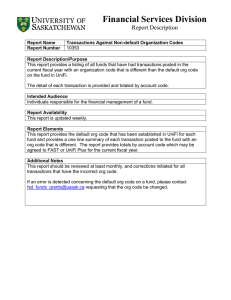

Repreve

advertisement

®

f o r

t h e

p l a n e t

Û Making Repreve fibers from r ec yc l e d m ate r i a l s

Û Making recycled fibers certifiably sustainable: U Trust ™ verification program

Û Providing competitive textile solutions

W E’ R E B IG I N R EC YCL ED.

Repreve is fiber made from recycled materials.

One of the most earth-friendly fabric ingredients you’ll find anywhere.

Wo r k i n g h a r d to m i n i m i ze o u r en v i ro n m en ta l i m pac t.

D o i n g e v ery t h i n g w e c a n to ac h i e v e t h e h i g h e s t

s ta n da r ds f o r su s ta i n a b l e t e x t i l e s .

Mar k ets U n ifi S e rve s : Hom e fu rni s hings

Office furnishings

H o s p i ta l i t y

A p pa r e l

S o c k s / h o s i e ry

Sewing thread

W e ’ r e U n i f i, a leading producer of synthetic fibers.

O u r goa l is to provide both customers and consumers

But Repreve is not just made with recycled content. It’s also made

with integrity. It took us years to develop our proprietary process,

to make Repreve certifiably sustainable. Since the beginning,

it’s been continually improving as we develop new technology.

But one thing hasn’t changed. As we commercialize new recycled

products, we still follow these Repreve brand principles:

Industrial

A u to m ot i v e

M i l i ta ry

Medical

1

2

3

4

Making repreve from

R e c yc l e d M at e r i a l s

M a k i n g r e c yc l e d f i b e r s

c e r t i f i a b ly s u s ta i n a b l e

Competitive

Te xtile Solution s

B r a n d i n g pa r t n e r s h i p s

for stronger marketing

Û

Û

Û Extensive recycled product line,

including filament polyester and nylon, and staple polyester fiber

Û True working partnerships, from product development to marketing Reduces energy consumption and

conserves petroleum-based resources

by offsetting the need to produce

virgin synthetic fibers, providing a

reprieve for our planet

with products that enhance the value of everyday things.

But we’re not just making products.

From offices to manufacturing to shipping, we’re doing

everything we can to provide s u s ta i n a b l e te x ti l e s o lu ti o n s .

bra n d p ri n c i p l e s

M a de r espon si b ly.

To m a k e a d i ffer en ce .

Our U Trust™ verification program

ensures that Repreve recycled fibers are traceable, transparent, and certifiably

sustainable

Û Unique Fiberprint ™ technology for

enhanced traceability

Û Recycled content certified by a third party

Û Repreve fabric certification by Unifi

Û Recycled performance fibers

Û Globally available

Û Consistent quality; adheres to Unifi’s first-quality standards

Û Repreve For the Planet; an engaging and educational marketing program

Û Repreve gives back through 1% For

The Planet™

With Repreve recycled yarn leading the way. Fo r th e pl a n e t.

{1}

Repre ve recycled fibers

w w w.repre ve.com

repre vemarke ting @ unifi.com

w w w.unifi.com

R ec ycl ed fi b er s .

A r epr i e v e for o u r pl a n e t.

M a k i n g R e p r e v e s ta p l e fib e rs

Post-industrial fiber waste and

post-consumer plastics are collected.

Post-industrial fiber waste and

post-consumer plastics are collected.

Û

Û

Repreve conserves resources because it offsets the need to use newly

refined crude oil. On average, every pound of Repreve yarn conserves

the equivalent of half a gallon of gasoline.

Û

The collected waste then enters a unique

material conversion process where it’s chopped,

ground, melted, and reformulated.

The processed material and post-consumer bottle

flake are blended, melted, and extruded to form

recycled fibers.

Repreve, a recycled chip, is formed.

Û

Û

Our process charts and comparisons tell the story. Û

To impart necessary physical properties, the fibers are then

drawn, crimped, cut, and compressed into bales.

The Repreve chip is extruded and textured

through a proprietary process.

Û

Û

Repreve—a family of 100% recycled fibers.

Behind every mound of post-consumer waste is a

mountain of post-industrial waste. That’s why our

process includes collecting and using post-industrial

waste from manufacturing. We start with ourselves—

collecting and reusing our own manufacturing waste

to conserve more natural resources.

ΠAll resource conservation calculations are specific only to the Repreve product.

Post-industrial fiber waste is processed and

post-consumer plastics are cleaned and chopped

into flake.

Û

Oil refining is a complex industrial process that turns crude oil into a multitude of

petroleum-based products. Some of these products are then made into ingredients

that go into plastics and synthetic fibers. Recycling materials to make Repreve helps

keep materials made from this precious resource out of the waste stream.

R e c yc l i n g t wo k i n d s o f wa s t e

R EC Y CLED F I B E R S

M a k i n g R e p r e v e f i l a m e n t fib e rs

Repreve—a family of 100% recycled fibers. The Repreve

fibers are further processed to form Repreve spun yarns.

P o ly e s t e r p r o c e s s c o m pa r i s o n

N y lo n p r o c e s s c o m pa r i s o n

S ta p l e p r o c e s s c o m pa r i s o n

For every 1 lb. of Repreve polyester yarn,

50,000 btu’s* are conserved, equivalent

to 0.4 gallons of gasoline.

For every 1 lb. of Repreve nylon yarn,

77,000 btu’s* are conserved, equivalent

to 0.6 gallons of gasoline.

For every 1 lb. of Repreve polyester yarn,

50,000 btu’s* are conserved, equivalent

to 0.4 gallons of gasoline.

V i rg i n P o ly e s t e r

R e p r e v e P o ly e s t e r

V i rg i n N y lo n

R e p r e v e n y lo n 6 , 6

V i rg i n P o ly e s t e r S ta p l e F i b e r

R e p r e v e P O LY E S T E R S ta p l e F i b e r

Crude oil wellhead

Process eliminated

Crude oil wellhead

Process eliminated

Crude oil wellhead

Process eliminated

Crude oil refinery

Process eliminated

Crude oil refinery

Process eliminated

Crude oil refinery

Process eliminated

Naptha

Process eliminated

Benzene

Process eliminated

Naptha

Process eliminated

Xylenes

Process eliminated

Cyclohexane

Process eliminated

Xylenes

Process eliminated

Paraxylenes

Process eliminated

HMD** & Adipic Acid

Process eliminated

Paraxylenes

Process eliminated

TA** & MEG***

Process eliminated

Nylon Salt

Process eliminated

TA** & MEG***

Process eliminated

Polymerization

Repreve chip production

Polymerization

Repreve chip production

Polymerization

Repreve feedstock preparation

Extrusion

Extrusion

Extrusion

Extrusion

Extrusion

Extrusion

Texturing

Texturing

Texturing

Texturing

Staple processing

Staple processing

* British Thermal Units

** TA is Terephthalic Acid

*** MEG is Mono Ethylene Glycol (Can be made from oil or natural gas)

Repreve nylon 6,6 does not contain post-consumer plastics.

* British Thermal Units

** Hexamethylene Diamine

* British Thermal Units

** TA is Terephthalic Acid

*** MEG is Mono Ethylene Glycol (Can be made from oil or natural gas)

{3}

TR ACE AB LE .

TR ANSPAR ENT.

CERTIFIAB LY

SUSTAINAB LE .

U TRUST

T RUS T W H AT

YOU ’ RE GE T T ING .

Our U Trust ™ verification program ensures that Repreve recycled

fibers (and your fabrics and products) are traceable, transparent,

and certifiably sustainable.

From our plant, Repreve fibers are third-party certified for recycled content

claims. From any point in the supply chain, using our unique Fiberprint™

technology, we can test your products to verify Repreve is in there,

and in the right amounts. And we protect what Repreve stands for.

Products made from fabrics with Repreve are tested and certified before the

Repreve brand name can be used.

U t ru s t

Verification Program

RECYCLED

CONTENT

U TR U ST™ V ERIFICATION PROGRAM

WITH FI B ERPRINT™ TECHNOLOGY

C e r t i f i e d f o r r e c yc l e d

content cl aims

C e r t i f i e d f o r h e a lt h

and safety

We certify

Repreve products

Trust and transparency are important to us.

That’s why the amount of Repreve can be

tested and analyzed in any fabric or product

with our unique Fiberprint technology.

Repreve fibers are certified by Scientific

Certification Systems (SCS) for recycled

content claims. Every year, Scientific

Certification Systems performs a full

examination of our recycled products,

including our recycling processes,

production records, and manufacturing

operations. SCS is a leading third-party

certifier and standards developer of

environmental and sustainability claims.

Repreve has also received the Oeko-Tex

Standard 100 certification, a well-known

international eco-label. Oeko-Tex offers

“Confidence in Textiles,” providing testing

and qualification that ensures that our yarns

are free of harmful levels of more than 100

restricted chemicals. The Oeko-Tex Standard

100 is the world’s leading label for textiles

screened for harmful substances.

Repreve is made better. And we protect what

it stands for, too. Products made from fabrics

with Repreve are tested and certified before

the Repreve brand name can be used.

ΠTo qualify for Repreve branding, fabrics must be certified to contain a minimum of 30% of Repreve by

weight of total fabric construction.

ΠOur goal is to have all products certified for recycled content claims. However, as we continue to evolve

our recycled product offering, some of our newer products may be under evaluation by a third party.

{5}

C o m p e titi v e t e x ti l e s o l uti o n s

Fi n d yo u r r epr e v e .

Now more choices. All traceable, transparent, and certifiably sustainable.

Avai l ab le

wor ldw i de .

W ith the

sam e qualit y.

An d th e sam e

i nteg r it y.

It started with one simple idea: to make Repreve one of the most earth-friendly

fabric ingredients in the world. It took us years to develop our proprietary process.

And now we continue to expand our recycled product offering to provide our

customers with an extensive array of sustainable solutions. This is our story so far...

®

R E C YC L E D F I L A M E N T

P o lye s ter F I B E R

R E C YC L E D F I L A M E N T

N Y LO N 6 , 6 F I B E R

R E C YC L E D S TA P L E

P O LY E S T E R F I B E R **

R E C YC L E D P E R F O R M A N C E

F I B E R S ***

Available as 100% hybrid blend*

Made entirely from post-industrial waste

The essential ingredient to make spun fibers

A family of recycled fibers

The original polyester filament fiber

Designed to provide performance

features, including:

A unique blend of post-industrial and

post-consumer waste

Û

Û

Û

Û

Û

Available as 100% post-consumer blend

We understand the importance of providing our customers with quality recycled

products. That’s why we have a dedicated team that closely monitors all things

Repreve from start to finish. We follow rigorous procedures to qualify varying waste

streams and ensure proper blending in manufacturing. This assures we provide our

customers quality products that are easily used in place of virgin fibers.

Made entirely from post-consumer waste

(PET bottles, of course)

* Repreve filament polyester fibers contain a minimum of 20%

post-consumer recycled content.

** Repreve staple polyester fibers contain a minimum of 50%

post-consumer recycled content.

Flame retardancy

Moisture wicking

Comfort and performance stretch

UV protection

Color technology

• Solution dyed

• Package dyed

*** Specific functional properties are available upon request.

Products containing functional and/or performance additives

contain a minimum of 95% recycled content.

{7}

A R EC YCLED

FAMILY

THAT K EEPS

GROWING .

Repreve has evolved from a recycled filament polyester fiber

to a family of recycled synthetic fibers.

And our family keeps growing. Recycled fibers are now available with performance

features including flame retardant, moisture wicking, and stretch, to name just a few.

Recycled fibers are also available with color technology, including solution and

package dyed products.

R e p r e v e f l a m e r e ta r da n t

Performance Possibilities

A recycled fiber with flame retardant technology

Û

Repreve with flame retardant (FR) technology utilizes proven

FR chemistry—phosphorus. The phosphorus is inherent

within the fiber so it’s durably sustainable. And because

Repreve FR can end up in a variety of fabric constructions,

we only certify the level of phosphorus within the fiber.

Of course, we can always certify the recycled content.

C o m p e titi v e t e x ti l e s o l uti o n s

N ow w ith per for m a n ce .

Repreve with moisture wicking technology

Permanent moisture management performance leaves the wearer cool, dry and comfortable.

Û

Repreve with stretch technology

A family of recycled fibers with varying levels of stretch

designed for comfort and performance.

Û

Repreve with UV protection technology

Provides permanent sun protection against harmful UVA

(aging) and UVB (burning) rays.

Û

Repreve with color technology

Solution Dyed

Coloration during the extrusion process locks in rich,

vibrant colors and eliminates the need for further

fabric dyeing, helping to conserve water.

Package Dyed

Œ All fibers sold as Repreve ® FR flame resistant or retardant ( FR ) are warranted only to

contain no less than 2000 parts per million phosphorus. Unifi makes no performance

claims of flame retardancy or flame resistance based upon any standard, whether

governmental, industry or otherwise. Unifi specifically disclaims any such performance

claims. All purchasers of Repreve ® FR yarns must sign the Unifi DISCL AIMER AND

ACKNOWLEDGMENT form before purchasing any Repreve ® FR yarns.

Coloration exhausted onto yarn when immersed in a

dye bath, creating long lasting, durable colors.

ΠSpecific functional properties are available upon request. Products containing functional

and/or performance additives contain a minimum of 95% recycled content.

Œ Unifi ® has the right to accept or reject fabric submissions based on minimum performance

requirements. Fabrics failing to meet the minimum required criteria may be submitted for

testing, but certification may be rejected on these grounds.

{9}

bra n d i n g p art n e rshi p s

B r a n d i ng pa rt n er sh i p s

for s t rong er m a r k e t i ng .

MADE B E T TER .

E ASY TO

WOR K WITH .

Repreve is made better. And we protect what it stands for, too.

Here’s how to get your products certified.

Products made from Repreve fabrics are tested and certified before they can

use the Repreve brand name. To qualify for Repreve branding, fabrics must be

certified to contain a minimum of 30% Repreve fiber by total fabric weight.

Wo r k i n g w i t h t h e R e p r e v e b r a n d n a m e

H e l p f u l h i n t s f o r wo r k i n g w i t h R e p r e v e f i b e r s

Easily enhance your brand’s products and packaging by using the

Repreve brand message. Once your product is certified by Unifi,

we’ll work with you to provide you the appropriate marketing

materials. These may include Repreve hang tags, artwork, language,

and legal guidelines.

Û Fabric processing and performance characteristics are

consistent with traditional virgin fibers.

To maintain our brand’s integrity, we’re very watchful of the claims

we and our partners make. Please contact reprevemarketing @ unifi.

com for details.

Û

Û

It’s easy and efficient for you

to work with our products.

If you’re a textile customer,

our Certification Portal and

Fabric Library put you in

immediate communication

with us. It’s quick, easy to use,

private, and totally free.

To start this process and

receive your log-in credentials,

follow the easy steps.

Û When working with Repreve, dye color selections should be

determined and tested during initial development stages.

Û For fabric construction recommendations and dyeing and

finishing guidelines, please refer to the Repreve Code of Best

Practices. Please contact your Unifi Account Representative

for more information.

N e w c u s to m e r

lo g - i n

A p p r ov e d

c u s to m e r lo g - i n

Certify

a fa b r i c

Lo o k f o r R e p r e v e

c e r t i f i e d fa b r i c s

Û

Log onto www.repreve.com.

Û Log onto www.repreve.com.

Û

Û

Look for the Fabric Library link.

Û Look for the Fabric Library and enter your log-in credentials.

Û Log onto the Fabric Library and

follow the easy directions.

Û

To enter, we just need you to submit a short application form. (Please complete all the fields to be sure it submits.)

The information you provide will stay

confidential and will not be used for

anything beyond this application.

Yes, we do screen out competitors and

curious bystanders.

Log onto the Certification

Portal through the Fabric Library link and follow the

easy directions.

Once you have submitted your product

for testing and certification, you can:

Use this Library to:

Û Research new and existing Repreve certified fabrics.

Û Check certification status.

Û Create and print your own fabric swatch book.

Û Request Repreve hangtags.

Û Request fabric samples.

Œ Unifi ® has the right to accept or reject fabric submissions based on minimum performance requirements.

Fabrics failing to meet the minimum required criteria may be submitted for testing, but certification may

be rejected on these grounds.

Repre ve recycled fibers

w w w.repre ve.com

repre vemarke ting @ unifi.com

w w w.unifi.com

{ 11 }

bra n d i n g p art n e rshi p s

R epr e v e .

For th e pl a n e t.

How can a little bitty R ECYCLED fiber make our big

world better? Just one can’t do it alone. (Too skinny.)

But when a bunch of these filaments get together, they make Repreve fiber. In the same way,

when we decide as manufacturers, brands, and retailers to make a better world, we can have a

huge impact on the environment. Because when more people buy products made with Repreve,

fewer resources get used up. Creating a reprieve for our planet. Our consumer-focused

marketing program will support and complement your marketing messages. And strengthen

your brand’s connection with consumers. Repreve allows your consumers to take part in our

give-back program with a simple pledge: We give back. You choose.

More questions ?

Please contact your Unifi representative

or email us at reprevemarketing @ unifi.com.

Wa n t to s h a r e o u r s to ry ?

And conserve paper at the same time?

Go to www.repreve.com for a downloadable,

email-able version of this brochure.

F o r th e

La n d

F o r th e

futur e

F o r th e

W i l d l if e

F o r th e

W at e r

F o r th e

R e s o ur c e s

Atte ntion -getting h a ng tag

G i v i n g b ac k 1 %

I n v i tat i o n to i n t e r ac t

Vot e o n t h e w e b s i t e

A series of five hang tags grabs consumers’ attention with

the theme “Repreve. For the Planet.” Each hang tag has

a different cover message, depicting the range of

environmental causes supported by the program.

Repreve is a member of 1%

for the Planet. And we pledge

one percent of all Repreve

sales to support environmental

non-profits.

The hang tag clearly communicates the

Repreve brand’s environmental message.

It also invites consumers to interact

with the brand online by helping Repreve

give back.

Consumers take the hang tag to the web site

www.repreve.com to learn more about the

program. They feel they’ve done something

good for the planet by casting a vote for the

cause they choose. They can also learn more

about Repreve recycled—why it’s different,

how it’s made, and where to find it.

ΠSpecific details of the Repreve For the Planet marketing campaign are

subject to change.

SW-COC-000668

© 20 09 Unifi, Inc .

Repre ve is a tr ademark of Unifi, Inc .

and is registered with U. S . Patent and

Tr ademark Office and with others .

U Trust and Fiberprint are tr ademarks

of Unifi, Inc .

U n i f i T e x t i l e s ( Su z h o u ) C o . , Lt d .

Unifi, inc.

7201 W. Friendly Ave.

Greensboro, nc 27410

p: 336 294 4410

f: 336 316 5422

email: reprevemarketing @ unifi.com

Repre ve recycled fibers

w w w.repre ve.com

Room 1101, Gold River Center

No. 88 Shishan Road

Suzhou New District,

Suzhou, Jiangsu Province,

P.R. China 215011

p: +86 512 6818 7198

f: +86 512 6818 7199

email: utsc.marketing @ unifi.com

repre vemarke ting @ unifi.com

w w w.unifi.com