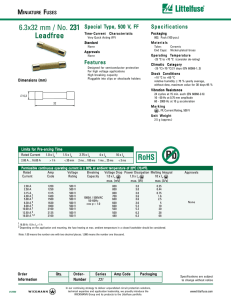

GDT Product Catalog

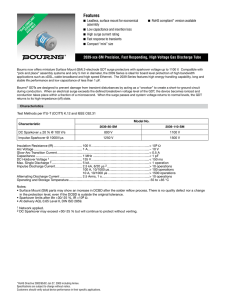

advertisement