Understanding optical screen technology

Technology Brief

Introduction

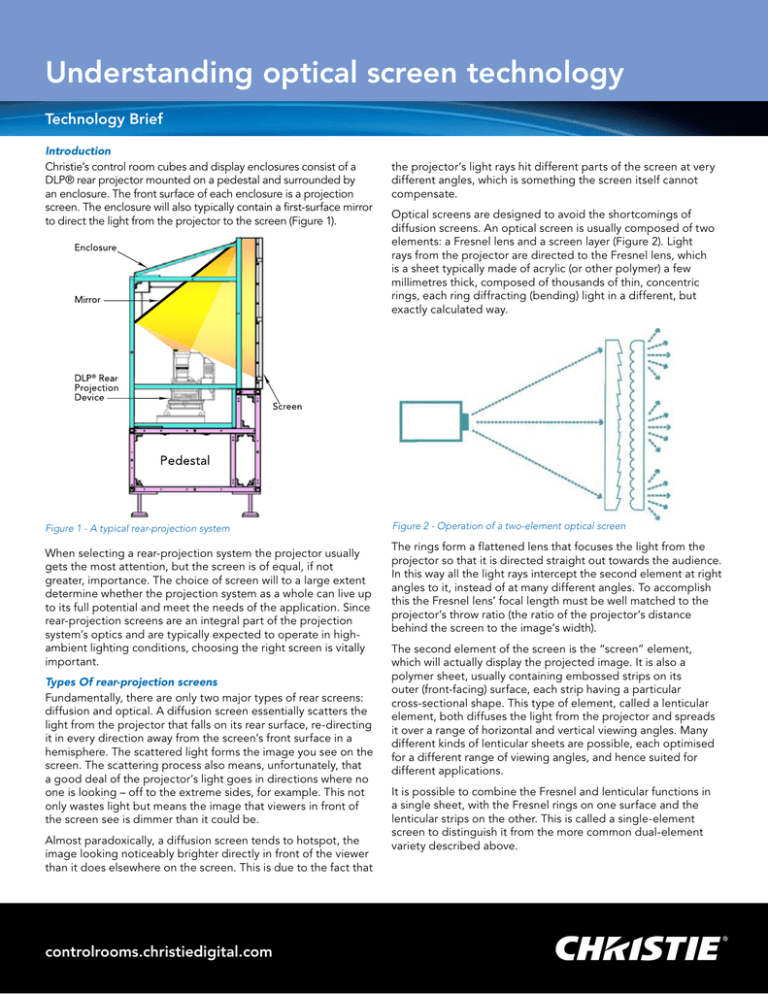

Christie’s control room cubes and display enclosures consist of a

DLP® rear projector mounted on a pedestal and surrounded by

an enclosure. The front surface of each enclosure is a projection

screen. The enclosure will also typically contain a first-surface mirror

to direct the light from the projector to the screen (Figure 1).

Figure 1 - A typical rear-projection system

When selecting a rear-projection system the projector usually

gets the most attention, but the screen is of equal, if not

greater, importance. The choice of screen will to a large extent

determine whether the projection system as a whole can live up

to its full potential and meet the needs of the application. Since

rear-projection screens are an integral part of the projection

system’s optics and are typically expected to operate in highambient lighting conditions, choosing the right screen is vitally

important.

Types Of rear-projection screens

Fundamentally, there are only two major types of rear screens:

diffusion and optical. A diffusion screen essentially scatters the

light from the projector that falls on its rear surface, re-directing

it in every direction away from the screen’s front surface in a

hemisphere. The scattered light forms the image you see on the

screen. The scattering process also means, unfortunately, that

a good deal of the projector’s light goes in directions where no

one is looking – off to the extreme sides, for example. This not

only wastes light but means the image that viewers in front of

the screen see is dimmer than it could be.

Almost paradoxically, a diffusion screen tends to hotspot, the

image looking noticeably brighter directly in front of the viewer

than it does elsewhere on the screen. This is due to the fact that

controlrooms.christiedigital.com

Figure 1 - A typical rear-projection system

the projector’s light rays hit different parts of the screen at very

different angles, which is something the screen itself cannot

compensate.

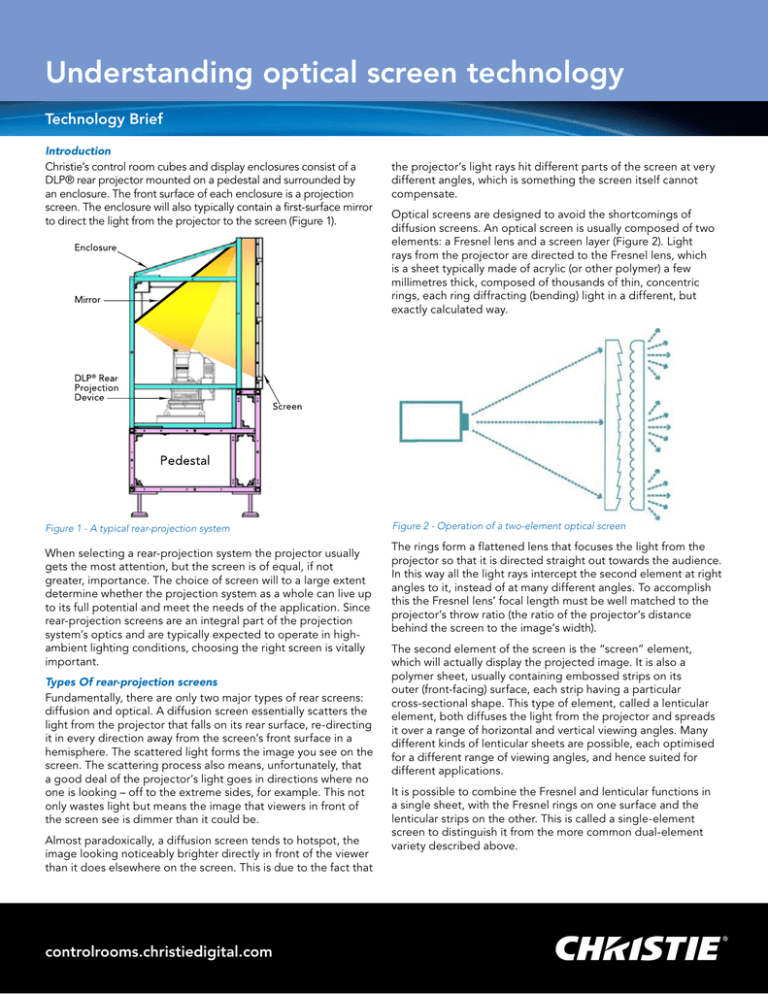

Optical screens are designed to avoid the shortcomings of

diffusion screens. An optical screen is usually composed of two

elements: a Fresnel lens and a screen layer (Figure 2). Light

rays from the projector are directed to the Fresnel lens, which

is a sheet typically made of acrylic (or other polymer) a few

millimetres thick, composed of thousands of thin, concentric

rings, each ring diffracting (bending) light in a different, but

exactly calculated way.

Figure 2 - Operation of a two-element optical screen

The rings form a flattened lens that focuses the light from the

projector so that it is directed straight out towards the audience.

In this way all the light rays intercept the second element at right

angles to it, instead of at many different angles. To accomplish

this the Fresnel lens’ focal length must be well matched to the

projector’s throw ratio (the ratio of the projector’s distance

behind the screen to the image’s width).

The second element of the screen is the “screen” element,

which will actually display the projected image. It is also a

polymer sheet, usually containing embossed strips on its

outer (front-facing) surface, each strip having a particular

cross-sectional shape. This type of element, called a lenticular

element, both diffuses the light from the projector and spreads

it over a range of horizontal and vertical viewing angles. Many

different kinds of lenticular sheets are possible, each optimised

for a different range of viewing angles, and hence suited for

different applications.

It is possible to combine the Fresnel and lenticular functions in

a single sheet, with the Fresnel rings on one surface and the

lenticular strips on the other. This is called a single-element

screen to distinguish it from the more common dual-element

variety described above.

Understanding optical screen technology

Technology Brief

Two additional numbers derived from the gain curves are

commonly quoted on screen datasheets. These are the

horizontal and vertical half-gain angles, which are simply the

angles at which the observed brightness is half of the maximum

seen from straight-on.

Ambient light rejection

Most optical screens also have the ability to reject ambient

light that falls on their front surface (the viewing side). This is

often achieved by embedding very thin black stripes within

the lenticular sheet, too small to notice from a normal viewing

distance. These stripes absorb a good portion of the ambient

light falling on the screen from the room, thus preventing that

light from reflecting back to viewers, which would reduce the

inherent contrast within the image. Other, more advanced

methods proprietary to particular screen manufacturers have

also been implemented, some of which cause the screen to

appear black even when the projector is off.

Figure 3

Figure 3 - A cross-lenticular screen

Alternatives to the traditional lenticular element are possible;

most are proprietary to a particular screen manufacturer. One

such alternative uses tiny, glass beads distributed within the

substrate of the sheet’s polymer material. Another uses crossed

lenticulars that together act like prisms to produce a much

wider usable vertical viewing range than a standard lenticular

yet yielding better brightness than available from most beaded

screens (Figure 3).

However it is done, the ambient light rejection function of most

optical screens, combined with an optical screen’s inherent gain

allows images with very good contrast to be achieved in normal

levels of ambient lighting, such as would be found in a control

room or the higher levels typical of a meeting room or office.

It should be noted that most rear-projection screens aren’t

designed to reject ambient light incident on the rear (projection)

side of the screen. That’s quite understandable, as this is the

Screen gain

An optical screen is a passive device and is therefore not able to

amplify light in the sense that a transistor amplifies an electrical

signal. Nevertheless, it is able to produce much brighter images

than a diffusion screen. This is due to the combination of the

Fresnel and optical screen elements, which allows light from the

projector to be concentrated in a range of viewing angles much

narrower than a hemisphere.

Instead of wasting light off to the sides where no one is viewing,

an optical screen preferentially directs that light toward the

audience, resulting in a substantial increase in brightness. The

increase in brightness directly in front of the center of the screen

compared to that which would be seen on a theoretically perfect

diffusion screen is called the screen gain.

Since it is only a single number, screen gain can’t completely

describe the gain performance of an optical screen. That

requires a pair of curves, one showing how the gain varies with

horizontal viewing angle and the other similarly showing how

gain varies with vertical viewing angle (Figure 4). Since an optical

screen directs light away from the sides towards the center, the

gain necessarily decreases with increasing viewing angle. How

fast and in exactly what manner it decreases depends on the

specific design of the screen.

Figure 4 - Vertical and horizontal half-angle curves

side the light from the projector is hitting: It generally wouldn’t

be a good idea to do anything that might decrease that light.

Hence, most rear-projection systems must be housed in an

enclosure, either a self-contained one – often called a “cube”

– or as part of a separate projection room adjacent to the main

room. In either case, it is common to use one or more firstsurface mirrors to fold the optical path between the projector

and the screen, thereby reducing the depth required behind the

screen.

Understanding optical screen technology

Technology Brief

Choosing an optical screen

Many different types of optical screen are available today, one

to fit almost every rear-projection application. The choice of

screen will depend upon a number of factors:

• Budget – Different types of screen use different materials

and manufacturing processes, both of which affect cost. In

general, lenticular screens will cost less than designs that

use embedded glass beads or crossed-lenticular elements.

• Viewing positions – The location of viewers in the room and

the angles at which they see the screen should be strongly

considered. For installations where viewers can be positioned

off to the sides, a screen with a wide horizontal viewing angle

will be required. When the screen may be viewed from a

different height, a large vertical viewing angle will be required.

A screen that is part of a videowall in a typical control room,

for example, will require wide viewing angles both horizontally

and vertically because of the various locations of the viewing

stations and the higher elevation of the upper rows of the wall.

The benefits of optical screens

By combining a Fresnel lens with a lenticular, beaded or crosslenticular structure, whether implemented in a single sheet or

multiple layers, optical rear-projection screens enable bright

images with excellent uniformity that are visible over a wide

range of viewing angles. In addition, they almost universally

employ technology to reject ambient light from the viewing

side, resulting in excellent contrast and enhanced readability.

When properly matched to a projector’s throw ratio, an optical

screen will ensure the best possible image quality for any given

rear-projection application.

• Size and shape of screens – Sizes range from 40 inches

diagonal to as large as 200 inches diagonal. The most

common aspect ratio (the ratio of width to height) is 4:3.

Other common aspect ratios are 5:4 and 16:9. However, not

all sizes are available for a given screen type. For example,

cross-lenticular screens are currently available only up to

80 inches diagonal when sized for a 4:3 aspect ratio.

• Ambient light - Since screens usually have to contend with

a certain level of ambient light, some degree of ambient

light rejection in the screen will be required in order to

ensure sufficient contrast in the image. A higher screen

gain can also combat ambient light but with most screen

types there is a trade-off between gain and viewing angle.

Wider viewing angles usually mean lower gain. However,

better screen designs, such as cross-lenticular, can provide

good performance for both parameters simultaneously.

Corporate offices

Worldwide offices

Christie Digital Systems Inc.

USA – Cypress

ph: 714 236 8610

United Kingdom

ph: +44 (0) 118 977 8000

Christie Digital Systems Canada, Inc.

Canada – Kitchener

ph: 519 744 8005

Germany

ph: +49 2161 664540

France

ph: +33 (0) 1 41 21 44 04

Eastern Europe and

Russian Federation

ph: +36 (0)1 47 48 100

Independent sales consultant offices

Dubai (United Arab

Emirates)

ph: +971 (0) 4 299 7575

India

ph: (080) 41468941-48

Singapore

ph: +65 6877 8737

China (Beijing)

ph: +86 10 6561 0240

Spain

ph: +34 91 633 9990

Korea (Seoul)

ph: +82 2 702 1601

Italy

ph: +39 (0) 2 9902 1161

Japan (Tokyo)

ph: +81 3 3599 7481

South Africa

ph: +27 (0) 317 671 347

China (Shanghai)

ph: +86 21 6278 7708

For the most current specification information, please visit controlrooms.christiedigital.com

Copyright 2009 Christie Digital Systems, Inc. All rights reserved. All brand names and product names are

trademarks, registered trademarks or tradenames of their respective holders. Canadian manufacturing facility

is ISO 9001 and 14001 certified. Performance specifications are typical. Due to constant research, specifications

are subject to change without notice. Understanding optical screen technology tech guide July 09.