Electric Heating Elements - Cover.qxd

advertisement

ELECTRIC FURNACES

ELECTRIC OVENS

KETTLES & MELTERS

MELTERS

Designing and Manufacturing Electrically Heated Process

Equipment SINCE 1927

ELECTRIC

HEATING ELEMENTS

F&F ® HEATING

HEATING ELEMENTS & RACKS

PLUG HEATERS

HEATERS

ELECTRIC JACKETS

OIL IMMERSION AND

FINTUBE HEATERS

WATER IMMERSION

HEATER

I MMERSION H EATERS

F INTUBE H EATERS

STRIP HEATERS

S TRIP H EATERS

CERAMIC RING

HEATERS

CONVEYOR OVENS & FURNACES

CARTRIDGE HEATERS

TUBULAR

HEATERS

C ARTRIDGE H EATERS

T UBULAR H EATERS

HOT PLATES

201 Leverington Avenue, Philadelphia, PA 19127

Toll Free: 800.544.TRENT

Website: www.trentheat.com

1-2004

Fax: 215.482.9389

E-mail: trentheat@aol.com

H OT P LATES

C ERAMIC R ING H EATERS

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

TABLE OF CONTENTS

PAGE

BULLETIN 90 - ELECTRIC HEATING ELEMENTS

1-2004

Water Immersion Heaters

2

Oil Immersion Heaters

5

Fintube Heaters

7

Strip Heaters

8

Cartridge Heaters

10

Tubular Heaters

12

Hot Plates

14

Ceramic Ring Heaters

15

Temperature Conversion Table

16

-i-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

WATER IMMERSION

HEATERS

TRENT Water Immersion Heaters are designed to give years of trouble-free service as long as they are completely covered with liquid and used on correct voltage.

CONSTRUCTION:

All TRENT Screw Plug Water Immersion Heaters are furnished with brass heads (National Pipe Thread) to which a brass

or copper sheath is silver soldered. The helically coiled heating element is supported in the tube/s by ceramic cores and/or

the highest grade dielectric filler material material.

The RA and RB Series come standard with a 4” octagonal outlet box. RA-Series heaters have a 1” pipe thread, and 1”

copper tube. RB-Series heaters have a 1-1/4” pipe thread, and 1” or 1-1/4” diameter copper tubing. Both series have

ceramic cores which support the coiled heating element. A Cap with BX connectors can be supplied upon request.

E - TERMINAL BOX

G - PIPE THREAD

F - NUMBER OF TUBES

1”

C

B

D

A

RA or RB SERIES

HEATERS

The TRS and TS Series use a dielectric material to support the coiled heating elements and the heater tubes are pressed

to increase thermal conductivity. TRS Series heaters come standard with a 4” octagonal terminal box, a 2” pipe thread and

are supplied with two (2) hairpin, copper tubes, nominally 1/2” in diameter. TS Series heaters are standard with a 6” square

terminal box, a 2-1/2” pipe thread, and three (3) 1/2” diameter hairpin, copper tubes (designed for 240 and 480 volt, three

phase).

E - TERMINAL BOX

G - PIPE THREAD

F - NUMBER OF TUBES

C

J

A

D

TS or TRS SERIES

HEATERS

The SWF Series have a flanged head rated either

150# or 300#. In the 3” size, three (3) hairpin tubular heaters are silver soldered to the flange. In the

5” size, the number of tubular heaters is increased

to six (6), while in the 8” size the number in

increased to 18 heaters. All heaters come with a

standard type terminal box, large enough to accommodate the number of tubular elements mounted to

the flange.

B

H - NUMBER OF TUBES

G - NUMBER

OF HOLES

E

COLD LENGTH 3”

F - HOLE

DIA.

D

C

B

A

SWF SERIES

HEATERS

1-2004

-2-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

WATER IMMERSION

HEATERS

TABLE LEGEND:

A - OVERALL LENGTH

B - LENGTH TO PIPE BUSHING NUT

C - TUBE LENGTH

D - BUSHING HEAD NUT

E - TERMINAL BOX SIZE

F - NUMBER OF TUBES

G - PIPE THREAD SIZE

J - TERMINAL BOX HEIGHT

E - TERMINAL BOX

E - TERMINAL BOX

G - PIPE THREAD

G - PIPE THREAD

F - NUMBER OF TUBES

F - NUMBER OF TUBES

1”

C

C

B

D

J

A

B

A

D

RA or RB SERIES

HEATERS

TS or TRS SERIES

HEATERS

RA SERIES - 1" O.D. Tube - 1" Pipe Thread

WATTS

300

500

750

1000

1250

1500

Voltage*

120

240

Model Num ber

RA

RA

RA

RA

RA

RA

-

13

15

17

101

112

115

RA

RA

RA

RA

RA

RA

-

23

25

27

201

212

215

Dim ensions

W.P.S.I

17.4

28.4

28.0

37.5

34.6

33.0

A

10-3/4"

10-3/4"

13-3/4"

13-3/4"

16-3/4"

19-3/4"

B

7"

7"

10"

10"

13"

16"

BBBBBB-

C

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

D

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

E

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

F

1

1

1

1

1

1

G

1"

1"

1"

1"

1"

1"

J

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

11"

11"

14"

14"

17"

20"

20"

7"

7"

10"

10"

13"

16"

16"

BBBBBBB-

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

1

1

1

1

1

1

1

1-1/4"

1-1/4"

1-1/4"

1-1/4"

1-1/4"

1-1/4"

1-1/4"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/8"

1-1/8"

1-1/8"

1-1/8"

1-1/8"

1-1/8"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

2

2

2

2

2

2

2"

2"

2"

2"

2"

2"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

E

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

F

3

3

3

3

3

3

G

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

RB SERIES - 1¼" O.D. Tube - 1¼" Pipe Thread

500

750

1000

1250

1500

2000

2500

RB - 15

RB - 17

RB - 101

RB - 112

RA - 115

RA - 122

RA - 125

RB - 25

RB - 27

RB - 201

RB - 212

RA - 215

RA - 222

RA - 225

21.2

31.8

28.4

35.4

31.9

34.0

42.5

TRS SERIES - 2 Tubes - 2" Pipe Thread

2000

TRS - 1252

TRS - 2252

50.0

12"

2500

TRS - 1272

TRS - 2272

50.0

13"

3000

TRS - 1352

TRS - 2352

50.0

14"

4000

TRS - 1452

TRS - 2452

50.0

18"

5000

TRS - 2552

50.0

21"

6000

TRS - 2652

50.0

24"

*Single or Three Heat, w ithout sw itch, or Three Phase Open Delta.

10"

11"

12"

16"

19"

22"

BBBBBB-

TS SERIES - 3 Tubes - 2½" Pipe Thread

Voltage

WATTS

120

240

480

Model Num ber

3000

TS - 133

TS - 233

4000

TS - 143

TS - 243

5000

TS - 253

6000

TS - 263

7500

TS - 273

9000

TS - 293

*Single Phase or Three Phase Open Delta

1-2004

TS TS TS TS TS TS -

433

443

453

463

473

493

Dim ensions

W.P.S.I.

40

40

40

40

40

40

A

14-1/2"

17-1/2"

20-1/2"

23-1/2"

26-1/2"

29-1/2"

-3-

B

11"

14"

17"

20"

23"

26"

C

B - 1"

B - 1"

B - 1"

B - 1"

B - 1"

B - 1"

D

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

1-3/4"

J

2-1/8"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

WATER IMMERSION

HEATERS

TABLE LEGEND

A - OVERALL LENGTH

B - IMMERSED LENGTH

C - FLANGE THICKNESS

D - SPAN BETWEEN OPPOSING

FLANGE HOLES

E - TERMINAL BOX DIMENSIONS

F -FLANGE HOLE DIAMETER

G - NUMBER OF FLANGE HOLES

H - NUMBER OF TUBES

SWF SERIES - Standard-150# or 300# Pipe Flange

kW

240

Voltage*

480

550

W.P.S.I.

Model Num ber

3 Inch Standard Pipe Flange

SWF Series Other Dimensions

Dim ensions

A

B

6.0

7.5

9.0

12

15

18

SWF - 3060

SWF - 3075

SWF - 3090

SWF - 3012

-

SWF - 3060

SWF - 3060 42.5

SWF - 3075

SWF - 3075 43.0

SWF - 3090

SWF - 3090 47.5

SWF - 3012

SWF - 3012 45.5

SWF - 3015

SWF - 3015 43.3

SWF - 3018

SWF - 3018 42.5

5 Inch Standard Pipe Flange

25-1/2"

29"

32"

37-1/2"

46-1/2"

54-1/2"

19"

22-1/2"

25-1/2"

31"

40"

48"

24

30

SWF - 5024

-

SWF - 5024

SWF - 5024 40.0

SWF - 5030

SWF - 5030 39.0

8 Inch Standard Pipe Flange

36"

42-1/2"

29-1/2"

36"

32-1/2"

42-1/2"

48-1/2"

25-1/2"

35-1/2"

41-1/2"

50

SWF - 8050

SWF - 8050

75

SWF - 8075

SWF - 8075

100

* Three Phase Open Delta

SWF - 8050

SWF - 8075

SWF - 8100

46.5

39.5

44.0

C

D

E

F

G

H

3"

150 # 300 #

FLANGE SIZE

5"

150 # 300 #

15/16" 1-1/8"

6"

6-5/8"

7-1/2" 8-1/4"

3/4"

7/8"

4

8

3

3

15/16"

8-1/2"

10"

7/8"

8

6

8"

150 #

300 #

1-3/8" 1-1/8" 1-5/8"

9-1/4" 11-3/4"

13"

11" 13-1/2"

15"

7/8"

7/8"

1"

8

8

12

6

18

18

SWF SERIES

HEATERS

H - NUMBER OF TUBES

G - NUMBER

OF HOLES

E

COLD LENGTH 3”

F - HOLE

DIA.

C

D

B

A

SELECTING THE APPROPRIATE HEATER

HEATER

CASING

WATTAGE

Watts Density

(W.P.S.I.)

Rinse Tank, using w ater and

solutions that w ill not attack

copper

As Rated

40/50

Steel

Alkali --- Cleaning Tanks --Okite, etc. or liquids that w ill

not attack steel

As Rated

Steel or

Stainless

Steel

Pitch

Asphalt

Grease

Steel or

Stainless

Steel

Wax

Paraffin

Vegetable Oils

Stainless

Steel

Electro-plating solutions.

Copper

1-2004

MATERIAL TO BE HEATED

{

{

40/50

Use Stainless if Derate Standard

any free acids

heater 75%

are present

10/12

Use Stainless if Derate Standard

any free acids

heater 75%

are present

20/22

As Rated

40/50

-4-

S P E C I A L F E AT U R E S

AND OPTIONS

RA-RB-TRS-TS SERIESS t a i n l e s s S t e e l H e a d & Tu b i n g .

Explosion Proof Heads.

S p e c i a l Wa t t a g e s & Vo l t a g e s .

SWF SERIESE x p l o s i o n P r o o f o r Va p o r R e s i s t a n t

Te r m i n a l E n c l o s u r e s .

S p e c i a l H i g h Te m p e r a t u r e & P r e s s u r e

Gasket.

S p e c i a l Wa t t a g e s & Vo l t a g e s

Special Alloy Flange or Sheath.

Bulletin - 90

OIL IMMERSION &

FINTUBE HEATERS

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

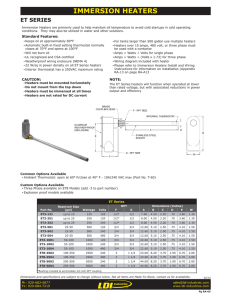

TRENT Oil Immersion Heaters are designed to give years of trouble-free service when the tubes are completely covered

with fluid, used on correct voltage and kept free of carbonization. These heaters listed as having watt densities (W.P.S.I.)

of 16-22 are designed for use with heat transfer oil and have a maximum operating temperature of 550° F. Those heaters

having lower W.P.S.I. are designed for use with Bunker C fuel oil preheaters and line and suction heaters with a maximum

operating temperature of 250° F.

CONSTRUCTION:

TYPICAL USES

FOR OIL PREHEATING,

OIL BATHS,

OTHER HEAT

TRANSFER FLUIDS,

SOME GASES.

All TRENT Oil Immersion Heaters are constructed with steel heads and tubing.

The TRO, TSO and TSOL Series use a dialectric material to support the coiled

heating elements and the heater tube is pressed to increase thermal conductivity. FO Series Fintube Heaters include coiled resistance heating elements that

are inserted in refractories. Powered refractory is used to fill intervening spaces

to readily transmit heat to the aluminum, finned, tubular casing.

The TRO Series have two (2) tubular heater tubes and come standard with a 4”

octagonal outlet box, a 2” pipe thread, and can be supplied for single heat, three

heat, or three phase open delta.

The TSO and TSOL Series have three (3) ½” diameter tubular heating

elements, a steel head with a 2½” pipe thread, and come standard with a

6” square terminal box. These heaters can be supplied for three phase

240, 480, or 550 volts.

TRO,TSO or TSOL

The FO Series heaters have a 7½” O.D. - 150# or 300# aluminum flange,

HEATERS

to which a longitudinal, finned, aluminum tubing is welded. The longintudinal fins increase the surface area, thus lowering the watts per square inch (W.P.S.I.), and enabling a higher KW to be

used in a shorter length. Heaters are supplied complete with a 6” square outlet box. Heaters are available in three phase

240, 480 and 550 volts with optional vapor resistant or explosion proof terminal boxes. Other flange sizes are also available.

Companion pipe assemblies are available as an optional feature for some models immersion heaters

FO HEATER with explosion

proof terminal box

SEE NEXT TWO PAGES FOR TABLES OF STANDARD SIZES AND SPECIFICATIONS

1-2004

-5-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

OIL IMMERSION

HEATERS

STANDARD SIZES AND SPECIFICATIONS

TABLE LEGEND

A - OVERALL LENGTH

B - LENGTH TO PIPE BUSHING HEX NUT

C - TUBE LENGTH

D - PIPE BUSHING HEX NUT

E - TERMINAL BOX SIZE

F - NUMBER OF TUBES

G - NPT SIZE

L - COMPANION PIPE ASSEMBLY LENGTH

J - CENTER SPREAD OF COMPANION PIPE OUTLETS

CONSTRUCTION:

All TRENT Oil Immersion Heaters are constructed with steel heads and

tubing. The TRO, TSO and TSOL Series use a dialectric material to support the coiled heating elements and the heater tube is pressed to increase

thermal conductivity.

COMPANION PIPE ASSEMBLIES

TRO,TSO or TSOL HEATERS

(STEEL ONLY)

E - TERMINAL BOX

L

G - PIPE THREAD

F - NUMBER OF TUBES

2-½”

C

2-1/8”

J

B

A

D

TRO Series - 2 Tubes

1-½”

22 W.P.S.I. 150 lbs Pressure

Voltage*

kW

120

1

1.5

2

2.5

3

4

5

6

TRO 1101

TRO 1151

TRO 1201

TRO 1251

TRO 1301

TRO 1401

TRO 1501

TRO 1601

240

550

Model Num ber

TSO Series - 3 Tubes

3

4

5

6

7.5

9

TSO 2303

TSO 2403

TSO 2503

TSO 2603

TSO 2753

TSO 2903

TSOL 2303

TSOL 2403

TSOL 2503

TSOL 2603

TSOL 2753

TSOL 2903

B

11"

14"

17"

21"

23"

32"

39"

46"

Dim ensions

C

1-1/16"

1-1/16"

1-1/16"

1-1/16"

1-1/16"

1-1/16"

1-1/16"

1-1/16"

D

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

E

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

4" OCT.

F

2

2

2

2

2

2

2

2

G

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

2" NPT

Catalog No.

L

J

BBBBBBBB-

BBBBBB-

1-3/16"

1-3/16"

1-3/16"

1-3/16"

1-3/16"

1-3/16"

3"

3"

3"

3"

3"

3"

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

3

3

3

3

3

3

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

P-9500

P-9502

P-9504

P-9506

P-9508

P-9510

21"

25"

31"

37"

45"

53"

14"

18"

24"

30"

38"

46"

3"

3"

3"

3"

3"

3"

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

6" SQ.

3

3

3

3

3

3

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

2-1/2" NPT

P-9500-L

P-9502-L

P-9504-L

P-9506-L

P-9508-L

P-9510-L

25"

31"

39"

45"

56"

65"

18"

24-1/2"

32"

38"

49"

58"

22 W.P.S.I. 150 lbs Pressure

TSO 4303

TSO 4403

TSO 4503

TSO 4603

TSO 4753

TSO 4903

TSOL Series - 3 Tubes

3

4

5

6

7.5

9

A

13"

16"

19"

23"

25"

34"

41"

48"

TRO 2101

TRO 2151

TRO 2201

TRO 2251

TRO 2301

TRO 2401

TRO 2501

TRO 2601

Com panion Pipe Assem blies

Dim ensions

TSO 5303

TSO 5403

TSO 5503

TSO 5603

TSO 5753

TSO 5903

20"

24"

30"

36"

44"

52"

17"

21"

27"

33"

41"

49"

16/17 W.P.S.I. 150 lbs Pressure

TSOL 4303

TSOL 4403

TSOL 4503

TSOL 4603

TSOL 4753

TSOL 4903

TSOL 5303

TSOL 5403

TSOL 5503

TSOL 5603

TSOL 5753

TSOL 5903

24"

30"

38"

44"

55"

64"

21"

27"

35"

41"

52"

61"

BBBBBB-

1-3/16"

1-3/16"

1-3/16"

1-3/16"

1-3/16"

1-3/16"

*Single Phase or 3- Phase Open Delta on TRO Series; 3-Phase Open Delta on TSO and TSOL Series.

1-2004

-6-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@aol.com

FINTUBE HEATERS

TABLE LEGEND

A - TUBE LENGTH (excluding terminal box)

B - IMMERSED LENGTH

C - FIN LENGTH

L - COMPANION PIPE ASSEMBLY LENGTH

J - CENTER SPREAD OF COMPANION PIPE OUTLETS

CONSTRUCTION:

TRENT FO Series Fintube Heaters include coiled resistance heating elements that are inserted in ceramic cores.

Powered refractory is used to fill intervening spaces to readily transmit heat to the aluminum, finned, tubular casing.

Overall size varies with type of terminal box selected. Steel

tubes are also available.

FO HEATER with explosion

proof terminal box

These heaters are designed as fuel oil pre-heaters, or line

and suction heaters, and are rated 250°F. Heaters for Heat Transfer Oil Circulation applications which require higher

W.P.S.I. are also available with a maximum temperature rating of 550°F.

ALUMINUM FINTUBE

7½” - 150 LB. FLANGE

COMPANION PIPE ASSEMBLIES

(STEEL ONLY)

THERMOCOUPLE

PORT

1/2” NPT

2” O.D.

2-7/8” O.D.

3” O.D.

DRAIN

PORT

1/2” NPT

C (FIN LENGTH)

J

15/16”

B

6” x 6” x 3”

TERMINAL BOX

2”

A

L

FO Series (Fintube) - 7½" O.D. Aluminum Flange 150 or 300 Lb. Pressure**

Voltage*

kW

240

480

550

W.P.S.I.

Model Num ber

4

6

7.5

9

12

16

FO 2403

FO 2603

FO 2753

FO 2903

FO 2123

FO 2163

*Three Phase Open Delta.

FO 4403

FO 4603

FO 4753

FO 4903

FO 4123

FO 4163

FO 5403

FO 5603

FO 5753

FO 5903

FO 5123

FO 5163

^Steel Only.

5.95

7.15

7.45

6.70

7.14

7.48

Com panion Pipe Assem blies^

Dim ensions

A

34"

40"

44-½"

58"

69-½"

80-½"

B

30-¼"

36-¼"

42-¼"

54-¼"

66-¼"

78-¼"

Dim ensions

C

25"

31"

37"

49"

61"

73"

Catalog No.

P-602

P-752

P-902

P-1202

P-1602

P-1702

L

35"

41"

47"

59"

71"

83"

J

27-½"

33-½"

39-½"

51-½"

63-½"

75-½"

**Pressure Rating ( 150# or 300#) must be specified.

S P E C I A L F E AT U R E S A N D O P T I O N S *

S t a i n l e s s S t e e l H e a t e r s Av a i l a b l e i n T R O , T S O a n d T S O L M o d e l s

E x p l o s i o n P r o o f & Va p o r R e s i s t a n t Te r m i n a l E n c l o s u r e s O p t i o n a l .

S p e c i a l Wa t t a g e s & Vo l t a g e s .

C o m p a n i o n P i p e A s s e m b l i e s Av a i l a b l e i n S o m e M o d e l s .

*Consult Factory

1-2004

-7-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

STRIP HEATERS

TRENT Strip Heaters are a general utility heating unit concentrating the heat where required.

These heaters are

designed for standard and special process machines, ovens, dryers, kettles and plastic process equipment.

CONSTRUCTION:

TRENT Strip Heaters are manufactured with steel or stainless tubes without grooves to alleviate distortion when under

heat. The ends are pressed tight and sealed, rendering the entire casing moisture resistant.

Terminals assemblies consist of high grade ceramic blocks with substantial bolts securely locked in position in all types

except the L Series. The L Series heaters have stainless steel terminal block with mica insulation. (See illustration below).

Steel Strip Heaters

Stainless Steel Strip Heaters

TYPE L - Strip Heaters

750°F Maximum Safe Surface Temperature

Voltage

Length

Watts

8"

12

18

24

24

30

36

42

48

55

65

72

150

250

350

250

500

750

1000

1200

1300

1500

1700

2000

120

240

Model Num ber

L - 4811

L - 4112

L - 4122

L - 4113

L - 4123

L - 4212

L - 4222

L - 4215

L - 4225

L - 4313

L - 4323

L - 4311

L - 4321

L - 4411

L - 4421

L - 4413

L - 4423

L - 4511

L - 4521

L - 4611

L - 4621

L - 4722

Watts

Density

(W.P.S.I.)*

16

11

9

4

8

10

10

10

10

10

9

10

1/2

1/2

1-5/16

5/16

1/2

1-9/16

7/8

2-3/4

10-32 THREAD

7/16

1”

9/32

TYPE LE - Strip Heaters

750°F Maximum Safe Surface Temperature

Length

Watts

8"

12

18

24

24

30

36

42

48

55

65

72

150

250

350

250

500

750

1000

1200

1300

1500

1700

2000

Voltage

120

240

Model Num ber

LE - 7811

LE - 7821

LE - 7112

LE - 7122

LE - 7113

LE - 7123

LE - 7212

LE - 7222

LE - 7215

LE - 7225

LE - 7317

LE - 7327

LE - 7311

LE - 7321

LE - 7411

LE - 7421

LE - 7413

LE - 7423

LE - 7511

LE - 7521

LE - 7611

LE - 7621

LE - 7722

Watts

Density

(W.P.S.I)*

16

11

9

4

8

10

10

10

10

10

9

10

1/2

1-5/16

5/16

1-7/8

1/4-20 THREAD

CERAMIC TERMINAL BLOCK

7/16

1”

9/32

* Watts Per Square Inch

OVENS, DRYERS, KETTLES,

PLASTICS PROCESS EQUIPMENT,

etc.

USED IN:

1-2004

1/2

1-1/2

-8-

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

STRIP HEATERS

TYPE H - Strip Heaters

TYPE HE - Strip Heaters

304 Stainless Steel Sheath

1300°F Maximum Safe Surface Temperature

Length

Watts

8"

12

18

21

24

24

24

30

36

42

48

54

60

66

72

200

350

500

500

500

750

1000

1000

1500

1500

1750

1900

2100

2400

2600

Voltage

120

240

Model Num ber

H - 5821

H - 5135

H - 5136

H - 5116

H - 5126

H - 5215

H - 5225

H - 5216

H - 5226

H - 5217

H - 5227

H - 5211

H - 5221

H - 5310

H - 5320

H - 5311

H - 5321

H - 5411

H - 5421

H - 5413

H - 5423

H - 5452

H - 5612

H - 5622

H - 5722

304 Stainless Steel Sheath

1300°F Maximum Safe Surface Temperature

Watts

Density

(W.P.S.I)*

21

16

12

10

8

13

17

13

15

13

13

12

12

13

13

1/2

Length

Watts

8"

12

18

21

24

24

24

30

36

42

48

54

60

66

72

200

350

500

500

500

750

1000

1000

1500

1500

1750

1900

2100

2400

2600

Voltage

120

240

Model Num ber

HE - 8821

HE - 8135

HE - 8136

HE - 8116

HE - 8126

HE - 8215

HE - 8225

HE - 8216

HE - 8226

HE - 8217

HE - 8227

HE - 8211

HE - 8221

HE - 8310

HE - 8320

HE - 8311

HE - 8321

HE - 8411

HE - 8421

HE - 8413

HE - 8423

HE - 8452

HE - 8612

HE - 8622

HE - 8722

Watts

Density

(W.P.S.I)*

21

16

12

10

8

13

17

13

15

13

13

12

12

13

13

1/2

1/2

1-11/32

5/16

1-11/32

5/16

1/2

1-9/16

1/2

1-1/2

7/8

1-7/8

1/4-20 THREAD

2-3/4

1/4-20 THREAD

CERAMIC TERMINAL BLOCK

CERAMIC TERMINAL BLOCK

7/16

7/16

9/32

1”

9/32

1”

TYPE LW - Strip Heaters

TYPE HW - Strip Heaters

750°F Maximum Safe Surface Temperature

1300°F Maximum Safe Surface Temperature

Length

Watts

5 1/2"

8

12

18

24

24

30

36

125

175

250

350

500

500

750

1000

*

atts perPer

squar

e inch

*WWatts

Square

Voltage

120

240

Model Num ber

LW LW LW LW LW LW LW LW -

2511

2811

2112

2131

2136

2118

2318

2311

LW LW LW LW LW LW LW -

2821

2122

2132

2137

2128

2328

2321

Watts

Density

(W.P.S.I.)*

23

14

10

8

10

8

10

10

Length

Watts

5 1/2"

8

12

18

24

24

30

36

250

400

350

500

750

750

1250

1500

Voltage

120

240

Model Num ber

HW - 3511

HW - 3814

HW - 3824

HW - 3817

HW - 3827

HW - 3116

HW - 3126

HW - 3217

HW - 3227

HW - 3231

HW - 3232

HW - 3321

HW - 3322

HW - 3316

HW - 3326

Watts

Density

(W.P.S.I.)*

46

32

14

11

14

10

15

15

Inch

1/2

480 VOLT STRIP HEATERS

1-11/32

5/16

TRENT Strip Heaters are available for direct 480 Volt line

service operation. Types of L, LE, H and HE series

heaters may be ordered at 480 Volt rating at additional

charge.

1/2

1-7/8

8-32 THREAD

CERAMIC TERMINAL BLOCK

7/16

NOTE: Types LW and HW Series Heaters are specifically

not available for 480 Volt ratings.

1-2004

9/32

1”

-9-

Bulletin - 90

CARTRIDGE HEATERS

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

Cartridge Type Heaters are general utility heating units that enable the concentration of heat where required. These

heaters are designed for standard and special process machines, platens, glue and compound vessels, heating of valves,

pipe lines, plastic forming dies, cigarette and shoe machinery.

CONSTRUCTION:

TRENT Cartridge Heaters are manufactured with brass or steel sheath with end opposite terminals spun in to make a

moisture-resistant heater. Silver soldered moisture proof ends are also available. A heavy duty nickel chromium coil provides the heat and is inserted into a pre-formed ceramic insulator with coils running parallel to the length of the heater.

Terminals are securely anchored in the top of the heater and can be supplied in various styles to meet specific applications (See illustration below).

Fig. A - Pigtails covered

by glass sleeving or

porcelain beads, available in all sizes.

Fig. B - Angle Type Brass using

6/32” screw. (Available on 5/8”

to 3/4” diameter sizes.)

SHEATHED CARTRIDGE HEATERS

Standard sheath is brass or carbon steel, but are also

available in stainless steel on all sizes. Wattages other

than those listed in the

specifications tables on

the following page are

also available. Check

with factory for special

applications.

When the heaters are

mounted in moving

machinery, the pigtail

leads must be securely

fastened to avoid rupturing where they enter the

heater.

Sheathed Cartridge Heaters

Cartridge Heaters are

designed to be used either in direct contact with the

object or material to be heated, or inserted snuggly into

a metal block to conduct the heat from heater and to

prevent overheating. All TRENT cartridge Heaters are

.003” undersize in diameter, except those with a stainless steel sheath which can be up to .015” undersize.

When drilling the hole for a cartridge heater in a block,

the customer should drill a pilot hole completely through

the block and then drill or ream the hole to the exact size

of heater listed.

1-2004

Fig. C - Spade Type Brass using

10/32” screw.

(Available on

15/16” and larger diameter sizes.)

SHEATHLESS CARTRIDGE HEATERS

Sheathless cartridge heaters are used in many applications. This heater has the advantage of faster heat conduction, as no metallic sheath is present to act as a heat

shield. The

lack of a sheath

also eliminates

sheath deterioration and permits operating

temperatures

beyond the limits of sheathed

Sheathless Cartridge Heaters

heaters.

Construction is very simple since the heater is no more

than a ceramic core containing heating element with a

cement seal at the top and bottom. Leads are restricted

to pigtail type (Fig. A above).

Since these heaters are ceramic extrusions, the sizes are

nominal and diameters may vary slightly.

These heaters should not be used in the presence of

liquids as the cores are porous.

To install, drill a hole as close to the heater diameter size

as possible, and pack any void with zircon heat transfer

material.

- 10 -

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

CARTRIDGE HEATERS

The following tables include our standard models. Contact TRENT for other configurations:

Standard Specifications - Steel or Brass Sheath Cartridge Heaters

Model #

K-6

K-8

K-10

K-11

K-20

K-21

K-22

K-23

K-25

K-29

K-30

K-31

K-32

K-33

K-34

K-39

K-300

K-302

K-322

K-303

K-333

K-306

K-326

K-336

K-308

K-318

K-319

K-309

K-320

K-310

K-311

K-312

K-314

K-315

Length

Volts

Diameter 3/8"

1-1/2"

120

1-1/2"

120

2-1/2"

120

2-1/2"

120

Diameter-1/2"

2-1/2"

120 or 240

2-1/2"

120 or 240

2-1/2"

120 or 240

2-1/2"

120 or 240

6"

120 or 240

6"

120 or 240

Diameter 5/8"

2-1/2"

120 or 240

2-1/2"

120 or 240

2-1/2"

120 or 240

2-1/2"

120 or 240

2-1/2"

120 or 240

4"

120 or 240

4"

120 or 240

4-1/2"

120 or 240

4-1/2"

120 or 240

5"

120 or 240

5"

120 or 240

6"

120 or 240

6"

120 or 240

6"

120 or 240

7"

120 or 240

7"

120 or 240

9"

120 or 240

9"

120 or 240

10"

120 or 240

10"

120 or 240

13"

120 or 240

15"

120 or 240

17"

120 or 240

18"

120 or 240

Watts

30

50

50

75

60

75

100

120

150

200

75

90

100

130

150

150

240

150

250

150

300

100

175

350

200

375

300

450

400

500

600

600

600

600

Model #

K-51

K-51

K-51

K-52

K-531

K-53

K-560

K-56

K-58

K-59

K-503

K-504

K-505

K-506

Length

Volts

Diameter 3/4"

2-1/2"

120 or

2-1/2"

120 or

3-1/2"

120 or

3-1/2"

120 or

5"

120 or

5"

120 or

8"

120 or

8"

120 or

10"

120 or

12"

120 or

15"

120 or

16-1/2"

120 or

18"

120 or

22"

120 or

Watts

240

240

240

240

240

240

240

240

240

240

240

240

240

240

100

200

150

250

250

350

350

450

550

600

750

800

900

1000

Custom sizes in special diameters,

lengths, w attages, voltages and sheath

materials are available --- contact

factory.

K-71

K-741

K-74

K-77

K-79

K-791

K-700

K-702

K-704

K-707

K-717

K-709

K-711

K-712

Diameter 15/16"

2-1/2"

120 or 240

3-1/2"

120 or 240

3-1/2"

120 or 240

5"

120 or 240

5"

120 or 240

5"

120 or 240

5"

120 or 240

6"

120 or 240

8"

120 or 240

12"

120 or 240

12"

120 or 240

14"

120 or 240

17"

120 or 240

18-1/2"

120 or 240

275

100

325

100

140

300

450

600

700

425

800

900

1000

1100

Model #

K-820

K-82

K-840

K-84

K-850

K-85

K-86

K-87

K-89

K-800

K-801

K-803

K-93

K-94

K-95

K-96

K-97

K-98

K-99

K-901

K-903

K-010

K-111

K-014

K-115

K-017

K-019

K-020

-

Length

Volts

Diameter 1"

3-1/2"

120 or 240

3-1/2"

120 or 240

5"

120 or 240

5"

120 or 240

6-1/2"

120 or 240

6-1/2"

120 or 240

8"

120 or 240

9 3/4"

120 or 240

12-1/2"

120 or 240

14"

120 or 240

15-1/2"

120 or 240

18-1/2"

120 or 240

Diameter 1-1/4"

3-1/2"

120 or 240

5"

120 or 240

6-1/2"

120 or 240

8"

120 or 240

9-1/4"

120 or 240

10-1/2"

120 or 240

12"

120 or 240

15"

120 or 240

18"

120 or 240

Diameter 1-5/16"

2-1/2"

120 or 240

5"

120 or 240

6"

120 or 240

7"

120 or 240

8"

120 or 240

10"

120 or 240

12"

120 or 240

-

Watts

100

300

250

375

300

500

500

700

800

850

1000

1300

230

325

450

650

700

775

875

1100

1400

200

300

550

750

800

900

1000

-

Sheathed Cartridge

Heaters

TYPICAL

USES

FOR HEATING

Dies, Molds,

Platens,

Sealing

Devices,

Defrosting,

Resistors

*550 volt heaters can be supplied on special factory order.

Standard Specifications - Sheathless Cartridge Heaters

Model #

S-10

S-11

S-12

S-20

S-21

S-22

S-23

S-24

S-30

S-31

S-32

S-33

S-40

S-41

S-42

S-43

S-50

S-51

S-52

S-53

1-2004

Length

Volts

Diameter 5/16"

1-1/2"

120

2"

120

2"

120

Diameter 7/16"

1-1/2"

120 or 240

2"

120 or 240

2"

120 or 240

2'

120 or 240

2"

120 or 240

Diameter 9/16"

1-1/2"

120 or 240

2"

120 or 240

2"

120 or 240

2"

120 or 240

Diameter 11/16"

1-1/2"

120 or 240

2"

120 or 240

2"

120 or 240

2"

120 or 240

Diameter 3/4"

1-1/2"

120 or 240

2"

120 or 240

2"

120 or 240

2"

120 or 240

Watts

30

50

75

50

60

75

100

130

75

100

150

200

75

100

150

200

75

100

150

200

Model #

S-60

S-61

S-62

S-63

S-64

S-65

S-66

S-67

S-68

S-70

S-71

S-72

S-73

S-74

S-75

S-76

S-77

S-78

S-79

S-700

S-701

S-702

-

Length

Volts

Watts

Diameter 29/32"

2'

120 or 240

2-1/2"

120 or 240

3'

120 or 240

3-1/2"

120 or 240

4"

120 or 240

4-1/2"

120 or 240

5"

120 or 240

5-1/2"

120 or 240

6"

120 or 240

Diameter 1-5/32"

3"

120 or 240

3-1/2"

120 or 240

4"

120 or 240

4-1/2"

120 or 240

5"

120 or 240

5-1/2"

120 or 240

6"

120 or 240

6-1/2"

120 or 240

7"

120 or 240

7-1/2"

120 or 240

8"

120 or 240

8-1/2"

120 or 240

9"

120 or 240

-

150

275

300

325

350

400

450

525

600

200

230

250

275

325

375

425

450

500

575

650

675

700

-

- 11 -

Sheathless Cartridge Heaters

SPECIAL FEATURES and OPTIONS*

Silver solder end opposite terminals.

Ceramic beads over bare pigtail wire.

String tie pigtail leads 3/4” above heater seal.

3/4” long protective spring over pigtail leads

above heater seal.

Moisture resistant conduit to contain pigtail

leads.

*CONSULT FACTORY.

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

TUBULAR

HEATERS

CONSTRUCTION:

TRENT Tubular Heaters, or “D” rods, may be used in straight lengths or formed to any required shape. Equipped with threaded fittings, these heaters are ready for installation and use as immersion heaters with oil, water, and corrosive liquids in tanks, kettles, baths,

pots or vessels of any kind. In straight lengths they are readily mounted, and do not require

special machining for installation on platens, dies and extruders for conductive heating. They

are also recommended in ovens with low temperature ranges requiring convection or radiant

Tubular Type heating.

Heaters

TRENT Tubular Heaters are manufactured with a copper, steel or 304 stainless steel sheath. Type of metal used in the sheath and

watts per square inch (W.P.S.I.) are determined by operating conditions. Inside the sheath is a helically coiled, nickel chromium, resistance wire heater coil that is embedded

in magnesium oxide insulating material.

RE

The cross section design of the metal

sheath assures maximum strength and

R

R

RE

RE

rigidity. The tubular design also permits

RE

ready bending and forming to fit a wide

range of applications, without damage

D

to the heating coil or insulation material.

R

ELECTRICAL

RESISTANCE COIL

TERMINAL

PIN

INSULATING

MEDIUM

BENDING RADIUS KEY

R - (Inside Radius)

RE - Edge Bend (Inside Radius)

D - (Inside Diameter)

Customer Minimum Bending

Radius

METAL

SHEATH

Steel &

Stainless

Copper

Steel

Dimensions

1/2"

2"

6"

3/4"

2-1/2"

7"

3-1/2"

4"

ALL DIMENSIONS ARE MINIMUM.

Tubular Heater Terminals are available in three configurations, as shown below, at the buyer’s option. The terminals depicted in Figure

A and Figure B, are brass, with copper and steel sheath elements and stainless steel for alloy sheath elements. Figure C configuration is

an optional threaded fitting which can be supplied at extra charge.

FIG. A

MICA WASHERS OR

RUBBER GROMMET

FIG. B

MICA WASHERS

METAL WASHER

COMPOSITION

WASHER

FIG. C

8-32 THREAD

TYPICAL USES

Heating Liquid in Tanks,

Kettles, Baths, etc.

Heaters for Ovens, Platens,

Dies, Extruders

SEE NEXT PAGE

FOR TABLES OF STANDARD

SIZES AND SPECIFICATIONS

1-2004

10-32 SCREW

FIG. A TYPE

GENERAL INFORMATION

- TRENT Tubular Heaters are available in one standard size, nominally 1/2” O.D.

- Standard sheath materials are copper, steel and alloy.

- Heaters are designed with a minimal sheath length of 12 inches and a

maximum length of 200 inches.

- Heaters are standard with 4” of cold tube length on each end; additional length

of cold end may be added. Consult factory.

- Special lengths and wattages are available. Consult factory.

- Lengths listed are tube lengths; overall length of any heater may be obtained by

adding combined terminal lengths to tube lenghts.

- 12 -

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

TUBULAR

HEATERS

TRENT TUBULAR OR “D” ROD HEATERS -

The following tables provide specifications of our standard models. Call TRENT for other configurations to meet your

requirements:

TUBE LENGTH

L

H

HEATED LENGTH

L minus 8”

COLD LENGTH 4”

COLD LENGTH 4”

3/8”

ROUND CROSS SECTION

D-SHAPED CROSS SECTION

ROUND CROSS SECTION

19/32”

TUBULAR Heaters

Standard Specifications - 1/2" Nominal O.D.

COPPER

50 WATTS PER SQUARE INCH

Maximum Sheath 350°F

Model #

5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU 5CU -

16

18

22

28

32

36

40

44

48

54

60

72

78

84

90

96

102

108

120

VOLTS

120

120

120

240

240

240

240

240

240

240

240

480

480

480

480

480

480

480

480

WATTS

675

800

1200

1500

1800

2100

2200

2400

2800

3000

3500

4100

4500

5000

5250

5600

6000

7000

7600

STEEL

20 WATTS PER SQUARE INCH

Maximum Sheath 750°F

Model #

5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE 5FE -

16

18

22

28

32

36

40

44

48

54

60

72

78

84

90

96

102

108

120

132

144

156

168

180

192

204

VOLTS

WATTS

120

120

120

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

240 or 480

240 or 480

240 or 480

240 or 480

240 or 480

240 or 480

240 or 480

240 or 480

480

480

480

480

480

480

480

300

350

500

750

800

900

1000

1200

1350

1500

1750

2050

2250

2450

2600

2800

3050

3500

3750

4000

4300

4700

5100

5500

5900

6300

304 STAINLESS STEEL

30 WATTS PER SQUARE INCH

Maximum Sheath 1350°F

Model #

5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR 5CR -

16

18

22

28

32

36

40

44

48

54

60

72

78

84

90

96

102

108

120

132

144

156

168

180

192

204

TUBE

LENGTH

VOLTS

WATTS

L

120

120

120

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

120 or 240

240

240

240 or 480

240 or 480

240 or 480

240 or 480

240 or 480

480

480

480

480

480

480

480

480

480

480

450

540

750

1000

1200

1350

1500

1725

1875

2000

2500

3000

3250

3500

3625

3750

4250

4500

5000

5300

5800

6250

6650

6850

7200

7400

12

14

18

24

28

32

36

40

44

50

56

68

74

80

86

92

98

104

116

128

140

152

164

176

188

200

*550 volt heaters can be supplied on special factory order.

1-2004

- 13 -

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

HOT PLATES

TRENT Hot Plates are heavy duty construction designed for industrial use in both production shops and laboratories.

Typical applications include heating pans and vessels, dehydrating and evaporating, heat treating materials, where applicable, sealing, and many others.

CONSTRUCTION

Each Hot Plate includes a removable 1/4” steel plate work surface, supported by a fabricated, 16- gauge carbon steel casing, which encloses the insulation and heating elements.

.

The heating source is a TRENT Folded and Formed® heater rack which radiates heat to the underside of the work surface. This low watts density heat source produces exceptionally long life and virtually precludes maintenance.

TRENT Hot Plates come with a standard automatic thermostatic control which operates in the range of 0° to 600°F.

HP SERIES - HOT PLATES

STANDARD SIZES AVAILABLE

600°F Maximum Temperature

TYPICAL USES

INCLUDE

Heating Pans

and Vessels,

Dehydrating,

Evaporating,

Heat Treating,

Sealing,

Etc.

Model #

kW

Voltage*

Single Phase

HP-14

HP-24

HP-26

HP-36

HP-46

1.5

3

6

6

6

120

240

240

240

240 or 480

*Not Dual Voltage.

TRENT Hot Plate without cover

12-2003

Overall Size

Work Space

Width Length Height

15"

15"

24"

18"

18"

19"

28"

30"

40"

46"

5"

5"

5"

5"

5"

Width

Length

15"

15"

24"

18"

18"

15"

24"

26"

36"

42"

** Contactor required for 480 Volt Units.

TRENT Hot Plate with cover

- 14 -

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

CERAMIC RING

HEATERS

TRENT Ceramic Ring Heaters have an infinite number of uses, as long as they are operated in a moisture-free environment. These heaters are are commonly used as heating elements for hot plates, glue pots, molds, circular tanks, and coffee urns, among others.

The heat source for TRENT Ceramic Ring Units is a coiled, wire, resistance, heating element that is mounted in a grooved

ceramic plate and embedded in cement to increase the heat transfer characteristics. Maximum operating surface temperatures range from 500° F to 1800°F, depending on how much heat is dissipated.

All sizes are supplied in single heat. Some sizes are available with low, medium and high temperature heat settings.

Electrical terminations are either pigtail or stud type.

RU SERIES - Ceramic Ring Heaters

550 - 1800°F Maximum Operating Surface Temperature

dependent on heat take-away

Model

Ceramic Ring Heater

with Pigtail Leads.

RU-3180-200

RU-3180-250

RU-3180-275

RU-3180-300

RU-3180-350

RU-3180-375

RU-3180-400

RU-3180-500

RU-2341-550

RU-2341-750

RU-2341-900

RU-2608-500

RU-2608-1000

Dim ensions

Diam eter

4"

4"

4"

4"

4"

4"

4"

4"

5-3/4"

5-3/4"

5-3/4"

7-1/2"

7-1/2"

Thickness

3/8"

3/8"

3/8"

3/8"

3/8"

3/8"

3/8"

3/8"

3/4"

3/4"

3/4"

7/8"

7/8"

Watts

Voltage*

200

250

275

300

350

375

400

500

550

750

900

500

1000

120

120

230

120

120

120 or 240

120 or 240

120 or 240

120

120

120

120 or 240

120

* Not Dual Voltage

TYPICAL USED AS

HEATING ELEMENTS

FOR

Hot Plates,

Glue Pots,

Molds,

Circular Tanks,

Coffee Urns,

Etc.

1-2004

- 15 -

Bulletin - 90

201 Leverington Avenue

Philadelphia, PA 19127

Phone: 215.482.5000

Fax:

215.482.9389

Website: www.trentheat.com

E-mail:

trentheat@ aol.com

TEMPERATURE

CONVERSION TABLE

0 to 100°

°C

-17.8

-17.2

-16.7

-16.1

-15.6

-15.0

-14.4

-13.9

-13.3

-12.8

-12.2

-11.7

-11.1

-10.6

-10.0

-9.44

-8.89

-8.33

-7.78

-7.22

-6.67

-6.11

-5.56

-5.00

-4.44

-3.89

-3.33

-2.78

-2.22

-1.67

-1.11

-0.56

0.00

0.56

1.11

1.67

2.22

2.78

3.33

3.89

4.44

5.00

5.56

6.11

6.67

7.22

7.78

8.33

8.89

9.44

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

°F

32.0

33.8

35.6

37.4

39.2

41.0

42.8

44.6

46.4

48.2

50.0

51.8

53.6

55.4

57.2

59.0

60.8

62.6

64.4

66.2

68.0

69.8

71.6

73.4

75.2

77.0

78.8

80.6

82.4

84.2

86.0

87.8

89.6

91.4

93.2

95.0

96.8

98.6

100.4

102.2

104.0

105.8

107.6

109.4

111.2

113.0

114.8

116.6

118.4

120.2

100 to 1000°

C

10.0

10.6

11.1

11.7

12.2

12.8

13.3

13.9

14.4

15.0

15.6

16.1

16.7

17.2

17.8

18.3

18.9

19.4

20.0

20.6

21.1

21.7

22.2

22.8

23.3

23.9

24.4

25.0

25.6

26.1

26.7

27.2

27.8

28.3

28.9

29.4

30.0

30.6

31.1

31.7

32.2

32.8

33.3

33.9

34.4

35.0

35.6

36.1

36.7

37.2

37.8

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

F

122.0

123.8

125.6

127.4

129.2

131.0

132.8

134.6

136.4

138.2

140.0

141.8

143.6

145.4

147.2

149.0

150.8

152.6

154.4

156.2

158.0

159.8

161.6

163.4

165.2

167.0

168.8

170.6

172.4

174.2

176.0

177.8

179.6

181.4

183.2

185.0

186.8

188.6

190.4

192.2

194.0

195.8

197.6

199.4

201.2

203.0

204.8

206.6

208.4

210.2

212.0

C

38

43

49

54

60

66

71

77

82

88

93

99

104

110

116

121

127

132

138

143

149

154

160

166

171

177

182

188

193

199

204

210

216

221

227

232

238

243

249

254

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

F

212

230

248

266

284

302

320

338

356

374

392

410

428

446

464

482

500

518

536

554

572

590

608

626

644

662

680

698

716

734

752

770

788

806

824

842

860

878

896

914

C

260

266

271

277

282

288

293

299

304

310

316

321

327

332

338

343

349

354

360

366

371

377

382

388

393

399

404

410

416

421

427

432

438

443

449

454

460

466

471

477

482

488

493

499

504

510

516

521

527

532

538

500

510

520

530

540

550

560

570

580

590

600

610

620

630

640

650

660

670

680

690

700

710

720

730

740

750

760

770

780

790

800

810

820

830

840

850

860

870

880

890

900

910

920

930

940

950

960

970

980

990

1000

1000 to 2000°

F

932

950

968

986

1004

1022

1040

1058

1076

1094

1112

1130

1148

1166

1184

1202

1220

1238

1256

1274

1292

1310

1328

1346

1364

1382

1400

1418

1436

1454

1472

1490

1508

1526

1544

1562

1580

1598

1616

1634

1652

1670

1688

1706

1724

1742

1760

1778

1796

1814

1832

C

537

543

548

554

559

565

571

576

582

587

593

598

604

609

615

620

626

632

637

643

648

654

659

665

670

676

682

687

693

698

704

709

715

720

726

731

737

743

748

754

759

765

770

776

781

787

793

798

804

809

F

1832

1850

1868

1886

1904

1922

1940

1958

1976

1994

2012

2030

2048

2066

2084

2102

2120

2138

2156

2174

2192

2210

2228

2246

2264

2282

2300

2318

2336

2354

2372

2390

2408

2426

2444

2462

2480

2498

2516

2534

2552

2570

2588

2606

2624

2642

2660

2678

2696

2714

1000

1010

1020

1030

1040

1050

1060

1070

1080

1090

1100

1110

1120

1130

1140

1150

1160

1170

1180

1190

1200

1210

1220

1230

1240

1250

1260

1270

1280

1290

1300

1310

1320

1330

1340

1350

1360

1370

1380

1390

1400

1410

1420

1430

1440

1450

1460

1470

1480

1490

C

816

821

827

832

838

843

849

854

860

866

871

877

882

888

893

899

904

910

916

921

927

932

938

943

949

954

960

966

971

977

982

988

993

999

1004

1010

1016

1021

1027

1032

1038

1043

1049

1054

1060

1066

1071

1077

1082

1088

1093

2000 to 3000°

1500

1510

1520

1530

1540

1550

1560

1570

1580

1590

1600

1610

1620

1630

1640

1650

1660

1670

1680

1690

1700

1710

1720

1730

1740

1750

1760

1770

1780

1790

1800

1810

1820

1830

1840

1850

1860

1870

1880

1890

1900

1910

1920

1930

1940

1950

1960

1970

1980

1990

2000

F

2732

2750

2768

2786

2804

2822

2840

2858

2876

2894

2912

2930

2948

2966

2984

3002

3020

3038

3056

3074

3092

3110

3128

3146

3164

3182

3200

3218

3236

3254

3272

3290

3308

3326

3344

3362

3380

3398

3416

3434

3452

3470

3488

3506

3524

3542

3560

3578

3596

3614

3632

C

1093

1099

1104

1110

1115

1121

1127

1132

1138

1143

1149

1154

1160

1165

1171

1177

1182

1188

1193

1199

1204

1210

1215

1221

1227

1232

1238

1243

1249

1254

1260

1265

1271

1277

1282

1288

1293

1299

1304

1310

1315

1321

1327

1332

1338

1343

1349

1354

1360

1366

2000

2010

2020

2030

2040

2050

2060

2070

2080

2090

2100

2110

2120

2130

2140

2150

2160

2170

2180

2190

2200

2210

2220

2230

2240

2250

2260

2270

2280

2290

2300

2310

2320

2330

2340

2350

2360

2370

2380

2390

2400

2410

2420

2430

2440

2450

2460

2470

2480

2490

F

3632

3650

3668

3686

3704

3722

3740

3758

3776

3794

3812

3830

3848

3866

3884

3902

3920

3938

3956

3974

3992

4010

4028

4046

4064

4082

4100

4118

4136

4154

4172

4190

4208

4226

4244

4262

4280

4298

4316

4334

4352

4370

4388

4406

4424

4442

4460

4478

4496

4514

C

1371

1377

1382

1388

1393

1399

1404

1410

1415

1421

1427

1432

1438

1443

1449

1454

1460

1465

1471

1477

1482

1488

1493

1499

1504

1510

1515

1521

1527

1532

1538

1543

1549

1554

1560

1565

1571

1577

1582

1588

1593

1599

1604

1610

1615

1621

1627

1632

1638

1643

1649

F

4532

4550

4568

4586

4604

4622

4640

4658

4676

4694

4712

4730

4748

4766

4784

4802

4820

4838

4856

4874

4892

4910

4928

4946

4964

4982

5000

5018

5036

5054

5072

5090

5108

5126

5144

5162

5180

5198

5216

5234

5252

5270

5288

5306

5324

5342

5360

5378

5396

5414

5432

2500

2510

2520

2530

2540

2550

2560

2570

2580

2590

2600

2610

2620

2630

2640

2650

2660

2670

2680

2690

2700

2710

2720

2730

2740

2750

2760

2770

2780

2790

2800

2810

2820

2830

2840

2850

2860

2870

2880

2890

2900

2910

2920

2930

2940

2950

2960

2970

2980

2990

3000

USEFUL ELECTRICAL DATA

r

E

i

i=I

i=I

r

r

e =E

I = 1.73 i

e

r

e =E

i=I

r

i = 1.4 I

i=I

i

e =E

e

I

I

r

r

e =E

E = 1.4 e

r

ST A R (WY E )

DE LT A

3 - P H A SE O P E N

2 - P H A SE 4 WI RE

2 - P H A SE 3 WI RE

P = 3 ei = 1 .7 3 E I

P = 3 ei = 1 .7 3 E I

P =2 * e * i

P =2 * e * i

P =2 * e * i

2

Deg. Fahrenheit = (1.8 x Deg. Centigrade) + 32

Single Phase, W = I * R = E * I

D.C. Amps. = I = W / E

Deg. Centigrade = .555 ( Deg. Fahrenheit - 32)

Three Phase Delta, W = 3 * E * i = 1.73 * E * I

A.C. 1 Phase Amps. = I = W / (E x PF)

1 Gallon Water = 8.3 lbs.

R = E / I; I = E / R; E = I * R;

1 BTU = .252 kg. calories 0.2930 watt hours

Three Phase Wye, W = 3 * e * I = 1.73 * E* I

2

Two Phase 4 Wire, W = 2 * I * R = 2 * E * I

2

Two Phase 3 Wire, W = 2 * I * R = 2 * E * I

1 BTU per lb. = 1.8 calories per gram

Voltage between outside wires = 1.41 * e

1 kW Hour will evaporate 3.5 lb. of water from and at 212°F.

1 kW hour = 3412 BTU's

1 HP = 746 Watts.

1 kW = 1000 Watts

D.C. Amps. = I = E / R

A.C. 3 Phase Amps. = I = W / ( 1.73 (E x PF))

2

2

W = E * I = I * R; W = E / R

A.C. 2 Phase 3 Wire middle Wire Amps. =

Amps. in outside wire x 1.41.

KEY:

1 kW Hour will raise 22.75 of water from 62°F to 212°F.

Wattage varies directly as ratio of voltage squared.

W = Power, Watts

1 Gallon = 231 cubic inches = 3.785 litres = .1337 cubic feet.

The energy put out by a heating unit is measured in watts.

E = Electro Motive Force, Volts PF = Power Factor

1 cubic ft. = 1728 cubic inches = .03704 cubic yards = 7.481 gallons

The power factor is always unity.

I = Current, Amperes

1-2004

R = Resistance, Ohms

201 Leverington Avenue

Philadelphia, PA 19127

Phone:

215.482.5000

Fax:

215.482.9389

Website:

www.trentheat.com

E-mail:

trentheat@ aol.com

SINCE 1927

SOLVE YOUR HEATING PROBLEMS WITH

TRENT Electrically Heated Industrial Equipment &

Folded and Formed® HEATING UNITS

TRENT exposed ribbon type heating elements have proven their advantages wherever

high-temperature, controlled, radiant heat is essential for efficient, low cost process

operations of every type. The TRENT Folded and Formed® heating element is the

heart of TRENT Custom-built Equipment and Heating Units......to assure a greater

radiating surface per square inch of cross-section than any other type of electrical

heating element!

TRENT’S COMPLETE LINE OF ELECTRICALLY HEATED PROCESS EQUIPMENT

AND HEATING ELEMENTS IS FEATURED IN THE FOLLOWING LITERATURE:

CAPABILITIES BROCHURE

PRODUCT BULLETIN

FOLDED AND FORMED® HEATING ELEMENTS

FOLDED AND FORMED® HEATING UNITS

Folded and Formed® Heating Elements

Folded and Formed® Heater Racks

Plug (Air Duct) Heaters

ELECTRIC FURNACES

ELECTRIC OVENS

ELECTRIC JACKETS

ELECTRIC KETTLES AND MELTERS

ELECTRIC HEATING ELEMENTS

Water Immersion Heaters

Oil Immersion and Fintube Heaters

Strip Heaters

Cartridge Heaters

Tubular Heaters

Hot Plates

Ceramic Ring Heaters

CONVEYOR OVENS AND FURNACES

FOR MORE INFORMATION

INFORMATION about our products,

to request literature, or a quote use one of

the following methods:

CALL

E-MAIL us at

VISIT our WEBSITE at

1.800.544.TRENT

trentheat@aol.com, or

www.trentheat.com

www.trentheat.com

Bulletin - CB

Bulletin - PB

Bulletin - FF

Bulletin - 11

Bulletin - 24

Bulletin - 37

Bulletin - 40

Bulletin - 52/62

Bulletin - 90

Bulletin - C-3

WARRANTY:

Most of our products carry a one-year warranty on material and workmanship.

Exceptions are products used in extreme

heat applications or products determined to

be damaged through improper use or mishandling.

1-2004

FINTUBE QUOTATION INFORMATION FORM

To effectively determine the appropriate Fintube for your needs and respond to your

RFQ, PLEASE COMPLETE AND RETURN THE FOLLOWING QUESTIONAIRE:

CONTACT NAME

TITLE

COMPANY

PHONE

ADDRESS

FAX

20.04

EMAIL

CITY

STATE

Zipcode

YOUR ELECTRICAL RATING REQUIREMENTS:

What ELECTRICAL SERVICE is available?

Voltage

What is your required KW?

Phase

Amps

Hz

KW

FINTUBE DIMENSIONS AND SPECIFICATIONS:

PLEASE REFER TO OUR ELECTRIC HEATING ELEMENTS

BULLETIN 90, page 7 for selected FINTUBE models.

Please Note:

The "Immersed Length" shown below represents

the B dimension, the "Fin Length" is the C dimension,

and the "Overall Tube Length" is the A dimension

in the diagram on page 7 of Bulletin 90.

Also, the sizes listed in the bulletin are common standard

sizes. Please feel free to request alternatives to fit

your needs.

DESIRED FINTUBE DIMENSIONS (in Inches):

Fin Length Immersed Length Overall Tube Length

(excluding Terminal box) What type of FINTUBE do you require?

ALUMINUM

What type of terminal box do you require?

NONE REQUIRED

STANDARD SQUARE 6" x 6" x 3" with Hinged Cover

VAPOR RESISTANT BOX

EXPLOSION PROOF BOX

What Size (Diameter) Flange do you require?

7½" O.D. (Standard)

6" O.D.

5" O.D.

4" O.D.

What Pressure Tolerance must the Flange withstand?

150 Lbs.

Other Options:

Drain Hole

STEEL

300 Lbs.

600 Lbs.

"O" Ring Groove

TRENT, Inc., 201 Leverington Avenue, Philadelphia, PA 19127

Phone: 800-544-TRENT FAX: 215-482-9389 Website: www.trentheat.com

Email: trentheat@aol.com