04 Trolley Hoist Equipment

advertisement

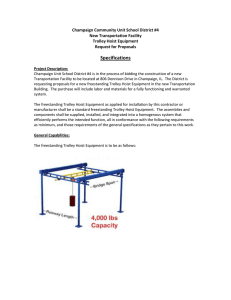

Champaign Community Unit School District #4 New Transportation Facility Trolley Hoist Equipment Request for Proposals Specifications Project Description: Champaign Unit School District #4 is in the process of bidding the construction of a new Transportation Facility to be located at 806 Dennison Drive in Champaign, IL. The District is requesting proposals for a new freestanding Trolley Hoist Equipment in the new Transportation Building. The purchase will include labor and materials for a fully functioning and warranted system. The freestanding Trolley Hoist Equipment as applied for installation by this contractor or manufacturer shall be a standard freestanding Trolley Hoist Equipment. The assemblies and components shall be supplied, installed, and integrated into a homogenous system that efficiently performs the intended function, all in conformance with the following requirements as minimum, and those requirements of the general specifications as they pertain to this work. General Capabilities: The freestanding Trolley Hoist Equipment is to be as follows: Runway Structure Design: Configuration: Customizable system consisting of a series of frames constructed of floor anchored columns connected with a header beam; two parallel runway beams supported by the frames; and a bridge suspended from the runway beams with a track and trolleys for anchoring workers. 4,000 lbs capacity (2 ton) Clear Span of 31’-0” Length of runway for bridge is 16’-0” center-to center 4 post configuration Track type: Enclosed type limiting dust and dirt collection on rolling surfaces with maximum deflection of 1/450 span based on capacity plus 15 percent for lifting device weight. Free-standing with adequate bracing/bridging Expansion anchor post bases to 8” concrete slab Construction: Fabricate from ASTM A36 steel sections with finished ends and surfaces. Support structure: Support crane runways with frames consisting of two columns and horizontal header. o Columns: Square tubes with bottom base plate and top header plate. o Header: Fabricated from two back-to-back channels spaced apart and joined with welded end plates. Provide clamp plates, threaded rods, lock washers, and hex nuts for attaching header to column. Hanger assemblies: Provide each support frame with pair of hanger assemblies that provide a rigid connection for suspending runways. Assembly to consist of clamp angle, clamp plates, threaded rods, lock washers, and hex nuts. Runways: Vierendeel truss fabricated from square steel tubes and enclosed steel track. o Track: Enclosed, cold formed, steel box track which serves as bottom cord of runway and permits end trucks and festoon carriers to ride on lower inside flanges. Fabricate lower running flanges with 2 degrees taper to center trolley within track. Flat, non-centering tracks are not acceptable. o Splice joint: Provide truss splice plates, channel-shaped track splice joint, bolts, lock washers, and nuts for joining runway sections. Splice joints must be located within four feet of a support point. o Runway Cantilevers: Up to 4 feet (1219 mm) of cantilever is allowed from a hanger location to the end of the runway. o o Festoon stack section: Provide enclosed track extension to provide for stacking festoon carriers at end of runway. Shop Finishing: Steam wash steel components with iron phosphate solution and apply thermoset enamel finish. Colors shall be as selected by Architect from manufacturer's full range. Provide spray cans of matching colors, air-drying paint for field touch-up. Warranty: 10-years Bridge Design: 4,000 lbs capacity (2 ton) Bridge Span Length: max for Runway Design above Quantity: 1 Material: Steel Track type: Enclosed type limiting dust and dirt collection on rolling surfaces with maximum deflection of 1/450 span based on capacity plus 15 percent for lifting device weight. Hoist Trolleys: 1 per bridge Hook height: 13’-0” Bridge: Single girder, Vierendeel truss fabricated from rectangular steel tubes and enclosed steel box track; truss design for 1000, 2000, and 4000 lb. capacities. o Track serves as bottom cord of bridge and permits hoist trolley and festoon carriers to ride on lower inside flanges. o Fabricate lower running flanges with 2 degrees taper to center trolley within track. Flat, non-centering tracks are not acceptable. Bridge: Enclosed, cold formed steel box track which permits hoist trolleys and festoon carriers to ride along track lower inside flanges. Fabricate lower running flanges with 2 degrees taper to center trolley within track. Flat, non-centering tracks are not acceptable. Bridge: Patented extruded aluminum enclosed track reinforced with extruded aluminum T-beam. o Provide as either one piece extrusion or with separate T-beam bolted to track. o Track: Enclosed, box track designed for trolleys and festoon carriers to ride on lower inside flanges. Fabricate lower running flanges with 2 degrees taper to center trolley within track. Flat, non-centering tracks are not acceptable. End trucks: Rigid frame end truck designed to ride inside enclosed runway track and connect to and suspend bridge. o Construction: Stamped steel fabrication with both vertical and horizontal wheels to prevent binding in runway. Designs with welds in tension are not acceptable. o Wheels: Removable, self-centering wheels with sealed lifetime lubricated bearings. Vertical wheels shall be tapered 2 degrees to match track profile. Nonremovable or non-tapered wheels are not acceptable. Drop lugs: Provide on both sides of truck to limit truck drop in the event of wheel, axle, or load bar failure. o Connection to the bridge: Provide a rigid connection between bridge and end truck. Articulating connections with threaded hardware are not acceptable. o Designed for easy attachment of peripherals. Hoist trolley: Rigid-body trolley designed to ride inside enclosed track of bridge and to carry hoist and load. Articulating trolleys are not acceptable. o Construction: Two-piece stamped steel body with two wheels each side and tapered clevis positioning hoist hook at center of trolley so load weight is evenly distributed to all four trolley wheels. Provide removable clevis pin of type and size determined by manufacturer for specified capacity. Trolleys with nonremovable clevis pins are not acceptable. Holes provided in body for mechanical connections. o Wheels: Removable, self-centering wheels with sealed lifetime lubricated bearings. Vertical wheels shall be tapered 2 degrees to match track profile. Nonremovable or non-tapered wheels are not acceptable. Steel wheels are not acceptable. o Drop lugs: Provide on both sides of trolley to limit trolley drop in the event of wheel, axle, or load bar failure. o Designed for easy attachment of peripherals. End stops: Molded composite, resilient bumper installed in runway and bridge tracks to prevent end trucks, hoist trolley, and festoon carriers from rolling out of track. Bolt stops without energy absorbing bumper are not acceptable. Shop Finishing: Steam wash steel components with iron phosphate solution and apply thermoset enamel finish. Colors shall be as selected by Architect from manufacturer's full range. Provide spray cans of matching colors, air-drying paint for field touch-up. Warranty: 10-years Hoist Design: Electrical: 208/3PH Shop absorbing end stops Latch hook Trolley adapter Motorized Lifting Assembly: Processor controlled servo drive system lifting and moving device for human operator. Maximum Capacity (Load & Tool): 1320 lb (600 kg). o Maximum Lifting Speed Fully Loaded: 21 ft/minute (6.40 m/minute). o Maximum Lift Range: 5.5 ft (1.68 m). Lift Voltage/Amps: 220 VAC/10. Motor Duty Cycle: H5. Lifting Media: Preformed stainless steel wire rope. Operating Temperature/Humidity Range: 41 to 122 degrees F (5 to 50 degrees C)/ 35 to 90 % non-condensing. Lift hoist to include the following: o Provide float mode lifting function. o Provide slide or pendant handle. o Provide teachable virtual limits. o Provide speed reduction points. o Provide shock absorbing end stop. o Provide latch hook. o Provide extended wire rope drop. o Provide slide on air hose. o Provide transformer. o Provide universal trolley adapter. Electrical Utility: The Electrical Contractor for the Transportation Building project will provide the required electrical feed, disconnect switch, and final electrical connection to the trolley hoist equipment. The equipment vendor is responsible for all installations downstream of this single point electrical connection (wiring for sensors, etc). A 208V/20A/3P feed is being provided. Warranty: Warranty: 2-years Acceptance Testing: Following installation, the equipment installer shall perform an acceptance test, including a load test, as recommended by the manufacturer. A test outline shall be provided to the Owner for approval prior to performing the test. The test program shall show that the equipment meets all of the conditions described by the specification and that the equipment will perform as intended. The installer shall provide a one week notification to the Owner of the scheduled start up date. The Contractor may be required to demonstrate the crane functions several times to assure the Owner the equipment is reliable. Training: After the completion of installation, the installer shall provide a training program to all operating personnel to correctly demonstrate the safe operation of the equipment. In addition to the operation training, the installer will provide maintenance training to the Owner’s staff. Maintenance training shall include servicing, routine maintenance, adjustment, troubleshooting and preventative maintenance. After 6-months of lift use, the Installer shall return and provide follow-up training on the use and maintenance of the equipment to the Owner’s staff. Submittals: A. Shop drawings: the successful bidder shall provide three (3) sets of complete shop drawings. B. Three (3) sets of detailed parts, maintenance and operation manuals and warranty information shall be provided. Manuals shall be three-hole punched in binders with tabs clearly labeling sections. In addition, one (1) electronic PDF copy of the same shall be provided to the Owner on electronic media (i.e. thumb drive, CD, etc.) The information shall be saved in a single, indexed PDF file. Quality Assurance: Manufacturer shall be a reputable manufacturing firm, regularly engaged in the design and manufacture of cranes. All cranes shall be the product of a single manufacturer. A manufacturer’s field service representative shall install the equipment; conduct and acceptance testing and train the Owner’s personnel on the proper operation and maintenance of the equipment. The following information shall be provided with the bid documents regarding the manufacturer’s and installer’s experience and qualifications: 1. Provide a minimum three (3) locations where similar proposed equipment has been provided / installed by the Manufacturer’s Authorized Installer including the date placed in service and total price for the project. 2. Provide the name and telephone number of individuals at the above locations who are familiar with the operation and maintenance of the crane equipment. 3. Provide professional licenses or certificates for personnel working on the project. Acceptable Manufacturers/Products: A. Gorbel, 600 Fishers Run, Fishers, NY 14453, Phone (800) 821-0086, care of: robertmonroe@hossiercrane.com Freestanding Bridge Crane: Gorbel Freestanding Workstation Bridge Crane GLCS-FS4000 Hoist: Gorbel Q-Force Intelligent Assist Lift Device, 2 ton capacity B. Demag Cranes, Terex MHP’s Corp, PO Box 39245, Cleveland, OH 44139-1895, Phone (440) 248-2400, Freestanding Bridge Crane: Demag KMK Freestanding Workstation Crane Hoist: Electric Chain Hoist, 2 ton capacity C. Engineered Material Handling (EMH), 550 Crane Drive, Valley City, Ohio 44280, Phone (330) 220-8600, emh@emhcranes.com Freestanding Bridge Crane: “Nomad” Freestanding Bridge Crane Hoist: EMH wire rope hoist, 2 ton capacity D. Hoosier Crane Service Company, 58144 Charlotte Avenue, Elkhart, IN 46517, Phone (800) 509-6131, care of: justinyoungs@hoosiercrane.com Freestanding Bridge Crane: Gorbel Freestanding Workstation Bridge Crane GLCS-FS4000 Hoist: Harrington electric chain hoist, 2 ton capacity Project Timeline for New Transportation Building: Anticipated Contract Award for General Trades: Notice to Proceed for General Trades: Transportation Building Substantial Completion: Transportation Building Final Completion: July 18, 2016 Board meeting July 19, 2016+/January 20, 2017 February 10, 2017 Bid Documents: Bids for the New Transportation Building project were opened on June 23rd. The complete set of Bid Documents for the building is available in PDF format for your use and information. The Bid Documents will be made available to you through SmartBidNet by contacting Tara Cox at O’Shea Builders: tarac@osheabuilders.com Phone: (217) 522-2826 x 126