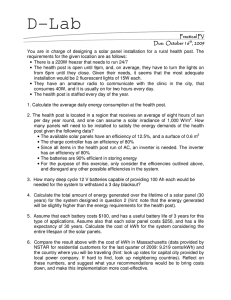

PV system desing of Juhannuslehto business park

advertisement