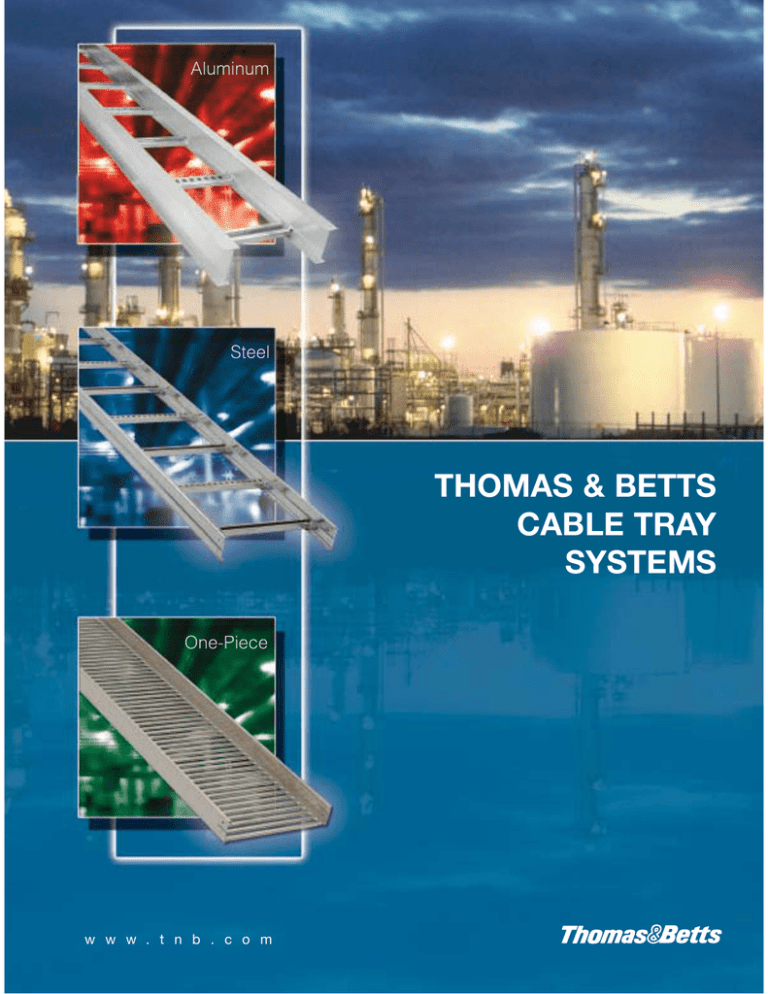

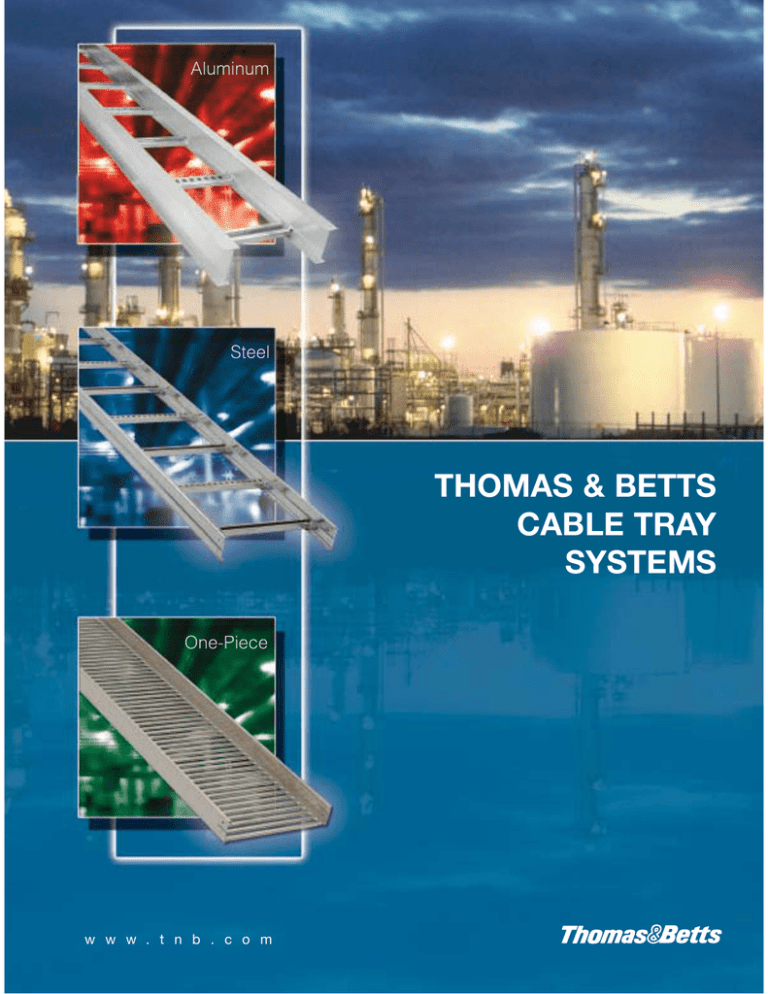

THOMAS & BETTS

CABLE TRAY

SYSTEMS

w w w . t n b . c o m

Cable Tray

Table of Contents

SECTION 1 - Technical Information

Benefits of Cable Tray ..................................................................4 - 5

Features & Benefits ......................................................................6 - 7

System Design...................................................................................8

Glossary of Terms ..............................................................................9

Cable Tray Selection Process ...................................................10 - 17

Materials and Finishes ..............................................................18 - 19

Corrosion .................................................................................20 - 21

Types of Corrosion...........................................................................22

Corrosion Resistance Guide .....................................................23 - 29

Electrical Grounding Capacity ..........................................................30

Thermal Expansion and Contraction ................................................31

Structural Design......................................................................32 - 34

Loading ....................................................................................36 - 37

Loading for Grades B, C and D .......................................................38

Engineering Cable Tray Specification ...............................................40

SECTION 2 - Aluminum Cable Tray

Features...........................................................................................45

Straight sections ......................................................................46 - 59

Fittings .....................................................................................60 - 99

Accessories and Covers.......................................................100 - 112

SECTION 3 - Steel Cable Tray

Straight sections ..................................................................116 - 127

Fittings .................................................................................128 - 142

Accessories and Covers.......................................................144 - 155

SECTION 4 - One Piece Cable Tray

Straight sections ..................................................................158 - 165

Fittings .................................................................................166 - 181

Accessories and Covers.......................................................182 - 189

SECTION 5

Common Accessories ..........................................................192 - 195

SECTION 6

Grounding ............................................................................198 - 200

SECTION 7

Superstrut® ............................................................................204- 211

SECTION 8

Channel Tray ........................................................................214 - 239

SECTION 9

Appendix..............................................................................242 - 250

Annex A.........................................................................................251

Annex B.........................................................................................252

Other Offering.......................................................................253 - 254

1

Technical Information

Section 1

Technical Information

Benefits of Cable Tray

The Benefits of Cable Tray

Cable tray wiring systems offer significant

advantages over conduit pipe and other wiring

systems. Cable tray is less expensive, more reliable,

more adaptable to changing needs and easier to

maintain. In addition, its design does not contribute

to potential safety problems associated with other

wiring systems.

An evaluation of the costs and benefits of various

wiring systems should be done in the design phase.

Unfortunately, many engineers who are unfamiliar

with wiring systems avoid the system selection

process or defer it until construction—often

resulting in higher costs, scheduling delays and a

system that will not meet future needs.

Selection of a wiring system that is not the most

suitable for a particular application in terms of cost,

potential corrosion and electrical considerations can

lead to numerous problems, including excessive

initial cost, poor design, faulty installation, extra

maintenance, future power outages and

unnecessary safety concerns.

Cost

Extensive experience has shown that the initial cost of a cable tray installation (including conductor, material and

installation labor costs) may be as much as 60% less than a comparable conduit wiring system.

Cable tray systems, including trays, supports, fittings and other materials, are generally much less expensive than

conduit wiring systems. In addition, major cost savings are generated by the relative ease of installation. Labor costs of

installing a cable tray system can run up to 50 percent less. Total cost savings will vary with the complexity and size of

the installation.

Direct cost savings are easy to calculate during the design phase of an installation, but the enormous advantages of

cable tray may accrue only over time. The system’s reliability, adaptability, ease of maintenance and inherent safety

features result in many other types of cost savings, including:

• lower engineering and maintenance costs

• less need to reconfigure system as needs change

• less down time for electrical and data handling systems

• fewer environmental problems resulting from loss of power to essential equipment.

4

Technical Information

Reliability

Cable tray systems offer unsurpassed reliability, resulting in less need for maintenance and less down time—important

considerations for all installations but especially for such industries as data communications and financial services.

Technical

Information

Benefits of Cable Tray

In addition, since cable tray is not a closed system, moisture build up problems are eliminated and damage to cable

insulation during installation is also greatly reduced.

Adaptability

A major advantage of cable tray systems derives from their adaptability to new needs and technology. The pace of

change in the economy, constantly shifting competitive pressures and rapid introduction of innovative technologies

are all accelerating. More than ever before, businesses must be prepared to quickly expand facilities, change

products or introduce new processes. The flexibility of the wiring system is a key consideration.

Modifying a cable tray system or adding cables to meet new needs is relatively easy because cables can enter or exit

a tray at any point. And initial design considerations can build-in extra capacity as part of the planning process. Cable

tray’s inherent adaptability allows rewiring for future expansion, building redesign or new technologies without

disruption or need to replace the entire wiring system.

Maintenance

Cable tray wiring systems require less maintenance than conduit systems. When maintenance is necessary, it is

easier, less time-consuming and less labor intensive.

The physical condition and status of both the cable tray and the tray cables can be inspected visually, something that

is not possible with conduit systems. In addition, it is also easy to see if there is sufficient capacity in the trays for

additional cables. As was noted above, changing or adding cables can also be accomplished without difficulty.

Another comparative benefit of cable tray systems is that they do not act as channels of moisture paths, as conduit

wiring systems do. Conduit systems tend to collect condensation resulting from changes in temperature and then

channel the moisture to electrical equipment, where it can lead to corrosion and failure.

Cable tray and tray cable are also less susceptible to fire loss than conduit. An external fire usually results in damage

to only a few feet of a cable tray system, while wire insulation inside a conduit suffers significant damage and

thermoplastic insulation may actually fuse to the conduit.

Safety

Cable tray wiring systems lack the inherent safety concerns of conduit systems.

By it’s nature, a conduit wiring system can serve as a flow-through for corrosive, explosive and toxic gases in the same

way that it channels moisture.

The conduit installation process can also present a safety issue for electricians. The process requires that a conduit

system be installed from one enclosure to another before pulling in the conductors, leaving the electricians exposed to

any live, energized equipment that may be in the enclosures. In contrast, installers can pull tray cables from near one

termination enclosure to the next before they are inserted into the enclosures and then terminated.

Finally, in installations where cable tray can be used as the equipment grounding conductor (per NEC standards), it is

easy to visually check the system components as well as conduct checks for electrical continuity.

5

Technical Information

Features & Benefits

The Thomas & Betts Unique Design Points

I-Beam Siderail

— Maximum structural strength.

Aluminum

Snap-in Splice Plates

— Snap-in aluminum splice plates for easy installation.

Aluminum

Alternating Rungs

— Alternating rungs for top and bottom

accessory installation and cable lashing.

Aluminum &

Steel

Continuous Open Slot

— Rungs have continuous open slot to

accept standard strut pipe clamps and

gives complete barrier strip adjustability.

Aluminum &

Steel

6

Technical Information

The Thomas & Betts Unique Design Points

Technical

Information

Features & Benefits

Ty-Rap® Cable Tie Slots

— Exclusive Ty-Rap® cable tie slots on 1” centers

on all ladder and ventilated bottoms.

Secures cables without kinks and keeps

cables uniform.

Aluminum &

Steel

Added Support

— Aluminum and Steel Solid bottoms are constructed

with a flat sheet for added cable protecton.

Aluminum &

Steel

Extra Wide Rung Design

— Extra wide rung design for maximum

cable bearing surface.

Aluminum &

Steel

Adjustable Barrier Strips

— Barrier strips are fully adjustable (side to

side) for use in straight sections and

fittings.

Aluminum &

Steel

1.5 m / 72”

3 m / 144”

7

Technical Information

System Design

Sample Plant Layout

CC

GG

H

H

EE

DD

II

LL

NO

PO

QR

FF

KK

AA

N

N

QP

JJ

M

M

BB

Application

COMMERCIAL

Schools

Hospitals

Office Buildings

Airports

Casinos

Stadiums

8

INDUSTRIAL

Petro-Chemical Plants

Automotive Plants

Paper Plants

Food Processing

Power Plants

Refineries

Manufacturing

Mining

A

B

C

D

E

F

G

H

I

Barrier Strip

Box Connector

Flat Cover

Horizontal Cross

Horizontal 45°

Horizontal 90°

Horizontal Tee

Ladder Tray

Peaked Cover

J

K

L

M

N

O

P

Q

Right Reducer

Solid Tray

Splice Connector

Solid Channel Tray

Ventilated Tray

Vertical 90° Inside

Vertical 90° Outside

Vertical Tee

Technical Information

Accessories. . . . . . . . . . . . . . . Devices which are used to supplement the function of straight sections and fittings, and

include such items as dropouts, covers, conduit adapters, hold-down devices and

dividers.

Cable Tray Connector . . . . . . . A device which joins cable tray straight sections or fittings, or both. The basic types of

connectors are: 1. Rigid, 2. Expansion, 3. Adjustable, 4. Reducer

Technical

Information

Glossary of Terms

Cable Tray Fitting . . . . . . . . . . A device which is used to change the direction, elevation or size of a cable tray

system.

Cable Support. . . . . . . . . . . . . A device which provides adequate means for supporting cable tray sections or fittings,

or both. The basic types of cable tray supports are: 1. Cantilever bracket, 2. Trapeze,

3. Individual and suspension

Channel Cable Tray. . . . . . . . . A prefabricated metal structure consisting of a one-piece ventilated bottom or solid

bottom channel section, or both, not exceeding 6 inches in width.

Ladder Cable Tray. . . . . . . . . . A prefabricated metal structure consisting of two longitudinal side rails connected by

individual transverse members.

Solid Bottom Cable Tray . . . . . A prefabricated metal structure consisting of a bottom with no openings within integral

or separate longitudinal side rails.

One Piece / Unit Cable Tray . . A prefabricated metal structure consisting of a one-piece solid or ventilated bottom.

Horizontal Cross . . . . . . . . . . . A cable tray fitting which is suitable for joining cable trays in four directions at 90-degree

intervals in the same plane.

Horizontal Bend . . . . . . . . . . . A cable tray fitting which changes the direction in the same plane.

Horizontal Tee . . . . . . . . . . . . . A cable tray fitting which is suitable for joining cable trays in three directions at

90 degree intervals in the same plane.

Metallic Cable Tray System . . . An assembly of cable tray straight section, fitting, and accessories that forms a rigid

structural system to support cables.

Reducer . . . . . . . . . . . . . . . . . A cable tray fitting which is suitable for joining cable trays of different widths in the same

plane. A straight reducer has two symmetrical offset sides. A right-hand reducer, when

viewed from the large end, has a straight side on the right. A left-hand reducer, when

viewed from the large end, has a straight side on the left.

Straight Section. . . . . . . . . . . . A length of cable tray which has no change in direction or size.

Ventilated Bottom . . . . . . . . . . A cable tray bottom having openings sufficient for the passage of air and utilizing

75 percent or less of the plan area of the surface to support cables.

Vertical Bend. . . . . . . . . . . . . . A cable tray fitting which changes direction to a different plane. An inside vertical elbow

changes direction upward from the horizontal plane. An outside vertical elbow changes

direction downward from the horizontal plane.

9

Technical Information

Cable Tray

Selection Process

Selection Process

A number of basic decisions must be made before a cable tray system can be specified. T&B has developed a simple

seven-step process to guide you in the process:

1. Select Material and Finish

2. Select the Tray Load Class

3. Select the Tray Type

4. Select the Tray Size

5. Select the Fittings

6. Consider Deflection

7. Electrical Grounding Capacity

Each step is described in detail below. For many applications, however, you may also have to take the following into

account:

10

•

Weight of the installation, which affects the cost of the support structure and the ease of installation.

•

Corrosion resistance of the material is one of the most important selection criteria. Cable tray materials may

not respond the same way in different environments. Chemicals or combinations of chemicals have corrosion

effects on some materials that can be compounded by temperature or even the speed at which the corrosive

elements contact the cable tray. For example, some grades of stainless steel may be resistant to salt water at

high flow rates (perfect for heat exchangers), while exhibiting some corrosion pitting in standing salt water.

Only the designer can quantify the various elements that affect the corrosion resistance of the cable tray

system in a specific application. While T&B can provide guidance, the designer is responsible for the final

selection. For more information, see “Corrosion” section.

•

Galvanic effect can cause corrosion even if the cable tray material is resistant to its chemical environment.

Dissimilar metals in contact (e.g., aluminum tray on steel supports or bare copper bonding conductor in

aluminum tray) in the presence of an electrolyte are susceptible to galvanic effect. If there is a hazard of

galvanic corrosion, it may be possible to isolate the tray system from other metals instead of using a more

expensive type of tray that would resist corrosion in a given application.

•

Melting point and flammability rating are primarily concerns for non-metallic tray. Local building codes may

restrict the use of a given product if certain performance levels are not met. Check with the appropriate

inspection authorities before specifying the product.

•

Relative cost varies dramatically, including material costs that float with the commodity index. For example,

stainless steel prices may vary significantly according to daily changes in the market.

•

Thermal expansion must also be taken into account on a long cable run, especially in areas where

temperature variation is extreme. Expansion connectors may be required if the temperature differential is 25°F

or greater. Refer to Tables 1 and 2 on page 31 for expansion plate spacing and gap settings. Two bonding

jumpers are required for every pair of splice plates for grounding continuity.

Technical Information

Cable Tray

Selection Process

1

Technical

Information

Selection Steps

Select Material and Finish

The most suitable material and finish for your application will depend on cost, the potential for corrosion, and electrical

considerations. T&B offers cable tray systems fabricated from corrosion-resistant steel, stainless steel and aluminum

alloys along with corrosion-resistant finishes, including zinc, PVC and epoxy. Special paint is also available. For more

information on material and finish, see the “Material Descriptions” section, page 18 and 19. T&B also offers a complete

non-metallic Cable Tray and strut system. Please refer to the catalog NMCT for further information.

2

Select the Tray Class / Load Capacity (loading)

The standard classes of cable trays, as related to their maximum design loads and to the associated design support

spacing based on a simple beam span requirement, shall be designated in accordance with Table 1. Please note the

load ratings in Table 1 are those most commonly used. Other load ratings are acceptable.

(according to NEMA VE-1 / CSA C22.2 No 126.1-02)

Costs vary between different load classes. Since labor and coupling costs are similar for a given length of tray, the

heavier classes are more cost-effective on a load length basis. The designer should therefore specify the lightest class

of tray compatible with the weight requirements of the cable tray.

TABLE 1

Load / Span Class Designation

LOAD

kg/m (lb/ft)

2.4 (8)

3.0 (10)

SPAN, m (ft)

3.7 (12)

4.9 (16)

6.0 (20)

37

(25)

–

A

–

–

–

67

(45)

–

–

–

–

D

74

(50)

8A

–

12A

16A

20A

97

(65)

–

C

–

–

–

112

(75)

8B

–

12B

16B

E or 20B

149

(100)

8C

–

12C

16C

20C

179

(120)

–

D

–

–

–

299

(200)

–

E

–

–

–

Deflection

Span

Note: 8A/B/C, 12A/B/C, 16A/B/C, and 20A/B/C are the traditional NEMA designations.

A, C, D, and E are the conventional CSA designations.

11

Technical Information

2

Cable Tray

Selection Process

Select the Tray Class / Load Capacity (cont’d)

Cable Loads: . . . . . . . . . . The cable load is the total weight, expressed in (kg/m), of all the cables that will be placed

in the cable tray.

Snow Loads: . . . . . . . . . . The additional design load from snowfall should be determined using the building codes

which apply for each installation.

Ice Loads: . . . . . . . . . . . . The additional load design due to the ice is determined by the following formula:

Wi = WxTixDi/144

Where:

Wi = ice load (lb/linear foot)

W = width of the tray (inches)

Ti = maximum ice thickness (inches).

Di = 57 lb/ft3 - ice density

Ice thickness will vary depending on installation location. A value of 1/2 inch can be

used as a conservative standard for Canada.

Wind Loads: . . . . . . . . . . . The additional loading to be considered is the effect of the impact pressure normal

to the side rail.

This loading is determined by the following formula:

Wp = 0.00256xV2 xH/12

Where:

Wp = loading due to the wind (lbs/linear foot)

V = wind velocity (mph)

H = Height of the side rail (inches)

It is important to note that

cable tray is not designed to

support personnel.

The user should display

appropriate warnings to

prevent the use of cable tray

as walkways.

Concentrated Loads

A concentrated static load is not included in the Table 1. Some user applications may require that a given concentrated

static load be imposed over and above the working load.

Such a concentrated static load represents a static weight applied on the centerline of the tray at midspan. When so

specified, the concentrated static load may be converted to an equivalent uniform load (We) in kilograms/metre

(pounds/linear foot), using the following formula, and added to the static weight of cable in the tray:

We = 2 x (concentrated static load, kg (lb))

Span length, m (ft)

12

3

Technical Information

Select the Tray Type

Cable tray is available with three styles of bottom:

Technical

Information

Cable Tray

Selection Process

Ladder Cable Tray is a prefabricated structure consisting of two longitudinal siderails connected by individual transverse

members.

Ventilated Cable Tray is a prefabricated structure consisting of a ventilated bottom within integral or separate longitudinal

siderails, with no openings exceeding 4 in. in a longitudinal direction.

Solid Bottom Cable Tray is a prefabricated structure without openings in the bottom.

Ladder tray is most often used because of its cost-effectiveness. The designer has a choice of four nominal rung

spacings: 6, 9, 12, and 18 inches. The greatest rung spacing compatible with an adequate cable bearing surface area

should be selected. Heavy power cables often require greater cable bearing area due to the possibility of creep in the

jacket material of the cable. If this is a concern, consult the cable manufacturer. This condition may require the use of

ventilated tray, which also offers additional mechanical protection for the cables.

Local building codes may require totally enclosed cable tray systems under certain conditions. The designer should verify

these before specifying the type of tray to be used.

4

Select the Tray Size

The width or height of a cable tray is a function of the number, size, spacing and weight of the cables in the tray.

Available nominal widths are 6, 9, 12, 18, 24, 30, 36 and 42 inches.

When specifying width, it is important to remember that the load rating does not change as the width increases. Even

with six times the volume, a 36 in. wide tray cannot hold any more weight than a 6 in. wide tray. If the load rating of the

tray permits, cable can be piled deeper in the tray. Most tray classes are available in a nominal 3-1/2, 4, 5, 6 and 7

inches (8 inch height also available as a special - see appendix). Cable ties or other spacing devices may be used to

maintain the required air space between cables.

13

Technical Information

5.

Cable Tray

Selection Process

Select the Fittings

Fittings are used to change the size or direction of the cable tray. The most important decision to be made in fitting

design concerns radius. The radius of the bend, whether horizontal or vertical, can be 12, 24, 36 or 48 in., or even

greater on a custom basis. The selection requires a compromise with the considerations being available space,

minimum bending radius of cables, ease of cable pulling, and cost. The typical radius is 24 in. Fittings are also

available for 30°, 45°, 60°, and 90° angles. When a standard angle will not work, field fittings or adjustable elbows can

be used. It may be necessary to add supports to the tray at these points. Refer to NEMA VE2 Installation Guidelines

for suggested support locations. Note that fittings are not subject to NEMA/CSA load ratings.

Support Locations for Fittings

14

6.

Technical Information

Consider Deflection

Deflection of the cable tray affects the appearance of an installation, but it is not a structural issue. In the case of

non-metallic cable tray, deflection may be affected by elevated temperatures.

Technical

Information

Cable Tray

Selection Process

The NEMA/CSA load test is a simple beam, uniformly distributed load test. (see Figure 1.2) This type of test was

initially selected because:

• It was easiest to test.

• It represents the worst case beam condition compared to continuous or fixed configurations. When consulting

the manufacturer’s catalog for deflection information, the designer must verify whether the data shown

represents simple or continuous beam deflection. If continuous beam deflection is shown, the calculation factor

should be given.

NEMA/CSA has one criterion for acceptance under their load test: the ability to support 150% of the rated load.

Test Load = 1.5 x rated load x length

Deflection

Measurements

Figure 1.2

15

Technical Information

Cable Tray

Selection Process

Simple Versus Continuous Beam Deflection

Theoretical maximum deflection for a simple beam, uniformly distributed load may be calculated as:

.0130

Where: w =

L=

E=

I=

w L4

EI

Load in lb/ft

Length in inches

Modulus of Elasticity

Moment of Inertia

The maximum deflection calculation for a continuous beam of two spans with a uniformly distributed load is:

.00541

w L4

EI

A continuous beam of two spans therefore has a theoretical maximum deflection of only 42% of its simple beam

deflection. As the number of spans increases, the beam behaves increasingly like a fixed beam, and the maximum

deflection continues to decrease. As this occurs, the system’s load carrying capability increases.

Simple vs. Continuous Beam Deflection

Simple Beam

Uniformly Distributed Load

Maximum Deflection

.0130 wL4

EI

Continuous Beam – Two Spans

Uniformly Distributed Load

Maximum Deflection

.00541 wL4

EI

16

Figure 1.3

Technical Information

Location of Couplings

Since different bending moments are created in each span, there is no simple factor to approximate deflection as the

number of spans increases. It is possible to calculate these deflections at any given point by using second integration of

the basic differential equation for beams. Testing shows that the center span of a three-tray continous beam can deflect

less than 10 % of its simple beam deflection.

Technical

Information

Cable Tray

Selection Process

Couplers at Supports - Not Recommended

23 mm

12 mm

23 mm

Couplers at 1/4 Span From Supports - Ideal Layout

1/4 span

23 mm

3 mm

23 mm

Figure 1.4

The support span should not be greater than the straight section length, to ensure no more than one splice is located

between supports.

Location of Couplers. (see Figure 1.4) The location of the coupler dramatically affects the deflection of a cable tray

system under equal loading conditions. Testing indicates that the maximum deflection of the center span of a

three-span tray run can decrease four times if the couplers are moved from one-quarter span to above the supports.

This can be a major concern for designers considering modular systems for tray and pipe racks.

17

Technical Information

Materials and

Finishes

Materials

Materials

Most cable tray systems are fabricated from a corrosion-resistant metal (low-carbon steel, stainless steel or an

aluminum alloy) or from a metal with a corrosion-resistant finish (zinc or epoxy). The choice of material for any particular

installation depends on the installation environment (corrosion and electrical considerations) and cost.

Aluminum

Cable trays fabricated of extruded aluminum are often used for their high strength-to-weight ratio, superior resistance to

certain corrosive environments, and ease of installation. They also offer the advantages of being light weight

(approximately 50% that of a steel tray) and maintenance free, and since aluminum cable trays are non-magnetic,

electrical losses are reduced to a minimum.

T&B cable tray products are formed from the 6063 series alloys which by design are copper free alloys for marine

applications. These alloys contain silicon and magnesium in appropriate proportions to form magnesium silicide,

allowing them to be heat treated. These magnesium silicon alloys possess good formability and structural properties, as

well as excellent corrosion resistance.

The unusual resistance to corrosion, including weathering, exhibited by aluminum is due to the self-healing aluminum

oxide film that protects the surface. Aluminum’s resistance to chemicals in the application environment should be tested

before installation.

Steel

T&B steel cable trays are fabricated from structural quality steels using a continuous roll-formed process. Forming and

extrusions increase the mechanical strength.

The main benefits of steel cable tray are its high strength and low cost. Disadvantages include high weight, low

electrical conductivity and relatively poor corrosion resistance.

The rate of corrosion will vary depending on many factors such as the environment, coating or protection applied and

the composition of the steel. T&B offers finishes and coatings to improve the corrosion resistance of steel. These

include pre-galvanized, hot dip galvanized (after fabrication), epoxy and special paints.

Stainless Steel

Stainless steel offers high yield strength and high creep strength, at high ambient temperatures.

T&B stainless steel cable tray is roll-formed from AISI Type 316 stainless steel.

Stainless Steel is resistant to dyestuffs, organic chemicals, and inorganic chemicals at elevated temperatures. Higher

levels of chromium and nickel and a reduced level of carbon serve to increase corrosion resistance and facilitate

welding. Type 316 includes molybdenum to increase high temperature strength and improve corrosion resistance,

especially to chloride and sulfuric acid. Carbon content is reduced to facilitate welding.

18

Technical Information

Finishes

Galvanized Coatings

The most widely used coating for cable tray is galvanizing. It is cost-effective, protects against a wide variety of

environmental chemicals, and is self-healing if an area becomes unprotected through cuts or scratches.

Technical

Information

Materials and

Finishes

Steel is coated with zinc through electrolysis by dipping steel into a bath of zinc salts. A combination of carbonates,

hydroxides and zinc oxides forms a protective film to protect the zinc itself. Resistance to corrosion is directly related to

the thickness of the coating and the harshness of the environment.

Pre-Galvanized

Pre-galvanized, also known as mill-galvanized or hot dip mill-galvanized, is produced in a rolling mill by passing steel

coils through molten zinc. These coils are then slit to size and fabricated.

Areas not normally coated during fabrication, such as cuts and welds, are protected by neighboring zinc, which works

as a sacrificial anode. During welding, a small area directly affected by heat is also left bare, but the same self-healing

process occurs.

G90 requires a coating of .90 ounces of zinc per square foot of steel, or .32 ounces per square foot on each side of the

metal sheet. In accordance with A653/A653M-06a, pre-galvanized steel is not generally recommended for outdoor use

or in industrial environments.

Hot-Dip Galvanized

After the steel cable tray has been manufactured and assembled, the entire tray is immersed in a bath of molten zinc,

resulting in a coating of all surfaces, as well as all edges, holes and welds.

Coating thickness is determined by the length of time each part is immersed in the bath and the speed of removal. Hot

dip galvanizing after fabrication creates a much thicker coating than the pre-galvanized process, a minimum of 3.0

ounces per square foot of steel or 1.50 ounces per square foot on each side of the sheet (according to ASTMA123,

grade 65).

The process is recommended for cable tray used in most outdoor environments and many harsh industrial environment

applications.

Other Coatings

Epoxy and special paint coatings are available on request.

19

Technical Information

Corrosion

Corrosion

Corrosion

Corrosion of metal occurs naturally when the metal is exposed to chemical or electrochemical attack. The atoms on the

exposed surface of the metal come into contact with a substance, leading to deterioration of the metal through a

chemical or electrochemical reaction. The corroding medium can be a liquid, gas or solid.

Although all metals are susceptible to corrosion, they corrode in different ways and at various speeds. Pure aluminum,

bronze, brass, most stainless steels and zinc corrode relatively slowly, but some aluminum alloys, structural grades of

iron and steel and the 400 series of stainless steels corrode quickly unless protected.

Various types of metal corrosion are categorized by its appearance or the method of acceleration:

• Chemical corrosion occurs through dissolution of the metal by reaction with a corrosive medium.

• Electrochemical corrosion involves chemical dissolution.

• Galvanic corrosion is accelerated by a difference in potential between metals that are in contact.

• Pitting corrosion is accelerated by a difference in the concentration of an ion or another dissolved substance.

• Crevice corrosion is accelerated by oxygen concentration or ion cell formation.

• Erosion corrosion is accelerated by a flow of liquid or gas.

• Intergranular corrosion occurs at grain (or crystal) boundaries.

Electrochemical Corrosion

Electrochemical corrosion is caused by an electrical current flow between two dissimilar metals, or if a difference of

potential exists, between two areas of the same metal surface.

The energy flow occurs only in the presence of an electrolyte, a moist conductor that contains ions, which carry an

electric charge. Solutions of acids, alkalies, and salts contain ions, making water—especially salt water—an excellent

electrolyte.

20

Common Types of Corrosion

Galvanic Corrosion

Galvanic corrosion results from the electrochemical reaction that occurs in the presence of an electrolyte when two

dissimilar metals are in contact. The strength of the reaction—and the extent of the corrosion—depend on a number of

factors, including the conductivity of the electrolyte and potential difference of the metals.

Technical

Information

Technical Information

Corrosion

The metal with less resistance becomes anodic and more subject to corrosion, while the more resistant becomes

cathodic.

The Galvanic Series Table, developed through laboratory tests on industrial metal alloys in sea water (a powerful

electrolyte), list metals according to their relative resistance to galvanic corrosion. Those less resistant to galvanic

corrosion (anodic) are at the top, and those more resistant (cathodic) are at the bottom.

The metals grouped together are subject to only slight galvanic effect when in contact, and metals at the top will suffer

galvanic corrosion when in contact with metals at the bottom (in the presence of an electrolyte). The farther apart two

metals are on the table, the greater the potential corrosion.

Galvanic Series Table

Anodic End

Magnesium

Type 304 stainless steel (active)

Magnesium alloys

Type 316 stainless steel (active)

Zinc

Lead

Galvanized steel

Tin

Naval brass (C46400)

Aluminum 5052H

Muntz metal (C28000)

Aluminum 3004

Manganese bronze (C67500)

Aluminum 3003

Aluminum 1100

Nickel (active)

Aluminum 6053

Inconel (active)

Alclad aluminum alloys

Aluminum bronze (C61400)

Cartridge brass (C26000)

Cadmium

Admiralty metal (C44300)

Copper (C11000)

Aluminum 2017

Red brass (C23000)

Aluminum 2024

Silicon bronze (C 65100)

Low-carbon steel

Copper nickel, 30% (C71500)

Wrought iron

Cast iron

Nickel (passive)

Monel

Inconel (passive)

Ni-resist

Type 304 stainless steel (passive)

Gold

Type 410 stainless steel (passive)

Type 316 stainless steel (active)

Platinum

50Pb-50Sn solder

Silver

Cathodic End

21

Technical Information

Types of

Corrosion

Common Types of Corrosion (cont’d)

Pitting

Pitting corrosion is localized and is identified by a cavity with a depth equal to or greater than the cavity’s surface

diameter. Pits may have different sizes and depths and most often appear randomly distributed. Aluminum and stainless

steels in chloride environments are especially susceptible to pitting.

Pitting begins when surface defects, foreign particles or other variations in the metal lead to fixation of anodic (corroded)

and cathodic (protected) sites on the metal surface. Acidic metal chlorides, which form and accumulate in the pit as a

result of anodes attracting chloride ions, accelerate the pitting process over time. The nature of pitting often makes it

difficult to estimate the amount of damage.

Crevice Corrosion

Crevice corrosion is a specialized form of pitting that particularly attacks metals or alloys protected by oxide films or

passive layers. It results from a relative lack of oxygen in a crevice, with the metal in the crevice becoming anodic to the

metal outside. For the crevice to corrode, it must be large enough to admit the electrolyte, but small enough to suffer

oxygen depletion.

Erosion Corrosion

While erosion is a purely mechanical process, erosion corrosion combines mechanical erosion with chemical or

electrochemical reaction. The process is accelerated by the generally rapid flow of liquid or gas over an eroded metal

surface, removing dissolved ions and solid particles. As a result, the metal surface develops grooves, gullies, waves,

rounded holes and valleys.

Erosion corrosion can damage most metals, especially soft ones like aluminum that are susceptible to mechanical wear,

and those that depend for protection on a passive surface film, which can be eroded. Resulting damage can also be

enhanced by particles or gas bubbles in a suspended state.

Intergranular Corrosion

Intergranular corrosion occurs between the crystals (or grains) that formed when the metal solidified. The composition of

the areas between the crystals differs from that of the crystals themselves, and these boundary areas can become

subject to intergranular corrosion. Weld areas of austenitic stainless steels are often affected by this form of corrosion,

and the heat-treatable aluminum alloys are also susceptible.

22

Technical Information

Corrosion Resitance Guide

The following table has been compiled as a guide for selecting appropriate cable trays for various industrial

environments. The information can only be used as a guide because corrosion processes are dictated by the unique

circumstances of any particular assembly.

Technical

Information

Corrosion

Resistance Guide

Corrosion is significantly effected by trace impurities which, at times, can become concentrated through wet/dry cycles

in locations that are prone to condensation and evaporation. It is not uncommon to find aggressive mists created from

contaminant species, notably from sulfur or halogen sources.

Temperature greatly influences corrosion, sometimes increasing the rate of metal loss, [a rule-of- thumb guide is that a

30°C change in temperature results in a 10X change in corrosion rate]. Sometimes corrosion attack slows down at

higher temperatures because oxygen levels in aqueous solutions are lowered as temperatures increase. If an

environment completely dries out then there can be no corrosion.

Stress-associated corrosion might occur when assemblies are poorly installed and/or fabricated, e.g., on-site welding or

mechanical fastening. Premature failure can result from: corrosion fatigue, which can occur in any environment; stress

corrosion cracking, which occurs in the presence of a specific chemical when the metal is under a tensile stress, which

may be residual or applied, (e.g., from poor fabrication or welding); fretting, where two adjacent surfaces (under load)

are subjected to an oscillatory motion across the mating surfaces.

Design - good design should minimize the risk of stress concentrations within a structure. Examples include sharp

profiles, abrupt section changes, and threaded screws. These measures are particularly important for metals that are

prone to stress corrosion cracking in specific media.

Design plays a significant role in exacerbating corrosion. Non-draining locations create liquid traps; local metal-to-metal

(or metal-to-non-metal) contact points (e.g., mechanical assemblies (bolts) with washers or spacers), permit crevice

corrosion and/or galvanic corrosion to occur. Areas that are poorly maintained, (e.g., surfaces are not regularly (or

properly) washed and stubborn deposits remain on the metal surface), are particularly prone to localized corrosion

damage due to different levels of oxygen under and adjacent to the location in question (differential aeration). Resulting

damage from these situations is in the form of small holes (pits). In each of the examples just quoted there is a

restricted supply of oxygen. Thus, metals (e.g., aluminum, stainless steels, zinc) that rely on oxygen to form protective

corrosion films (oxides, hydroxides, carbonates, etc.,) may be prone to localized pitting and/or crevice corrosion.

A further example of localized corrosion occurs when dissimilar metals contact each other in the presence of a

corrodent, i.e., galvanic corrosion. Each metal will corrode but the one that is most active [anode] can be more

corroded especially when there is a large surrounding area of the less active [cathodic] metal. It is wise to avoid small

anodic areas. Some examples include: steel bolts [small area of anodic metal] in stainless steel plate, [large area of

cathodic metal]; steel bolts in copper plate - the steel corrodes). There can be environmental influences, for example a

fluid that contains active metallic species, for example copper ion contact with aluminum (copper picked up from

aqueous solutions conveyed in copper pipe) - the aluminum corrodes. A further dramatic example is provided when

trace quantities of mercury contact aluminum - the aluminum corrodes very rapidly. These are examples of deposit

corrosion.

23

Technical Information

Corrosion

Resistance Guide

Key to Symbols in Table

The following symbols have been used throughout the TABLE in order to provide an indication about the suitability of a

potential candidate material for a specific chemical environment.

NOTE: These tables should be regarded only as GUIDES to anticipated performance because of

possible contributions from temperature, pollutant (contaminant) species, etc. Further

details have been given elsewhere.

SYMBOLS:

24

++

first choice; very low corrosion rate, typically <5 mpy, or <0.005 inch/year, (1 mil = 1/1000 inch).

+

good choice; low corrosion rate, typically <20 mpy, or <0.02 ipy.

-

can use; corrosion rate up to 50 mpy (0.05 ipy); some limitations may apply.

X

not recommended.

(-)

brackets indicate probable limitations, e.g., at higher temperatures, [symbol “T”]; at higher

concentrations, [symbol “C”]; due to pitting, [symbol “P”]; due to local grain boundary attack in

the metal - intergranular corrosion, [symbol “I”]; or, due to stress corrosion cracking,

[symbol “S”].

nd

no available data

Chemical Species

Aluminum

HDG/Steel

316SS

Technical

Information

Technical Information

Corrosion

Resistance Guide

Acetaldehyde . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . . .++

Acetic acid - aerated . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)T,C . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(++)T

Acetic acid - not aerated . . . . . . . . . . . . . . . . . . . . . . . . (+)T,C . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(++)T

Acetone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .++

Acetylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .++

Allyl alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .++

Aluminum chloride - dry . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .(+)T,P

Aluminum chloride - wet. . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .(-)P

Aluminum sulfate - satd.. . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . . .+

Ammonia - anhydrous. . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .++

Ammonia - gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ammonium acetate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

Ammonium bicarbonate . . . . . . . . . . . . . . . . . . . . . . . . . . Ammonium carbonate - satd.. . . . . . . . . . . . . . . . . . . . . . +

Ammonium chloride - 28%. . . . . . . . . . . . . . . . . . . . . . . . X

. . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .(+)P,S

Ammonium

Ammonium

Ammonium

Ammonium

Ammonium

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . .(++)C

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(++)S

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . . . . .+

chloride - 50%. . . . . . . . . . . . . . . . . . . . . . . . X

hydroxide . . . . . . . . . . . . . . . . . . . . . . . . . . . +

nitrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

phosphate - 40% . . . . . . . . . . . . . . . . . . . . . X

sulfate - to 30%. . . . . . . . . . . . . . . . . . . . . . . X

Amyl acetate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Asphalt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Beer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Benzene (benzol). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Benzoic acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

. . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .(+)P

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . . .+

Benzol - see benzene

Boric acid (boracic acid). . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . .(++)T,P

Bromine - wet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . . .X

Butadiene (butylene). . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . . . .+

Butyl alcohol (butanol) . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .++

Butyric acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . . .+

Cadmium sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .++

Calcium carbonate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . . .+

25

Technical Information

Corrosion

Resistance Guide

Chemical Species (cont’d)

Aluminum

HDG/Steel

316SS

Calcium chloride - satd. . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(+)S

Calcium hydroxide - satd. . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

Calcium hypochlorite - satd.. . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X

Carbon dioxide - wet . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .+

Carbon disulfide (bisulfide) . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .+

Carbon tetrachloride. . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .+

Carbolic acid - see phenol

. . . . . . . . . . . . . . . . .(-)P

. . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . .(++)P,S

Carbonic acid - see carbon dioxide

Caustic potash - see potassium hydroxide

Caustic soda - see sodium hydroxide

Chlorine gas - wet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . .(-)P,S

Chloroform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)dry . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . .(+)T,S

Chromic acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . nd . . . . . . . . . . . . . . .(+)P

Citric acid - dilute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)T,C . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . .(++)P

Copper chloride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .(-)P

Copper nitrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . nd . . . . . . . . . . . . . . . .++

Copper sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . . . .+

Cresol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . . +

Crude oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++

Diethylamine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .++

Dimethyl ketone - see acetone

Ethyl acetate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (++)dry . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .+

Ethyl alcohol (ethanol) . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

Ethylene dichloride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (-)dry . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . .(+)P,S

Ethylene glycol (glycol) . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

Ferric chloride. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Ferric nitrate - 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

Ferrous sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . nd . . . . . . . . . . . . . . .(+)P

Formaldehyde (methanal) . . . . . . . . . . . . . . . . . . . . . . . . (+)P . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . .(++)T,C

Fluorine gas - moist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Formalin - see formaldehyde

Formic acid (methanoic acid) - 10% . . . . . . . . . . . . . . . (+)T . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . .(+)P,C

26

Chemical Species (cont’d)

Aluminum

HDG/Steel

316SS

Furfural (furfuraldehyde) . . . . . . . . . . . . . . . . . . . . . . . . . . +

Furol - see furfural

Gelatin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Glycerine (glycerol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Hexamine - 80% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

. . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Hydrobromic acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Hydrochloric acid (muriatic acid) . . . . . . . . . . . . . . . . . . . X

Hydrocyanic acid - dilute . . . . . . . . . . . . . . . . . . . . . . . . . +

Hydrocyanic acid - conc . . . . . . . . . . . . . . . . . . . . . . . . . X

Hydrofluoric acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Hydrogen

Hydrogen

Hydrogen

Hydrogen

Hydrogen

Technical

Information

Technical Information

Corrosion

Resistance Guide

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

chloride gas - dry . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . .(++)S

chloride gas - wet . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .+

fluoride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (-)T . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

peroxide - to 40%. . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

sulfide - wet . . . . . . . . . . . . . . . . . . . . . . . . . . (+)P . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . .(+)P,S

Hypo - see sodium thiosulfate

Hypochlorous acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Iodine solution - satd.. . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Lactic acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)T . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . .(+)P,I

Latex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . .++

Lithium chloride - to 30% . . . . . . . . . . . . . . . . . . . . . . . . . X

Linseed oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

Magnesium chloride - 50% . . . . . . . . . . . . . . . . . . . . . . . X

Magnesium hydroxide . . . . . . . . . . . . . . . . . . . . . . . . . . . +

Magnesium sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(+)P,S

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .+

Maleic acid (maleinic acid) - 20%. . . . . . . . . . . . . . . . . . . +

Methyl alcohol (methanol) . . . . . . . . . . . . . . . . . . . . . . . . ++

Methyl ethyl ketone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

Milk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++

Molasses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Naptha . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . . .+

Natural fats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

Nickel chloride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . .(+)P,S

27

Technical Information

Corrosion

Resistance Guide

Chemical Species (cont’d)

Aluminum

HDG/Steel

316SS

Nickel sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

Nitric acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(++)I

Oleic acid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (++)T . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Oxalic acid - dilute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

Oxalic acid - saturated . . . . . . . . . . . . . . . . . . . . . . . . . . (+)T . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .X

Paraformaldehyde - to 30% . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Perchloroethylene. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . .(++)P

Phenol (carbolic acid) . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

Phosphoric acid - dilute . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .++

Phosphoric acid - 50%. . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(++)I

Picric acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . . .+

Potassium bicarbonate - 30% . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Potassium

Potassium

Potassium

Potassium

Potassium

carbonate . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

chloride - to 25% . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . .(++)P

dichromate - 30% . . . . . . . . . . . . . . . . . . . . (++)T . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .++

hydroxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .(+)S

nitrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . . .+

Potassium sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++

Propionic acid (propanoic acid) . . . . . . . . . . . . . . . . . . . (+)T . . . . . . . . . . . . . . . . .X

Propyl alcohol (propane). . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .++

Prussic acid - see hydrocyanic acid

Pyridine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . nd

28

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .++

Soaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +

Sodium bicarbonate - 20% . . . . . . . . . . . . . . . . . . . . . . . +

Sodium bisulfate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Sodium bisulfite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Sodium chloride - to 30% . . . . . . . . . . . . . . . . . . . . . . . . X

. . . . . . . . . . . . . . . . . .- . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(+)P,S

Sodium

Sodium

Sodium

Sodium

Sodium

. . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . .(+)S

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . .(++)S

. . . . . . . . . . . . . . . . . .X . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . .(-)P,S

cyanide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

hydroxide - 10-30% . . . . . . . . . . . . . . . . . . . . . . X

hydroxide - 50% . . . . . . . . . . . . . . . . . . . . . . . . . X

hydroxide - conc . . . . . . . . . . . . . . . . . . . . . . . . . X

hypochlorite - conc . . . . . . . . . . . . . . . . . . . . . . . X

Chemical Species (cont’d)

Aluminum

Sodium

Sodium

Sodium

Sodium

Sodium

HDG/Steel

nitrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .X

peroxide - 10% . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd

silicate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd

sulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (++)30% . . . . . . . . . . . . . . . . X

sulfide - to 50%. . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . .nd

316SS

Technical

Information

Technical Information

Corrosion

Resistance Guide

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .(+)T

Sodium thiosulfate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . nd . . . . . . . . . . . . . . . .++

Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)P . . . . . . . . . . . . . . . . .++ . . . . . . . . . . . . . . . .++

Stearic acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Sorbital (hexahydric alcohol) . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

Sulfur dioxide - dry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

Sulfur dioxide - wet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Sulfuric acid - to 80%. . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Sulfuric acid - 80-90% . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Sulfuric acid - 98%. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Tannic acid (tannin). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

. . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . . .X

Tartaric acid - to 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . (+)T . . . . . . . . . . . . . . . .nd

Toluene (Toluol; methyl benzene) . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . .++

Trichloroethylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (++)T . . . . . . . . . . . . . . . . .+

Turpentine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .(+)T

. . . . . . . . . . . . . . . . . .X

. . . . . . . . . . . . . . . . .(-)I

. . . . . . . . . . . . . . . . .(+)I

. . . . . . . . . . . . . . . . . .+

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .++

. . . . . . . . . . . . . . . .(+)P

. . . . . . . . . . . . . . . .++

Water - acid, mine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X . . . . . . . . . . . . . . . . . .- . . . . . . . . . . . . . . .(++)P

Water - potable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

Water - sea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + . . . . . . . . . . . . . . . . . .+ . . . . . . . . . . . . . . . . .++

Xylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . . . . .++

Zinc chloride - dilute . . . . . . . . . . . . . . . . . . . . . . . . . . . . ++ . . . . . . . . . . . . . . . . .nd . . . . . . . . . . . . .(++)P,S

29

Technical Information

7

Electrical Grounding

Capacity

Electrical Grounding Capacity

The National Electrical Code, Article 392-7 allows

cable tray to be used as an equipment grounding

conductor. All T&B standard cable trays are

classified by Underwriter’s Laboratories per US NEC

Table 392-7 based on their cross sectional area.

The corresponding cross-sectional area for each

siderail design (2-siderails) is listed on the label. This

cable tray label is attached to each straight section

that is UL classified. Fittings are not subject to

CSA or UL.

NEC TABLE 392.7 (B)

Metal Area Requirements for Cable Trays

Used as Equipment Grounding Conductors

Maximum Fuse Ampere Rating,

Circuit Breaker Ampere Trip

Setting, or Circuit Breaker

Protective Relay Ampere Trip

Setting for Ground Fault

Minimum Cross-Sectional

Area of Metal*

In Square Inches

Protection of any Cable Circuit

Steel

Aluminum

in the Cable Tray System

Cable Trays

Cable Trays

60

0.20

0.20

100

0.40

0.20

200

0.70

0.20

400

1.00

0.40

600

1.50 **

0.40

1000

-

0.60

1200

-

1.00

1600

-

1.50

2000

-

2.00 **

For SI units: one square inch = 645 square millimeters.

* Total cross-sectional area of both side rails for ladder or trough-type

cable trays: or the minimum cross-sectional area of metal in

channel-type cable trays or cable trays of one-piece construction.

** Steel cable trays shall not be used as equipment grounding

conductors for circuits with ground-fault protection above 600 amperes.

Aluminum cable trays shall not be used as equipment grounding

conductors for circuits with ground-fault protection above 2000

amperes.

For larger ampere ratings an additional grounding conductor must be

used.

See pages 198 to 201 for grounding and bonding products.

For more information on grounding and bonding cable tray refer to section 4.7 of the

NEMA VE 2-2006 Cable Tray installation guidelines.

30

Thermal Expansion and Contraction

A cable tray system may be affected by thermal expansion and contraction, which must be taken into account during

installation. To determine the number of expansion splice plates you need, decide the length of the straight cable tray

runs and the total difference between the minimum winter and maximum summer temperatures. To function properly,

expansion splice plates require accurate gap settings between trays. To find the gap (see Table 2):

MAXIMUM DISTANCE BETWEEN EXPANSION JOINTS

(For 1” Movement)

PLOT YOUR GAP SETTING

Locate the lowest metal temperature on low

temperature line.

Locate the highest metal temperature on high

temperature line.

Connect these two points.

Locate installation temperature and plot to

high/low line. Drop plot to gap setting.

a.

b.

c.

d.

Technical

Information

Technical Information

Thermal Expansion

and Contraction

Temperature

Differential (oF)

Steel

(Feet)

Aluminum

(Feet)

25

50

75

100

125

150

175

512

256

171

128

102

85

73

260

130

87

65

52

43

37

Note: Every pair of expansion splice plates requires two bonding

jumpers for grounding continuity.

Table 1

The support nearest the midpoint between expansion splice plates should be anchored, allowing the tray longitudinal

movement in both directions. All other support location should be secured by expansion guides. (see Table 3)

When a cable tray system is used as an equipment grounding conductor, it is important to use bonding jumpers at all

expansion connections to keep the electrical circuit continuous.

Gap Setting of Expansion Splice Plate

Max. Temp.

METAL TEMPERATURE AT TIME

FOR INSTALLATION (FO OR CO)

50

40

30

20

1” (25.4) Gap Maximum

Min. Temp.

Fo

Co

Fo

Co

130

130

110

110

90

90

70

70

20

50

40

30

10

50

50

10

0

30

30

0

-10

10

10

-20

-30

-10

-10

-30

-30

-30

-40

-40

0

(0.0)

1/8

(3.2)

1/4

(6.3)

3/8

(9.5)

1/2

(12.7)

5/8

(15.9)

GAP SETTING, Inches (mm)

Table 2

-10

-20

3/4

(19.9)

7/8

(22.2)

1

(25.4)

Typical Cable Tray

Installation

Expansion Splice Plates

(Bonding Jumpers required

on each side of tray)

Table 3

31

Technical Information

Structural

Design

Structural Design

Structural Design

An installed cable tray system functions as a beam under a uniformly distributed load. The four basic beam

configurations found in cable installations are simple, continuous, cantilever and fixed. Each is attached to the cable tray

support in a different way.

Continuous Beam

Cable tray sections forming spans constitute a continuous beam configuration, the most common found in cable tray

installations. This configuration exhibits characteristics of the simple beam and the fixed beam. For example, with loads

applied to all spans at the same time, the ends spans function like simple beams, while the counterbalancing loads on

either side of a support function like a fixed beam. As the number of spans increases, the continuous beam behaves

increasingly like a fixed beam, and the maximum deflection continues to decrease. As this occurs, the system’s load

carrying capability increases.

Simple Beam

A straight section of cable tray supported at both ends but not fastened functions as a simple beam. Under a load, the

tray will exhibit deflection. The load carrying capacity of a cable tray unit should be based on simple beam loading,

since this type of loading occurs at run ends, offsets, etc., in any tray system. The NEMA/CSA Load Test is a simple

beam, uniformly distributed load test, used primarily because it is easy to test and represents the worst case beam

condition compared to continuous or fixed configurations. The only criterion for NEMA/CSA acceptance is the ability to

support 150% of the rated load.

Fixed Beam

Like the cantilever beam, a fixed beam applies more to the cable tray supports than the tray itself, because both ends

of a fixed beam are firmly attached to the supports. The rigid attachment prevents movement and increases load

bearing ability.

Cantilever Beam

A cantilever beam has more to do with the cable tray supports than the tray. Attaching one end of a beam to a support

while the other end remains unsupported, as when wall mounting a bracket, creates a cantilever beam configuration.