497 Demonstrate knowledge of workplace health and

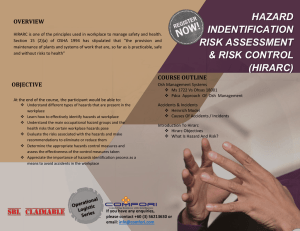

advertisement

497 Demonstrate knowledge of workplace health and safety requirements Course Notes Occupational Health and Safety Practice Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice 2007 New Zealand Industry Training Organisation All these materials are subject to copyright. Apart from copying permitted under the Copyright Act 1994 and its amendments, neither this document nor any part of it nor any audio visual programs associated with this booklet may be reproduced in any form or by any means without written permission. NZITO P.O. Box 488 Mail Centre Hamilton New Zealand www.nzito.co.nz Copyright © 2007. New Zealand Industry Training Organisation Incorporated -2- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Contents INTRODUCTION ................................................................................................................. 4 UNIT STANDARD 497........................................................................................................... 4 WHO IS THIS TRAINING FOR?................................................................................................ 4 WHAT DOES THIS TRAINING COVER? ..................................................................................... 4 ASSESSMENT ..................................................................................................................... 4 WORKING THROUGH THIS TRAINING ...................................................................................... 4 WORKPLACE HEALTH AND SAFETY REQUIREMENTS ................................................ 5 LEGISLATIVE RIGHTS AND RESPONSIBILITIES............................................................ 5 RESPONSIBILITIES OF EMPLOYERS UNDER THE HSE ACT: ...................................................... 5 RESPONSIBILITIES AND RIGHTS OF EMPLOYEES UNDER THE HSE ACT: .................................... 6 QUIZ 1 ............................................................................................................................... 7 THE SYSTEMS APPROACH .............................................................................................. 9 THE PRINCIPAL SYSTEMS ..................................................................................................... 9 HIERARCHY OF HAZARD MANAGEMENT CONTROLS ............................................................... 13 QUIZ 2 ............................................................................................................................. 15 HAZARDS AS DEFINED IN THE HSE ACT ..................................................................... 18 QUIZ 3 ............................................................................................................................. 19 Copyright © 2007. New Zealand Industry Training Organisation Incorporated -3- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Introduction Unit Standard 497 Unit Standard 497, Demonstrate knowledge of workplace health and safety requirements sits within the Occupational Health and Safety Practice domain on the National Qualifications Framework. Unit Standard 497 is worth 3 credits at level 1 on the National Qualifications Framework. Who is this training for? This training is for all people in the workplace. It is also for people who need to do unit standard 497 for a national certificate. What does this training cover? This training covers: legislative rights and responsibilities for workplace health and safety the systems approach to workplace health and safety hazards as defined in the HSE Act. Assessment For Assessment you will need to answer questions about workplace health and safety. The questions in the assessment cover what is in this training. You can look at the training notes when you answer the questions. You do not have to answer them from memory. Your assessor might want to ask you these questions and get you to tell him or her the answers rather than have you write the answers down. If you think you can do the assessment without doing the training that s fine, you can answer the questions and give them to your assessor. It is suggested you do the practices in the training before you answer the questions in the assessment just to make sure you do know everything covered in the training. Working through this training This training is self-paced. You choose how you work on it, you can work at your own pace and work the hours that suit you. If there are others at your work doing the training you can work with them, or work on your own. The training is made up of chunks; each chunk is made up of: Information on the topic. A practice exercise. If you get stuck, don t understand something or need some help to plan your study, talk to your work mates (especially those who have done this course), supervisor or work site trainer. Copyright © 2007. New Zealand Industry Training Organisation Incorporated -4- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Workplace health and safety requirements In New Zealand, workplace health and safety requirements are governed by the Health and Safety in Employment Act 1992 (HSE Act). This Act was put in place to promote the prevention of harm to all people at, or in the vicinity, of work. The Act applies to all New Zealand workplaces and is administered and enforced in most workplaces by the Department of Labour. Legislative rights and responsibilities Under the HSE Act, employers and employees have certain responsibilities and employees have certain rights. Responsibilities of employers under the HSE Act: Your employer must take all practicable steps to ensure the safety of employees. Practicable means: practical, reasonable, and physically possible. For example, your employer can protect you by providing you with personal protective clothing and equipment but cannot guarantee that the workplace will be 100% safe at all times as this is not practicable. Examples of taking practicable steps to ensure your safety include: Providing personal protective clothing and equipment. For example, providing you with ear muffs or ear plugs, safety goggles, gloves, aprons, hard hats, safety jerkins, steel cap boots, dust masks and so on. Managing hazards. For example, replacing toxic materials with non-toxic ones, removing tripping hazards, installing safety features on equipment, placing signs around the workplace to warn people of hazards that cannot be eliminated. Copyright © 2007. New Zealand Industry Training Organisation Incorporated Providing supervision and training. For example, training new employees on how to use equipment then supervising those employees until they are able to complete the associated tasks safely. -5- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Responsibilities and rights of employees under the HSE Act: The HSE Act doesn t just apply to your employer. It also applies to you and you can be prosecuted under the act if you fail to take responsibility for health and safety at work. Examples of taking responsibility include: Protecting the health and safety of self and others. In addition to protecting your own health and safety, such as wearing personal protective equipment and following health and safety guidelines, you also need to look out for others in the workplace. For example, if you create a hazard, such as a wet floor, you need to warn others of the hazard. You need to be aware of things you do or don t do at work that can cause harm to others, for example, turning off a machine when you have finished with it, placing a sharp knife in its holder rather than leaving it on a bench, sweeping debris off the floor, placing a sign over a wet floor until it dries, and so on. Using protective clothing and equipment. Your employer should supply you with protective clothing and equipment as and when necessary so your responsibility is to wear it and to inform your employer if it doesn t fit, is damaged or not working for any reason. Protective clothing and equipment has been carefully designed to reduce the likelihood of hazards causing you harm so it s very important you use it properly and at all times when working with or around workplace hazards. The right to refuse unsafe work. You have the right, under the HSE Act to refuse to do work that you feel is unsafe. For example, heavy lifting or working with chemicals. You need to explain to your employer why you feel it is unsafe. If your employer doesn t agree with you or puts pressure on you to work when you feel it is unsafe to do so you will need to talk to your health and safety representative or to a governing authority such as the Department of Labour. To be adequately supervised and/or trained. You should be trained to do your job safely and in a way that does not cause you any harm. In addition to training you should be supervised until you are able to work competently and safely. For example, Joe is trained how to operate some equipment and advised when to take a break and how often to reduce the risk of strain. He is then supervised by Pete who watches over him to make sure he uses the equipment safely and takes the regular breaks as required. Copyright © 2007. New Zealand Industry Training Organisation Incorporated -6- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Quiz 1 1. What is the primary purpose of the Health and Safety in Employment Act (HSE Act): a. To promote prevention of harm to all people at, or in the vicinity, of work. b. To protect employees from an unsafe workplace. c. To promote employers to be more responsible. 2. Who enforces the HSE Act? a. The Police. b. The National Health System. c. The Ministry of Health. d. The Department of Labour. 3. The Act requires people at work to take all practicable steps to protect health and safety at work. What does practicable mean? a. Practical, reasonable, and physically possible. b. It s another word for legal. c. Authorised, validated and tested. 4. Pete is asked to operate a machine that he hasn t been trained on. If he has an accident who is responsible? a. Pete for not refusing to work. b. Pete s workmates for not supervising Pete. c. Pete s employer for not training Pete. 5. Kath leaves work related debris on the floor despite being told to keep passageways clear at all times. Soon after, Sue slips on a piece of debris and breaks her arm from the fall. Who is responsible? a. Kath for not protecting others. b. Sue for not protecting herself. c. Kath s employer. 6. You have a right to refuse work that you think is unsafe: a. True b. False Copyright © 2007. New Zealand Industry Training Organisation Incorporated -7- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice 7. Wearing personal protective clothing and equipment is optional as you are individually responsible for your health and so it s up to you if you want to risk it. a. True b. False 8. If Fiona is trained on how to operate a machine but is not supervised, who is responsible if she has an accident while operating the machine alone? a. Fiona for not paying enough attention in training. b. The employer c. No one for not providing supervision. in this case her training should be sufficient. 9. If Sam receives instructions on how to operate a machine but doesn t understand those instructions. Who is responsible if he has an accident while operating the machine? a. Sam for not telling the employer he doesn t understand. b. The employer for not making sure Sam understands or supervising him while working on the machine. c. No one in this case it s a matter of Sam having literacy issues. 10. Bill hates wearing ear protection and tends to either wear it loosely or not at all (when the supervisor isn t watching). In time he suffers hearing loss. Who is responsible? a. Bill for not taking responsibility to wear the protection. b. Bills employer for not supervising Bill more closely. c. Both Bill and his employer. Copyright © 2007. New Zealand Industry Training Organisation Incorporated -8- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice The systems approach The emphasis of the HSE Act is on the systematic management of health and safety at work. It requires employers and others to maintain safe working environments, and implement sound practice. It recognises that successful health and safety management is best achieved through good faith co-operation in the place of work and, in particular, through the input of those doing the work. The principal systems All workplaces should have in place the following systems: Emergency procedures Training and supervision Employee participation Incident and hazard reporting Hazard management Emergency procedures Emergency procedures are the actions that all people in and around any workplace need to do in the event of an emergency, for example a fire, earthquake or chemical spillage. Emergency procedures should include a series of instructions on what to do and what not to do in the event of an emergency. Here is an example: Stop work and leave the building IMMEDIATELY when the fire alarm sounds or when you are instructed to do so! Follow instructions, avoid panic, and cooperate with those responding to the emergency. Proceed to the designated or nearest exit. DO NOT delay your exit from the building by looking for belongings or other people. DO NOT use the elevators use the stairs. DO help those with disabilities. When leaving the building, proceed to the designated assembly area. DO NOT obstruct fire hydrants or the responding fire/rescue workers and their equipment. DO NOT re-enter the building until instructed to do so by your supervisor or emergency warden. Copyright © 2007. New Zealand Industry Training Organisation Incorporated -9- Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Training & supervision You must be adequately trained in the safe use of all plant, objects, substances, protective clothing and equipment that you are or may be required to use or handle. Your employer must also ensure that you are supervised by an experienced person until you are sufficiently experienced to do your work safely. You also have a duty to follow instruction and not to endanger yourself or others. Your training may come in many forms. Most workplaces provide induction training which happens when you begin employment at a workplace. Induction or basic on-the-job training should include: How to carry out the job in a safe and healthy manner. Information on hazards and hazardous work practices. Where applicable, details of any isolation or "tag-out" procedures. Reporting of accidents or incidents. Selection, use, fitting, storage, and maintenance of protective clothing and equipment. Where to obtain occupational safety and health information. Emergency procedures. Many workplaces repeat induction training a few months after a person has started. In addition to your basic workplace training you should be given specific training such as how to use any equipment you will be using. You should also receive training (and supervision) with every significant change of duties or work environment. Example: Joe begins work at a processing factory and completes his induction training. A month later he is shown how to work some equipment and is stationed there for the rest of the day. Half way through the day a piece of machinery gets jammed. Joe reaches in to try and pry the jammed bit loose but instead manages to crush his finger. After the accident investigation is carried out, Joe s employer is convicted under the HSE Act for failing to provide adequate training and supervision (Joe wasn t told about safety procedures when working with the machine, and there was no one around for him to ask when the machine jammed). Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 10 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Employee participation Your workplace should have a system in place that gives you reasonable opportunities to participate effectively in ongoing processes for the improvement of health and safety at work. The reason for this is that the HSE Act recognises that you can help make your workplace safe and that you can provide information on health and safety issues (such as workplace hazards) you face at work. This system usually takes the form of a Health and Safety committee or representative(s). Each health and safety representative or committee may represent a particular type of work, or place of work of the employer and is likely to carry out some or all of the following functions: To foster positive health and safety management practices in the place of work; To identify and bring to the employer's attention hazards in the place of work and discuss with the employer ways that the hazards may be dealt with; To consult with inspectors on health and safety issues; To promote the interests of employees in a health and safety context generally and in particular those employees who have been harmed at work, including in relation to arrangements for rehabilitation and return to work; and To carry out any other functions conferred by the particular system of employee participation, a code of practice, or by the employer (with the agreement of the representative or a union representing them). Incident and hazard reporting Incidents and hazards need to be recorded in registers. Incidents and accidents are recorded in an accident register and hazards in a hazard register. Accident register Details of all work-related accidents or incidents that have harmed or might have harmed any person must be recorded in an accident register. This includes accidents or incidents involving employees, self-employed people, customers and other visitors to a place of work. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 11 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice When a work-related accident results in serious harm: Make sure anyone injured or suspected of injury has received first aid or medical attention if necessary. Do NOT interfere with the accident scene, unless: A Department of Labour health and safety inspector has given permission, It is necessary to save someone's life or prevent harm or suffering to them, It is necessary to maintain access by the general public to an essential service or utility, or It is necessary to prevent serious damage to property. Advise the local Department of Labour health and safety office as soon as possible by phone or fax. Carry out / co-operate with any subsequent investigation. Mail or fax written notice to the nearest Department of Labour health and safety office within 7 days. The written notice can use the Accident or Serious Harm Form (see example in the appendices) or else must contain the same details as this form. Keep the original (or a copy) written notice in the accident register. If the accident register is kept in a different form, the same details must be recorded. Take steps to eliminate, isolate or minimise any identified hazard, once an Inspector gives permission to interfere with the accident scene. Hazard register Details of ALL identified work-related hazards are recorded in a Hazard register. Each Hazard should be listed on a Hazard Identification form (see example in the appendices) or, if the hazard register is kept in a different form, the same details must be recorded. Hazard management To keep a workplace safe and healthy, employers should make sure there are no hazards to which employees and others in the workplace could be exposed. Employers should look for hazards in advance, as part of their risk management and work planning, so that potential hazards are anticipated and prevented. In all of this employers should get the benefit of their employees knowledge by talking to them and/or their representatives (including unions) in good faith about the best way to do things. Employers have to put in place an effective system for identifying existing and emerging (new) hazards. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 12 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Methods of hazard identification include: Physical inspections of the workplace, equipment, and work practices; Analysis of tasks and how they are carried out by employees in the workplace; Analysis of processes carried out in the workplace; Analysis of previous 'near miss' incidents. Employers should then also have an effective system for responding to and managing the hazards that they identify. Hierarchy of hazard management controls How the employer responds to and manages a particular hazard will depend on the circumstances. The hierarchy of hazard management is: Eliminate Isolate Minimise Eliminate The preferred response is to eliminate the hazard; that is, change things so that the hazard no longer exists. Examples of eliminating hazards are: Replacing a toxic chemical with a non-toxic substitute. Relocating electrical plugs close to work stations to eliminate the hazard of cords running across passageways. Covering a tripping hazard with a ramp. Replacing a manual task with a machine to eliminate the hazard of repetitive strain injury. Isolate If the hazard cannot be reasonably eliminated, the next response should be to isolate the hazard; that is, put in place a process or mechanism that keeps employees away from the hazard. Examples of isolating hazards are: Placing a noisy machine inside a sound proof enclosure. Installing a safety guard around a dangerous piece of machinery. Placing chemicals in a secure location away from the general workplace. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 13 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Minimise If the hazard cannot be reasonably isolated, then the hazard must be minimised; that is, do what can reasonably be done to lessen the likelihood of harm being caused by the hazard and to protect employees. Examples of minimising hazards are: providing employees with suitable protective clothing or equipment, for example, monitoring employees exposure to the hazard; and with their informed consent, monitoring employees health in relation to the hazard. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 14 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Quiz 2 1. 1. The HSE Act recognises that successful health and safety management is best achieved through: a. good faith co-operation and input of those doing the work b. heavy penalties and fines for non-compliance. c. Effective managers who complete regular training programmes. 2. All workplaces should have which of the following systems? a. Emergency procedures b. Training and supervision c. Employee participation d. Incident and hazard reporting e. Hazard management f. All of the above 3. Emergency procedures instruct employees on: a. How to put out fires and control other emergencies at work. b. What to do in the event of an emergency. c. Civil Defence actions to take when there is an emergency. 4. If you are adequately trained on the use of equipment you don t need any supervision. a. True b. False 5. You should be supervised until you have enough experience to safely handle all situations that may arise at work. a. True b. False Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 15 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice 6. When is it necessary to receive training: a. At induction b. When using any plant, objects, substances, protective clothing and equipment that you are or may be required to use or handle c. with every significant change of duties or work environment d. All of the above. 7. Why should there be system in place that gives you reasonable opportunities to participate effectively in ongoing processes for the improvement of health and safety at work? a. So that the workload is shared between all employees. b. So that you can feel important and possible advance your career in this direction. c. Because you can provide information on health and safety issues you face at work. 8. All known hazards need to be listed in: a. A hazards register. b. An emergencies procedures manual. c. A legal document that is filed with the Department of Labour health and safety office. 9. The first thing you should do when there has been an accident is: a. Report to the Department of Labour health and safety office. b. Ensure any injured people receive first aid or medical attention. c. Sound the fire alarm. 10. The Department of Labour health and safety office need to be informed: a. When an accident resulting in serious harm or death has occurred. b. When any accident whether anyone was injured or not, has occurred. c. Only when an accident resulting in death has occurred. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 16 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice 11. You need to report to the Department of Labour health and safety office about an accident: a. Within 7 days. b. Within 7 weeks. c. Within 7 months. 12. Which of the following are methods to identify hazards: a. Physical inspections. b. Analysis of tasks. c. Analysis of processes. d. Analysis of previous 'near miss' incidents. e. All of the above. 13. The hierarchy of hazard management is: a. Minimise, isolate, eliminate. b. Eliminate, isolate, minimise. c. Isolate, minimise, eliminate. d. Eliminate, minimise, isolate. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 17 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Hazards as defined in the HSE Act Under the HSE Act, Hazard : (a) means an activity, arrangement, circumstance, event, occurrence, phenomenon, process, situation, or substance (whether arising or caused within or outside a place of work) that is an actual or potential cause or source of harm; and (b) includes(i) a situation where a person's behaviour may be an actual or potential cause or source of harm to the person or another person; and (ii) without limitation, a situation described in subparagraph (i) resulting from physical or mental fatigue, drugs, alcohol, traumatic shock, or another temporary condition that affects a person's behaviour. Hazards can: be actual or potential. be physical, biological, or behavioural (including temporary conditions that can affect a person's behaviour, such as fatigue, shock, alcohol or drugs) arise or be caused within or outside a place of work. The term hazardous has a corresponding meaning. Examples of hazards: Sharp or protruding pieces of equipment that can harm people as they walk past. Toxic chemicals that can poison people who breathe in the fumes or damage their skin. A wet, slippery floor that people can slip on. A loud workplace that can cause hearing loss and/or stress. Moving parts of machinery that people can get their fingers, hair, etc., caught in. A person skylarking with a knife or other piece of dangerous equipment. A person operating a machine while under the influence of alcohol. SLIPPERYWHEN WET Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 18 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Quiz 3 1. A hazard is an activity, arrangement, circumstance, event, occurrence, phenomenon, process, situation, or substance that is an actual or _?_ cause or source of harm. 2. Hazards can be: a. Actual b. Potential c. Physical d. Biological e. Behavioural f. All of the above 3. Hazards can arise or be caused within or _?_ a place of work. 4. A hazard is anything that can cause or has the potential to cause harm. a. True b. False 5. Which of the following is a hazardous: a. Working when very tired. b. Working while under the influence of alcohol or drugs. c. Breathing in toxic fumes. d. Manual tasks that put strain on the body. e. A wet floor. f. All of the above. Copyright © 2007. New Zealand Industry Training Organisation Incorporated - 19 - Unit Standard 497 Demonstrate knowledge of workplace health and safety requirements Occupational Health and Safety Practice Appendix Form of register or notification of circumstances of accident or serious harm Required for section 25(1), (1A), (1B), and (3)(b) of the Health and Safety in Employment Act 1992 For non-injury accident, complete questions 1, 2, 3, 9, 10, 11, 14 and 15 as applicable 1 Particulars of employer, self-employed person or principal: 2 The person reporting is: an employer a principal 3 4 11 Agency of accident/ serious harm: machinery or (mainly) fixed plant mobile plant or transport powered equipment, tool, or appliance non-powered handtool, appliance, or equipment chemical or chemical product material or substance environmental exposure (e.g. dust, gas) animal, human or biological agency (other than bacteria or virus) bacteria or virus a self-employed person Location of place of work: Name Residential address 5 6 7 Sex (M/F) Occupation or job title of injured person: The injured person is: an employee self 9 13 Nature of injury or disease: fatal puncture wound poisoning or toxic effects multiple injuries damage to artificial aid disease, nervous system disease, musculoskeletal system disease, skin disease, digestive system disease, infectious or parasitic disease, respiratory system disease, circulatory system tumour (malignant or benign) mental disorder 14 Where and how did the accident/serious harm happen? a contractor (self-employed person) other Period of employment of injured person: 1st week 6 months-1 year non-employee 8 trunk multiple locations fracture of spine other fracture dislocation sprain or strain head injury internal injury of trunk amputation, including eye open wound superficial injury bruising or crushing foreign body burns nerves or spinal chord Personal data of injured person: Date of birth 12 Body part: head neck upper limb lower limb systemic internal organs 1st month 1-5 years Treatment of injury: None Doctor but no hospitalisation 1-6 months Over 5 years First aid only Hospitalisation Time and date of accident/ serious harm: Time am/pm Date Shift Day Afternoon Night 15 If notification is from an employer: (a) Has an investigation been carried out? (b) Was a significant hazard involved? yes yes Hours worked since arrival at work Signature and date ________________________ ___ / ___ / ___ 10 Mechanism of accident/ serious harm: fall, trip or slip hitting objects with part of the body sound or pressure being hit by moving objects body stressing heat, radiation or energy biological factors chemicals or other substances mental stress Name and position - 20 - no no