11 - SEW Eurodrive

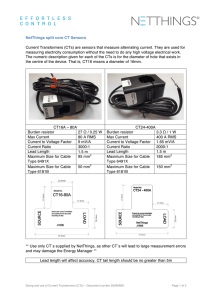

advertisement