Section 15

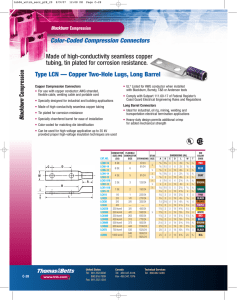

advertisement

Section 15 Application Data Contents Reference Guide 15/2 Table 1: Ampacities of Insulated Conductors 15/3 Table 2: Correction Factors for Ambient Temperatures 15/3 Table 4A: Motor Full-Load Currents of Three Phase AC Induction Type Motors 15/4 Table 4B: Motor Full-Load Currents in Amperes, Single Phase AC 15/4 Table 4C: Motor Full-Load Currents in Amperes, DC 15/4 Table 4D: Conversion Table of Polyphase Design 15/4 Table 5: Normal-Load and Fault Currents of Three Phase Transformers 15/4 Table 6: Electrical Formulas for Finding Amperes, Horsepower Kilowatts, and kVA 15/5 Table 7: Grounding Electrode Conductor for AC Systems 15/5 Table 8: Minimum Size Grounding Conductors for Grounding Raceways and Equipment 15/5 Conversion Table 15/6 15 Application Data REFERENCE GUIDE General In the application of fusible switches and circuit breakers, consideration should be given to the following factors: 1. Voltage of circuit. 2. Ampacity of circuit. 3. Frequency of power source. 4. Operating conditions. 5. Fault current available. Voltage of Circuit — The system voltage should not exceed the listed voltage rating of the circuit breaker, fuse or switch. Ampacity of Circuit — The listed continuous current rating of the fuse or circuit breaker should not exceed the allowable ampacity of the conductors. Where the allowable ampacity of the conductor does not correspond to listed current ratings for fuses or circuit breakers, the next larger rating of fuse or circuit breaker is permitted providing it does not exceed the conductor ampacity by more than 25%. An exception to this rule is permitted for motor circuits or other circuits where high inrush currents may persist for an appreciable time. Frequency of Power Source — Circuit breakers and fusible switches are calibrated for use on direct current or 48–68-Hertz alternating current. For frequencies above 62-Hertz, some fuses, switches and circuit breakers must be derated. The derating varies with each type and size of protective device. Consult your local representative for specific information. 15 APPLICATION DATA 15/2 Operating Conditions — Molded case circuit breakers and fuses are calibrated without any enclosure as specified by the Underwriters’ Laboratories, Inc. Sound engineering practice dictates that continuous loads should not exceed 80% of the breaker or fuse current rating for most types of enclosures. Electrical Connections — Molded Case Circuit Breakers are to be connected with 60 or 75°C wire for breakers having a rated ampacity of 125 amperes or less. For circuit breakers having a rated ampacity greater 125 amperes, only 75°C cable shall be used unless otherwise indicated on the circuit breaker label. Note: Exceptions to this rule are outlined in Article 110-14-C(1) and C(2) of the 2002 National Electric Code. Conductors should be derated in accordance with the National Electrical Code for both ambient temperature and continuous loading. Table 2 on page 16-3 lists the correction factors to be applied to the allowable current-carrying capacities of conductors for application in temperatures above 30°C. Conductors which are loaded continuously should be derated to 80% of their allowable currentcarrying capacity except when supplied by an assembly including its overcurrent device that is listed for continuous operation at 100% of its rating. When the type of load is unusual, intermittent, or one which involves momentary peak currents such as motor loads, consideration should be given to the heating effect on the protective device over a period of time. The duty cycle of a motor which is started and stopped frequently may require a circuit breaker or fuses with a higher rating than an infrequently started motor. The presence of excessive dust, moisture, corrosive fumes, or explosive atmosphere requires the use of enclosures suitable for such atmospheres. For applications in regions where fungus growth may occur, some circuit breakers should be treated with a fungus and moisture resistant material. Fault Current Available — The interrupting rating of the circuit breaker or fused switch should be greater than the available short circuit current at the point of application. The short circuit current from some power sources, such as engine driven generators, is limited, and the protective device characteristics should be selected to clear such faults without delay. Some systems require a study of protective device characteristics to assure proper protection and coordination for any possible value of fault current. Your representative is available to assist in making coordination studies. Application Data general Table 1 Ampacities of Insulated Conductors (From NEC Table 310-16) Not More Than Three Conductors in Raceway or Cable or Earth (Directly Buried). (Based on Ambient Temperature of 30°C, 86°F) Size Copper Conductors 60°C 75°C (140°F) (167°F) Types Types AWG Kcmil 0018 0016 0014 0012 0010 0008 0006 0004 0003 0002 0001 00001⁄0 00002⁄0 00003⁄0 00004⁄0 250 300 350 400 500 600 700 750 800 900 1000 1250 1500 1750 2000 TW UF — — 020 025 030 040 055 070 085 095 110 125 145 165 195 215 240 260 280 320 355 385 400 410 435 455 495 520 545 560 RHW THW THWN XHHW USE ZW — — 020 025 035 050 065 085 100 115 130 150 175 200 230 255 285 310 335 380 420 460 475 490 520 545 590 625 650 665 90°C (194°F) Types TBS SA SIS FEP FEPB RHH THHN THHW XHHW 014 018 025 030 040 055 075 095 110 130 150 170 195 225 260 290 320 350 380 430 475 520 535 555 585 615 665 705 735 750 Aluminum Conductors Copper-Clad Aluminum Conductors 60°C 75°C 90°C (140°F) (167°F) (194°F) Types Types Types TBS, SA, SIS, THHN RHW THHW THHW THW-2, THWN-2, THW RHH, RHW-2 THWN USE-2 TW XHHW XHH, XHHW UF USE XHHW-2, ZW-2 — — — — — — — — — 020 020 025 025 030 035 030 040 045 040 050 060 055 065 075 065 075 085 075 090 100 085 100 115 100 120 135 115 135 150 130 155 175 150 180 205 170 205 230 190 230 255 210 250 280 225 270 305 260 310 350 285 340 385 310 375 420 320 385 435 330 395 450 355 425 480 375 445 500 405 485 545 435 520 585 455 545 615 470 560 630 Size AWG Kcmil — — — 12 10 8 6 4 3 2 1 00001⁄0 00002⁄0 00003⁄0 00004⁄0 250 300 350 400 500 600 700 750 800 900 1000 1250 1500 1750 2000 15 Table 2 Ambient Temperature°C 21–25 26–30 31–35 36–40 41–45 46–50 51–55 56–60 61–70 71–80 For ambient temperature over 30°C, (86°F) multiply the ampacities shown above by the appropriate factor shown below. 1.08 1.05 1.04 1.08 1.05 1.04 1.00 1.00 1.00 1.00 1.00 1.00 .91 .94 .96 .91 .94 .96 .82 .88 .91 .82 .88 .91 .71 .82 .87 .71 .82 .87 .58 .75 .82 .58 .75 .82 .41 .67 .76 .41 .67 .76 — 0.58 .71 — 0.58 .71 — 0.33 .58 — 0.33 .58 — — .41 — — .41 load current rating and the overcurrent protection for conductor types shall not exceed 15 amperes for 14 AWG, 20 amperes for 12 AWG, and 30 amperes for 10 AWG copper; or 15 amperes for 12 AWG and 25 amperes for 10 AWG aluminum and copper-clad aluminum after any correction factors for ambient temperature and number of conductors have been applied. Ambient Temperature°F 70–77 78–86 87–95 96–104 105–113 114–122 123–131 132–140 141–158 159–176 The 15/3 APPLICATION DATA Correction Factors for Ambient Temperature Over 30°C, 86°F Application Data GENERAL Table 4A Table 4B Table 4C Motor Full-Load Currents of Three Phase AC Induction Type Motors Motor Full-Load Currents In Amperes, Single-Phase, AC Motor Full-Load Currents In Amperes, DC Motor Rating Horsepower 0001⁄4 0001⁄3 0001⁄2 0003⁄4 001 0011⁄2 002 003 005 0071⁄2 010 015 020 025 030 040 050 060 075 100 125 150 200 250 300 350 400 450 500 Current in Amperes 208V 230V 460V 575V 1.11 1.34 2.4 3.5 4.6 6.6 7.5 10.6 16.7 24.2 30.8 46.2 59.4 74.8 88 114 143 169 211 273 343 396 528 —0 —0 —0 —0 —0 —0 .38 .47 .9 1.3 1.7 2.4 2.7 3.9 6.1 9.0 11.0 17.0 22 27 32 41 52 62 77 99 125 144 192 242 289 336 382 412 472 .96 1.18 2.2 3.2 4.2 6 6.8 9.6 15.2 22.0 28.0 42.0 54 68 80 104 130 154 192 248 312 360 480 —0 —0 —0 —0 —0 —0 .48 .59 1.1 1.6 2.1 3 3.4 4.8 7.6 11.0 14.0 21.0 27 34 40 52 65 77 96 124 156 180 240 302 361 414 477 515 590 Horsepower 001⁄6 001⁄4 001⁄3 001⁄2 003⁄4 01 011⁄2 02 03 05 071⁄2 10 115V 4.4 5.8 7.2 9.8 13.8 16 20 24 34 56 80 100 230V 2.2 2.9 3.6 4.9 6.9 8 10 12 17 28 40 50 Horsepower 001⁄4 001⁄3 001⁄2 003⁄4 01 011⁄2 02 03 05 071⁄2 10 120V 3.1 4.1 5.4 7.6 9.5 13.2 17 25 40 58 76 240V 1.6 2.0 2.7 3.8 4.7 6.6 8.5 12.2 20 29 38 Table 4D Conversion Table of Polyphase Design B, C, D, and E Maximum Locked-Rotor Currents for Selection of Disconnecting Means and Controllers as Determined from Horsepower and Voltage Rating and Design Letter For use only with Sections 430-110, 440-12, 440-41, and 455-8(c) of the National Electric Code. 15 Maximum Motor Locked-Rotor Current Amperes Two- and Three-Phase Design B, C, D, and E Rated 115 Volts 200 Volts 208 Volts 230 Volts HP B, C, D E B, C, D E B, C, D E B, C, D E 0001⁄2 40 40 23 23 22.1 22.1 20 20 3 000 ⁄4 50 50 28.8 28.8 27.6 27.6 25 25 001 60 60 34.5 34.5 33 33 30 30 1 001 ⁄2 80 80 46 46 44 44 40 40 002 100 100 57.5 57.5 55 55 50 50 003 —0 —0 73.6 84 71 81 64 73 005 —0 —0 105.8 140 102 135 92 122 0071⁄2 —0 —0 146 210 140 202 127 183 010 —0 —0 186.3 259 179 249 162 225 015 —0 —0 267 388 257 373 232 337 020 —0 —0 334 516 321 497 290 449 025 —0 —0 420 646 404 621 365 562 030 —0 —0 500 775 481 745 435 674 040 —0 —0 667 948 641 911 580 824 050 —0 —0 834 1185 802 1139 725 1030 060 —0 —0 1001 1421 962 1367 870 1236 075 —0 —0 1248 1777 1200 1708 1085 1545 100 —0 —0 1668 2154 1603 2071 1450 1873 125 —0 —0 2087 2692 2007 2589 1815 2341 150 —0 —0 2496 3230 2400 3106 2170 2809 200 —0 —0 3335 4307 3207 4141 2900 3745 250 —0 —0 —00 —00 —00 —00 —00 —00 300 —0 —0 —00 —00 —00 —00 —00 —00 350 —0 —0 —00 —00 —00 —00 —00 —00 400 —0 —0 —00 —00 —00 —00 —00 —00 450 —0 —0 —00 —00 —00 —00 —00 —00 500 —0 —0 —00 —00 —00 —00 —00 —00 460 Volts B, C, D E 10 10 12.5 12.5 15 15 20 20 25 25 32 36.5 46 61 63.5 91.5 81 113 116 169 145 225 183 281 218 337 290 412 363 515 435 618 543 773 725 937 908 1171 1085 1405 1450 1873 1825 2344 2200 2809 2550 3277 2900 3745 3250 4214 3625 4682 575 Volts B, C, D E 8 8 10 10 12 12 16 16 20 20 25.6 29.2 36.8 48.8 50.8 73.2 64.8 90 93 135 116 180 146 225 174 270 232 330 290 412 348 494 434 618 580 749 726 936 868 1124 1160 1498 1460 1875 1760 2247 2040 2622 2320 2996 2600 3371 2900 3746 Table 5 Normal-Load and Fault Currents of Three-Phase Transformers APPLICATION DATA Values may vary depending on manufacturer, type of motor and NEMA design. For full load currents of 200 volt motors, increase the corresponding 230 volt motor full-load current by 15 percent. Table 5 Notes: 1. Primary source available is assumed as 500 MVA at the primary of the transformer with a source circuit X/R ratio of 12. 2. Motor contribution is included in the table at twice the full-load current for 208 volt transformers and at 4 times the full-load current for 240 volt and 480 volt transformers. These values are derived from the assumption that 208 volt systems are 50% motor load and 240 and 480 volt systems are 100% motor load. 3. All short circuit current values are in symmetrical RMS amperes. 15/4 Transformer Characteristics 3 Phase kVA Rating 112.5 150 225 300 500 750 1000 1500 2000 2500 1000 1500 AC Voltage 3 Phase 280V Normal Load Short % Continuous Circuit Impedance Amperes Current 2.25 312 14,491 3.00 416 14,699 4.50 625 15,139 5.00 834 18,326 5.00 1388 30,536 5.75 2080 40,373 5.75 2780 53,830 5.75 4162 80,745 5.75 —00 —0 0 0 5.75 —00 —0 0 0 8.00 —00 —0 0 0 8.00 —00 —0 0 0 240V Normal Load Continuous Amperes 271 361 541 722 1203 1804 2406 3610 4812 6010 —00 —00 Short Circuit Current 13,128 13,477 14,186 17,328 28,872 38,590 51,467 77,201 102,914 128,647 —0000 —0000 480V Normal Load Continuous Amperes 135 180 271 361 601 902 1203 1805 2406 3008 1203 1805 Short Circuit Current 6,540 6,720 7,106 8,664 14,424 19,295 25,734 38,590 51,467 64,324 19,850 29,766 Application Data general Table 6 Electrical Formulas for Finding Amperes, Horsepower, Kilowatts and kVA Kilowatts kVA Horsepower (Output) Amperes when Horsepower is Known Amperes when Kilowatts is Known Amperes when kVA is Known Single-Phase I x E x pf 1000 IxE 1000 I x E x % EFF x pf 746 Alternating Current Two-Phase , Four-Wire I x E x 2 x pf 1000 IxEx2 1000 I x E x 2 x % EFF x pf 746 Three-Phase I x E x 1.73 x pf 1000 I x E x 1.73 1000 I x E x 1.73 x % EFF x pf 746 Direct Current IxE 1000 I x E x % EFF 746 HP x 746 E x % EFF x pf HP x 746 2 x E x % EFF x pf HP x 746 1.73 x E x % EFF x pf HP x 746 E x % EFF KW x 1000 E x pf KW x 1000 2 x E x pf KW x 1000 1.73 x E x pf KW x 1000 E kVA x 1000 E kVA x 1000 2xE kVA x 1000 1.73 x E Average Efficiency and Power Factor Values of Motors When the actual efficiencies and power factors of the motors to be controlled are not known, the following approximations may be used. Efficiencies: DC motors, 35 horsepower and less 80% to 85% DC motors, above 35 horsepower 85% to 90% Synchronous motors (at 100% power factor) 92% to 95% “Apparent” Efficiencies ( = Efficiency x Power Factor); Three-phase induction motors, 25 horsepower and less 85% Three-phase induction motors above 25 horsepower 90% These figures may be decreased slightly for single-phase and two-phase induction motors. Fault-Current Calculation on LowVoltage AC Systems In order to determine the maximum interrupting rate of the circuit breakers in a distribution system it is necessary to calculate the current which could flow under a three-phase bolted short circuit condition. For a three-phase system the maximum available fault current at the secondary side of the transformer can be obtained by use of the formula: ISC = kVA x 100 KV x √3 x % Z where: ISC = Symmetrical RMS amperes of fault current. kVA = Kilovolt-ampere rating of transformers. KV = Secondary voltage in kilovolts. % Z = Percent impedance of primary line and transformer. Table 5 on page 15-4 has been prepared to list the symmetrical RMS fault current which is available at the secondary terminals of the transformer. Table 8 Minimum Size Grounding Conductors for Grounding Raceways and Equipment (From NEC Table 250–122) Rating or Setting of Automatic Overcurrent Device in Circuit Ahead of Equipment, Conduit etc., Not Exceeding (Amperes) 15 20 30 40 60 100 200 300 400 500 600 800 1000 1200 1600 2000 2500 3000 4000 5000 6000 Size Copper Wire Number 14 12 10 10 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 kcmil 350 kcmil 400 kcmil 500 kcmil 700 kcmil 800 kcmil Aluminum or Copper Clad Aluminum Wire Number 12 10 8 8 8 6 4 2 1 1/0 2/0 3/0 4/0 250 kcmil 350 kcmil 400 kcmil 600 kcmil 600 kcmil 800 kcmil 1200 kcmil 1200 kcmil 15 To Find Table 7 Size of Largest Service Entrance Conductor or Equivalent Area for Parallel Conductors Copper 2 or smaller 1 or 1/0 2/0 or 3/0 Over 3/0 to 350 kcmil Over 350 kcmil to 600 kcmil Over 600 kcmil to 1100 kcmil Over 1100 kcmil Aluminum or Copper Clad Aluminum 1/0 or smaller 2/0 or 3/0 4/0 or 250 kcmil Over 250 kcmil to 500 kcmil Over 500 kcmil to 900 kcmil Over 900 kcmil to 1750 kcmil Over 1750 kcmil In three-wire, two-phase circuits the current in the common conductor is 1.41 times that in either other conductor. E = Volts I = Amperes % EFF = Per Cent Efficiency APPLICATION DATA Grounding Electrode Conductor for AC Systems (From NEC Table 250–66) Size of Grounding Electrode Conductor Aluminum or Copper Clad Copper Aluminum 8 6 6 4 4 2 2 1/0 1/0 3/0 2/0 4/0 3/0 250 kcmil Additional information and exceptions are stated in Article 250 — Grounding, National Electric Code. pf = Power Factor 15/5 Fraction, Decimal, and Millimeter Equivalents Fractions to Decimals to Millimeters 15 APPLICATION DATA Fractions 1/64 1/32 3/64 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 17/64 9/32 19/64 5/16 21/64 11/32 23/64 3/8 25/64 13/32 27/64 7/16 29/64 15/32 31/64 1/2 33/64 17/32 35/64 9/16 37/64 19/32 39/64 5/8 41/64 21/32 43/64 11/16 45/64 23/32 47/64 3/4 49/64 25/32 51/64 13/16 53/64 27/32 55/64 7/8 57/64 29/32 59/64 15/16 61/64 31/32 63/64 1 0.001” = 0.0254 mm 1 mm = 0.03937” 15/6 Decimals 0.015625 0.03125 0.046875 0.0625 0.078125 0.09375 0.109375 0.1250 0.140625 0.15625 0.171875 0.1875 0.203125 0.21875 0.234375 0.2500 0.265625 0.28125 0.296875 0.3125 0.328125 0.34375 0.359375 0.3750 0.390625 0.40625 0.421875 0.4375 0.453125 0.46875 0.484375 0.500 0.515625 0.53125 0.546875 0.5625 0.578125 0.59375 0.609375 0.6250 0.640625 0.65625 0.671875 0.6875 0.703125 0.71875 0.734375 0.7500 0.765625 0.78125 0.796875 0.8125 0.828125 0.84375 0.859375 0.8750 0.890625 0.90625 0.921875 0.9375 0.953125 0.96875 0.984375 1.000 Millimeters 0.397 0.794 1.191 1.588 1.984 2.381 2.778 3.175 3.572 3.969 4.366 4.763 5.159 5.556 5.953 6.350 6.747 7.144 7.541 7.938 8.334 8.731 9.128 9.525 9.922 10.319 10.716 11.113 11.509 11.906 12.303 12.700 13.097 13.494 13.891 14.288 14.684 15.081 15.478 15.875 16.272 16.669 17.066 17.463 17.859 18.256 18.653 19.050 19.447 19.844 20.241 20.638 21.034 21.431 21.828 22.225 22.622 23.019 23.416 23.813 24.209 24.606 25.003 25.400 conversion tables Millimeters to Inches Millimeters 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Inches 0.0039 0.0079 0.0118 0.0157 0.0197 0.0236 0.0276 0.0315 0.0354 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 0.0394 0.0787 0.1181 0.1575 0.1969 0.2362 0.2756 0.3150 0.3543 0.3937 0.4331 0.4724 0.5118 0.5512 0.5906 0.6299 0.6693 0.7087 0.7480 0.7874 0.8268 0.8661 0.9055 0.9449 0.9843 1.0236 1.0630 1.1024 1.1417 1.1811 1.2205 1.2598 1.2992 1.3386 1.3780 1.4173 1.4567 1.4961 1.5354 1.5748 1.6142 1.6535 1.6929 1.7323 1.7717 Millimeters 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 Inches 1.8110 1.8504 1.8898 1.9291 1.9685 2.0079 2.0472 2.0866 2.1260 2.1654 2.2047 2.2441 2.2835 2.3228 2.3622 2.4016 2.4409 2.4803 2.5197 2.5591 2.5984 2.6378 2.6772 2.7165 2.7559 2.7953 2.8346 2.8740 2.9134 2.9528 2.9921 3.0315 3.0709 3.1102 3.1496 3.1890 3.2283 3.2677 3.3071 3.3465 3.3858 3.4252 3.4646 3.5039 3.5433 3.5827 3.6220 3.6614 3.7008 3.7402 3.7795 3.8189 3.8583 3.8976 3.9370