Temperature Sensors - Steven Engineering

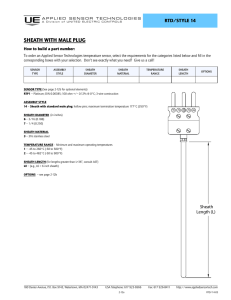

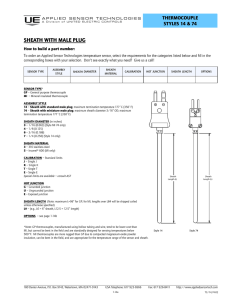

advertisement