UNIFI

Employee Newsletter // Issue 6 // January 2016

//

Completions and Well Architecture

Unlocking Complexities

New Corporate

Literature Suite

Drilling Tools, Technology and Services

Unlocking Complexities

FEATURE STORY

The Communications and External Affairs team is rolling out a new corporate literature system that reflects Frank’s visual identity and tells our story in a

fresh and modern way.

Tubular Products and Fabrication

Unlocking Complexities

Mid-water Shelf

Unlocking Complexities

Land

Unlocking Complexities

Deepwater and Ultra-deepwater

Unlocking Complexities

Unlocking Complexities

UNIFI

Issue 6

//

January 2016

CONTENTS

New Corporate

Literature

Suite

Unlocking

Complexities

Global Supply Chain - Operation Phoenix

Story on page 2

Story on page 3

First Mixed String Success with Petronas

in Malaysia

Improving Talent Mobility

Story on page 4

Story on page 3

Frank’s Manager Orientation Program

Compliance Matters

Story on page 4

Story on page 5

Upcoming Events

On page 5

This document contains confidential and proprietary information which is property of Frank’s International. None of the information contained herein may be disclosed, reproduced, distributed or used without prior written consent from

Frank’s International. © 2016 Frank’s International. All rights reserved.

This contains forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. All statements, other than statements of historical facts, included herein that

address activities, events or developments that the company expects, believes or anticipates will or may occur in the future are forward-looking statements. Without limiting the generality of the foregoing, forward looking statements

contained herein may include statements, estimates and projections regarding the Company’s future financial position, operations, performance, returns, divestitures, capital expenditure budget, and other guidance. These statements are

based on certain assumptions made by the Company based on management’s experience, expectations and perception of historical trends, current conditions, anticipated future developments and other factors believed to be appropriate.

Forward-looking statements are not guarantees of performance. Although the Company believes the expectations reflected in its forward-looking statements are reasonable and are based on reasonable assumptions, no assurance can be

given that these assumptions are accurate or that any of these expectations will be achieved (in full or at all) or will prove to have been correct. Moreover, such statements are subject to a number of assumptions, risks and uncertainties,

many of which are beyond the control of the Company, which may cause actual results to differ materially from those implied or expressed by the forward-looking statements. These include the factors discussed or referenced in the “Rick

Factors” section on the Company’s Annual Report on Form 10-K most recently filed with the U.S. Securities and Exchange Commission (the “SEC”). Any forward-looking statement speaks only as of the date on which such statement is made,

and the Company undertakes no obligation to correct or update any forward-looking statement, whether as a result of new information, future events or otherwise, except as required by applicable law.

EXECUTIVE LETTER

President and CEO, Gary Luquette

Happy New Year! I trust you had a peaceful and restful holiday season. As we prepare to take on the

challenges we will face in 2016, it’s important to pause to reflect on our accomplishments last year.

We have all endured much change as we have positioned our company to be more resilient in the

difficult market we find ourselves in.

2015 Accomplishments

D

espite the level of change and difficult market conditions, we never

lost our hold on safety as a core value,

and we improved our overall safety

performance significantly in 2015. I’m

extremely proud of that accomplishment and know that we will find ways

to continue to improve upon that in

2016.

We’re also fortunate to have made a

number of improvements to maintain

our strong balance sheet and position

ourselves well for the future. Some of

our improvements include: right-sizing

our inventory to more appropriate

levels; decreasing our days of sales

outstanding; injecting new talent into

the workforce; and launching Frank’s

Business System (FBS).

We have used this economic downturn

wisely so far, and are poised to be a

much stronger and leaner competitor

than we were when we went into this

down market. Based on feedback we’ve

received from our customers, 2016 will

be another challenging year with further reductions in activity and additional pressure on our rates. However,

the adjustments we made in 2015,

along with the progress we have

planned for 2016, should continue to

preserve our financial strength and

keep us ahead of our competition.

“Much progress has been

made in 2015 and more

good things are planned for

2016.”

Being a 37-year veteran in our industry

and having experienced multiple

downturns, I’m confident that global

supply and demand fundamentals will

eventually correct and commodity

prices will recover. Until then, we will

continue to focus on the things we can

control and prepare for the eventual

market recovery.

2016 Opportunities

Our 2016 plan is in the final stages of

development and includes a number of

improvement opportunities that will be

added to our ongoing 2015 initiatives.

Some of these are:

• Quality and Reliability – As our

customers continue to look for ways to

reduce capital and improve cash flow,

our revenues continue to be impacted.

By focusing on quality and reliability,

we minimize waste and reduce our

costs. Our cost of poor quality is

significant and making progress in this

area will have a significant positive

impact on our financials.

• Supply Chain – We can also lower our

cost of procurement through globally

leveraged spending in supply chain. This

includes not only the goods and services we procure, but the freight and

logistics costs to move our equipment.

We are currently sourcing our materials

and parts in many locations around the

world. By reducing the number of suppliers and increasing the size of our

orders, we can lower our overall cost

while increasing quality.

generating significant savings in a

number of key areas. Expanding FBS

internationally, conducting more Kaizen

(Lean) events, sharing best

practices and lessons learned will allow

us to leverage the momentum across

Frank’s global footprint. FBS enables us

to meet or exceed our customers’

expectations at a lower overall cost of

ownership and with higher reliability.

As you can see, much progress has been

made in 2015 and more good things are

planned for 2016. While we don’t know

how long this down-cycle will last, I’m confident that when the market turns, we’ll

be ready to hit the ground running and be

a more formidable competitor and more

desirable partner for our customers.

• Franks’ Business System (FBS) – We

launched FBS in the U.S. last year,

UNIFI // 1

NEW CAPABILITIES & MARKETS

Accessing the New Brochures

New Corporate Literature Suite

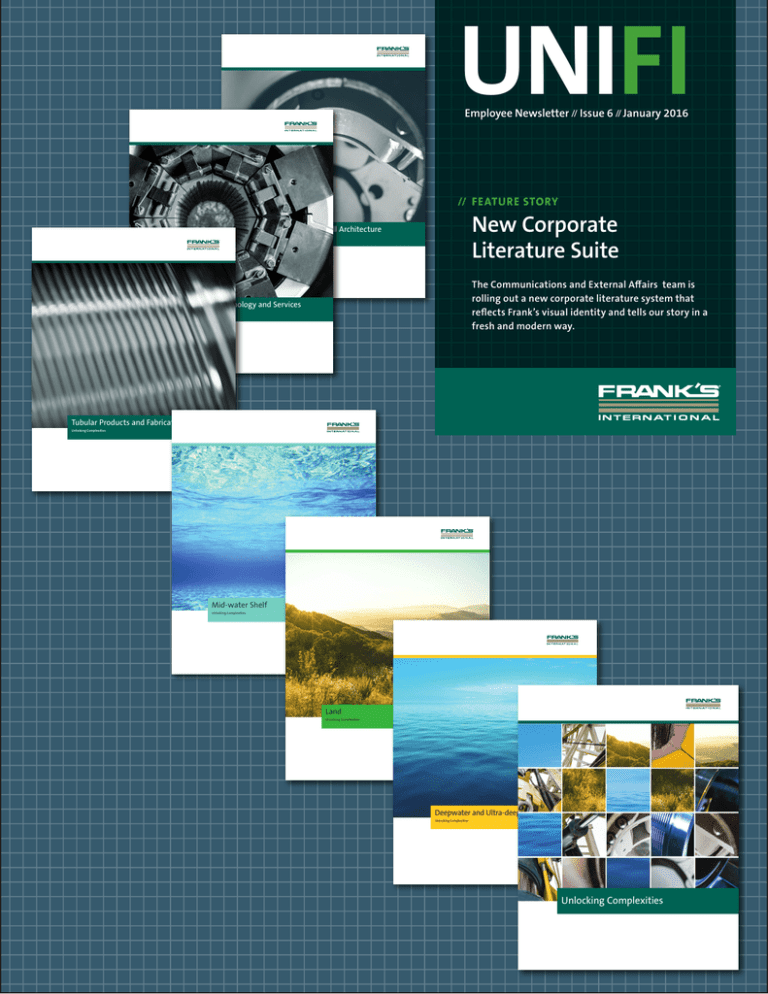

T

he Communications and External

Affairs team (CEA) is proud to

introduce the latest addition to Frank’s

International’s updated communication

materials. The CEA team is rolling out a

new corporate literature suite that

reflects Frank’s visual identity and tells

our story in a fresh and modern way.

These brochures were created to give

our global workforce the resources to

communicate the unique value we

offer to our customers, investors, and

employees.

The corporate brochure will provide an

overview of how Frank’s helps “unlock

complexities” within our industry independently focusing on the land,

mid-water shelf and deepwater basins.

The suite will also include an overview

of our products, services, and capabilities that are grouped together by: completions and well architecture, tubular

products and fabrication, drilling tools,

Corporate Literature Architecture

FranksIn

Corporate Brochure

Applications

Deepwater

Brochure

Mid-water

Shelf

Brochure

Products &

Corporate

Services

Land

Brochure

Completions

&

Well

Architecture

Brochure

technology, and services. A new product

and spec sheet will round-out the suite

as a complete package of Frank’s capabilities.

Tubular

&

Fabrication

Brochure

• Individua

Print on D

Individual

Product

Brochures

Broch-

Drilling Tools,

Technology

&

Services

Brochure

Spec

Sheet

relations, sales and business development, trade shows, and even for your

own viewing to get to know more

about our company. The brochures can

be accessed at http://franksinternational.com/brochures.

We encourage you to use these

resources

forcontains

onboarding,

investor

This document

confidential and

proprietary information which is property of Frank’s International. None of the information contained herein

distributed or used without prior written consent from Frank’s International. © 2015 Frank’s International. All rights reserved.

Maximizing Value + Minimizing Cost

hore.

d hydraulic

f Frank’s

With the vast experience and high-grade equipment we provide, our customers benefit from

increased efficiencies of their drilling operations and reduced downtime, resulting in a lower

total cost of ownership across the well lifecycle.

ern Africa

lve complex

ur foothold

• All Rema

Order Bro

Innovat

Our ability to e

with our safet

Customers ben

through equip

Innovation

Solutions versus Products

Value

Frank’s industry longevity provides

the experience to solve complex

challenges and develop leadingedge tools and equipment.

With our combined knowledge and

experience, we tailor solutions to

the needs of our customers’ specific

drilling projects.

Our services combined with

engineering, manufacturing and

execution expertise reduce well

construction and intervention

times by 20 to 50 percent.

Completions an

Well Architectu

f Technology

industry-leading

ilities to provide

mers with the

al sophistication

nd deepwater

k’s safe, reliable

bilities provide

omers by keeping

on schedule and

time.

Safe.

Reliable.

Efficient.

2

//

January 2016

Safety

Service

Our proven safety record is due

in part to the reliability of our

equipment, which provides

greater efficiencies and reduces

equipment malfunctions, creating

a safer working environment.

Frank’s teams have the ability

to maintain equipment on-site,

reducing downtime and generating

more productive construction and

intervention timelines, exceeding

customers’ expectations.

Well integrity is cru

ration and product

success. Frank’s lon

leader in tubular ru

and as an expert in

resistant alloy, pos

top provider of we

intervention and re

With our intelligen

technology and wo

capabilities, Frank’

through service ex

high-quality produ

a more predictable

wellbore environm

CONTINUOUS IMPROVEMENTS

Global Supply Chain - Operation Phoenix

I

n December’s UNIFI Executive Letter,

Jeff Bird identified the critical few

priorities we need to focus on in 2016

including the implementation of a global

supply chain process led by Global Supply

Chain Director, Doug Seal.

About Supply Chain

Operation Phoenix

Doug and his team have launched what

they’re calling “Operation Phoenix” to

streamline and simplify our current

processes as we capitalize on creating a

real competitive advantage.

“Supply chain” is defined as the internal

and external processes necessary to

produce and distribute a commodity. Our

supply chain team will be the driving

force to improve quality, efficiency, and

performance while identifying costsaving opportunities.

“Operation Phoenix will concentrate on

the sourcing of materials, goods, and

services along with global logistical

functions,” Doug said. “More emphasis

will be placed on leveraging our spending

of the materials and assets we utilize and

purchase globally – lowering our cost of

procurement.”

Changes over the coming months will

affect how equipment is transported as

we reduce our vendor list. We will focus

on cost efficiency and a consistent

standard of high-quality products and

services. This translates to providing

improved service and reliability to our

customers with the opportunity to

increase market share and revenue.

Alexander Proudfoot, an operational

performance company, will assist

Operation Phoenix by analyzing areas for

improvement beginning with the U.S.

region. Changes will begin to take effect

shortly after analysis in Q1 and Q2 of

2016 and will be communicated through

email by a member of the Supply Chain

Team prior to application.

Going from “good to great” will be an

ongoing organizational process as we

consistently strive to improve our

processes and work together

collaboratively as One Frank’s.

CUSTOMER SUCCESS

First Mixed String Success with Petronas in Malaysia

I

n November 2015, Frank’s International

Malaysia (Selaut Oil Tools) ran its first

successful job with Frank’s proprietary

primary tools, FA-1® and Extended

Range™ Split Bushing Spider (SBS), in the

Sarawak waters off the coast of Malaysia.

Frank’s ran 2006 meters of casing string

(9 5⁄8”-10 3⁄4”) to reach the desired Total

Depth (TD) for Petronas. By using four of

our components as a package, FA-1, Praying Mantis®, Horseshoe® Single Joint Elevator, and SBS, Frank’s International’s

ability to pick-up the casing from the catwalk to a vertical position was integral to

the success of the operation. Our SBS

allowed the drilling and casing crew to

change over successfully to the next size

of casing in a safe, controlled and efficient

manner on board the SKD T-10.

Casing was set at the TD, and the running

speed was increased compared to the use

of conventional equipment. Since Petronas required a system that could handle

both casing sizes without the need to

change out the spider, the 14” 500 ton

FA-1 and 1000 ton SBS reduced the time

required to switch from 9 5/8” to 10 3/4” as the casing string would already be in

the open hole.

Using our technology, Petronas had the

luxury of increased running speeds in

terms of joints per hour, and this client

also successfully filled, circulated, rotated

and reciprocated the casing string without any downtime.

UNIFI // 3

PERFORMANCE

Improving Talent Mobility

I

n October 2015, Frank’s International’s Leadership Team identified

“Improving Talent Mobility” as one

of our key strategic initiatives to be

managed with Frank’s Business

System (FBS). To support this broad

initiative in a difficult price environment, the Leadership Team recognized the need to enhance field

workforce utilization to help the

organization control our operation

effectiveness.

The following month, a cross-functional team consisting of HR, operations, and finance, participated in a

Kaizen event to jumpstart the workforce utilization effort. The Kaizen’s

purpose was to design a program

that improved the utilization of our

workforce through calculated measurements and enhanced awareness

as to how Frank’s field employees

are utilized globally. The team is

confident that the tools and measures developed during this event

will enable a positive impact on the

effectiveness of our operations.

Going forward, a new Workforce

Utilization Measurement Standard

(WUMS), will be used to measure

workforce utilization. In addition,

each country or region will have a

Key Performance Indicator (KPI)

based on regulatory and operating

requirements so that we can accurately assess workforce utilization

with a common metric (Billable

Time ÷ 365 = Utilization Measurement).

WUMS will provide an opportunity

for Frank’s to allocate appropriately

field workers where and when

needed, and allow us to deploy

available employees outside their

region to give Frank’s more flexibility in meeting customer requirements. These employees will not be

required to deploy outside of their

regular home base but will have an

opportunity to be involved in

different projects during the regular

upward and downward cycles of our

industry, allowing operations to

account for gaps.

A pilot program has been launched

for Land – Alvin, TX; U.S. GOM; U.K.;

Angola; and Malaysia – with a global

launch scheduled for January 2016.

More information and training will

be announced over the coming

weeks by team lead Raleigh

Boudreaux, Casing Department

Manager – GOM.

EMPLOYEE SUCCESS

Frank’s Manager Orientation Program

spanning from QHSE, manufacturing,

engineering and operations, to administrative and finance.

Left - Right: Tyler Oliva, Rene Brockholz, Jason Hardy,

Jose Xavier, Romeo Miller, Samira Mammadova, Patrick

Lemmers, Sergei Koronikov, Sergio Huertas, Caroline

Mansur, Kevin Hartigan, Ryan Sheppard, Ronald Toomer

C

ongratulations to the managers who

recently completed the Frank’s Manager Orientation Program (FMOP) in

December 2015. The FMOP program

consists primarily of in-depth presentations and guided tours, with topics

4

//

January 2016

The initial idea of the FMOP came from

John Walker, EVP-Global Operations,

and Robert Gilbert, SVP-Strategic

Projects, who wanted to familiarize new

managers with the Company’s technology and engineering capabilities, system processes and personnel associated

with global support, as well as the culture of Frank’s International. Now open

to new and experienced managers from

our operations all over the globe – and

with the addition of a Houston session

– FMOP provides a sense of where

Frank’s began, how we have come to

where we are and where we are headed.

Twenty-two speakers shared their

expertise and knowledge and gave

guided tours covering the deepwater

fabrication, manufacturing, pipe sales,

remanufacturing, training, and operations facilities in Lafayette. Managers

returned to their home base with a better understanding of Frank’s diverse

products and services, and are better

equipped to lead their respective teams

more effectively and more efficiently.

This recent session was a huge success,

thanks to the thorough planning of the

support team, as well as the preparation

and dedication of the many presenters

and the participation of the attendees.

Cooperatives on this scale, for the purpose of investing in our own personnel,

exemplify the meaning of One Frank’s.

LEGAL

Compliance Matters

B

ribery is an act of corruption, and

the U.S. Foreign Corrupt Practices

Act (FCPA) defines it as the giving of

anything of value to a foreign public

official in an effort to obtain or retain

business. “Anything of value” is interpreted very broadly but can include

cash, jewelry, cars, vacations, country

club memberships and tuition for

college-age children.

The Department of Justice and the

U.S. Securities and Exchange Commission ramped up enforcement of FCPA

in the early 2000s, demanding transparency in U.S. and foreign companies.

Companies in violation have paid millions of dollars in fines, and some individuals have gone to federal prison for

failure to comply with the statute. In

late 2014, Paris-based rail transport

company, Alstom SA, along with several other entities agreed to pay a

$772 million fine for altering their

books and records. In December 2015,

two men, one being the president of

Houston-based Tradequip Services

and Marine, were arrested on charges

that violated the FCPA in an effort to

secure contracts with Venezuelan

national oil company PDVSA.

In response to this increased enforcement, Frank’s International has developed an Anti-Corruption and Bribery

Policy to educate employees and

implement requirements for conducting our business in accordance with

the FCPA and other anti-corruption

laws. The policy applies to all of

Frank’s operations and employees

worldwide. The policy can be found

on My Frank’s under the legal tab.

Frank’s operates in approximately 60

countries, some of which are considered high-risk in terms of bribery and

corruption activity, a status based on

factors such as natural resources, population, socio-economic strata, presence of a national oil company and

energy company competition. Some

of these high-risk countries include

Angola, Azerbaijan, Brazil, China,

Egypt, India, Indonesia, Mexico,

Nigeria and Venezuela. Additional

caution must be used in operations

involving these high-risk

countries to avoid even the appearance of corrupt business activity.

If you have any questions or concerns

on this topic, please consult your

supervisor and/or the legal

department, or contact

compliance@franksintl.com.

UPCOMING EVENTS

January 26-28: SPE/IADC Middle East Drilling Technology Conference and Exhibition Abu Dhabi

If you have an article you would like to share please email corp.communications@franksintl.com.

UNIFI // 5