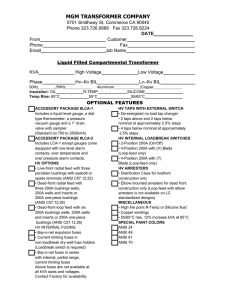

Bulletin 20A - MGM Transformer Company

advertisement

ISO 9001 MGM Three Phase Liquid Filled Pad Mounted Transformers BULLETIN 20 T R A N S F O R M E R C O M PA N Y Standardized Designs) Three Phase Liquid Padmount Transformers ( LC APPLICATION MGM’s three-phase, liquid-filled, padmount compartmental transformers are specifically designed for use on underground distribution systems. Their tamper resistant construction permits installation in areas accessible to the public without the necessity for special fencing or enclosures. Their visually pleasing low profile appearance is ideal for shopping centers, schools, hospitals or commercial buildings. They are designed, manufactured and tested to meet or exceed applicable ANSI, NEMA and IEEE. Standards. Transformers can be supplied with the HV arranged for either live-front radial feed or dead-front radial or loop feed applications. CORE & COIL CONSTRUCTION MGM’s transformers utilize a fivelegged wound core construction that is suitable for delta-wye, deltadelta, wye-delta and wye-wye connections. The core is fabricated from high grade, grain oriented, burr free, silicon steel and has excellent performance characteristics. The primary coils are wound with round or rectangular aluminum or copper magnet wire depending on kVA rating, voltage and customer requirements. The secondary coils are wound with rectangular magnet wire or full width copper or aluminum sheet depending on kVA rating, voltage and customer requirements. The winding insulation consists of high quality thermally upgraded epoxy coated kraft paper. The thermosetting epoxy coated kraft paper, after baking, fuses the winding together to provide excellent short circuit strength. Units rated 55/65˚C, when operated at 65˚C, have an additional 12% kVA capacity with normal life expectancy. RATINGS 75 through 2500 kVA, TANK CONSTRUCTION 3 Phase, 60Hz, 65˚C & 55/65˚C Rise HIGH VOLTAGES 2400 @ 45kV BIL through 14400 @ 95kV BIL LOW VOLTAGES 208Y/120, 240, 480Y/277 & 480 @ 30kV BIL All MGM tanks are manufactured from precision cut steel and are braced to withstand the stresses associated with shipping, installation and operation. They will withstand normal operating pressures and vacuums without damage, deterioration or leaking. The tank base is designed to permit rolling in directions perpendicular to the centerlines of the segments. A bolted, gasketed handhole is provided in the tank cover to allow easy inspection of the interior. Leak tests are performed before painting and a final pressure test is performed prior to shipping. TERMINAL COMPARTMENTS MGM’s terminal compartments are strong, tamper-resistant and designed for operating convenience. The bottom sill is removable to permit skidding over conduit stubs during initial installation. The compartment HV and LV doors are secured with a rugged three-point latch assembly that has both a locking bolt and provisions for a user supplied padlock. For safety reasons the padlock must be removed, then the locking bolt loosened before you can gain access to the LV compartment. A steel divider completely isolates the HV compartment from the LV compartment and a second safety bolt must be removed before the HV door can be opened. Both the doors and the compartment cover can be removed to permit easy installation and servicing. Doorstops are provided to hold the doors in the open position. MGM QUALITY All transformers are subject to MGM’s quality inspection checkpoints and each unit must pass the following tests before being approved for shipping: • • • • • • • • • • Winding Resistance Impedance Turn Ratio Load Loss Polarity & Phase Relation Applied Potential Test No Load Loss Induced Potential Test Exciting Current Pressure Leak Test STANDARD FEATURES • Sealed tank construction • Tank base with jacking and rolling provisions • Bolted tank cover • Tank ground pads (ANSI Standard) • Lifting lugs • Panel type radiators (as required) • Bolted and gasketed tamper-resistant hand hole • Bolt-on HV & LV terminal compartments • Removable compartment top cover and bottom sill OPTIONAL FEATURES ACCESSORY PACKAGE #LCA-1 HV TAPS WITH EXTERNAL TAP SWITCH Includes a liquid level gauge, a dial type thermometer, a pressure vacuum gauge and a 1” drain valve with sampler (1” drain valve and sampler is supplied standard on 750 to 2500kVAs). The following options are available: ACCESSORY PACKAGE #LCA-2 Includes same accessories as LCA-1 except gauges come equipped with low level alarm contacts, over temperature and over pressure alarm contacts. • Removable hinged doors with door stops HV OPTIONS • Three point latching, padlock provisions and with safety bolt • Internal HV door safety bolt (holds HV door closed) • Steel divider between HV and LV compartments • Provision for arrestors (live-front only) • LV epoxy bushings with spade terminals • Neutral bushing ground strap (Wye LV only) • 1” Top filter and filling plug • 1” Drain plug (75 to 500 kVA) • 1” Drain valve with sampler (750 to 2500 kVA) • Auto/manual pressure relief valve • Nameplate • Electrical grade mineral oil • Munsell green #7GY3.29/1.5 paint color • Live-front radial feed with three porcelain bushings with eyebolt or spade terminals (ANSI C57.12.22) • Dead-front radial feed with three 200A bushings wells, 200A wells and inserts or 200A one-piece bushings (ANSI C57.12.26) • Dead-front loop feed with six 200A bushings wells, 200A wells and inserts or 200A one-piece bushings (ANSI C57.12.26) HV INTERNAL FUSING • De-energized no load tap changer • 2 taps above and 2 taps below nominal at approximately 2.5% steps • 4 taps below nominal at approximately 2.5% steps HV INTERNAL LOADBREAK SWITCHES • 2-Position 200A (On/Off) • 4-Position 200A with (V) Blade (Loop-feed only) • 4-Position 200A with (T) Blade (Loop-feed only) HV ARRESTERS • Distribution Class for livefront construction only • Elbow mounted arresters for dead-front construction only (Loop-feed with elbow arresters is not available on LC standardized designs) MISCELLANEOUS • High fire point R-Temp or Silicone fluid • Bay-o-net expulsion fuses • Copper windings • Current limiting fuses in non-loadbreak dry-well fuse holders (Loadbreak switch is required) • 55/65˚C rise with 12% increase in kVA at 65˚C rating • Bay-o-net fuses in series with internal, partial range, current limiting fuses Above fuses are not available at all kVA sizes and voltages. Contact Factory for availability • Special paint colors (ANSI 24, ANSI 49, ANSI 61 & ANSI 70) E 5 5 D 20 18 6 7 6 6 A MGM TRANSFORMER COMPANY 20 5701 SMITHWAY STREET C B CITY OF COMMERCE, CA 90040 kVA 75 112.5 150 225 300 500 750 1000 1500 2000 2500 Transformer Wts. A B 62 62 62 62 62 72 72 72 82 82 82 Dimensions-Ins. C GALS. LBS. 66 66 66 66 66 72 72 72 78 78 78 54 54 56 60 62 80 80 82 84 84 98 160 160 170 200 200 270 280 300 390 410 490 2600 2800 3100 3700 4000 5700 6800 8000 10000 11500 13900 Phone: 323-726-0888 Fax: 323-726-8224 Website: www.mgm-transformer.com e-mail: sales@mgm-transformer.com Pad and Mounting Detail - Inches kVA 75 - 150 225 - 500 750 - 1500 2000 - 2500 D 56 62 70 80 E 75 75 81 87 F 63 63 69 75 PAD THICK 6 6 8 8 NOTE: Dimensions and weights are approximate, not for construction, subject to change without notice. The basic physical arrangements for MGM LIQUID FILLED PADMOUNT TRANSFORMERS are shown below in Figures 1 to 3. For further information consult MGM Factory. Live Front-Radial Feed Ansi Fig. 1,2, and 3 C57.12.22 Dead Front-Radial Feed Ansi Fig. 1, 3, and 4. C57 12 26 Dead Front-Loop Feed Ansi Fig. 2, 3, and 4. C57 12 26 Bulletin 20-0600 10/00 Printed in U.S.A.