A galvanic isolated evaluation of a NTC thermistor using a

advertisement

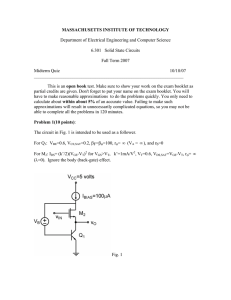

16th International Power Electronics and Motion Control Conference and Exposition Antalya, Turkey 21-24 Sept 2014 A galvanic isolated evaluation of a NTC thermistor using a logarithmic amplifier Yevgen Polonskiy, Denis Surmann, Christian Laudensack, Dieter Gerling Φ Abstract -- This paper presents a possibility to evaluate a NTC (negative temperature coefficient) thermistor, which exhibits an exponential behavior, using a logarithmic circuit. The presented method allows a quicker and precise processing compared to look-up tables or linearizing circuits. The resistance value is converted into a galvanic isolated voltage signal. Furthermore the presented design is optimized for a low current consumption. Both features allow a direct application on the power stage side with a supply given by IGBT driver auxiliary supply. Index Terms—Isolated circuit; logarithmic amplifier; NTC thermistor; operational amplifier; temperature monitoring. I. NOMENCLATURE B: thermistor temperature constant [°K] k: Boltzmann constant [§1.38Â10-23 J/K] RT: resistance of the thermistor [] RT,0: reference resistance value of the thermistor [] T: temperature of the thermistor [°K or °C] T0: reference temperature of the thermistor [°K] TA: (ambient) temperature of the electronics [°K or °C] UT: temperature voltage (= kÂTA/q) [V] q: electron charge [§1.602Â10-19 C] II. given in this paper describes a circuit requiring less parts and calibration effort. The improvements are largely thanks to the modern electronics, which provide much more freedom and better accuracy than in the past. The presented solution is intended to provide an easy and continuous data processing, low current consumption and galvanic isolation for the control part. III. BEHAVIOR OF A NTC THERMISTOR The thermistor is a semiconductor compound, which resistance depends on temperature in a nonlinear way. A simple form to describe its resistance is given by B 1/ T −1/ T 0 (1) RT = R0 e To evaluate the temperature (1) is reordered T = 1 / 1 / T + ln R / R / B (2) 0 T 0 For the chosen IGBT module [11] the resistance behavior is shown in Fig. 1 below. ( ( ) ( ) ) INTRODUCTION T he current application is a 3 phase power electronics based on the topology [1], which feeds a switched reluctance drive [2]. The power stage is built up of 9 IGBT modules. Each of them is equipped with a NTC thermistor. The motivation to use a logarithmic circuit arose from a wish to implement an easy processing of temperature data from a multiple number of IGBT modules. An additional isolation via an optocoupler protects the control part in case of a blow-up in a power module [3]. The nonlinear behavior of a NTC thermistor has enforced different approaches to linearize it. The methods vary from passive resistor bridge circuits [4]-[5], advanced active circuits [6]-[9] to mathematic curve fitting functions [10]. Each way has its own benefits and shortcomings, so the user should meet the decision based on the application needs. From our point of view the idea to use a logarithmic circuit to overcome the thermistor’s nonlinearity was proposed in [6] at first and shows a proven implementation. The design Φ The authors gratefully acknowledge financial support from Federal Ministry for Economic Affairs and Energy (BMWi). Y. Polonskiy is with the Department of Electrical Drives and Actuators, Universitaet der Bundeswehr, Muenchen, Germany (e-mail: yevgen.polonskiy@unibw.de). D. Surmann is with the Department of Aerospace, Universitaet der Bundeswehr, Muenchen, Germany (e-mail: denis.surmann@unibw.de). C. Laudensack is with the Department of Electrical Drives and Actuators, Universität der Bundeswehr, Muenchen, Germany (e-mail: christian.laudensack@unibw.de). D. Gerling is Full Professor and Head of the Department of Electrical Drives and Actuators, Universitaet der Bundeswehr, Muenchen, Germany (e-mail: dieter.gerling@unibw.de). PEMC 2014 Fig. 1. Behavior of the thermistor resistance, values from [11] IV. LOGARITHMIC CIRCUIT A. Basic theory To process (2) easily there should be a possibility to evaluate ln(RT) directly. This task is accomplished by a logarithmic amplifier, which basic circuit is shown in Fig. 2. The functional details can be recalled from [12]. Fig. 2. Basic logarithmic circuit proposed in [12] This topology is lightly adopted to fit the application as shown in Fig. 3. The thermistor is supplied by the amplifier IC1B, configured as a unit buffer. The gates IC1A and IC1D 1138 16th International Power Electronics and Motion Control Conference and Exposition Antalya, Turkey 21-24 Sept 2014 Fig. 3. Logarithmic amplifier circuit for the evaluation of the NTC thermistor work identically to the logarithmic amplifier from Fig. 2 while IC1A converts the thermistor resistance value into a voltage signal ULOG, the IC1D helps to get rid of the typical transistor transfer characteristics as current gain ȕ and reverse saturation current IB0 in the final equation (9). The mesh equation for the voltage over resistor R6 is (3) +U −U =0 R6 BE,1 BE,2 For the base emitter voltages the usual equation for the linear transistor operation is used (4) U § I1 · § I2 · ¸ ;U ¸ (4) = U ln¨ = U ln¨ ¸ BE,2 BE,1 T ¨β ⋅I T ¨β ⋅I ¸ © B0 ¹ © B0 ¹ Under assumption, that the voltage divider R5, R6 is almost unloaded because the resistance R6 is much smaller than the base-emitter resistance, the relation for voltage signal ULOG is valid: R +R 5 6 =K U U ≅U (5) LOG R6 N R6 R 6 with KN = (R5+R6)/R6. Combining (3) and (4) results in U §I · ≅ U ln¨ 2 ¸ (6) R6 T ¨I ¸ © 1¹ The amplifiers IC1A and IC1D force the collector currents I1 and I2 to be as following U ⋅K R 1 S 2 I =U ⋅ = 15V int (7) 1 15V int R + R + R R R 1 2 4 T T U U I = 15V int = 15V int (8) 2 R +R R 8 16 R with the factor KS = R2/(R1+R2+R4) and the resistor sum RR = R8+R16. Equations (6), (7) and (8) can be inserted into (5) yielding in the final solution U § R · (9) ≅ U K ln¨ T ¸ LOG T N ¨K R ¸ © S R¹ From (9) one recognizes the benefit of a logarithmic circuit, which avoids any steady state dependency on the supply voltage (here U15Vint). So there is no need for a precise current or voltage reference. Still there is the temperature dependent voltage UT, which can be compensated by choosing the resistor R6 with a temperature coefficient of +3500ppm/K [12]. U PEMC 2014 B. Circuit components As already mentioned the purpose of the current circuit is to simplify the temperature monitoring of IGBT modules under laboratory conditions. Hence the component values in Fig. 3 are chosen regarding a realistic temperature range between 20°C and 130°C. In order to simplify the transfer of ULOG via an analog optocoupler the voltage signal should be greater or equal to 0V. This requirement constrains the ratio of RT/(KSRR) for the maximum temperature of 130°C to R (@ 130°C ) T ≥1 K R ≤ 243Ω (10) S R K R S R To simplify the following calculations the lowest presumable resistance value of RTmin is set to 250. The factor KS influences the current I1, which is supplied to the thermistor. I1 should be kept low to meet the requirements on the low consumption, self-heating of the thermistor and the logarithmic operation range of the transistor T1. For the minimum resistance value from (10) the maximum allowable current is set to 0.5mA. With the nominal supply voltage U15Vint=15V the factor KS results in 0.5mA ⋅ R T min = 1 (11) 120 S U 15V int To keep the steady state current consumption low the branch R1, R2, R4 is set to 120kȍ common resistance. From (10) and (11) the resistance RR is determined in (12), yielding in a sufficient high resistance value. 250Ω R = = 30kΩ (12) R K S Considering (9) and temperatures between 20°C and 130°C ULOG ranges from 0V to ca. 0.92V. The capacitors C9 and C10 add a low pass filter for the supply voltage U15Vint with a cut-off frequency of about 212Hz. The capacitors C3, C4 stabilize the feedback path of the amplifier gates IC1A and IC1D. The value of 100nF is chosen intuitively; the current application does not require any high frequency bandwidth. The transistor pair T1 should be a matched one with high current gain ȕ. Unfortunately, there is only a small amount of suitable parts, which are available from common distributors. In case costs are not a key factor SSM2212 [13] is a good match. For the current application PMP4201 [14] is chosen, offering a compromise between costs and precision. As already stated the resistor R6 should compensate the K = 1139 16th International Power Electronics and Motion Control Conference and Exposition temperature dependency of UT. Here it is also difficult to find suitable parts, which are available from common distributors. Applicable parts can be sourced from Panasonic or KOA. For the current application Panasonic’s ERAS33 type [15] is chosen. It possesses a temperature coefficient of +3300ppm/K. It should be noticed from (9), that effective temperature compensation requires a high ratio of R5/R6. Obviously one of the important parts is the operational amplifier IC1. During the selection a low current consumption, offset voltage and offset bias currents are considered. For the final design ADA4096-4 [16] is opted. A good alternative is MAX44245 [17]. Other circuit components fulfill the supplementary functions. The diode D1 protects T1 from reversed baseemitter voltage; resistors R17, R18 compensate bias currents. The resistor R7 carries the sum of I1+I2 and is usually set to a value, which allows the amplifier to stay within the supply voltage range. V. ISOLATED SIGNAL TRANSFER A. Basic theory The voltage signal ULOG is transferred to the control part via the analog optocoupler IC2 as shown on the top in Fig. 4. Thereafter, the signal is amplified by IC3A to make better use from the A/D-converter input range, see bottom side Fig. 4. Fig. 4. Isolated signal transfer The depicted circuit is a rather simple “photovoltaic” operation mode [18], which is used for a precise signal transfer. A positive voltage ULOG forces the amplifier’s IC1C output to become negative. This leads to a current flow through the transmitter (LED) diode of IC2 (pins 1,2). Accordingly the “servo”-photodiode (pins 3,4) becomes active and drives the current IS. The overall process is balanced in case IC1C provides the virtual ground for the voltage ULOG. On the secondary side the receiver diode of IC2 (pins 5,6) becomes active too and forces a current flow IR. The current in the “servo”- and the receiver photodiode are matched by a common named transfer gain K3, which is given in the optocoupler datasheet. I K = R (13) 3 I S The current IR passes the T-network of the amplifier IC3A giving the output voltage UO. The overall transfer ratio of the voltage ULOG to UO is PEMC 2014 U O U =K Antalya, Turkey 21-24 Sept 2014 R11 ⋅ R15 R3 =K K 3 A R9 R11 + R15 + 3 (14) LOG with the gain KA = (R11+R15+R11ÂR15/R3)/R9. Combining (9) and (14) results in § R · (15) ≅ U K K K ln¨ T ¸ O T 3 A N ¨K R ¸ © S R¹ Finally (15) has to be inserted into (2). First two “correction” factors C0 and C1 are introduced. Assume that U R · 1 §¨ (16) C ln C T ¸ = U 1B ¨ 0 R ¸ O © 0¹ By a simple comparison of coefficients with (15) it is obvious that C1 = BUTK3KAKN and C0 = R0/(KSRR). Now logarithmic rules can be used and (2) is expressed as C 1 1 (17) T= = R C C R C § · § · 1 1 ¨ T¸ 1 + 1 ln¨ C T ¸ − 1 ln C + ln 0 T B ¨R ¸ T B ¨ 0 R ¸ B © 0¹ © 0 0 0¹ It can be easily recognized that the second denominator term in (17) equals (16). The final expression for the temperature is given by (18) C 1 (18) T= C C 1 − 1 ln C + U 0 O T B 0 Due to the logarithmic circuit the temperature calculation in Kelvin is simplified to one sum and one division operation. For a result in Celsius an additional subtraction is needed. The form (18) can be processed more quickly, than e.g. look-up tables or the approximated by Taylor series logarithm. The dual diode D3 and the resistor R24 have an optional functionality to provide a hardware temperature threshold monitoring. If ULOG reaches a level 0V the output of IC1C swings to the positive supply rail. The right diode D3 protects the transmitter diode of IC2 from a reverse voltage. The left diode D3 together with R24 and R20 forms a voltage divider and forces the positive input of IC1C to some positive voltage level. Now IC1C “locks” itself and works as a comparator until ULOG tops the voltage at the positive input. By connecting the output of IC1C with e.g. pre-biased open-collector transistor a trigger for the error input of the IGBT driver [19] can be realized. Regarding temperature compensation of UT it should be noted from (15), that a better possibility is to use R9 with the suitable temperature coefficient rather than R6. Unfortunately, there is no part available to fulfill this. B. Circuit components The resistor R9 is set to 150k to insure a low current consumption. The transfer gain KA is set to 10 to resolve the low voltage signal of ULOG properly. The simplest way to amplify ULOG would be to put a feedback resistor over IC3A. Thus the required value should be 1.5M to achieve the desired gain. Such a high value could impose problems with leakage currents. Therefore the decision to use a low impedance T-network was made. On the other side the voltage offset and noise are amplified with the gain of 1+R15/R3, while a simple feedback resistor does not 1140 16th International Power Electronics and Motion Control Conference and Exposition contribute such drawbacks; the reader should consider [20] for a discussion of pros and contras of the different feedback circuits. To achieve KA = 10 using practical resistance values R11 and R15 are set to 56k while R3 measures 2.26k. The resistor divider R24, R20 determines the threshold where IC1C recovers to the normal operation. During usual operation R20 compensates the input bias current and its value is set to 100k, being closely to R9. Choosing R24 = 2Mȍ results in a recovery threshold of approx. 0.72V, or expressed in temperature the recovery happens when the thermistor cools down below 43°C, Fig. 13. The capacitors C5, C8 stabilize the feedback path of the amplifiers and are set intuitively to 100nF. R10 decouples the output of IC1C from the low dynamic resistance of the transmitter diode. R12 is used for the compensation of the bias currents. The requirements for the op-amp IC3A are moderate compared with IC1, here TL062AC [21] as a general purpose amplifier is chosen. VI. MEASUREMENTS The circuit discussed above is built up with the possibility to test two optocouplers – LOC117 [22] and HCNR200 [23], Fig. 5. The optocouplers can be connected alternately via simple switches. Additionally, the circuit is equipped with a sub-D connector to route important test points to the acquisition board NI-6221 [24]. The electronics is tested at different ambient temperatures TA to verify its functionality. The circuit is supplied with a bipolar voltage of +15V/-8V. The thermistor resistance is emulated by a potentiometer. Antalya, Turkey 21-24 Sept 2014 Fig. 6. Output voltage ULOG of the logarithmic amplifier ULOG shows a negligible dependency on the ambient temperature. The relation between the ideal and measured curves is showed exemplary on the profile at TA = 50°C. Beside the high deviation nearby 0V (due to offset errors) the ratio stays almost constant at a mean value of 1.09. This facilitates a calibration capability as discussed in section VII. The next Fig. 7 and 8 show curves of the gain KA at different ambient temperatures. With lower resistance values the voltage ULOG tends to 0V and offset errors distort the gain factor. Fig. 7. Amplifier gain KA with HCNR200 Fig. 5. PCB with the implemented circuit The reason to implement two optocouplers is to test the transfer behavior at low voltage levels of ULOG. For example [23] shows, that with lower current IS the required LED current increases rapidly. This effect could lead to an unwanted higher current consumption. In contrast [22] states, that so called servo gain increases at low LED currents. This could counteract a higher current consumption. First the behavior of the voltage ULOG is tested at different ambient temperatures TA and compared with the ideal curve calculated from (9), Fig. 6. PEMC 2014 Fig. 8. Amplifier gain KA with LOC117 The transfer gain of LOC117 tends to be slightly lower than of HCNR200. Together with a too high voltage ULOG, Fig. 6, the overall error with LOC117 appears lower than with HCNR200, referred to Fig. 9. The thermistor (real) temperature is calculated from (2), while the evaluated temperature comes from (18). 1141 16th International Power Electronics and Motion Control Conference and Exposition Antalya, Turkey 21-24 Sept 2014 Fig. 12. Current consumption with LOC117 Fig. 9. Error between the thermistor (real) and evaluated temperature The maximum error is about 11°C, which is measured with HCNR200 at 85°C ambient temperature. During the usual operation under laboratory conditions the temperature inside the housing of the power electronics could reach about 50°C to 70°C. For this condition the maximum error with HCNR200 is 4°C to 8°C accordingly. For LOC117 the maximum error reaches 2°C to 5°C. This error is acceptable for a usual monitoring of power modules. The next Fig. 10 gives an example for the temperatures evaluated from both ULOG (9) and UO (18). Finally, the function of the threshold triggering as discussed in section V.A is depicted in the Fig. 13. Fig. 13. Threshold triggering VII. CALIBRATION POSSIBILITY In case the application requires a precise temperature monitoring the transfer function can be calibrated by operating the circuit at the expected ambient temperature and adjusting the coefficients to meet the real transfer characteristics. The equation (18) can be inversed giving a simple linear function in form f(x) = a + bx Fig. 10. Calculated temperatures from ULOG and UO, HCNR200, TA=85°C The overall current consumption of the circuit (thermistor side) is depicted below, Fig. 11 and 12. The initial concerns about a possible excessive current consumption at low voltage levels ULOG (thus at high temperatures) proved to be unfounded. The use of LOC117 exhibits a lower current consumption due to a higher servo gain compared with HCNR200. 1 §¨ 1 ln C0 ·¸ 1 (19) = − + U T ¨T B ¸ C1 O © 0 ¹ Regarding the chosen component values the coefficients of the function (19) can be easily calculated. The straight line given by (19) is an ideal transfer function, which is naturally distorted, Fig. 14. The user emulates known resistance values and measures the output voltage UO. Thus, the real curve and its linearized function can be obtained. Fig. 14. Ideal and measured temperature curves Fig. 11. Current consumption with HCNR200 The coefficients gained from the measurement in Fig. 14 are inserted into (19) and the temperature is calculated with the PEMC 2014 1142 16th International Power Electronics and Motion Control Conference and Exposition corrected factors. The measurement accuracy can be improved gratefully as shown in Fig. 15. [9] [10] [11] [12] [13] [14] [15] [16] [17] Fig. 15. Influence of the calibration on the measurement error Keep in mind that the calibration routine is valid only for a specific ambient temperature. It is possible to implement an additional ambient temperature sensor; therefore the control part can adjust the coefficients according to the stored data. VIII. CONCLUSION The paper presented a possibility to obtain the temperature of a NTC thermistor as an analog voltage signal and transfer it via an optocoupler to insure galvanic isolation. The presented method uses a logarithmic amplifier circuit, which converts the logarithmic temperature dependency in a linear one. The theoretical background and design are verified by measurements. The transfer ratio of the circuit can be calibrated to improve the accuracy at a given ambient temperature. IX. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] M. Hiller and R. Marquardt, "A new converter concept for switched reluctance drives with multiple energy sources," IEEE Power Electronics and Drive Systems PEDS 2003, vol. 2, pp. 1235-1240, Nov. 2003. C. Laudensack, Q. Yu and D. Gerling, "Dynamic design tool for canned switched reluctance machines," International Aegean Conference on Electric Machines and Power Electronics & Electromotion Joint Conference (ACEMP), Istanbul, Turkey, pp. 775-780, Sept. 2011. Eupec, "Application Note: Using integrated NTC with reliable isolation", 2001. Available: www.igbt.cn/UserFiles/Support_IGBT/file_071.pdf H. J. Hoge, "Comparison of circuits for linearizing the temperature indications of thermistors," Review of Scientific Instruments, vol. 50, issue 3, pp. 316-320, May 1979. Microchip, "Application Note AN685: Thermistors in single supply temperature sensing circuits", 1999. Available: http://ww1.microchip.com/downloads/en/AppNotes/00685b.pdf R. K. Chakravarty, K. Slater and C. W. Fischer, "Linearization of thermistor resistance-temperature characteristics using active circuitry," Review of Scientific Instruments, vol. 48, issue 12, pp. 1645-1649, Dec. 1977. A. A. Khan and R. Sengupta, "A linear temperature/voltage converter using thermistor in logarithmic network," IEEE Transactions on Instrumentation and Measurement, vol. 33, issue 1, pp. 2-4, March 1984. R. N. Sengupta, "A widely linear temperature to frequency converter using a thermistor in a pulse generator," IEEE Transactions on Instrumentation and Measurement, vol. 37, issue 1, pp. 62-65, March 1988. PEMC 2014 [18] [19] [20] [21] [22] [23] [24] Antalya, Turkey 21-24 Sept 2014 A. R. Sarkar, D. Dey and S. Munshi, "Linearization of NTC thermistor characteristics using op-amp based inverting amplifier," IEEE Sensors Journal, pp. 4621-4626, Dec. 2013. Y. Cong, Z. Wang-chao, S. Bin and Z. Hang-xia, "Study on NTC thermistor characteristics curve fitting methods," International Conference on Computer Science and Network Technology (ICCSNT), Harbin, China, vol. 4, pp. 2209-2213, Dec. 2011. SEMiX553GAR128Ds: IGBT module, datasheet, Semikron. Texas Instruments, "Application Note AN-311: Theory and Applications of Logarithmic Amplifiers", revised 2013. Available: www.ti.com/lit/pdf/snoa575 SSM2212: dual NPN matched transistor pair, datasheet, Analog Devices. PMP4201: dual NPN matched transistor pair, datasheet, NXP Semiconductors. ERAxxx: metal film thermosensitive chip resistors, datasheet, Panasonic. ADA4096: micropower, rail-to-rail input/output amplifier, datasheet, Analog Devices. MAX44245: precision, low power amplifier, datasheet, Maxim Integrated. IXYS Integrated Circuits Division, "Application Note AN-107: LOC Series Linear Optocouplers", 2013. Available: http://www.ixysic.com/home/pdfs.nsf/www/AN107.pdf/$file/AN-107.pdf Skyper 32Pro R: IGBT driver core, datasheet, Semikron. Burr Brown (currently Texas Instruments), "Application Note SBOA061: Designing photodiode amplifier circuits with OPA128", 1994. Available: www.ti.com/lit/an/sboa061/sboa061.pdf TL062: low power, JFET-input operational amplifier, datasheet, Texas Instruments. LOC117: linear optocoupler, datasheet, IXYS Integrated Circuits Division. HCNR200: linear optocoupler, datasheet, AVAGO Technologies. NI USB-6221: M series multifunction DAQ for USB, datasheet, National Instruments. X. BIOGRAPHIES Yevgen Polonskiy was born in Dnepropetrowsk, Ukraine on March 24, 1982. He graduated from the technical high school in Konstanz in 2002 and started studying Electrical Engineering at the University of Applied Sciences, Konstanz. He completed with M.Eng. in 2008 and worked from 2009 to 2011 as development engineer at Maccon GmbH, Munich. Since August 2011 he is with Institute of Electrical Drives and Actuators at the Universitaet der Bundeswehr Muenchen, Neubiberg. His research interests are control of switched reluctance drives and power electronics. Denis Surmann was born in Hoexter on August 15, 1989. He graduated from high school in Bad Driburg in 2009 and was awarded by the German Physics Society. Thereafter, he joined the German Air Force and began his officer’s career. Surmann is currently a graduate student in the aerospace program at the Universitaet der Bundeswehr Muenchen, Neubiberg and received his B.Sc. in Aerospace Engineering in 2013. His bachelor thesis focused on a switched reluctance drive control. Christian Laudensack was born in Germany, 1981. He graduated in 2007 in University of Federal Defense, majoring in aerospace engineering. His employment experience included the German Federal Armed Force, the IAB GmbH, Ottobrunn, the Systemzentrum für Luftfahrzeugtechnik, Erding, and the Institute of Electrical Drives and Actuators, Universitaet der Bundeswehr Muenchen, Neubiberg. His special fields of interest include the design analyses of switched reluctance drives. Dieter Gerling, born in 1961, got his diploma and Ph.D. degrees in Electrical Engineering from the Technical University of Aachen, Germany in 1986 and 1992, respectively. From 1986 to 1999, he was with Philips Research Laboratories in Aachen, Germany as Research Scientist and later as Senior Scientist. In 1999, Dr. Gerling joined Robert Bosch GmbH in Bühl, Germany as Director. Since 2001, he is Full Professor and Head of the Institute of Electrical Drives and Actuators at the Universitaet der Bundeswehr Muenchen, Neubiberg, Germany. 1143