Contract Testing Services

advertisement

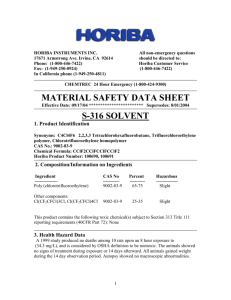

Contract Testing Services Your Product-Proving Partners Explore the future Automotive Test Systems | Process & Environmental | Medical | Semiconductor | Scientific Applications and Services Mobile Industry: ● Passenger Car ● Commercial Vehicle ● Hybrid/Electric Vehicle ● Military ● Non-Road ● Rail ● Marine Other Applications: Battery (Cycling and Structural) ● Wind Turbines ● Generator Systems ● Amusement Ride Passenger Cars ● Testing Services ● ● ● ● ● ● ● ● Engine, Powertrain and Driveline Testing Multi-Axis and SingleAxis Component Testing MAST System Testing 4-Poster Testing Environmental Chamber Testing On-Board Emissions and Particulate Measurement Pressure, Evaluation or Burst Testing for Small Production Runs Road Load Data Acquistion (RLDA) ● ● ● ● Simulation Technologies, Developed by HORIBA ● Service Load Replication (SLR) – Applying customer-specific data to products-under-test using simulation technology ● Road Load Simulation (RLS) – Applying standard data files to products-under-test using simulation technology Virtual Battery – The ultimate combination of dynos, DC power converters, connectors and software necessary to emulate the effects of a variety of battery technologies on your application. Virtual Engine – Powered by HORIBA’s real-time ETPS software (Engine Torque Pulsation System) Virtual Wheel – Simulates wheel-slip conditions Complete Vehicle Simulation – The complete package of simulation capabilities for testing in a full-vehicle environment. Terry Sobczak, Manager, Project Management and Steve Witter, Service Engineer Leading the industry for over 40 years with fast, reliable testing results Innovation Quick, Accurate Service HORIBA’s contract test engineers have been solving the unsolvable with solid engineering and the drive to get their hands dirty until the job is done right. See what our team can do for your application using exclusively HORIBAowned and manufactured equipment, and an entire test lab devoted to fast, accurate results. HORIBA’s contract test facility provides a true ‘one stop shop’ experience in our on-site labs, featuring dedicated test equipment rigs for fast, efficient set-ups on both structural integrity testing and dynamometer testing. Or, partner with our innovative team early in your development process for the ultimate testing experience. Structural Testing The HORIBA Contract Testing Team leads the industry in servo-hydraulic structural testing with a full lab of unique configurations, test rig sizes, and setups to accommodate the most challenging performance and durability testing protocols. Pair these capabilities with our wide variety of environmental chamber and software simulation options for a full spectrum of testing possibilities. A wide-variety of testing options to achieve 2 to 6 degrees of freedom Simulation Capabilities: Exclusively from HORIBA Service Load Replication (SLR) – Applying customer-specific data to products-under-test using simulation technology ● Road Load Simulation (RLS) – Applying standard data files to products-under-test using simulation technology ● Virtual Battery – The ultimate combination of dynos, DC power converters, connectors and software necessary to simulate the effects of a variety of battery technologies on your application. ● ● ● ● ● ● ● Multiple MAST system configurations available to accommodate a range of testing from single component, to full body-in-white, and complete battery pack and instrument panels. Both single-axis and multi-axis testing options 4 poster testing Chassis coupled 4 Poster testing configurations for a variety of vehicle configurations Combined structural and rotational wind turbine testing High MASS flow rates and temperature cycles for exhaust system testing Environmental Conditions ● Environmental chambers available to cool (-70°C) / heat (150°C) specimens under test Torsional Testing ● Rotational loading for fatigue ● Ultimate strength testing Jay Drake, Lab Manager Powertrain Testing Choose HORIBA when you require high-speed / high-performance powertrain testing to prove the performance or durability requirements of your product. Our specialized labs feature HORIBAmanufactured dynamometers, powered by a team of contract testing engineers with extensive experience in coupling and balancing high-speed systems. Reduce your time to market by adding HORIBA-designed RLS and SLR simulation to your testing protocol. Ask us today how these exclusive software packages and advanced dynamometers can enhance the in-use performance and durability of your products. Experienced, Results-Driven Contract Testing Engineers ● Fast results, industry-leading professionalism ● “Proof of concept” set-ups available to confirm new test configurations ● Both in-lab and customer-site training available for fulltesting system purchases ● ● Powerful High-Speed, HORIBA-Manufactured Dynos ● Capable of up to 18,000 RPM ● Small diameter dyno systems that accommodate direct drive trans axles and hybrid applications without belts, pulleys, or severe prop-shaft angles ● High-torque, low-inertia capabilities available for E-motor applications Simulation Technologies, Developed by HORIBA ● Service Load Replication (SLR) – Applying customer-specific data to products-under-test using simulation technology ● Road Load Simulation (RLS) – Applying standard data files Dave Balaka, Project Engineering Specialist Dmitry Frankstein, R&D Specialist ● ● to products-under-test using simulation technology Virtual Battery – The ultimate combination of dynos, DC power converters, connectors and software necessary to emulate the effects of a variety of battery technologies on your application. Virtual Engine – Powered by HORIBA’s real-time ETPS software (Engine Torque Pulsation System) Virtual Wheel – Simulates wheel-slip conditions Virtual Vehicle – The complete package of simulation capabilities for testing in a full-vehicle environment. Environmental Conditions: ● Environmental chambers available to cool (-70°C)/ heat (150°C) specimens under test ● Chiller systems available to cool E Motors to -20C for low temperature start and running condition evaluations A Variety of Additional Services… Need a fresh approach to your current testing challenge? Let us put the combined talents of our experienced team of Contract Test Engineers to work on your project. From passenger car in-field data collection, to instrumentation of an entire non-road commercial vehicle—we can help you design a testing protocol that will achieve the results you need. ● ● ● ● ● ● In-field data collection (RLDA) at your track, a HORIBAprovided track, or at your customer’s facility. Exhaust Powertrain Battery & hybrid systems Steering system Interior systems ● ● ● ● ● ● ● Jim Schultz, Testing Engineer Back cover: Damon Graham, Testing Engineer Doug Farrar, Senior Testing Engineer Gjina Ibisaj, Contract Testing Scheduler Jay Drake, Lab Manager Dmitry Frankstein, R&D Specialist On-board emissions analysis and fuel consumption rate calculations On-board particulate analysis Rotational device measurement and evaluation Data analysis and data processing Specialty testing (pressure and product sample inspection) Instrumentation installation for both low and high temp applications Wind turbine instrumentation Your Lab, Or Ours? • Wide variety of high-torque/low-inertia dynamometers for E-motor testing (up to 18,000 RPM) • Small diameter dynamometer systems specifically designed for work with hybrids • Full spectrum of simulation capabilities and environmental conditioning Total Solution from HORIBA’s Hybrid Team Comprehensive Test Stand Solution for Electric Motor Development, Validation, and Durability Testing Electric Motor Test Stand TITAN-EMTS Versatile Application Support Electric Motor Test Stand (EMTS) series is a complete development and testing solution for electric motors (E-motor) and components related to PHV, HV and extended range EV. Optimized to E-motor specifications and test cycles, the system offers broad application support for: D C E B ● Evaluation and Development of Thermal Management Systems ● Power and Efficiency Measurements ● Torque Analysis A ● Accelerated Life Cycle Testing F ● E-Component Validation ● Vehicle Range Studies ● Optimization of Energy Management System Controls Electric Motor Test Stand Rugged Mechanical Design A AC Dynamometer, Headstock, Bedplate B Fluid Conditioning Units (Optional) C SPARC Controller, AC Motor Inverter, Battery Simulator D Drive Isolation Transformer E Interface & Lockout Enclosure with Power Quality Analyzer for TPIM F STARS Test Automation System The central feature of EMTS is a high-speed, lowinertia, liquid-cooled dynamometer engineered specifically for E-motors. Available in single-ended and double-ended configurations, this proven dynamometer has a very stiff shaft, provides 200% overload, and maintains full torque at zero speed. The E-motor housing is custom designed to duplicate in-vehicle geometry. E-motor lubrication and forced cooling/heating are integral features of the housing. Temperature Extremes for Endurance Testing Internally and externally sealed, the E-motor housing supports hot and cold temperature cycles from -40℃ to +120℃ for accelerated life cycle (endurance) testing. Condensate and corrosion mitigation reduce maintenance. The optional Fluid Conditioning Units are capable of handling multiple fluids (ethylene glycol and ATF) depending on customer requirements. Advanced Simulation & Measurement EMTS incorporates HORIBA’ s Virtual Battery Solution, allowing E-motors to be tested with accurate simulation of in-vehicle battery performance. A fully integrated power analyzer precisely measures electric motor efficiency and torque-speed characteristics. Stored data can be used to generate efficiency maps of the E-motor specimen. Total Solution from HORIBA’s Hybrid Team Electric Motor Test Stand with Environmental Housing and Battery Simulation Proven Dynamometer Design Space-Efficient Bedplate ● Single- or double-ended configuration ● Provides excellent vibration dampening with polymer composite material filling ● High-speed, low-inertia design specifically for E-motors ● Isolation pads reduce the vibration amplitude and decouple the system from the test cell floor ・Speed: up to 18000 rpm single-ended; up to 12500 rpm double-ended ● Leveling features assure easy and proper installation ・Inertia: 0.1 kg/m or less 2 ● Can be mounted on industrial flooring ● Excellent torque density and extremely quiet operating levels ● Precision T-Slot allows the headstock to translate axially without having to realign the system ● Extremely rigid steel base and stiff shaft Headstock Engineered for Ease of Use E-motor Environmental Housing Headstock ● Easy setup with specially designed piloted E-motor in Fixture inserts for E-motor fixtures ● Simplified maintenance with slide-out lubrication and cooling unit ● Separate circuits for E-motor lubrication and for thermal cycling provide maximum flexibility, ease of E-motor installation, and thermal transfer ● Axial translation allows easy access to both ends of the dynamometer for E-motor/shafting changes and torque calibration Torque Meters Isolation Pads mounted under polymer composite filled bedplate Slide-out Manifold for lubrication and cooling Please read the operation manual before using this product to assure safe and proper handling of the product. http://www.horiba.com ● HORIBA, Ltd. Head Office Miyanohigashi, Kisshoin Minami-ku, Kyoto Japan Phone: 81 (75) 313-8123 Fax: 81 (75) 321-5725 ● HORIBA India Private Limited Delhi Office 1212A, Hemkunt Tower, 98 Nehru Place, New Delhi - 110019 INDIA Phone: +91 11-4669-5001/5002 ● HORIBA EUROPE GmbH Head Office Hans-Mess-Str.6 D-61440 Oberursel/Ts. Germany Phone: 49 (6172) 1396-0 Fax: 49 (6172) 137385 Bulletin:HRE-2197A e-mail: info@horiba.co.jp Tokyo Sales Office 1-7-8 Higashi-Kanda Chiyoda-ku, Tokyo, Japan Phone: 81 (3) 3861-8231 Fax: 81 (3) 3861-8259 TAIWAN Representative Office 3F, NO.18 Lane 676, Chung Hua Rd, Chupei City, Hsinchu Hsien, 302,Taiwan Phone: 886 (3) 656-1012 Fax: 886 (3) 656-8231 ● HORIBA INSTRUMENTS INCORPORATED Ann Arbor Facility Irvine Facility 5900 Hines Drive 17671 Armstrong Avenue Ann Arbor, MI 48108 Irvine, CA 92614, U.S.A. U.S.A. Phone: 1 (949) 250-4811 Phone: 1 (734) 213-6555 Fax: 1 (949) 250-0924 Fax: 1 (734) 213-6525 Darmstadt Office Landwehrstrasse 55 64293 Darmstadt Germany Phone: 49 (6151) 32-3098 Fax: 49 (6151) 32-3865 Leichlingen Facility Julius-kronenberg Strasse D-42799 Leichlingen Germany Phone: 49 (2175) 8978-0 Fax: 49 (2175) 8978-50 ● HORIBA TRADING (SHANGHAI) CO., Ltd. Beijing Office Shanghai Office Room 1701, United Plaza, Room 1801, Capital Tower, Beijing, Tower 1 No.6Jia, 1468 Nanjing Rd. West, Jianguomenwai Ave., Shanghai, 200040, China Chaoyang District, Beijing, Phone: 21-6289-6060 100022 China Fax: 21-6289-5553 Phone: 10-8567-9966 Fax: 10-8567-9066 Troy Facility 2890 John R. Road Troy, MI 48083 U.S.A. Phone: 001 (248) 6899000 Fax: 001 (248) 6898578 HORIBA SWEDEN Sydhamnsvägen 55-57, SE-151 38 Södertälje, Sweden Phone: 46 (8) 550-80701 Fax: 46 (8) 550-80567 ● HORIBA INSTRUMENTS LIMITED Kyoto Close Summerhouse Road Moulton Park, Northampton NN3 6FL, U.K. Phone: 44 (1604) 542500 Fax: 44 (1604) 542699 Netherland Office HORIBA Benelux Science Park Eindhoven 5080 (Industrial park "Ekkersrijt") 5692 EA, Son, Netherlands Phone: 31 (0) 40-2900-240 Fax: 31 (0) 40-2900-624 ● HORIBA KOREA Ltd. 112-6 Sogong-Dong Choong-ku, Seoul, Korea Phone: 82 (2) 753-7911 Fax: 82 (2) 756-4972 ● HORIBA GmbH Kaplanstrasse 5 A-3430 Tulln, Austria Phone: 43 (2272) 65225 Fax: 43 (2272) 65230 ● HORIBA FRANCE 12, Avenue des Tropiques 91955 LES ULIS France Phone: 33 (1) 69-29-96-23 Fax: 33 (1) 69-29-95-77 ● HORIBA INSTRUMENTS Pte. LTD. 10 Ubi Crescent #05-11/12, Ubi Techpark Singapore 408564 Phone: 65 6745-8300 Fax: 65 6745-8155 HORIBA CZECHIA Organizachi slozka Praha Petrohradska 13 CZ-101 00 Praha 10, Czech Republic Phone: 420 (2) 717-464-8 Fax: 420 (2) 717-470-64 ● HORIBA Jobin Yvon SRL Torino Office Europalace Corso Torino 43/45 10043 Orbassano,Torino Italy Phone: 39 (011) 9040601 Fax: 39 (011) 9000448 Printed in Japan T-G(SK)23 Total Solution from HORIBA’s Hybrid Team Advanced Battery Emulation for Development and Validation of HV, PHV and Extended Range EV Virtual Battery Solution for Development of HV/EV Powertrain HORIBA’ s Virtual Battery provides the most accurate and convenient battery pack emulation solution available for developing, calibrating, validating, and optimizing the hybrid testing. Interfacing to most programmable DC power sources, as well as most automation or HIL systems, Virtual Battery makes possible: ● Parallel development of engine, transmission, electronics, auxiliaries, and battery packs ● Verification of ‘‘what-if scenarios’’ on the test stand without actual battery specimen ● Emulation of stress and extreme environmental conditions without damaging or destroying batteries ● Battery pack development HORIBA Virtual Battery Closely Replicates Actual In-Vehicle Lithium-Ion Battery Performance Simulation Actual Value Variations of Integration Add HORIBA Virtual Battery on Top of Existing DC Power Supplies for HV/EV and Upgrade to Advanced Battery Emulation HORIBA’ s Battery Emulator is engineered for quick, easy integration with nearly any programmable DC power supply for HV/EV. HORIBA DC power supplies are also available as well as any necessary electronics or accessories to upgrade existing systems. Battery Pack Voltage [V] Choose a Complete, Turn-Key HORIBA Test Stand with Virtual Battery Emulation Included RMS Voltage Difference of under 1% Elapsed Time [s] D C E B A F Add Virtual Battery into any HORIBA E-motor, powertrain or vehicle turn-key test stand and benefit from the optimal combination of hardware and software for your testing needs. Choose the dynamometer, DC power supply, DC interface, control system and accessories that best fit your application. Vehicle-Specific Battery Models Virtual Battery includes a standard set of battery pack models, each built up from cell level and calibrated specifically for vehicle-based applications. The calibrated models not only assure exceptional fidelity to in-vehicle battery performance but also eliminate the need for time-consuming parameterization work. Simply choose one of the batteries and start testing. Safety and Convenience Image of HORIBA E-Motor Test Stand (EMTS) A AC Dynamometer, Headstock, Bedplate B Fluid Conditioning Units (Optional) C SPARC Controller, AC Motor Inverter, Battery Simulator D Drive Isolation Transformer E Interface & Lockout Enclosure with Power Quality Analyzer for TPIM F STARS Test Automation System *E-motor : Electric motor Virtual Battery includes a Hybrid DC Power Interface Panel that safely organizes electrical connections in one convenient location. The Interface Panel allows quick and safe switch-overs from emulation to battery specimen. Unplug the emulation power source, plug in the actual battery pack, throw a switch, and go. All other connections remain in tact as well as the many safety features provided by the Interface Panel. Total Solution from HORIBA’s Hybrid Team Comprehensive and Flexible Battery Emulation Solution Simulation Performance HORIBA Battery Emulation Solution provides high-accuracy modeling with the ability to truly replicate battery behavior, performance, and road load events for more reliable and accurate results. It differs from common solutions based on simulation alone only offer battery and hybrid developer tools that mimic simple charge and discharge events. Left: Battery parameters and calibration factors are modifiable Battery Pack Models ● Lithium Ion, LiFePO4, NiMH and Pb-acid battery pack models specifically calibrated for vehicle applications. ● Ultra Capacitor modeling is provided with all Virtual Battery programming. Three time sequence phases are offered to reflect short, medium, and long term effects. Above: Easily create new battery pack models ● Model parameters and battery controls can be changed and optimized even while a test is in progress. ● Flexibility to create new battery models by identifying parameter values: Left: Strip chart provides instant visualization of Virtual Battery performance ・Open Circuit Voltage ・Maximum Available Current ・Battery Cell Capacity ・Discharge and Charge Power Limit ・Ohmic Resistance ・Operating Pack Temperature Limit ・Resistance and Conductance of Short/Long Time Effect ・Cell Geometry (cylindrical/prismatic) Control Parameters Test Conditions External Influences ● High-speed access and control of: Power Limits (Amp / V / W), State of Charge (SOC), Depth of Discharge (DOD), Thermal Control, Slew Rate and Cell Numbers ● Driving cycles from automation system via CANbus, Ethernet and Analog, Environmental conditions, Stress (maximum performance), Battery age, Battery pack thermal management ● Real-time (1 kHz) interface to external simulators and automation system for simulation of: Accessory Power demand, Current or Power demand from E-motor, Ambient Temperature, Cabin Temperature and SOC Windows ・Numbers of Parallel / Series Connections Intuitive GUI Interface is available to any networked computer using a Web browser Hardware Options Hybrid DC Interface DC Power Supply ● Interface panel offers convenient, safe hook-up for two E-motors with access to signals for measurement devices ● Low ripple and fast response assures accuracy during transient modes ● Easy switch-back between battery pack and DC power supply without E-motor disconnection ● True voltage symmetry protects electronics from unrealistic voltage to reference ground ● Wall mounted junction box with circuit breaker ● Voltage indicators for power on/off indication ● Insulation monitoring device to detect ground fault ● E-Stop tie-in for safe removal of power and PLC communication to TAS for proper shut down ● Voltage matching start up prevents damaging current rush ● Power circuit health and safety monitoring Please read the operation manual before using this product to assure safe and proper handling of the product. http://www.horiba.com ● HORIBA, Ltd. Head Office Miyanohigashi, Kisshoin Minami-ku, Kyoto Japan Phone: 81 (75) 313-8123 Fax: 81 (75) 321-5725 ● HORIBA India Private Limited Delhi Office 1212A, Hemkunt Tower, 98 Nehru Place, New Delhi - 110019 INDIA Phone: +91 11-4669-5001/5002 ● HORIBA EUROPE GmbH Head Office Hans-Mess-Str.6 D-61440 Oberursel/Ts. Germany Phone: 49 (6172) 1396-0 Fax: 49 (6172) 137385 Bulletin:HRE-2198A e-mail: info@horiba.co.jp Tokyo Sales Office 1-7-8 Higashi-Kanda Chiyoda-ku, Tokyo, Japan Phone: 81 (3) 3861-8231 Fax: 81 (3) 3861-8259 TAIWAN Representative Office 3F, NO.18 Lane 676, Chung Hua Rd, Chupei City, Hsinchu Hsien, 302,Taiwan Phone: 886 (3) 656-1012 Fax: 886 (3) 656-8231 ● HORIBA INSTRUMENTS INCORPORATED Ann Arbor Facility Irvine Facility 5900 Hines Drive 17671 Armstrong Avenue Ann Arbor, MI 48108 Irvine, CA 92614, U.S.A. U.S.A. Phone: 1 (949) 250-4811 Phone: 1 (734) 213-6555 Fax: 1 (949) 250-0924 Fax: 1 (734) 213-6525 Darmstadt Office Landwehrstrasse 55 64293 Darmstadt Germany Phone: 49 (6151) 32-3098 Fax: 49 (6151) 32-3865 Leichlingen Facility Julius-kronenberg Strasse D-42799 Leichlingen Germany Phone: 49 (2175) 8978-0 Fax: 49 (2175) 8978-50 ● HORIBA TRADING (SHANGHAI) CO., Ltd. Shanghai Office Beijing Office Room 1701, United Plaza, Room 1801, Capital Tower, 1468 Nanjing Rd. West, Beijing, Tower 1 No.6Jia, Shanghai, 200040, China Jianguomenwai Ave., Chaoyang District, Beijing, Phone: 21-6289-6060 100022 China Fax: 21-6289-5553 Phone: 10-8567-9966 Fax: 10-8567-9066 Troy Facility 2890 John R. Road Troy, MI 48083 U.S.A. Phone: 001 (248) 6899000 Fax: 001 (248) 6898578 HORIBA SWEDEN Sydhamnsvägen 55-57, SE-151 38 Södertälje, Sweden Phone: 46 (8) 550-80701 Fax: 46 (8) 550-80567 ● HORIBA INSTRUMENTS LIMITED Kyoto Close Summerhouse Road Moulton Park, Northampton NN3 6FL, U.K. Phone: 44 (1604) 542500 Fax: 44 (1604) 542699 Netherland Office HORIBA Benelux Science Park Eindhoven 5080 (Industrial park "Ekkersrijt") 5692 EA, Son, Netherlands Phone: 31 (0) 40-2900-240 Fax: 31 (0) 40-2900-624 ● HORIBA KOREA Ltd. 112-6 Sogong-Dong Choong-ku, Seoul, Korea Phone: 82 (2) 753-7911 Fax: 82 (2) 756-4972 ● HORIBA GmbH Kaplanstrasse 5 A-3430 Tulln, Austria Phone: 43 (2272) 65225 Fax: 43 (2272) 65230 ● HORIBA FRANCE 12, Avenue des Tropiques 91955 LES ULIS France Phone: 33 (1) 69-29-96-23 Fax: 33 (1) 69-29-95-77 ● HORIBA INSTRUMENTS Pte. LTD. 10 Ubi Crescent #05-11/12, Ubi Techpark Singapore 408564 Phone: 65 6745-8300 Fax: 65 6745-8155 HORIBA CZECHIA Organizachi slozka Praha Petrohradska 13 CZ-101 00 Praha 10, Czech Republic Phone: 420 (2) 717-464-8 Fax: 420 (2) 717-470-64 ● HORIBA Jobin Yvon SRL Torino Office Europalace Corso Torino 43/45 10043 Orbassano,Torino Italy Phone: 39 (011) 9040601 Fax: 39 (011) 9000448 Printed in Japan T-G(SK)23 Total Solution from HORIBA’s Hybrid Team A Complete Hardware-in-the-Loop (HIL) Driveline Test System Featuring Advanced Engine Simulation Virtual Engine Shorten the Product Launch Cycle ● Use production-intent engine performance characteristics early in the development cycle ● Eliminate invalid tests due to incorrect engine calibration ● Easily connect and test any type of transmission as if it were installed in a real vehicle ・FWD and RWD ・ Right-hand and left-hand output shafts ・ HEV, DCT, CVT, manual, and automatic ● Improve test repeatability with predictable, controlled “engine” performance Increase Test Cell Efficiency ir tual ehicle Testin ● Quickly set up single cylinder to V16 “engines” of different fuel types and displacements to get different torque signatures Virtual Engine uses advanced software control and a specialized AC dynamometer to accurately simulate IC engine performance. ● Test transmissions of varying sizes (with inertia values up to 0.5 kgm2) Reduce Capital and Operational Costs ● Eliminate frustration and costs associated with fueled engines : ・No fuel handling ・No exhaust extraction ・No engine calibration ・No bolt-up headaches ● Eliminate costly and labor-intensive prototype engines prior to test start up ● No engine cooling requirement ● No fuel, oil, filters or labor for engine maintenance Expect Excellent Correlation to ICEs Virtual Engine accurately replicates the torque signature of an internal combustion engine (ICE) using real-time closed loop feedback with adaptive control algorithms. The closed-loop adaptive controls compensate for : ● Mismatch between real engine inertia and input dynamometer inertia ● Mechanical dynamics due to specimen and attachment properties ● Electro-mechanical conversion of energy at different torque levels and speed Ultra-High Response Dynamometer [DYNAS TP260] Total Solution from HORIBA’s Hybrid Team Three-Part Solution for Driveline Development and Validation without a Fueled Engine Advanced Simulation Software Advanced, torque-control based, real time model of ICE. Provides 48 engine orders, closed loop torque correction in amplitude and frequency, and correction for friction loss. Includes simulation of engine torque management schemes for driving and operating events. Generates CAN bus messages and/or special pulse train signals to satisfy any power train control unit. ● Engine Controls Simulation (ECS) ● Engine Torque Pulsation Simulation (ETPS) ・Altitude affects, Fuel cutoff ・Torque from combustion pressure ・Variable displacement ・Piston bore, inertia, the number of cylinders, stroke ・Accessory load variations ・Mean torque by special “rotating” filter ・Electronic throttle ・Angular Acceleration on FEAD ・Torque intervention schemes ・Engine friction ・Engine start /stop strategy ・Engine flywheel inertia ・Timing & Position Pulse Train Engine Torque Pulsation Simulation (ETPS) Ultra-Low Inertia AC Dynamometer Mechanical Support HORIBA’ s TP-series high performance AC dynamometers produce high torque and acceleration rates of 50000 rpm/sec for gasoline and 20000 rpm/sec for diesel. It also features extremely small motor diameters, allowing a production half shaft connection for FWD transmissions. HORIBA’ s Virtual Engine System offers superior mechanical support components engineered to withstand the rigorous requirements of transmission development and durability testing. The dynamometer headstand offers superb flexibility, quickly accommodating different transmissions at mounting angles that match in-vehicle installations. Torque (Nm) 1000 800 Transmission Fixture Interface 600 400 200 0 0 5000 10000 Speed (rpm) 15000 T-DYN380 hs TP460 kw PM360/230 kw TP 260 kw ULI 220 kw T-DYN-150 kw ULI 90 kw ± 90°Rotation, ± 7°Tilting Optional Specimen Mounting Plate Variations of AC Dynamometer Please read the operation manual before using this product to assure safe and proper handling of the product. http://www.horiba.com Bulletin:HRE-2265A e-mail: info@horiba.co.jp Printed in Japan TH-G(SK)13 The OBS Series Robust and Reliable PEMS Gaseous/Particulate Measurement System Closest Correlation with Laboratory Results Heated PM Filter (HF-47) PM Measurement Diffusion Charger Sensor (DCS) OBS-2000 TRPM PM Measurement Proportional Dilution Sampler (DLS) • Measurement of Total PM (not just soot) with same heated filter and pre-classifier used in laboratory tests. PM Measurement • Proportional Sampling for accurate accounting of volatiles. • Laboratory-grade analyzers plus exhaust flow meter for mass analysis of CO, CO2, THC, and NOx. • Compliant with CFR Part 1065 Exhaust Emissions Measurement System Control Interface Unit & Power Supply Gaseous Analysis Strongest Technical Solution Using Two PM Measurement Technologies • Gravimetric (filter-based) sampling only during NTE events assures traceable mass results. • Diffusion Charger Sensor (DCS) has sensitivity for real-time measurement of post-2010 PM standard. Total PM Measurement Includes: • Selected by the EU PEMS Program as the reference PM mass measurement principle. Broad Range of Applications • • • • • • Heavy duty highway (CFR 1036) Non-road CI (CFR 1039) Marine (CFR 1042) Locomotive (CFR 1033) Light duty diesel & gas direct injection On-board reference fuel economy (OBS-2200 only) Ask HORIBA about custom vibration isolation for challenging terrains! Our Road, Or Yours? Access the powerful OBS series without the commitment of ownership when you choose HORIBA’s new contract testing program. Contact us today to learn more. Automotive Test Systems | Process & Environmental | Medical | Semiconductor | Scientific Explore the future Automotive Test Systems | Process & Environmental | Medical | Semiconductor | Scientific APPLICATION SOLUTIONS The OBS Series for In-Use Compliance and NTE Testing M ost land-based diesel engines are required by EPA to be tested in the field while installed in the vehicle or equipment. Brake-specific gaseous and total particulate emissions are measured by a portable emissions measurement system while the engine operates • within its Not-to-Exceed (NTE) zone. • 40 CRM Part 1065 defines the test procedure, equipment requirements, and data that must be reported. HORIBA offers two portable emission measurement systems that comply with the 1065 requirements when used together. • Left: Engine conditions define the NTE Zone, which dictates when emissions are measured during in-use testing. phase of the EU PEMS PM mass measurement program for the in service conformity testing of heavy duty diesel vehicles. The system has these features: A GPS provides position and velocity data. • Proportionally dilutes raw exhaust. Optional OBD module logs ECU data using J1939 and J1708 HDD interfaces. • No back pressure on vehicle exhaust/after-treatment. Signal inputs allow monitoring of engine parameters and atmospheric conditions in real time. Optional additional inputs available for other signals. T he OBS-2000 TRPM is a real-time particulate mass emissions measurement system. The system meets all of the 1065 requirements. In addition, it has been selected as the reference method for the next Only a small portion of the HDD Highway transient test cycle falls into the NTE zone. he OBS-2200 measures CO, CO2, THC, and NOx mass emissions as well as air-to fuel ratio and fuel consumption. T • Compact and portable, the OBS-2200 requires just 0.8 m2 of space in--or on-- the vehicle. • Includes real-time particulate measuring device for in-situ analysis. • Collects particulates on standard 47mm filter. • Measured filter mass calibrates real-time PM measurement device for engine-specific calibration. • No user input required during testing. • Long test times possible; well beyond 8 hours. Requirement Solution Simultaneous testing of both gaseous and PM emissions A combination of both OBS-2200 & OBS-2000 TRPM Gaseous analysis only OBS-2200 PM testing only OBS-2000 TRPM www.HORIBA.com - 800.346.7422 031411 Explore the future Automotive Test Systems | Process & Environmental | Medical | Semiconductor | Scientific • Passenger • Hybrid • Commercial • Military • Non-Road • Wind Energy • Rail • Marine • Passenger • Hybrid • Commercia • Military • Non-Road • Wind Energy • Rail • Marine • Passen ger • Hybrid • Commercial • Military • Non-Road • Wind Energy • Rail • Marine • Passenger • Hybrid • Commercial • Military • Non-Road • Wind Energy • Rail • Marine • Passenger • Hybrid • Commercial • Military • Non-Road • Wind Energy • Rail • Ma rine • Passenger • Hybrid • Commercial • Military • Non-Road • Wind Energy • Rail • Marine • Passenger • Hybrid • Commercia Contract Testing Services • Military • Non-Road • Wind Energy • Rail • Marine • Passen ger • Hybrid • Commercial • Military • Non-Road • Wind Energy