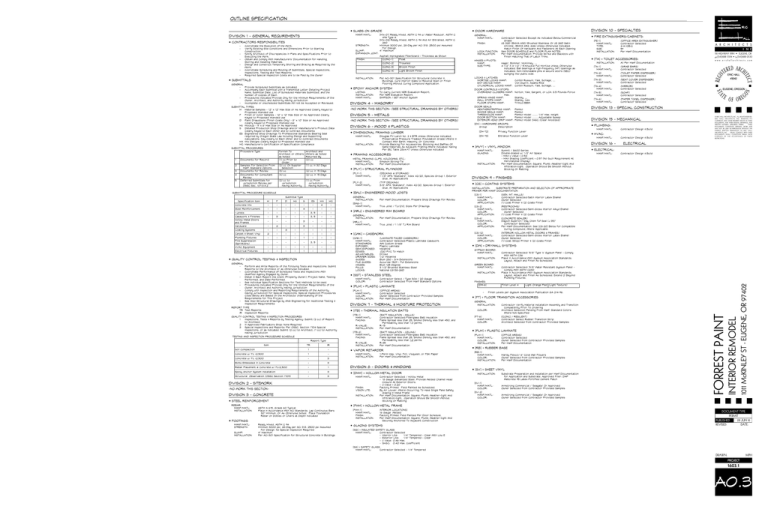

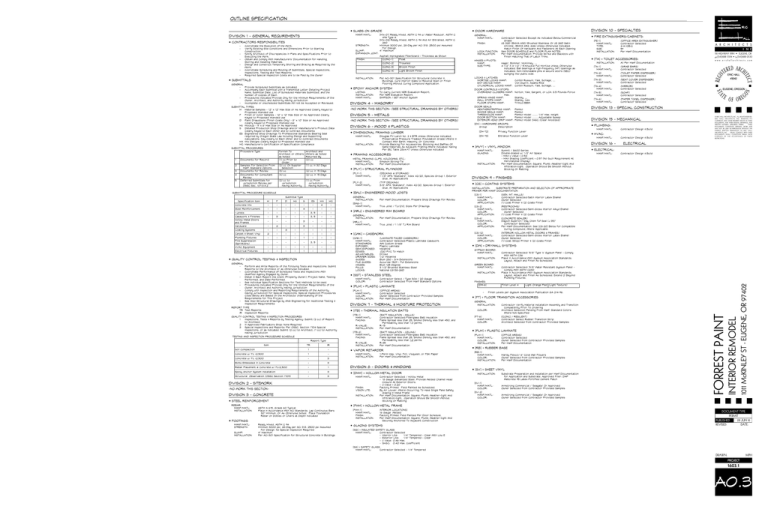

OUTLINE SPECIFICATION

-

Coordinate the Execution of the Work.

Verify Existing Site Conditions and Dimensions Prior to Starting

Construction.

Notify Architect of Discrepancies in Plans and Specifications Prior to

Executing the Work.

Obtain and Comply With Manufacturers' Documentation for Handling,

Storing and Installing Materials.

Design and Construct Temporary Shoring and Bracing as Required by the

Work.

Coordinate Scheduling and Routing of Submittals, Special Inspections,

Inspections, Testing and Test Reports.

Required Special Inspection Costs are to be Paid by the Owner

GENERAL

Provide Scheduled Submittals as Indicated.

Accompany Each Submittal with a Transmittal Letter Detailing Project

Name, Submittal Date, List of Scheduled Materials Submitted, and the

Number of Copies of Each.

Procedures Indicated Provide Only for the Minimum Requirements of the

Owner, Architect, and Authority Having Jurisdiction

Incomplete or Unscheduled Submittals Will not be Accepted or Reviewed.

SUBMITTAL TYPES

M Material Samples - 12" x 12" Max Size or As Approved Clearly Keyed to

Proposed Intended Use

F

Finish or Color Samples - 12" x 12" Max Size or As Approved Clearly

Keyed to Proposed Intended Use

D Paint Drawdowns (Finish Coats Only) - 8" x 10" Size or As Approved

Clearly Keyed to Proposed Intended Use

MU Mockup - 4' x 6' Max Size or As Approved

S

Detailed Production Shop Drawings and/or Manufacturer's Product Data

Clearly Keyed to Each Other and to Contract Documents

ES Engineered Shop Drawings To Professional Standards Bearing Seal

required by Oregon State Law Including Design and Supporting

Calculations. Key Clearly to Each Other and to Contract Documents

MX Mix Designs Clearly Keyed to Proposed Intended Use

MC Manufacturer's Certification of Specification Compliance

SUBMITTAL PROCEDURES

Procedure Type

1

Documents for Record

2

Samples For Selection From

Manf. Standard Options

Documents for Review

4

5

SLUMP:

EXPANSION JOINT:

FINISH:

INSTALLATION:

• SUBMITTALS

3

STRENGTH:

Documents for Consultant

Review

Deferred Submittals for

Jurisdiction Review per

OSSC Sec. 107.3.4.2

[CONC-2]

Troweled

[CONC-3]

Broom Finish

[CONC-4]

Light Broom Finish

Per ACI-301 Specification for Structural Concrete in

Buildings. Cure Interior Slabs to Receive Stain or Finish

Flooring Without Curing Compound Application.

• EPOXY ANCHOR SYSTEM

LISTING:

INSTALLATION:

MANF/MATL:

To Carry Current NER Evaluation Report.

Per NER Evaluation Report

SIMPSON / SET Anchor System

DIVISION 4 - MASONRY

• DIMENSIONAL FRAMING LUMBER

MANF/MATL:

INSTALLATION:

Douglas Fir-Larch No. 2 & BTR Unless Otherwise Indicated,

Preservative Pressure Treated (Foundation Grade) Where In

Contact With Earth, Masonry, Or Concrete

Provide Backing For Accessories, Blocking And Baffles Of

Same Materials As Adjacent Framing Where Indicated. Nailing

Per IBC Table 23o4.9.1 Unless Otherwise Indicated

(2) cc in 15 Days

[PLY-1]

MANF/MATL:

(2) cc to

Jurisdiction

Having Authority

(1) cc From

Jurisdiction

Having Authority

(DECKING @ STORAGE)

1 1/8" APA "Standard", Index 42/20, Species Group 1. Exterior

Glue, All Applications

[PLY-2]

MANF/MATL:

(TYP DECKING)

3/8" APA "Standard", Index 42/20, Species Group 1. Exterior

Glue, All Applications

METAL FRAMING CLIPS, HOLDOWNS, ETC.:

MANF/MATL:

Simpson Strong-Tie

INSTALLATION:

Per Manf Documentation

• [EWJ] = ENGINEERED WOOD JOISTS

GENERAL:

INSTALLATION:

Per Manf Documentation, Prepare Shop Drawings For Review

[EWG-1]

MANF/MATL:

Trus Joist / TJI/210, Sizes Per Drawings

M

F

D

MU

S

ES

MX

MC

Concrete Mix

-

-

-

-

-

-

4

-

Steel Reinforcement

-

-

-

-

4

-

-

-

I-Joists

-

-

-

-

-

3, 5

-

-

Casework & Finishes

Hollow Metal Doors

and Frames

Hardware

-

3

-

-

-

3, 5

-

-

GENERAL:

INSTALLATION:

Per Manf Documentation, Prepare Shop Drawings For Review

-

-

-

-

3

-

-

-

-

2

-

-

3

-

-

-

[WRJ-1]

MANF/MATL:

Trus Joist / 1 1/8” TJ Rim Board

Coating Systems

-

-

3

-

-

-

-

-

Carpet & Sheet Vinyl

2

-

-

-

-

-

-

-

Plumbing Fixtures

Fire Suppression

(Sprinklers)

HVAC Equipment

-

-

-

-

1

-

-

-

-

-

-

-

-

3, 5

-

-

-

-

-

-

1

-

-

-

Electrical Fixtures

-

-

-

-

1

-

-

-

• QUALITY CONTROL TESTING & INSPECTION

GENERAL

Perform and Write Reports of the Following Tests and Inspections. Submit

Reports to the Architect or as Otherwise Indicated.

Coordinate Performance of Scheduled Tests and Inspections With

Qualified Agency Engaged by Owner.

Detail in Each Report the Client (Property Owner), Project Name, Testing

Performed, and Date Performed.

See Individual Specification Sections for Test Methods to be Used.

Procedures Indicated Provide Only for the Minimum Requirements of the

Owner, Architect and Authority Having Jurisdiction

Comply with Inspection and Reporting Requirements of the Authority

Having Jurisdiction for Special Inspections. Special Inspection Procedures

Cited Below are Based on the Architects' Understanding of the

Requirements for This Project

See Also Structural Drawings by ANG Engineering for Additional Testing &

Inspection Requirements

REPORT TYPE

TR Test Reports

IR Inspection Reports

• [WRJ] = ENGINEERED RIM BOARD

• [CWK] = CASEWORK

[CWK-1]

MANF/MATL:

STANDARDS:

EXPOSED:

SEMI-EXPOSED:

EDGES:

ADJUSTABLES:

DRAWER SIDES:

GUIDES:

FILE GUIDES:

HINGES:

PULLS:

LOCKS:

(LAMINATE FACED CASEWORK)

Contractor Selected/Plastic Laminate Casework

AWI Custom Grade

Plastic Laminate

Melamine

.020 PVC To Match

Drilled

1/2" Melamine

Blum 230 - 3/4 Extensions

Accuride 150# - Full Extensions

Blum 125 Degree

3 1/2" Brushed Stainless Steel

National C8138-26D

• [SST] = STAINLESS STEEL

MANF/MATL:

COLOR:

Contractor Select / Type 304 / 20 Gauge

Contractor Selected From Manf Standard Options

• [PLM] = PLASTIC LAMINATE

[PLM-1]

MANF/MATL:

COLOR:

INSTALLATION:

(OFFICE AREAS)

Contractor Selected

Owner Selected from Contractor Provided Samples

Per Manf Documentation

DIVISION 7 - THERMAL & MOISTURE PROTECTION

• [ITB] = THERMAL INSULATION BATTS

QUALITY CONTROL TESTING & INSPECTION PROCEDURES

1

Inspections, Tests & Reports by Testing Agency: Submit (2 cc) of Report

to Architect

2

In Approved Fabricators Shop: None Required

3

Special Inspections and Reports: Per OSSC. Section 1704 Special

Inspections, or as Indicated. Submit (2 cc) to Architect; (1 cc) to Authority

Having Jurisdiction

TESTING AND INSPECTION PROCEDURE SCHEDULE

Report Type

[ITB-1]

MANF/MATL:

FACING:

R-VALUE:

INSTALLATION:

[ITB-2]

MANF/MATL:

FACING:

R-VALUE:

INSTALLATION:

(BATT INSULATION - WALLS)

Contractor Selected/Fiberglass Batt Insulation

Flame Spread less than 25; Smoke Density less than 450, and

Permeability less than 1.0 perms

R-15

Per Manf Documentation

(BATT INSULATION - CEILING)

Contractor Selected/Fiberglass Batt Insulation

Flame Spread less than 25; Smoke Density less than 450, and

Permeability less than 1.0 perms

R-35

Per Manf Documentation

TR

IR

Soil Compaction

1

-

Concrete w/ f'c <2,500

1

-

Concrete w/ f'c >2,500

-

3

Bolts Embedded in Concrete

-

3

Rebar Placement @ Concrete w/ f'c>2,500

-

1

DIVISION 8 - DOORS & WINDOWS

Epoxy Anchor System Installation

-

3

• [DHM] = HOLLOW METAL DOOR

Structural Observation (OSSC Section 1709)

-

3

• VAPOR RETARDER

MANF/MATL:

INSTALLATION:

MANF/MATL:

DIVISION 2 - SITEWORK

-NO WORK THIS SECTION-

FINISH:

VISION LITE:

DIVISION 3 - CONCRETE

INSTALLATION:

• STEEL REINFORCEMENT

ASTM A 615, Grade 60 Typical

Place In Accordance With ACI Standards. Lap Continuous Bars

30" Minimum, Or As Otherwise Noted. Place Foundation

Rebar on Dobies or Chairs at Depth Indicated

• FOOTINGS

MANF/MATL:

STRENGTH:

SLUMP:

INSTALLATION:

LOCKS & LATCHES:

MORTISE LOCKS MANF:

EXIT DEVICE MANF:

CYLINDRICAL LOCKS MANF:

DOOR CONTROLS & STOPS

OVERHEAD CLOSERS MANF:

Max.

SPRING HINGE MANF:

WALL STOPS MANF:

FLOOR STOPS MANF:

Ready Mixed, ASTM C 94

Minimum 3000 psi, 28-Day per ACI 318. 2500 psi Assumed

For Design. No Special Inspection Required

4" Maximum.

Per ACI-301 Specification for Structural Concrete in Buildings

1-Perm Max. Vinyl, Foil, Visqueen, or FSK Paper

Per Manf Documentation

Contractor Selected / Hollow Metal

- 18 Gauge Galvanized Steel. Provide Welded Channel Head

Closure At Exterior Doors.

- U-Value = 0.20

Factory Primed. Field Painted As Scheduled.

By Air Louver, Where Occurring, To Have Single Pane Safety

Glazing In Metal Frame

Per Manf Documentation. Square, Plumb, Weather-tight And

Infiltration-tight. Operation Should Be Smooth Without

Sticking Or Rattling

(OFFICE AREA EXTINGUISHER)

Contractor Selected

2-A:10B:C

5#

Per Manf Documentation

• [TA] = TOILET ACCESSORIES:

INSTALLATION:

All Per Manf Documentation

[TA-2]

MANF/MATL:

(TOILET PAPER DISPENSER)

Contractor Selected

Corbin Russwin, Yale, Schlage, ....

Von Duprin, Adams-Rite

Corbin Russwin, Yale, Schlage, ....

[TA-3]

MANF/MATL:

(SEAT COVER DISPENSER)

Contractor Selected

[TA-4]

MANF/MATL:

(MIRROR)

Contractor Selected

Norton, Yale, Sargent, or LCN. 8.5 Pounds-Force

[TA-5]

MANF/MATL:

(SOAP)

Contractor Selected

[TA-6]

MANF/MATL:

(PAPER TOWEL DISPENSER)

Contractor Selected

Stanley, ,,,

Stanley, Ives

Trimco/BBW

Pemko

Pemko

Pemko Model ......... 1/4” Max. Height

Pemko Model ......... Adjustable Sweep

Pemko Model 346C (Clear Anodized)

Entrance Function Lever

DIVISION 15 - MECHANICAL

MANF/MATL:

Summit / 8600 Series

Double-Glazed w/ 1/2" Air Space

- MAX U Value = 0.54

- MAX Shading Coefficient = 0.57 (No Such Requirement At

Merchandise Display)

Per Manf Documentation. Square, Plumb, Weather-tight And

Infiltration-tight. Operation Should Be Smooth Without

Sticking Or Rattling

Contractor Design & Build

• HVAC:

MANF/MATL:

DIVISION 16 -

• [WVY] = VINYL WINDOW

116 HIGHWAY 99N • EUGENE, OR

ph (541)688 5594 • fx (541)688 0530

www.erichallarchitects.com

DIVISION 13 - SPECIAL CONSTRUCTION

• PLUMBING:

[DH-73]

INSTALLATION:

[FE-1]

MANF/MATL:

TYPE:

SIZE:

INSTALLATION:

(GRAB BARS)

Contractor Selected

Privacy Function Lever

MANF/MATL:

GLAZING:

• FIRE EXTINGUISHERS/CABINETS:

[TA-1]

MANF/MATL:

[DH-72]

• [PLY] = STRUCTURAL PLYWOOD

(2) cc in 15 Days

Hager, Bommer, McKinney, ....

4 1/2" X 4 1/2" / 5-Knuckle Full Mortise Unless Otherwise

Indicated. Ball bearings @ high-frequency (HF) openings as

indicated. Non-removeable pins @ secure doors (SEC)

swinging into public side.

[DH] = HARDWARE GROUPS:

Group

Description

• FRAMING ACCESSORIES

Submittal Type

REBAR:

MANF/MATL:

INSTALLATION:

HINGES & PIVOTS:

MANF:

SIZE/TYPE:

DIVISION 6 - WOOD & PLASTICS

(4) cc

Item

LOCK FUNCTION:

INSTALLATION:

-NO WORK THIS SECTION- (SEE STRUCTURAL DRAWINGS BY OTHERS)

DIVISION 5 - METALS

Architect and

Others as Noted

Returned By

(0) cc

(1) cc in 30 Days

FINISH:

Contractor Selected Except As Indicated Below/Commercial

Grade

US 32D (BHMA 630) Brushed Stainless Or US 26D Satin

Chrome, (BHMA 652, 626) Unless Otherwise Indicated.

Match Finish Of Hardware And Fasteners At Each Opening

See DOOR SCHEDULE and FLOOR PLAN NOTES.

Per Manf Documentation. Provide Strike and Backbox with

Finish Matching That of Latch Trims.

DOOR SEALS:

WEATHERSTRIPPING MANF:

SMOKE SEALS MANF:

THRESHOLDS MANF:

DOOR BOTTOM MANF:

EXTERIOR HEAD DRIP MANF:

-NO WORK THIS SECTION- (SEE STRUCTURAL DRAWINGS BY OTHERS)

Furnish To

Architect or Others

as Noted

(1) cc Prior to

Order

(2) cc On Supplier

Selection

(3) cc

SUBMITTAL PROCEDURE SCHEDULE

Specification Item

Asphalt Impregnated Fiberboard - Thickness as Shown

[CONC-1]

Float

GENERAL:

MANF/MATL:

Contractor Design & Build

© ERIC HALL ARCHITECTS, INC.- ALL RIGHTS RESERVED.

ERIC HALL ARCHITECTS, INC. RESERVES IT'S

COPYRIGHT AND OTHER PROPERTY RIGHTS IN THESE

DOCUMENTS, AND THEIR DESIGNS, DRAWINGS, AND

WRITTEN MATERIAL APPEARING HEREIN.

THESE

DOCUMENTS CONSTITUTE ORIGINAL WORK AND

MAY NOT BE USED OR REPRODUCED WITHOUT THE

EXPRESS WRITTEN PERMISSION OF ERIC HALL

ARCHITECTS, INC.

VISUAL CONTACT WITH THESE

DOCUMENTS SHALL CONSTITUTE PRIMA FACIE

E V I D E N C E O F T H E AC C E P TA N C E O F T H E S E

RESTRICTIONS.

ELECTRICAL

• ELECTRICAL:

MANF/MATL:

Contractor Design & Build

DIVISION 9 - FINISHES

• [CS] = COATING SYSTEMS

INSTALLATION:

SUBSTRATE PREPARATION AND SELECTION OF APPROPRIATE

PRIMER PER MANF DOCUMENTATION

[CS-1]

MANF/MATL:

COLOR:

APPLICATION:

(GEN. INT. WALLS)

Contractor Selected/Satin Interior Latex Enamel

Owner Selected

(1) Coat Primer & (2) Coats Finish

[CS-2]

MANF/MATL:

COLOR:

APPLICATION:

(RESTROOMS)

Contractor Selected/Semi-Gloss Interior Alkyd Enamel

Owner Selected

(1) Coat Primer & (2) Coats Finish

[CS-6]

MANF/MATL:

COLOR:

APPLICATION:

(CONCRETE SEALER)

Dayton Superior/ 'Day Chem Tuf Seal (J 35)"

Contractor Selected

Per Manf Documentation. See [CS-20] Below for Compatible

Curing Compound, Where Applicable.

[CS-12]

MANF/MATL:

COLOR:

APPLICATION:

(INTERIOR HOLLOW METAL DOORS & FRAMES)

Contractor Selected/Semi-Gloss Interior Latex Enamel

Owner Selected

(1) Coat (Shop) Primer & (2) Coats Finish

• [DW] = DRYWALL SYSTEMS

GYPSUM BOARD:

MANF/MATL:

INSTALLATION:

GREEN BOARD:

MANF/MATL:

INSTALLATION:

FINISHES:

[DW-6]

-

Contractor Selected/ 5/8" Type 'x' Gypsum Panel - Comply

With ASTM C36

Place in Accordance With Gypsum Association Standards.

Layout, Attach and Finish As Scheduled.

Contractor Selected/ 5/8" Water Resistant Gypsum Panel Comply With ASTM C630

Place in Accordance With Gypsum Association Standards.

Layout, Attach and Finish As Scheduled. Extend 2' Beyond

Plumbing Fixtures.

Finish Level 4

Light Orange Peel (Light Texture)

Finish Levels per Gypsum Association Publication GA 214-96.

• [FT] = FLOOR TRANSITION ACCESSORIES

GENERAL

INSTALLATION:

COLOR:

[FT-6]

MANF/MATL:

COLOR:

Contractor Verify Material Installation Assembly and Transition

Compatibility Prior To Ordering

Architect Selection Pending From Manf. Standard Colors

Where Not Specified

([CONC] / RESILIENT)

Contractor Select Rubber Transition Strip

Architect Selected from Contractor Provided Samples

• [PLM] = PLASTIC LAMINATE

[PLM-1]

MANF/MATL:

COLOR:

INSTALLATION:

(OFFICE AREAS)

Contractor Selected

Owner Selected from Contractor Provided Samples

Per Manf Documentation

• [RB] = RUBBER BASE

[RB-1]

MANF/MATL:

COLOR:

INSTALLATIO`N:

Marley Flexco/ 6" Cove Wall Flowers

Owner Selected from Contractor Provided Samples

Per Manf Documentation

• [SV] = SHEET VINYL

INSTALLATION:

Substrate Preparation and Installation per Manf Documentation

for Application and Substrate. Approved Filler: DAP

Webcrete 95 Latex-Fortified Cement Patch

[SV-1]

MANF/MATL:

COLOR:

Armstrong Commercial / 'Seagate' Or Approved

Owner Selected from Contractor Provided Samples

[SV-2]

MANF/MATL:

COLOR:

Armstrong Commercial / 'Seagate' Or Approved

Owner Selected from Contractor Provided Samples

1011 McKINLEY ST - EUGENE, OR 97402

• CONTRACTORS RESPONSIBILITIES

[Mix-01] Ready Mixed, ASTM C 94 w/ Water Reducer, ASTM C

494 Type A

[Mix-02] Ready Mixed, ASTM C 94 And Air Entrained, ASTM C

260

Minimum 3000 psi, 28-Day per ACI 318. 2500 psi Assumed

For Design.

4" Maximum

INTERIOR REMODEL

MANF/MATL:

DIVISION 1 - GENERAL REQUIREMENTS

DIVISION 10 - SPECIALTIES

• DOOR HARDWARE

FORREST PAINT

• SLABS ON GRADE

• [FHM] = HOLLOW METAL FRAME

[FHM-1]

MANF/MATL:

FINISH:

INSTALLATION:

INTERIOR LOCATIONS]

16 Gauge Welded

Factory Primed. Field Painted Per Door Schedule.

Per Manf Documentation. Square, Plumb, Weather-tight And

Securely Anchored To Adjacent Construction

• GLAZING SYSTEMS

DOCUMENT TYPE

PERMIT

28 JUN 16

PUBLISHED

REVISED:

DATE:

[ISG] = INSULATED SAFETY GLASS

MANF/MATL:

Contractor Selected

- Interior Lite:

1/4" Tempered - Clear With Low E

- Exterior Lite:

1/4" Tempered - Clear

- U Value: 0.46 Max.

- SHGC: 0.40 Max. Coefficient

[SG] = SAFETY GLASS

MANF/MATL:

Contractor Selected - 1/4" Tempered

DRAWN:

MPH

PROJECT

1603.1

A0.3