vertical junction high-efficiency concentrator photovoltaic cells

advertisement

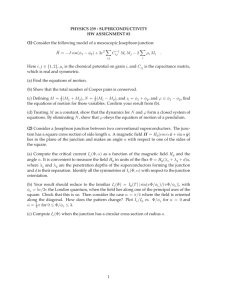

Tel Aviv University Ort Braude College VERTICAL JUNCTION HIGH-EFFICIENCY CONCENTRATOR PHOTOVOLTAIC CELLS Researchers TAU OBC Yossi Rosenwaks (EE) yossir@eng.tau.ac.il Avi Kribus (ME) kribus@eng.tau.ac.il Rona Sarfaty (EE) rsarfaty@braude.ac.il Students TAU R. Pozner, G. Segev OBC M. Jubran, L. Grinberg, V. Timofeyev, A. Gabai, N. Slame Funding Israel Ministry of National Infrastructures IP Provisional patent application. Planar (horizontal junction) solar cell under concentrated illumination Cyrium Technologies Inc III-V MHJ 28 Amonix 27 26 25 Efficiency [%] its biggest disadvantage is the phenomenon of the decline of efficiency at concentrations of a couple of hundred suns. 24 23 Sun Power Chip size cell 22 21 20 2 1 10 100 Concentration 1000 10000 The Vertical Junction (VJ) Our claim is that changing the geometry of the junction will lead to improved cell performance. A) Better Optimization Capabilities B) Ideal For High Concentration C) Avoiding the trade-off between front contact grid shading and series resistance 3 Low Series Resistance 1. Components Vertical 1. 2. 3. 4. 5. Electrode Resistance (RSE) Contact Resistance (RSC) p+ Layer Resistance (RSP) Bulk Resistance (RSB) n+ Layer Resistance (RSN) Main Resistance Component: Bulk Resistance RSB. 4 Horizontal Lower Series Resistance under illumination 2 Photoconductivity x, y 0 x, y ph x, y, C q n Horizontal Vertical 0 x, y ph x, y, C 5 Illumination contributes significantly to conductivity and decreases resistance 0 x, y ph x, y, C σ hardly change with illumination Simulation Results L 1 RSB C d w0 dx x, y, C dy Resistivity [Ωcm] 0 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 1 6 10 100 Concentration 1000 High Voltage series connected VJ High-voltage cells with low series resistance, and low currents, and under illumination photoconductivity reduce significantly the resistivity, can be good candidates for concentrating PV (CPV) systems. 7 7 Realization: Other VMJ Cells Multi-wafer process, Si Green Field Solar High-voltage VMJ cells have been produced by stacking multiple wafers followed by orthogonal cutting. 40 junctions/cell 25.5 V 19.2% at ×2,500Suns Sater & Sater, 29 IEEE PV Specialists Conference, 2002 Our approach Monolithic production of junctions in a single wafer If the vertical junctions in a VMJ cell are manufactured monolithically on a single wafer, rather than by stacking of multiple wafers, then the width of each junction can be varied independently of the wafer thickness 8 = better use of materials. Assumed monolithic implementation 1. Next Cell SOI Substrate 2. Surface treatments: Passivation, Front AR, Back reflector, Front texturing Previous Cell 3. Trench fabrication using DRIE process 5. Ion implantation of the p+ side of the trench 6. Contact fabrication using deposition/filling the trenches with Metal ~40[um] 4. Ion implantation of the n+ side of the trench ~40[um] ~0.5[um] SiO2 Handle wafer Generic concept Can be applied to III-V material. We will send you soon alternative process steps 9 ~0.5[um] Junction Modeling and Optimization setup Schematics of a Vertical Junction 10 We have used the Sentaurus TCAD (Synopsys Inc.), device software tools. The device simulator solves the coupled continuity and Poisson equations, under specific boundary conditions. It was assumed that the device characteristics are uniform in the third dimension, L in Figure (a) which permits a twodimensional analysis. Tel Aviv University School of Electrical Engineering We insert material parameters of realistic wafer quality and fabrication processes The Shockley-Read-Hall (SRH) bulk lifetime - 1 ms for both electrons and holes corresponding to Floating Zone (FZ) silicon substrate . The back surface recombination (BSR) (the silicon-insulator, 1 µm SiO2, interface). No surface treatments are assumed in the back surface region, leading to high BSR 1000 cm/s. Recombination velocity at the side metal contacts was set to 106 cm/s for both electrons and holes; High value - for possible damage during the trench fabrication, implantation (or diffusion) through the sidewalls and the metallization interface. Lower interface recombination velocities were found to increase the efficiency by about 3%. 11 Junction Optimization Current analysis for Si N+ 1019 P+ 1018 Pyramids Depth, width, widths of the N+, P+ layers And the Metal contact. h e 1 ms 25–50 m Optimize: Junction geometry Double AR Coating P 1016 Reflective Coating 0.5 m 0.5 m 40m Process dependent 12 Representative graphical results 1.Effect of surface recombination Efficiency vs. width and front surface recombination velocity for BSR=1000 cm/s under 1sun (a) and 1000 sun (b), Optimal width and depth ~80x50m are smaller compared to the junctions presented in the past (~250X500m) 13 2. Effect of bulk doping resistivity vs. minority carrier lifetime and mobility Efficiency vs. junction width and bulk doping, 1sun (a), 1000 suns (b); dashed lines show the location of the optimal width for each doping level 14 14 Tel Aviv University School of Electrical Engineering Effect of solar concentration The efficiency continues to increase for concentration levels well over a 1000. 15 Efficiency as a function of solar flux concentration for a VJ of width 43.6 µm and depth 60 µm, FSR=0, BSR=0 cm/s (a), depth of 60 µm, FSR=10, BSR=1000 cm/s (b), depth of 200 µm, FSR=10, BSR=0 cm/s (c), depth of 200 µm, FSR=10 cm/s , BSR=1000 cm/s (d). VJ under Concentrations 32 30 28 Vertical Junction Efficiency [%] Amonix 26 24 22 20 1 10 Sun Power Chipsize cell 100 Concentration 16 1000 10000 Summary 1. We presented an analysis and optimization of a vertical junction Silicon solar cell under 1 to 2000 suns concentration, using a set of properties representing realistic wafer quality and fabrication processes, and a full 2-D model without major simplifying assumptions. 2. The junction optimal design was found for different values of fabrication characteristics such as FSR, BSR and SRH lifetime. 17 conclusions 1. The optimal junction dimensions are much smaller than the dimensions used in previous VMJ cell tests and analyses 2. Conversion efficiency under high concentration can reach close to 30%, much higher than the 20% reported for past VMJ cells 3. In addition to the inherently low series resistance effect, photoconductivity is responsible for the outstanding performance of VMJ cells under high concentration 18 18 19