high voltage metal glaze resistors

advertisement

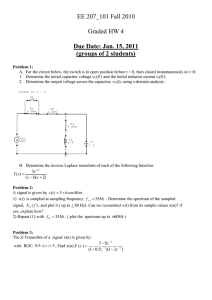

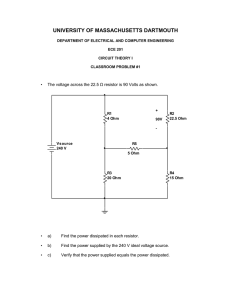

HIGH VOLTAGE METAL GLAZE RESISTORS- RI SERIES (DIP)高壓金屬釉電阻 ▲ FEATURE High resistance resistors Free direction for mounting due to cylindrical design. High solder ability due to specially plated electrodes. Provide good stable performance to against overload and environmental condition. High operating voltage resistors. ▲ DIMENSION: TYPE D L d H 1/4W 2.3±0.2 6.3±0.5 0.55±0.05 28±3 1/2W 3.2±0.3 8.8±0.5 0.55±0.05 28±3 1W 4.5±0.5 11±0.5 0.8±0.05 28±3 2W 5.5±0.5 15±0.5 0.8±0.05 28±3 3W 6.5±0.5 17±0.5 0.8±0.05 28±3 5W 12±0.5 45±0.5 1±0.05 28±3 10W 12±0.5 75±0.5 1±0.05 28±3 20W 12±0.5 105±0.5 1±0.05 28±3 25W 12±0.5 130±0.5 1±0.05 28±3 RI Unit:mm 5W~25W are no color band just print mark. ▲ ELECTRICAL SPECIFICATIONS V: Rated voltage V=√W*R Derating curve W: Power rating R: Nominal resistance Operating Temp Max Operating Max Overloading Resistance Resistance range Voltage Voltage Tolerance Range 1/4W –55–+155℃ 500V 700V 10K ohm–100M ohm 1/2W –55–+155℃ 700V 1000V 10K ohm–100M ohm 1W –55–+155℃ 1000V 1400V 10K ohm–100M ohm 2W –55–+155℃ 1000V 1400V 10K ohm–100M ohm 3W –55–+155℃ 1200V 1600V 5W –55–+155℃ 15KV 30KV 10K ohm–200M ohm 10W –55–+155℃ 30KV 60KV 10K ohm–500M ohm 20W –55–+155℃ 40KV 80KV 10K ohm–750M ohm 25W –55–+155℃ 50KV 100KV 10K ohm–1000M ohm TYPE ± 1% , ±5% 10K ohm–100M ohm ▲ Performance Specifications: characteristics Temperature coeffici Test Methods Limits Natural resisitance changge per temp.degree centigrade 106(PPM/℃) × R1: Resistance value at room temperature(t1) ±100PPM/℃ JIS – C – 5202 5.2 R2: Resistance value at room temp. plus 100ºC(t2) Shot-time overload JIS-C-5202 5.5 Permanent resistance change after the application Resistance change rate is(1% + 0.05Ω) Of 2.5 times RCWV for 5 seconds No evidence of mechalnica damage Dielectric with standing Resistors shall be clamped in the trough of a 90 metalic voltage No evidence of flashover mechalnica damage,arcing or insulation break down V-block and shall be tested at AC potential respectively JIS-C-5202 5.7 Soecified in the tabe 1.for 60+10/-0 seconds Pulse overload Resistance change after 10,000 cycles (1 second “on”, 25 seconds “off”) at 4 Resistance change rate is ±(2.0% + 0.05Ÿ). With no evidence of mechanical damage JIS – C – 5202 5.8 times RCWV or the max. pulse overload voltage. Temperature cycling Resistance change after continuous five cycles for duty cycle specified below: Step temperature Time 1 -55℃±3℃ 30 mins 2 Room temp 10-15 mins 3 +155℃±2℃ 30 mins 4 Room temp 10-15 mins JIS – C – 5202 7.4 Resistance change rate is ± ( 5%+0.05Ω) No evidence of mechalnica damage Load life in humidity Resistance change after1,000 hours operating at RCWV with duty cycle of(1.5 hours Resistance change rate is ± ( 5%+0.05Ω) “on”,0.5 hour“off”)in a humidity test chamber controlled at 40℃±2℃ and No evidence of mechalnica damage JIS - C -5202 7.9 90% to 95% relative Load life C - 5202 7.10 Permanent resistance change after 1,000 hours operating at RCWV with duty cycle of(1.5 hours “on”,0.5 hour“off”)at 70℃±2℃ ambient Terminal strength Direct load: Resistance to a 2.5kgs direct load for 10 seconds in the direction of the longitudinal axis of the terminal leads JIS-C-5202 6.1 Twist test: Terminal leads shall be bent through 90° at a point of about 6 mm from the body of the resistor and shall be rotated through 360° about the origi­nal axis of the bent terminal in altaernting direction for a total of 3 rotations Resistance change rate is ± ( 5%+0.05Ω) No evidence of mechalnica damage No evidence of mechalnica damage Resistance to soldering heat Permanent resistance change when leads immersed to 3.2 to 4.8 mm from the body Resistance change rate is ± ( 5%+0.05Ω) in 350℃±10℃ solder for 3±0.5 seconds No evidence of mechalnica damage JIS-C-5202 6.4 Solderability The area covered with a new,smooth,clean,shiny and continuous surface free from concentrated pinholes 95% coverage Min. Test temp of solder: 235ºC ± 5ºC JIS-C-5202 6.5 Dwell time in solder: 3 ± 0.5/ -0 seconds The following discharge cycle is repeated in the circuit on the lefe fig. (2.5 sec.“on ”,2.5 sec“off”)10 cycles.Applied volage (DC Source) 1/4W Surge Withstanding 100KΩ~1M 3000V Voltage Ω 1.1M Ω ~ 4000V 6.2MΩ ≧6.8MΩ 6000V 1/2W 1W 2W 3W 4000V 5000V 8000V 10000V 5000V 6000V 9000V 11000V 8000V 9000V 10000V 12000V Allowable resistance change ±10% Test circuit: ORDER: RI 5W 100M ohm 5% PS :1) 5W 以上的規格呎吋較多,請確認你要的呎吋. 2) 1/4W ~3W 灰色塗裝+色碼 ,5W以上綠色塗裝+印字 TEL:02-77316666 mail: sales@sesh.com.tw sesh electronics corp 尚聲電子股份有限公司