RPS Station - Bonfiglioli

advertisement

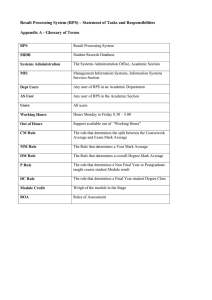

RPS Station Solutions for the North American Solar Market Power, control and green solutions 3 RPS Station Bonfiglioli’s RPS Station is a fully integrated photovoltaic power conversion system that is designed to minimize field installation time and maximize system uptime over a longer lifetime. The RPS Station is equipped with Bonfiglioli RPS TL-UL inverters (certification pending). Flexibility The RPS Station is available in a wide range of configurations, electrical power ratings and design options to meet even the most demanding requirements. Optional design features include air-conditioning, insulation, wind loading, snow loading and seismic limits, all in compliance with the NEC and CEC where required. Reliability and Performance The complete RPS Station from Bonfiglioli is factoryassembled with either a pre-fabricated metal building or pre-cast concrete building. The completely weatherproof, NEMA 3R-rated structure offers two distinct advantages: it protects the equipment from the environment (resulting in less maintenance and a longer lifetime), and protects maintenance personnel from the elements. The standard system includes a temperature-controlled cooling system and air filters. The oil-filled transformer is an ANSI standard pad-mount style and is supplied completely filled with environmentally friendly oil (sealed for longer lifetime). A wide range of features are available including: • Standard power ratings from 1.0 MWac to 2.8 MWac • Primary voltages from 12.47KV to 34.5KV • Wye or delta configuration • Dead front elbows (radial or loop feed) • Under-oil load break switch • Primary fuse protection • Surge arrestors • Direct mounting to pre-poured concrete slab base or pier mounted • PE certified design and construction Proven Technology and Longevity Supported by more than 40 R&D engineers and over 25 years of engineering excellence in power conversion technology, Bonfiglioli has the required footprint, experience and infrastructure to develop and deliver complete cost-effective solutions, from MPPT tracking to utility interconnection. In addition, the overall business composition of Bonfiglioli ensures financial stability to support installations long-term, and to provide and support an uptime guarantee and wide range of extended warranty options. Contact us or visit BonfiglioliUSA.com/PV for more information. INVERTER ENCLOSURE MV TRANSFORMER INTEGRAL MV SWITCH 4 RPS Station Design Features • Available with and without integrated MV transformer • Bottom DC cable entry glands • Bottom AC cable entry direct to MV transformer terminals • Power cabling from inverters to power transformer fully installed • Inverter cooling duct system, air inlet louver and outlet louver • Temperature-controlled cooling fans where required • Insulation to prevent excessive heat build-up from solar radiation • Removable lifting lugs • Utility power distribution equipment, lighting receptacles, cooling fans and optional customer loads or external tracker motors • Optional SCADA control panel • Optional fused metal-clad switchgear Transformer Design • Wide range of MV connection voltages available • Pad-mount oil filled, ONAN cooling • Integral 300A under-oil loadbreak switch • Off-load tap changer with 4 taps from -5% to 5% • 6 dead-front bushings for loop feed • Integral MV fuse protection • Optional MV surge arrestors • Internal gauges: liquid level, thermometer, pressure (optional external mounting) • One or two isolated LV windings with electro-static shield Additional customized features and options are available. Please contact us today to learn more. Design Standards • NEC, OSHA & CEC compliant working clearance including 2 personnel access doors with panic hardware • Designed according to the UBC code for wind, seismic, snow and floor loading • Suitable for all non-hazardous and non-harsh industrial environments • Direct mounting to pre-poured concrete slab base or pier mounted • PE certified design and construction Equipment layout 2.8 MW RPS Station (typical) MAN DOOR W/ PANIC HARDWARE INVERTER #1 D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) A/C CABLE ENTRY (TOP/BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) A/C HIGH VOLTAGE INPUT MV TRANSFORMER 805 [31.693] 5000 [196.85] D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) A/C CABLE ENTRY (TOP/BOTTOM) D/C CABLE ENTRY (BOTTOM) INVERTER #2 D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) D/C CABLE ENTRY (BOTTOM) 5 The flexibility of the Bonfiglioli RPS Station allows utility-scale solar power plants to be easily designed while providing a very cost effective solution for a wide range of applications. A typical arrangement of the Bonfiglioli RPS Station for a utility scale solar plant. Utility Network MV Cables in “Loop-feed” configuration RPS Station MV Substation/POI 6 RPS Station 1000 1500 1600 2000 2800 1750 2600 2800 3500 4900 Input ratings Maximum input current A Maximum input voltage V MPPT range V Inverter configuration Number of Inverters - MPPT Trackers 1000 550 ... 875 Multi-MPPT Multi-MPPT Master-Slave Multi-MPPT Multi-MPPT 1-5 2-8 2-2 2-10 2-14 Inverter Output Ratings AC voltage V 360 C voltage range V 317 - 396 (-12% to +10%) Frequency Hz Rated power kW 1000 1500 1600 2000 2800 Rated current A 1 x 640 2 x 1200 2 x 1280 2 x 1600 2 x 2240 Power factor - >0.99 at rated power (adjustable 0.9 lead to 0.9 lag) % 3 Maximum Harmonic Distortion (THD) 60 MV Transformer (optional) Utility voltage kW 12.47/ 13.2/ 13.8/ 27.6/ 34.5 (others possible) Transformer Type MV Winding Configuration Rated power Pad-Mount Oil Filled (with environmentally friendly oil) - Delta or Wye kVA 1000 1500 1600 2000 2800 LV Winding Configuration - 1 x Delta 2 x Delta 2 x Delta 2 x Delta 2 x Delta MV Connection - Radial or loop feed with tap changer and integrated MV loadbreak switch Transformer Protection - Wide range of features including elbow connections, fusing and surge arrestors Auxiliary Power External auxiliary voltage Auxiliary loads - 480V or 600V - 3 Phase (internal feed optional) W Lighting, receptacles, cooling fans (optional external tracker power) Efficiency Maximum efficiency - inverter % 98.6 CEC weighted efficiency - inverter % 98.0 (estimated) Transformer efficiency % > 99.0 (CEC weighting) Mechanical Details* Dimensions (WxHxD) - with transformer Weight (approx.) - with transformer Dimensions (WxHxD) without transformer Weight (approx.) - with transformer m 2.6 x 3.1 x 7.9 3.3 x 3.3 x 7.9 3.3 x 3.3 x 8.5 3.3 x 3.3 x 8.5 ft 8 x 9.5 x 24 10 x 10 x 24 10 x 10 x 26 10 x 10 x 26 3.3 x 3.3 x 9.9 10 x 10 x 30 Lbs/kg 30,700 / 13,900 39,200 / 17,750 42,700 / 19,320 46,200 / 20,905 56,000 / 25,340 m 2.6 x 3.1 x 5.3 3.3 x 3.3 x 5.3 3.3 x 3.3 x 5.9 3.3 x 3.3 x 5.9 3.3 x 3.3 x 7.2 ft 8 x 9.5 x 16 10 x 10 x 16 10 x 10 x 18 10 x 10 x 18 10 x 10 x 22 Lbs/kg 18,200 / 8,235 25,200 / 11,400 28,250 / 12,780 29,400 / 13,300 36,500 / 16,500 Cooling system - Forced air cooling with fans and filter (optional space heaters and air conditioner) Protection class - Nema 3R °C 14°F … 122°F (-10°C ... +50°C) - RS-485 (ModBus® or proprietary), Options: CAN, Profibus®, Modbus® TCP/IP Standards - NEC , UL1741/ CSA 107.1 / IEEE 1547 (Inverter Certification Pending) Testing - IEEE 1547.1/ IEEE C62.41.2/ IEEE C62.45/ IEEE C37.90.1/ IEEE C37.90.2 Environmental conditions - EN 60721-3-3 (3K3, 3B1, 3C2, 3S2 , 3M2) Power management functions (optional) - LVRT, Power Factor Control, Grid Fault Support, Power Control and Ramp Rate Temperature Operating Ambient temperature range** Interfaces Communication interface Standards & Certification * Estimated data, final values may change based on final design of system and selection of optional features. 7 Bonfiglioli Solutions As one of the world’s leading providers of clean energy solutions, with utility-scale PV installations currently in place around the world, Bonfiglioli has the innovative know-how and technical capacity to bring commercial and utility-scale PV power plants to life. For the PV sector, Bonfiglioli designs and manufactures highly efficient and innovative electronic control systems for photovoltaic fields and has the expertise to manage every aspect of photovoltaic energy generation from MPPT tracking to utility interconnection. Bonfiglioli also designs and manufactures a complete range of gearmotors, drive systems and planetary gearboxes for industrial processes, automation, mobile machinery and wind energy applications. Over 50 years of engineering excellence makes Bonfiglioli a preferred supplier and partner for market leaders around the world. For more information, visit Bonfiglioliusa.com wind industrial mobile photovoltaic Bonfiglioli has been designing and developing innovative and reliable power transmission and control solutions for industrial, mobile machinery and renewable energy applications since 1956. Bonfiglioli USA 3541 Hargrave Drive, Hebron, Kentucky 41048 tel. (+1) 859 334 3333 - fax (+1) 859 334 8888 www.bonfiglioliusa.com VEC 869 R0