 ) Io 1 . = 3 Ii s C1 (L1 + L2 )C2 R + s2 C1 (L1 + L2 ) + sR (C1 + C2 ) + 1 Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply. . (5) (4) CHEN et al.: AN ACTIVE EMI FILTERING TECHNIQUE FOR IMPROVING PASSIVE FILTER LOW-FREQUENCY PERFORMANCE Fig. 9. 175 Effectiveness of the active and passive filter. (a) Active control circuit installed. (b) Passive EMI filter installed. It could be seen that fH has nothing to do with the ratio n. To improve the high-frequency response, it is necessary to decrease the product of C1 C2 (L1 + L2 ), which means to minimize the parasitics. Fig. 6 shows the bode plot of the current transformer. IV. EXPERIMENT RESULTS In this section, several experiment results are shown. Fig. 7 shows the configuration of the experimental system. A 250-W buck converter operating at 100 kHz is used as a high-frequency noise source. The input filter is composed of the active circuit and additional passive filtering elements. An LISN is used to provide the stable source impedance at the high frequency and the peak detector is used in the measurement of conducted EMI spectrum. Fig. 8 shows the conducted EMI spectrum of the system without any EMI filter. The conducted EMI spectrum includes both common- and differential-mode EMI. Although they should be separately considered, the differential-mode EMI will not be discussed in this paper with the assumption that some appropriate differential-mode components are installed for each design stage. After sufficient differential-mode filtering, the commonmode EMI becomes the bottleneck of the total conducted EMI. Fig. 9(a) shows the conducted EMI spectrum when the proposed active circuit is added into the system. For comparison, in Fig. 9(b), we also give the measured spectrum when only a passive EMI filter is used. As can be seen, although the EMI spectrum of 400 kHz to 2 MHz is much attenuated by the passive component, the spectrum of 150–400 kHz is still greater than the standard. It is also comparatively difficult for the passive EMI filter to improve its performance during these frequencies because the size and weight of the passive components would increase to a great degree, while the proposed active circuit can do this with ease. In Fig. 10(a), both an AEF and a passive EMI filter are added to the system. With the aid of the AEF, the EMI spectrum of 150–700 kHz is highly attenuated so that it is possible to meet the standard. Although the level of the EMI spectrum is increased especially above 1 MHz, the entire level is below the given limit line. Fig. 10(b) shows the experiment result when a 4.7 nF Y-capacitor Cy2 is used. By introducing simple additional filter stage, one can dramatically increase the amount Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply. 176 Fig. 10. IEEE TRANSACTIONS ON ELECTROMAGNETIC COMPATIBILITY, VOL. 48, NO. 1, FEBRUARY 2006 One active EMI filter (AEF) with one passive EMI filter. (a) Cy2 uninstalled. (b) Cy2 installed. of noise attenuation attainable for the hybrid system. Because the additional Y capacitor provides a low impedance path for high frequency noise current, so that the noise current flowing into LISN will be reduced, then the conducted CM interference will be reduced too. Therefore, as illustrated in Fig. 10, the combination of active and passive filter systems yields a superior result over either one alone. At low frequencies, the active filter compensates for the limitations of the passive filter and at higher frequencies only passive filtering is effective. These two complementary schemes allow for the maximum usage of the filtering technique. V. CONCLUSION In this paper, we have attempted to compare the characteristics of APF and AEF in order to justify the feasibility of using AEF into the IPEMs. A hybrid passive/active filter topology that reduces EMI noise by injecting a compensating current is built. First, conventional passive filters reduce the EMI noise to a few percent. Then an active filter gives substantial noise attenuation, especially at low frequencies. Finally, some high-frequency passive filters take over where the active filtering becomes ineffective. The experimental results demonstrate the feasibility and high performance of the new approach and illustrate its potential benefits. It is demonstrated that the proposed approach is most effective in case where it is desirable to minimize the passive component size and cost. REFERENCES [1] C. Rengang, “Integration of EMI filter for distributed power system (DPS) front-end converter,” in Proc. IEEE Power Electronics Specialist Conf. ’03, Jun. 15–19, 2003, pp. 296–300. [2] P. J. Wolmarans, “Technology for integrated RF-EMI transmission line filters for integrated power electronic modules,” in Proc. 37th Industry Applications Conf., Oct. 13–18, 2002, pp. 1774–1780. [3] L. LaWhite and M. F. Schlecht, “Design of active ripple filters for power circuits operating in the 1–10 MHz range,” IEEE Trans. Power Electron., vol. 3, no. 3, pp. 310–317, Jul. 1988. [4] N. K. Poon, “Techniques for input ripple current cancellation: Classification and implementation,” IEEE Trans. Power Electron., vol. 15, no. 6, pp. 1144–1152, Nov. 2000. [5] Y. C. Son and S.-K. Sul, “A new active common-mode EMI filter for PWM inverter,” IEEE Trans. Power Electron., vol. 18, no. 6, pp. 1309– 1314, Nov. 2003. [6] P. Cantillon-Murphy, “An active ripple filtering technique for improving common-mode inductor performance,” IEEE Power Electron. Lett., vol. 2, no. 2, pp. 45–50, Jun. 2004. Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply. CHEN et al.: AN ACTIVE EMI FILTERING TECHNIQUE FOR IMPROVING PASSIVE FILTER LOW-FREQUENCY PERFORMANCE [7] D. C. Hamill, “An efficient active ripple filter for use in DC-DC conversion,” IEEE Trans. Aerosp. Electron. Syst., vol. 32, no. 3, pp. 1077–1084, Jul. 1996. [8] T. Farkas and M. F. Schlecht, “Viability of active EMI filters for utility applications,” IEEE Trans. Power Electron., vol. 9, no. 3, pp. 328–337, May 1994. [9] A. C. Chow and D. J. Perreault, “Design and evaluation of an active ripple filter using voltage injection,” in Proc. IEEE Power Electronics Specialist Conf. ’01, Jun. 17–21, 2001, pp. 390–397. [10] Y.-C. Son and S.-K. Sul, “Generalization of active filters for EMI reduction and harmonics compensation,” in Proc. 38th Industry Applications Conf., Oct. 12–16, 2003, pp. 1209–1214. [11] S. Ogasawara, “An active circuit for cancellation of common-mode voltage generated by a PWM inverter,” IEEE Trans. Power Electron., vol. 13, no. 5, pp. 835–841, Sep. 1998. [12] M. El-Habrouk, “Active power filters: A review,” Proc. Inst. Elect. Eng. Electric Power Appl., vol. 147, pp. 403–413, Sep. 2000. [13] E. Laboure, “Current measurement in static converters and realization of a high frequency passive current probe,” in Proc. 5th European Conf. Power Electronics and Applications, 1993, pp. 478–483. Wenjie Chen was born in Xi’an, China, in 1974. She received the B.S. and M.S. degrees from Xi’an Jiaotong University, Xi’an, China, in 1996 and 2002, respectively, both in electrical engineering. She is currently pursuing the Ph.D. degree at Xi’an Jiaotong University, Xi’an, China, with her research focused on the EMI and integration design of power electronics modules. She has been a member of the faculty of the School of Electrical Engineering, Xi’an Jiaotong University, since 2002, where she is currently a Lecturer. Her main research interests include soft-switching dc/dc converters and active filters and power electronic integration. 177 Xu Yang (M’02) was born in China in 1972. He received the B.S. and Ph.D. degrees from Xi’an Jiaotong University, Xi’an, China, in 1994 and 1999, respectively, both in electrical engineering. He has been a member of the faculty of the School of Electrical Engineering, Xi’an Jiaotong University, since 1999, where he is presently a Professor. From November 2004 to November 2005, he was with the Center of Power Electronics Systems (CPES), Virginia Polytechnic Institute and State University, Blacksburg, as a Visiting Scholar. He then came back to Xi’an Jiaotong University and engaged in the teaching and researches in power electronics and industrial automation area. His research interests include soft switching topologies, PWM control techniques and power electronic integration, and packaging technologies. Zhaoan Wang (SM’98) was born in Xi’an, China, on June 9, 1945. He received the B.S. and M.S. degrees from Xi’an Jiaotong University in 1970 and 1982, respectively, and the Ph.D. degree from Osaka University, Osaka, Japan, in 1989. From 1970 to 1979, he was an Engineer at Xi’an Rectifier Factory. Starting in 1982, he became a Lecturer at Xi’an Jiaotong University, where he is now a Professor. He is engaged in research on power conversion system, harmonics suppression, reactive power compensation and power electronic integration, and active power filters. He has published over 150 technical papers and has led numerous government and industry-sponsored projects in the areas of power and industrial electronics. Authorized licensed use limited to: UNIVERSIDADE FEDERAL DE MINAS GERAIS. Downloaded on March 14, 2009 at 10:09 from IEEE Xplore. Restrictions apply.