Abcd Eukaryotic Cells Ride the Wave

advertisement

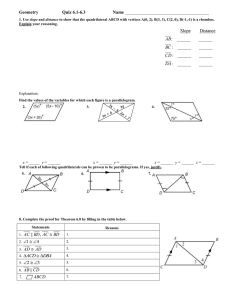

Abcd Eukaryotic Cells Ride the Wave Expanding the Drug Discovery Pipeline by Improving Protein Production Technology Joey M. Studts, Ph.D. Boehringer Ingelheim, Ridgefield, CT Keck Graduate Institute October 24, 2006 Riding the Wave Outline Abcd • Introduction to Boehringer Ingelheim • Overview of Drug Discovery Process • Introduction of protein production strategies at BI • Expression Screening – Two methods for different problems • Method to optimize time from DNA to Biomass (known protein targets) • Protocols • Overview of current data • Parallelized method for screening and expression optimization (novel protein targets) • Protocol and protocol optimization • Two case studies Abcd Boehringer Ingelheim Worldwide Finland Canada USA Egypt Mexico Panama Venezuela Colombia Ecuador Peru Chile Belarus Russia Ukraine Kazakhstan Uzbekistan Japan Korea Turkmenistan China Hong Kong Taiwan United Arab Emirates Philippines Saudi Arabia Vietnam Thailand India Malaysia Indonesia Brazil Uruguay Argentina South Africa Boehringer Ingelheim companies Minority interest, or agency Research Sites Australia New Zealand Abcd Boehringer Ingelheim The Fastest Growing Company Growth (%) in 2005 BI Growth +23.3% ( 1) Boehringer Ingelheim ( 2) Amgen ( 3) Teva + Ivax ( 4) Novo Nordisk ( 5) Roche ( 6) Otsuka ( 7) Merck KGaA ( 8) Novartis + Chiron ( 9) AstraZeneca (10) Abbott (11) Sanofi-Aventis (12) Daiichi Sankyo (13) Takeda (14) Schering AG (15) Lilly (16) Eisai (17) GlaxoSmithKline (18) Astellas Pharma (19) Bayer (20) Wyeth (21) Schering Plough (22) Johnson & Johnson (23) Merck & Co. (24) Bristol-Myers Squibb (25) Pfizer Global Market Growth +6.2% -10 -5 0 5 10 15 20 25 Boehringer Ingelheim Ridgefield, Connecticut Therapeutic Areas: • Cardiovacular • Immunology & Inflammation Size • 400 Acres • ~3500 People on site • >750 in R&D Abcd Drug Discovery Key Players… ¾ Target: A protein involved in a disease whose activity can be modified to improve health. ¾ Lead: A chemical entity that can modulate a target’s function and putatively modify disease. Abcd Abcd Timelines for protein production R&D vs. PD/Production Average: 12 Years and $800 Million (in 2003) 2-3 Years + 2 Years + + 5 -6Years 1Year 12 = Years Discovery Preclinical Development Clinical Trials FDA Rx 1 2 3 4 5 6 7 8 9 10 11 12 13 I II III Protein target required quickly to being drug discovery process Process development starts in years 2-3, have delivery target of year 5-7. Abcd Timelines for protein production R&D vs. PD/Production Average: 12 Years and $800 Million (in 2003) 2-3 Years + 2 Years + + 5 -6Years 12 = Years 1Year Discovery Preclinical Development Clinical Trials FDA Rx 1 2 3 4 5 6 7 8 9 10 11 12 13 I II III Research and Discovery* Process Development* Production* 12 -16 weeks 40 weeks 2-3 years Biomass Scale 0.1 – 25 L 1 – 80 L 80 – 15,000 L Product Scale 10 – 100 mg 1-10 g > kg Timelines *Averages from literature references and CMO websites Abcd Protein Resource Responsibilities Screening, LI, and LO Structural Research Target Validation Protein Characterization Protein Resources Cloning, Expression, Purification Tox Proteomics Collaborations Cellular Genomics Protein Production The Critical Path… Abcd • Often the critical path to High Throughput Screening • Always the critical path to getting structural information on a protein target. • Faster we can produce 10-100 mg of a target protein, the more efficient the drug discovery process. Keys Points to Take Away • Look at the process • Understand process: strategy and science! • Identify bottlenecks in that process to improve efficiency and effectiveness • Expand bottlenecks via strategy changes and scientific changes. Project Flow – Protein Resources ~4 months to protein delivery Abcd Cloning Gene Synthesis • Collaborators Deliver • Sequence verified DONOR vector • Raw Sequencing Data • Advantages • Paralleled process • Guaranteed/reproducible timelines • 3 weeks to DONOR • 4 weeks to Expression vector • For HT Strategy used to obtain wild-type construct • FTE Focus on expression screening, not cloning Abcd Target Protein Sequence (in silico) Reverse transcription Codon optimization Target DNA Sequence Oligo Synthesis PCR primer extension Target DNA Sequence Sequence verification Subcloning into vector Target DNA Sequence Introduction to BEVS Benefits of BV for R&D production Abcd • Eukaryotic cell lines • Cells fairly robust • Species fairly well defined. • Eukaryotic protein processing & post-translational modifications. • Expression protocols fairly rapid and highly reproducible • Timelines fairly short relative to other eukaryotic expression technologies. • Once virus produced, bench scale fermentation highly reproducible • Yields 1-50 mg/L, consistent with research needs. Introduction to BEVS Infection Progression Abcd • Viral RNA can be detected 30 minutes after inoculation – Viral DNA arriving in the nucleus and initiation of early transcription is a rapid process. • DNA replication begins 6 hours post infection • Early Phase: First 6 hours of infection – Cytoskeletal rearrangement, nucleus enlargement, host chromatin disperses • Late Phase: 6 – 24 hpi - Characterized by viral DNA replication, late gene expression, and BV production – Virogenic Stroma form in nucleus • Very Late Phase: Begins around 20-24 hpi – Production of BV greatly reduced, p10 accumulation, by 72hpi cells are no longer synthesizing proteins Baculovirus Expression Screening Two Pronged Approach Abcd Known Target Design 5-10 Constructs Synthesize & Subclone Transfect, Screen and Scale-up Virus Target Approval Design 10-100 Constructs < 10 Construct & Subclone Novel Target Transfect & Screen Select Optimal < 5 Construct(s)* Biomass Production < 10 Identify Optimal >10 Small Scale Expression Constructs* and Characterization *optimal construct selected based on expression levels Production Process Goals Baculovirus Expression Group: Alycia Shoultz Terry Wilson Abcd Nene Kalu Goals • Develop process to rapidly screen and scale up construct for baculovirus expression • Optimized for time to protein • Process designed to be reproducible and to supply protein for long term projects Abcd Virus Scale-up to Production Standard Strategy Expression Screen Standard Strategy 1 5 Transfection 10 Plaque P1 Purification. 15 19 20 P2 P3 Virus Stock 25 27 Plaque Assay Express. Opt. P4 • Initial expression screening via SDS-PAGE and Western analysis at ~3 weeks, very slow feedback times • 48 days to biomass with titered virus bank • MOI optimization studies added 1-2 weeks and often not reproducible in bioreactor 48 Days to Biomass Abcd Viral Scale-up to Production Screening and Production Process Expression Screen Standard Strategy 1 5 10 Plaque P1 Purification. Transfection 15 19 20 P2 P3 Virus Stock 25 Virus Stock Expression Screen 20 P3 1 5 Transfection Plaque Purification. 10 P1 Express. Opt. P4 Current Process Expression Screen 27 Plaque Assay Plaque Assay 15 P2 20 Wave Reactor 20 Days to Biomass • Expression Screening at 4 days • Earlier read on expression helps with project decisions 48 Days to Biomass Abcd Viral Scale-up to Production Screening and Production Process Expression Screen Standard Strategy 1 5 Transfection 10 P1 Plaque Purification. 15 19 20 P2 P3 Virus Stock 25 P4 Virus Stock Current Process Expression Screen Expression Screen 20 P3 1 5 Transfection Plaque Purification. 10 P1 Plaque Assay 15 P2 • Biomass in 20 Days! • • • 27 Plaque Assay 20 Wave Reactor 20 Days to Biomass Directly from P2 to fermentation Carry-out plaque purification maintain reproducibility Viral titer after initial fermentation • Not in critical path Express. Opt. 48 Days to Biomass Current Process Protocol… Optimized for time to biomass Abcd Step Description Transfection Plaque Purification 1 mL of viral supernatant, 4 days, 6 well plate, adherent cells 60 mm tissue culture plates, 5 days, adherent cells Screen P1 P2 Expression screen with Western 5 mL viral supernatant, 5 days, T-25 flask, adherent cells 100 mL viral supernatant, 3 days, 250 mL shake flask suspension cells Expression screen with Western 5L Wave BioReactor, 48-72 hour infection 500 mL viral supernatant, 3 days Master virus bank Titered (normally 10 fold increase between P2 and P3) Archived Screen Fermentation P3 Protein Expression- Baculovirus Cedex Information Abcd Abcd Following the Course of Infection Cedex Instrument • Cedex Data • Cell viability • Cell density • Cell diameter 100 Cell Density 28 90 27 Cell Viability 80 Cell Size 26 Infected 25 Harvest 135.9 grams 50 40 % Viable Cells / ml 60 24 23 30 22 20 10 5 0 10 0 1 2 Day 3 21 20 Cell Diameter (uM) 70 Viral Scale-up Monitoring Key Statistics for Volume Based MOI Abcd Infect Wave Bags with the P2 Virus. (The amount of virus used to infect is determined by the cell data and the SDS-PAGE/Western Blot results.) If at the P2 stage: Viability Cell Diameter Cell Density Expression 5L Infection Range Range Range Level @ P2 Volume <70% <24 μm No significant Fair 0.5-1.0 mL/L increase >80% but >26 μm No significant Good to 2.0 mL/L <90% increase Excellent < 28 μm >95% >24 μm Slight Decent to 5 mL/L increase Excellent <26 μm >90% <24 μm Significant Fair to Decent 10-20 mL/L increase Expression Level Rating System: 1. Poor 2. Fair 3. Decent 4. Good 5. Excellent Abcd Expression Screening Example Western Rankings MW 567 A 100kD ► 75kD ► 1 567 634 634 697 697 703 703 718 718 B A A A B 5 B 4 A B 3 Neg B 2 50kD ► Subjective Rating System: 1. Poor 2. Fair 3. Decent 4. Good 5. Excellent MW Protein Expression – Eukaryotic Abcd Large Scale Expression Stir Tank Bioreactors 3x25L, 1x15L Wave Bioreactors 4x25L, or 4x10L, or 8x5L (6x25, or 6x10L, or 12x5L) Large Scale Expression Wave BioReactor • Greatly increased capacity and decreased timelines!!! • 1 reactor = 2x5L or 1x10L • 2 rounds/reactor/week • No cleaning/sterilization • Turn-around time a matter of minutes • FTE costs are very low!!! Abcd Optimized Throughput System Abcd Statistics on Success Key: This is not an Expression Optimization Strategy Success based: on reproducing deliveringscreening protein toresults project • • • • • 95% - Successful on 1st run + 4% - Successful on 2nd run 1% - Follow-up optimization required Constructs labeled as “poor expressers” not included Purified Protein Yields • • • • Average Production Level – 6.8 mg/L Median Production Level – 3.4 mg/L High is 69.0 mg/L Low is 0.11 mg/L • 80% of proteins going for Structural Research efforts Abcd Purified Protein Yields Optimized for time to biomass… 80 Protein Yield (mg/L 70 60 50 40 30 20 10 0 1 8 15 22 29 36 43 50 57 64 71 Fermentation Number 78 85 92 99 106 Parallelized Expression Screening Goals Abcd HTC&E Group - Jim King, Ph.D. Mike DiCandido Jonathan Hill Xiaoyan Yang Alycia Shoultz Goals • Develop protocols for a paralleled approach for cloning and expression screening • Develop automated processes for executing these protocols • Provide highly paralleled expression screening data to quickly and efficiently identify highly expressing clones. Construct Design Parallelized Screening Process Abcd • Currently the major variable being tested in expression screening • Two approaches • N- and C-terminal truncations • Mutation scanning • Other expression variables tested • • • • infection time MOI temperature cell density at induction Two Approaches Domain Scouting by PCR Truncation Screening Domain 1 Domain 2 Abcd Target Domain etc… Abcd Two Approaches Mutation Scanning (single or multiple AA) Mutation Scanning (single or multiple amino acids) * * * * * * * * * * Target Domain * * * * * * * * * * Abcd Paralleled Approach - Cloning HTC&E Skill Center Gateway Cloning™ efficiently switch expression systems High-Throughput PCR Construct Design Qualify templates Primer ordering PCR BP-LR recomb. Sequence confirm clones Bacmid trans. Bacmid Prep Bacmid QC Transformation O/N growth Cloning Timeline 7 14 Design constructs, order supplies, qualify template 3 – 4 weeks 21 1 PCR & minipreps 3 weeks 7 14 Sequence Analysis 21 Bacmid Prep. & QC Abcd Protein Expression Screening Expression Data in 7 Days Virus Stock Viral Scale-up – 15 clone throughput Expression Screen Expression Screen 20 P3 1 5 10 Transfection Plaque Purif. P1 Plaque Assay 15 P2 20 HT Expression Testing - Scalable Expression Screen 1 Wave Reactor 20 Days to Biomass 5 Transfection P1 • Optimized timelines and protocols for small scale reproducibility • Expression screen by magnetic beads purification and Caliper LC90 give objective, quantifiable results Parallelized Expression Screening Initial Protocol Step Abcd Description Cloning DNA Plate delivered in 96 well plate format. Transfection 24 well plate, 2 mL, 5 Days, suspension cells. P1 Expression Screen 24 deep-well plate, 48 hrs, suspension cells, 5 mL culture Transfect at two different volume based MOI (100 and 400 uL virus) Screen using affinity purification and Caliper LC90 Prioritize Identify optimal expressing clones If > 10 Constructs 100 ml, 48 hour expression test in shake flask for biomass generation Small scale purifications to access protein stability and solubility Abcd Case Study Domain Scanning Project A BD 1 Functional Domain 158 675 158 665 675 298 298 N-terminal GST – 13/13 constructs N-6xHis – 10/13 constructs C-6xHis – 12/13 constructs BD = Binding Domain 675 665 309 675 309 665 318 675 318 665 328 675 328 665 675 338 665 338 352 352 675 665 Abcd Expression Screening MagneGST, SDS-PAGE, Western, LC90 1 2 3 4 5 6 7 8 9 10 11 12 13 14 N 1 2 3 4 5 6 7 8 9 10 11 12 13 14 N 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 BD-FD(158-675)-100 2 BD-FD(158-675)-400 3 FD(298-665)-100 4 FD(298-665)-400 5 FD(298-675)-100 6 FD(298-675)-400 7 FD(309-665)-100 8 FD(309-665)-400 9 FD(309-675)-100 10 FD(309-675)-400 11 FD(318-665)-100 12 FD(318-665)-400 13 FD(328-675)-100 14 FD(328-675)-400 15 Negative control Abcd Expression Trails – Project A Reproducibility Lower with P1 Screening Conc. 100 Inoc. (ng/ul) - clone #1 3000 Conc. 500 Inoc. (ng/ul) - clone #1 Conc. 100 Inoc. (ng/ul) - clone #2 2500 Conc. 500 Inoc. (ng/ul) - clone #3 Conc. 400 Inoc. (ng/ul) - clone #1 ng/ul 2000 Conc. 400 Inoc. (ng/ul) - clone #3 1500 1000 500 - - - - - - - - - - - 0 • Data from multiple screening tests at two different MOI levels. • Variability seemed high • Different MOI not as reproducible Abcd Data Collection Caliper LC90 • Micro-fluidic implementation of electrophoretic separation of protein samples. Instrument scans the fluid path over time to detect protein bound dye. • Data is captured as a trace, area of peaks are integrated to give a protein concentration measure. Software can convert data to a “Gel View”. Caliper claims 30% conc. CV Average of 7 LC90 runs 120 100 ng/ul 80 60 40 20 0 1 800 LM 600 500 157 ng/μl 53.3 kDa 400 300 200 157.11 * 14.29 5.52 7.05 5.67 91.74 209.02 100 0 2 3 4 5 6 7 Samples 700 Fluorescence Reproducibility of LC90 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 Time (seconds) 8 9 10 11 12 Abcd Protein Expression Screening Expression Data in 9 Days Virus Stock Viral Scale-up – 15 clone throughput Expression Screen Expression Screen 20 P3 1 5 10 Transfection Plaque Purif. P1 Plaque Assay 15 P2 20 HT Expression Testing - Scalable Expression Screen 1 5 Transfection P1 Wave Reactor 20 Days to Biomass 9 P2 • Each passage results in ~ 10-fold increase in viral titer • Increased virus titer increases reproducibility and protein production Case Study Project B Construct Design Binding 1 Binding 2 Abcd Disordered in crystal Catalytic Domain 433-725 448-725 N-terminal GSTN-terminal 6HisC-terminal 6His- 433-718 433-725 433-735 436-718 436-725 439-718 439-725 442-718 442-725 445-718 445-725 448-718 448-725 462-718 462-725 0 433-718 436-718 439-718 442-718 445-718 448-718 462-718 433-725 436-725 439-725 442-725 445-725 448-725 462-725 433-735 433-718 436-718 439-718 442-718 445-718 448-718 462-718 433-725 436-725 439-725 442-725 445-725 448-725 462-725 433-735 433-718 436-718 439-718 442-718 445-718 448-718 462-718 433-725 436-725 439-725 442-725 445-725 448-725 433-735 ng/ul Project B Construct Design Expression Screening GST N-terminal 6xHis Abcd 350 300 250 200 150 100 50 C-terminal 6xHis • Expression Screening Carried out after P2 amplification • Higher titers after P2 amplification but same volume • Carry-out duplicate experiments with single MOI • Increased reproducibility after P2 Parallelized Expression Screening Protocol Overview Step Abcd Description Cloning DNA Plate delivered in 96 well plate format. Transfection 24 well plate, 5 Days, adherent cells. P1 P2 Expression Screen 24 deep-well plate, 48 hrs, suspension cells, 5 mL culture. 24 deep-well plate, 48 hrs, suspension cells, 5 mL culture. Pellets frozen over week-end. Screen using affinity purification and Caliper LC90 Prioritize Identify optimal expressing clones If > 10 Constructs 100 ml, 48 hour expression test in shake flask for biomass generation Small scale purifications to access protein stability and solubility Overview… Abcd Expression Screening – Two methods for different problems • Method to optimize time from DNA to Biomass (known protein targets) • Parallelized method for screening and expression optimization (novel protein targets) • Understand a process • Strategy • Science • Eliminate bottlenecks in process • Strategy • Technology • Science Abcd Acknowledgements Translational Sciences Department – Sheenah Mische, Ph.D. John Miglietta Gale Hansen Biologics and Biomolecular Sciences Department - Christine Grygon, Ph.D. Protein Resources - Joey Studts, Ph.D. Kevin Barringer – cloning Alycia Shoultz – expression Terry Wilson – expression Anthony Kronkaitis – expression Xiang Zhu, Ph.D. - expression Daniela Cazacu – exp./purif. Elda Gautschi – purification Teresa Roma – purification Alistair Baptiste – expression High Throughput Cloning and Expression – Jim King, Ph.D. Michael Dicandido – cloning Jonathan Hill – IT/cloning Xiaoyan Yang – expression Structural Research Department – Sandy Farmer, Ph.D. Neil Farrow Mariana Margarit Kathleen Haverty Boehringer Ingelheim Production Biberach, Germany Abcd New Biopharmaceutical Production Plant Image: Boehringer Ingelheim GmbH http://www.boehringer-ingelheim.com/biopharm/news/biberach.htm Boehringer Ingelheim Production Biberach, Germany Abcd New Biopharmaceutical Production Plant Image: Boehringer Ingelheim GmbH http://www.boehringer-ingelheim.com/biopharm/news/biberach.htm Boehringer Ingelheim Production Biberach, Germany Abcd New Biopharmaceutical Production Plant Image: Boehringer Ingelheim GmbH http://www.boehringer-ingelheim.com/biopharm/news/biberach.htm