tru waste management – past, present, and future at oak ridge

advertisement

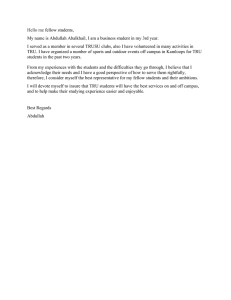

WM’01 Conference, February 25-March 1, 2001, Tucson, AZ TRU WASTE MANAGEMENT – PAST, PRESENT, AND FUTURE AT OAK RIDGE NATIONAL LABORATORY K. M. Billingsley Advanced Integrated Management Services, Inc. K. P. Guay Bechtel Jacobs Company, LLC J. R. Trabalka U.T. Battelle, LLC G. L. Riner U.S. Department of Energy ABSTRACT Oak Ridge National Laboratory (ORNL) has performed research and development (R&D) supporting national defense and energy research initiatives since its inception as Clinton Laboratories in east Tennessee in 1943 as part of the World War II Manhattan Project. R&D activities at ORNL resulted in radioactive and hazardous waste legacies that pose significant environmental challenges. ORNL is a U.S. Department of Energy (DOE) facility. The Tennessee Department of Environment and Conservation and the U.S. Environmental Protection Agency directed DOE to address environmental issues at ORNL, including the disposal of transuranic (TRU) waste. The ORNL TRU Waste Treatment Project is an important component of the ORNL cleanup effort. This project includes on-site waste retrieval, transport, treatment, and packaging of TRU and low-level radioactive waste streams for final safe off-site disposal at other DOE facilities. Historically, most of the TRU waste generated at ORNL was placed in on-site interim storage facilities. These facilities include unlined trenches, underground storage tanks, concrete bunkers, and metal buildings. The ORNL Site Treatment Plan requires off-site disposition of ORNL TRU waste at the Waste Isolation Pilot Plant (WIPP) in New Mexico. Waste treatment and packaging is required to meet the waste acceptance criteria of the WIPP. The ORNL Management and Operating contractor completed a detailed conceptual design of a waste treatment facility in the late 1980’s. DOE determined that the construction and operating costs of the concept facility were excessive. DOE explored alternatives that could reduce the estimated costs. An independent study was conducted in 1995 evaluating ORNL facility upgrades for processing the ORNL TRU waste. The study recommended a competitive contracting approach for a privatization project to construct a new on-site TRU waste treatment facility at ORNL. DOE issued a draft Invitation for Bid in 1996 for the construction and operation of an on-site TRU waste treatment facility. DOE awarded a contract to the Foster Wheeler Environmental Corporation (Foster Wheeler) in 1998, which was contingent on the completion of the National Environmental Policy Act process for the proposed facility. An Environmental Impact Statement was prepared and DOE issued a Record of Decision in July 2000 selecting the facility and treatment processes proposed by Foster Wheeler. The first shipment of treated TRU waste is scheduled for disposal at the WIPP in January 2003. INTRODUCTION (1, 2) One of the greatest challenges facing the U.S. Department of Energy (DOE) is the safe and effective cleanup of radioactive waste remaining from the World War II Manhattan Project, and from subsequent WM’01 Conference, February 25-March 1, 2001, Tucson, AZ research and development of radiochemical processing and radioisotope production. Overall, DOE sites store millions of liters of radioactive sludge and liquid waste contained in approximately 300 aging, underground storage tanks; and thousands of cubic meters (m3) of radioactive solid waste contained in burial grounds and other facilities. Oak Ridge National Laboratory (ORNL) manages the largest inventory of remote-handled (RH-) transuranic (TRU) waste in the DOE complex. In the DOE Order 435.1-1 TRU waste is defined as “ radioactive waste containing more than 100 nCi (3,700 Bq) of alpha-emitting transuranic isotopes per gram of waste, with half-lives greater than 20 years”. TRU waste is further defined and managed as either contact-handled (CH-) TRU waste with surface dose rates less than 200 mRem/hr, or RH-TRU waste with surface dose rates greater than or equal to 200 mRem/hr. Much of the ORNL TRU waste was generated when the definition of TRU waste included radioactive waste with concentrations of 10 to 100 nCi/gr, or waste contaminated with non-transuranic isotopes (e.g., U-233), or with TRU isotopes with half-lives less than 20 years (e.g., Cm-244). In addition, some special-case CH-TRU waste at ORNL has been managed in a manner similar to RHTRU waste. The TRU Waste Treatment Project at ORNL is an important component of the overall DOE cleanup effort to meet the objectives of the ORNL Site Treatment Plan. The goal of the ORNL TRU Waste Treatment Project is to successfully process the waste included in the project scope for final off-site disposal in a manner that is safe, efficient, and providing the best value to the American taxpayer. This project includes on-site TRU and associated low-level waste retrieval, transport, treatment, and packaging, and the safe off-site transportation and permanent disposition of the treated wastes at designated federal facilities. The approximate volumes of TRU and associated low-level wastes in storage at the ORNL: • 822 m3 of RH-TRU mixed waste sludge located in the active waste storage tanks at ORNL (as of 1/1/01), • 3,243 m3 of low-level supernatant associated with the RH-TRU mixed waste sludge located in the active waste storage tanks (2,107 m3) and Gunite and Associated Tanks (GAAT) (1,136 m3) (as of 1/1/01), • 698 m3 of RH-TRU/alpha low-level waste solids (includes some mixed waste) located in storage facilities and subsurface trenches (as of 11/00), and • 1,407 m3 of CH-TRU/alpha low-level waste solids (includes some mixed waste) located in storage facilities and subsurface trenches (as of 11/00). Waste processing will be achieved through a privatization contract between the DOE and the Foster Wheeler Environmental Corporation (Foster Wheeler), who will design, construct, operate, and decontaminate and decommission (D&D) a waste treatment facility. The combined baseline and optional waste volumes included in the original scope of the ORNL TRU Waste Treatment Project contract are: • 900 m3 of RH-TRU mixed waste sludge located in the Melton Valley Storage Tanks (MVSTs), • 1,600 m3 of low-level supernatant associated with the TRU mixed waste sludge and also located in the MVSTs, WM’01 Conference, February 25-March 1, 2001, Tucson, AZ • 550 m3 of RH-TRU/alpha low-level waste solids (may consist of some mixed waste) located in bunkers and subsurface trenches, and • 1,000 m3 of CH-TRU/alpha low-level waste solids (may consist of some mixed waste) located in metal storage buildings. The first phase (design and permitting) of the project allowed for DOE and Foster Wheeler to determine additional waste volumes/streams that could be treated at the new facility, so the current waste volumes and waste generated over the course of the project’s operational phase will be treated at the ORNL TRU Waste Treatment Facility. The facility will have the capability to treat the specified ORNL waste streams, with enough flexibility to treat other DOE waste streams. DOE will lease the MVSTs and approximately five acres of adjacent land to Foster Wheeler for the construction of the treatment facility. The TRU Waste Treatment Project will meet the cleanup challenges associated with TRU waste, which is the top priority of the DOE, the Tennessee Department of Environment and Conservation (TDEC), and the U. S. Environmental Protection Agency (EPA). This project will focus on the processing and certification of RH- and CH-TRU waste to meet Resource Conservation and Recovery Act (RCRA) land disposal requirements (LDRs) and the waste acceptance criteria (WAC) for disposal at the Waste Isolation Pilot Plant (WIPP). The associated primary and secondary low-level wastes will be disposed of at the Nevada Test Site (NTS). TRU WASTE GENERATION AT ORNL (8, 9, 10, 11, 13, 14, 15) Overview of ORNL ORNL was constructed in 1943 as a pilot scale plutonium processing facility as part of the Manhattan Project during World War II. In the immediate post-war years, ORNL embarked on an ambitious, multi-faceted program of research and development (R&D) devoted to civilian and defense uses of atomic energy. Located approximately 65 km northwest of Knoxville, Tennessee, ORNL is on the federally owned, and DOE controlled, Oak Ridge Reservation (ORR). Other major facilities on the ORR include the East Tennessee Technology Park (ETTP), a former gaseous diffusion plant previously known as the K-25 site, and the Y-12 National Security Complex. ORNL sprawls across two valleys located between three parallel ridges (Chestnut Ridge, Haw Ridge, and Copper Ridge) that run northeast to southwest. Bethel Valley comprises the northern half of ORNL, while Melton Valley comprises the southern half. The Clinch River runs along the southern border of ORNL. ORNL’s main plant area is situated in Bethel Valley. The operational High-Flux Isotopes Reactor (HFIR), the Radiochemical Engineering Development Center (REDC), and many waste storage areas are located in Melton Valley. ORNL Operations and Facilities Generating TRU Waste The generation of radioactive solid, liquid, and sludge waste at ORNL began in 1944 when plutonium was first separated from irradiated graphite reactor fuel as part of the Manhattan Project, and it continues to be generated under the current mission of ORNL (Figure 1). Byproducts of ORNL radiochemical processing and radioisotopes production operations include a wide variety of liquid and solid radioactive wastes, including TRU wastes, the most hazardous wastes on the ORR. ORNL is the largest generator of TRU waste on the ORR, and manages DOE’s largest inventory of RH-TRU waste. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ The relative contributions of the various ORNL activities to overall waste generation, or to liquid versus solid waste generation have varied significantly with time. Listed in approximate order of significance, the principal sources of liquid and solid low-level wastes at ORNL were/are: • • • • • • • • Radiochemical processing research, development, and deployment (RD&D), Radioisotope production, distribution, and applications development, Operation of experimental and research reactors, Reactor fuels development, Transuranium element research, Analytical support and R&D, Environmental Management (EM) activities (treatment wastes, and collection of contaminated water), and Biological, chemical, and physical research. ORNL’s major role was the development of chemical processes associated with nuclear fuel cycles and radioisotope development and production. Fuel preparation and reprocessing R&D, as well as materials research and testing were conducted in Bethel Valley facilities in support of the ORNL reactors. Fuel for the Graphite Reactor was processed on-site in Building 3019-A from 1943 to 1945. ORNL researched, developed, and implemented chemical separation processes for uranium and plutonium products until 1976; separating these materials from each other and from the fission products resulting from reactor operations. Improvements in the separation processes resulted in the recovery of plutonium that exceeded, by several orders of magnitude, the amount produced during the pilot-scale processing conducted during the Manhattan Project. A major ORNL achievement was the development of the PUREX process, which was widely used in defense applications and commercial nuclear fuel reprocessing. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ 1940’s 1950’s 1960’s 1970’s 1980’s 1990’s 2000’s 2010’s Bismuth Phosphate (Pu-239) Redox (Pu-239) Chemical Processing RaLa Hexone-25 and Hexone-23 Uranyl Ammonium Phosphate Metal Recovery TBP-25 and TBP- Interim-23 Purex (Pu-239) Fluoride Volatility Fuel Preparation Raw Materials Thorex Feed Materials Head End TRU Element Production Nuclear Auxiliary Power Source Development (Sr-90, Cs-137, Ce-144, Cm-242, Cm243, and Cm-244 Special Radioisotope Sources (Co-60, H-3, Kr-85, Am-241) Radioisotope Production & Distribution Target Development and Fabrication Transuranic Isotope Enrichment and Distribution Radioisotope Production and Applications Development (Medical, Industrial, and Research) Graphite Reactor Reactor Development & Operations Low Intensity Test Reactor Bulk Shielding Reactor Homogeneous Reactor Experiment Aircraft Reactor Experiment Oak Ridge Reasearch Reactor High Flux Isotope Reactor Molten Salt Reactor Experiment Fig. 1. Timeline of ORNL operations that generated TRU waste WM’01 Conference, February 25-March 1, 2001, Tucson, AZ ORNL also became a major center for the production and distribution of radioisotopes. ORNL began the production of radioisotopes used in research, medical, and industrial applications in 1946. Radioisotope production developed into a prominent activity. Most of the radioisotopes were separated and purified at ORNL’s Fission Product Development Laboratory. These operations generally involved the chemical separation of materials, including targets irradiated in accelerators or reactors, small amounts of reactor fuel, or the manipulation of previously separated radioactive materials. ORNL developed and implemented processes that produced heavy transuranium elements, and tested other processes and improved methods for purifying thorium, uranium, transuranium, and fission product materials. The REDC was constructed in the mid 1960s, adjacent to the HFIR, and includes facilities for the production, storage, and distribution of radioactive heavy elements. The work primarily involves recovery and purification of transplutonium elements (americium through fermium) from target elements irradiated in the HFIR or in the Savannah River Plant reactors. Transplutonium radioisotopes, particularly Cf-252, are supplied for use in • • • medical, defense, and industrial applications, research on the properties of the heavy elements, and production of super-heavy elements (atomic numbers beyond 104). DOE’s predecessor, the Atomic Energy Commission (AEC), transferred the responsibility for reactor development to the Argonne National Laboratory in late 1947. Despite the AEC’s shift in responsibility for reactor R&D, a number of reactors were developed or built at ORNL. All reactors located in Bethel Valley were completed in the 1940s (Graphite Reactor), or the 1950s (Low-Intensity Test Reactor, Bulk Shielding Reactor, and Oak Ridge Research Reactor). Other reactor development was focused primarily on liquid or molten salt-fueled systems built and operated in Melton Valley before 1970 (HFIR and Molten Salt Reactor). Liquid wastes from all ORNL reactors were piped underground to facilities in Bethel Valley for treatment and/or storage. All Bethel Valley reactors and the Molten Salt Reactor in Melton Valley are shut down and partially decommissioned. By the mid 1960s, radioisotope production, distribution, and applications development had overtaken radiochemical processing RD&D as the principal contributor to radioactive wastes at ORNL. By 1970, when the decision was made to begin storing TRU wastes in a geologic repository, ORNL performed a full range of activities; from fundamental biological, chemical, and physical research, to pilot-plant and reactor operations in support of nuclear energy development. The diversity of ORNL activities increased after 1973, when Congress authorized the AEC to investigate all energy sources. Activities became more diversified when the Energy Research and Development Agency (ERDA) was created from the AEC in 1974. By 1981 most radioactive waste at ORNL was generated by just a few programs (Figure 1). The focus of ORNL’s research programs has become increasingly nonnuclear with the passage of time. Although all of the major programs or activities identified with the 1980s era are still in existence and still generate wastes, the scope has been narrowed in several cases. The HFIR in Melton Valley is the only operational reactor remaining at ORNL. Most isotope production activities in Bethel Valley have ceased and nuclear fuel cycle R&D activities have diminished significantly. As other radioactive waste-generating programs declined from the 1970s through the early 1990s, production of transuranium elements at the REDC (e.g., Cf-252, which has a wide range of defense, industrial, medical, and research applications) became the principal source of radioactive materials in both radioactive liquid low-level waste (LLLW) and solid TRU wastes at ORNL. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Approximately 90% of the RH-TRU solid waste was generated at the REDC. The remaining RH-TRU solid waste came from eleven other ORNL facilities and the Knolls Atomic Power Laboratory. Although the REDC is the principal generator of solid TRU waste on the basis of both radioactivity and volume, it produces less than 5% of the volume of the LLLW generated annually by ORNL. The liquid wastes from the REDC do not retain their integrity, and are extensively diluted by mixing with lower activity LLLW streams from a wide range of other ORNL sources. The facilities and programs that generated solid TRU waste were also the primary sources of TRU constituents to LLLW, and hence to TRU waste sludge generation. ORNL adopted an operational approach to waste generation designed to minimize worker exposure. Rather than generating TRU solid wastes, LLLW was generated (when possible) and diverted into underground piping and transferred into the LLLW system storage tanks and disposal facilities. The history of liquid radioactive waste generation and management at ORNL must be considered in order to understand how and when the TRU waste sludges were created, as the origins of TRU waste sludges are linked to LLLW generation and treatment. TRU waste sludges were produced as a result of the collection, treatment, and storage of liquid radioactive wastes originating from ORNL radiochemical processing and radioisotopes production programs. Most of the RH-TRU sludge volume was created over the past 30 years as particulates settled out of the stored liquid waste. Sludge residuals from tank waste retrieval operations were found in some waste storage tanks dating to ORNL operations in the 1940s and 1950s. The generation of TRU waste sludges at ORNL is projected to cease in 2003 due to the completion of waste retrieval and closure from the remaining inactive waste storage tanks at ORNL, as well as the implementation of pretreatment of liquid waste at the REDC. However, under its current missions it is estimated that ORNL will generated an additional 3,500 m3 of TRU waste over the life cycle of ORNL operations. ORNL WASTE INVENTORY AND STORAGE (3, 4, 5, 13, 14) TRU wastes stored at the ORNL include RH-TRU sludge and the associated LLLW, solid RHTRU wastes, and solid CH-TRU wastes. ORNL stores about 90% of the RH-TRU waste in the DOE complex. TRU waste is the most hazardous waste on the ORR. ORNL was the interim storage facility for defense wastes from one AEC facility, at least two commercial facilities, and several DOE facilities. Non-defense R&D activities at several commercial and federal facilities also generated CH-TRU wastes that have been stored at ORNL on behalf of the DOE and its predecessor organizations. Following is a summary of the TRU and associated low-level waste inventories at ORNL by waste type. RH-TRU Sludges and Associated LLLW The RH-TRU waste sludge at ORNL formed as precipitants settled out of LLLW during storage. ORNL began and aggressive tank waste consolidation campaign in 1997 to prepare for the future treatment of RH-TRU sludge and associated LLLW. Sludge consolidation activities are complete from eight large 161 m3 to 643 m3 (42,500 gal to 170,000 gal) capacity gunite tanks constructed in 19431944 that originally held the majority of ORNL’s RH-TRU sludge. Waste consolidation activities for most of the remaining inactive tanks at ORNL are expected to be completed by the end of Fiscal Year (FY) 2001. Upon completion of the tank waste consolidation activities, approximately 822 m3 of RHTRU sludges will be consolidated into ORNL’s active tank system [the MVSTs , the Melton Valley WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Storage Tanks Capacity Increase Project (MVST-CIP), and the Bethel Valley Evaporator Service Tanks (BVESTs)]. The active tank system and six large inactive gunite tanks (GAAT) will also contain the approximately 3,243 m3 of LLLW associated with the RH-TRU sludges. Table I summarizes the volumes of RH-TRU sludge and associated LLLW managed at ORNL. Since the consolidated RHTRU sludges were retrieved from various inactive storage tanks, the past waste characterization data are no longer directly applicable. However, the patterns in the existing data suggest that all of the consolidated sludges could meet the current TRU waste definition, and the draft Data Quality Objectives for radioassay, with appropriate waste characterization and judicious blending/mixing. Table I. Approximate inventory of RH-TRU sludge and associated low-level waste at ORNL (1/1/01) WASTE WASTE TYPE VOLUME FACILITY 740 m3 RH-TRU Sludge TOTAL Melton Valley Storage Tanks (MVSTs) 63 m Melton Valley Storage Tanks Capacity Increase Project (MVST-CIP) 19 m3 Bethel Valley Evaporator Service Tanks (BVESTs) 3 822 m3 131 m3 LLLW associated with the RHTRU Sludge TOTAL Melton Valley Storage Tanks (MVSTs) 1,478 m Melton Valley Storage Tanks Capacity Increase Project (MVST-CIP) 498 m3 Bethel Valley Evaporator Service Tanks (BVESTs) 1,136 m3 Gunite and Associated Tanks (GAAT) 3 3,243 m3 WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Fig. 2. All RH-TRU sludge and LLLW are contained in ORNL’s active waste storage tanks and six large tanks (GAAT) located in ORNL’s South Tank Farm. Tank waste will be consolidated in the MVSTs under ORNL’s Integrated Tank Waste Management Plan for waste treatment and off-site disposal. RH-TRU Solids Solid TRU waste at ORNL is a heterogeneous mixture that consists mainly of hot-cell trash such as paper, plastic and glass bottles, rubber gloves, equipment, manipulator boots, tools, equipment racks, etc. Waste characterization data are limited for most of these wastes. The majority of these materials were placed in steel paint cans, plastic buckets, or plastic bags, and then packaged in metal boxes, drums, and concrete casks. Before April 1972, all but one of approximately 110 casks (about 170 m3) of solid RH-TRU wastes were disposed of in shallow-land burial trenches located in Solid Waste Storage Area 5 South (SWSA 5S). After April 1972 the RH-TRU wastes were retrievably stored, initially in a series of 23 earthen trenches located in the southeastern part of Solid Waste Storage Area 5 North (SWSA 5N). The SWSA 5N trenches continued to receive a few large boxes of RH-TRU wastes until April 1981, and assorted containers of special-case (alpha) solid low-level waste until August 1981. At the start of calendar year 2000, about 350 m3 of RH-TRU solid wastes were stored in earthen trenches in SWSA WM’01 Conference, February 25-March 1, 2001, Tucson, AZ 5N in Melton Valley. The RH-TRU solid wastes within the 23-trench storage area of SWSA 5N are contained in approximately 200 large concrete casks, 7 steel/wooden boxes, and several steel drums. These wastes are considered retrievable, but the logistics of retrieval are complicated. The materials in the majority of the containers buried in the SWSA 5 N trenches may be recharacterized as solid CHalpha low-level waste based on the historical reported contents, but additional characterization will be required to determine the actual RH- and CH-TRU contents because historical information on waste container contents is often of poor quality or uncertain. The REDC generated 185 of the casks and 1 of the boxes found in SWSA 5N. The wastes in 11 of the 15 remaining casks and one of the drums were derived in part from defense-related activities. Table II summarizes the location and approximate volume and number of containers of RH-TRU solid waste at ORNL. Two concrete “bunker-type” facilities (Buildings 7855 and 7883) provide the primary storage facilities for RH-TRU solid wastes produced after September 1979. These facilities hold 117 containers (about 171 m3) of RH-TRU waste. The wastes in these facilities are considered readily accessible. Building 7834 (a CH-TRU storage facility) contains about 7 m3 of RH-TRU wastes within 4 containers. Table II. Location and approximate volume and number of containers of RH-TRU solid waste at ORNL (11/00) NO. OF FACILITY CURRENT CONTAINE # FACILITY DESCRIPTION INVENTORY (m3) RS SWSA 5 S Shallow burial trenches - pre 1972 (estimated 170 number of containers) 110 SWSA 5 N 23 burial trenches - post 1972 (estimated number of containers) 350 >200 7855 Concrete Bunker Remote Handled Waste Storage 157 105 7883 Concrete Bunker Remote Handled Waste Storage 14 12 7834 Drum Storage Facility 7 4 698 > 400 TOTAL RH-TRU WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Fig. 3. Various methods of historical and current solid TRU waste storage at ORNL. CH-TRU Solids Storage of CH-TRU wastes at ORNL began in late 1970. Approximately 405 m3 of special-case CH-TRU wastes (typically bulky items, such as gloveboxes, were not considered practical to certify for disposal at the WIPP) were disposed in a four-trench area in SWSA 5N during 1975–1977. These wastes are stored in various types of metal and wooden boxes, and a metal tank. At the start of calendar year 2000, over 3,650 containers of CH-TRU solid waste from 44 ORNL facilities and 13 off-site waste generators were stored at ORNL. Most CH-TRU wastes are currently stored at ORNL in Buildings 7572, 7574, 7834, 7842, 7878, 7879, and 7934, which are secure facilities. The wastes in these facilities are considered readily accessible. Table III summarizes the CH-TRU waste inventories in these facilities as of November 2000. The measured dose rate on the surface of twelve stored containers exceeds the CH-TRU dose-rate limit of less than 200 mrem per hour. In addition, three containers from the Knolls Atomic Power Laboratory are known to contain RH-TRU wastes; added internal shielding has reduced the dose rates at the containers surface to less than 200 mrem per hour. Because this approach was reportedly used routinely at ORNL to reduce external dose rates on containers, there is a significant potential to encounter RH-TRU waste items during the treatment and repackaging of the stored CH-TRU waste containers. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Table III. Location and approximate volume and number of containers of CH-TRU solid waste at ORNL (11/00) CURRENT FACILITY INVENTORY # FACILITY DESCRIPTION (m3) NO. OF CONTAINERS SWSA 5 N 4 burial trenches - 1975 to 1977 405 Unknown number of bulky items such as gloveboxes 7572 TRU Storage 177 795 7574 NFS Waste Storage Facility 203 943 7834 Drum Storage 52 218 7842 Contact Handled Waste Storage 250 1,189 7878 Waste Storage 220 63 7879 Waste Storage 97 463 7934 Contact Handled Waste Storage 3 1 1,407 3,672 TOTAL CH-TRU ORNL TRU WASTE PROCESSING ALTERNATIVES - PAST, PRESENT & FUTURE (1, 2, 6, 7, 12) The ORNL Site Treatment Plan requires off-site disposition of ORNL TRU waste at the WIPP in New Mexico. In addition the TDEC and the EPA directed the DOE to address environmental issues at ORNL, including the disposal of transuranic (TRU) waste. The ORNL TRU Waste Treatment Project is an important component of the ORNL cleanup effort. DOE awarded a phased, contingent contract to Foster Wheeler in 1998 for the construction, operation, and D&D of the ORNL TRU Waste Treatment Facility. This project also includes on-site waste retrieval and transport to the waste treatment facility, treatment, and packaging of TRU and associated low-level radioactive waste streams for final safe off-site disposal at other DOE facilities. Following is a summary of the events that led up to the approval and implementation of the TRU Waste Treatment Project and the construction of an onsite TRU Waste Treatment Facility at ORNL. LATE 1980’S THROUGH MID 1990’S – CONCEPTUAL DESIGN ACTIVITIES Waste Handling and Processing Plant In the late 1980’s, the ORNL Management & Operating (M&O) contractor completed a detailed conceptual design for a TRU waste treatment facility referred to as the Waste Handling and Packaging Plant (WHPP). The proposed WHPP was a key element in the DOE’s TRU waste program for WM’01 Conference, February 25-March 1, 2001, Tucson, AZ repackaging special-case and RH-TRU waste. The WHPP was designed to process approximately 1,500 m3 of RH-TRU solids, sludge, and associated supernatant. DOE also proposed that the facility also receive RH-TRU solid waste from other DOE sites. The waste streams anticipated to exit the facility included: repackaged and certified RH-TRU waste drums and canisters ready for shipment to the WIPP, process wastewater, non-radiological wastewater, and a gaseous effluent exhaust. DOE attempted to have the project validated from 1990 to 1994 and proposed the construction of the WHPP at ORNL as a FY 92 capital line-item, with a mission to retrieve, receive, repackage, certify and ship TRU waste to the WIPP. The project scope included construction of two facilities (a waste packaging facility and a sludge mobilization facility) with required hot-cells, equipment, utilities and services for waste retrieval, treatment, packaging and on- and off-site transportation. In response to federal legislation requiring DOE to become compliant with all federal regulations at its facilities, the WHPP facility was reevaluated to include operational and D&D costs, which resulted in a final cost of $1.2 billion. Due to the high cost and impact on the remainder of the Oak Ridge Operations programs, DOE recommended that completion of the TRU waste processing be delayed until 2025. There was strong stakeholder opposition to this recommendation. GLOVEBOX FOR REPACKAGING CH-TRU WASTE The M&O contractor conducted activities from January 1994 to May 1995 associated with the design and preparation of an existing ORNL facility to repackage and certify some or all of the CHTRU drums at ORNL to meet the waste acceptance criteria of the WIPP. The Irradiated Fuel Examination Laboratory in Building 3525 was selected as the reference facility for modification, which would include a glovebox for processing CH-TRU waste. Four designs were developed. The initial design provided minimal radiation protection and utilized the bag and tape approach used in ORNL hot cells for loading the drums into or out of the repackaging facility. The second design utilized commercially available devices to bag the waste drums into and out of the facility. The third design included radiation shielding adequate to handle any drum in the ORNL TRU waste inventory and the capability to access difficult to open drums. The fourth design incorporated improved features that reflected all of the information gathered during the course of the project, provided considerable savings in both the design of the glovebox and the modifications of the building. None of the three initial designs were considered optimal from a programmatic perspective, while the fourth design provided the ability to process a significant number of drums and could be subsequently expanded to handle more hazardous drums in the future without retrofitting. Design activities were terminated in May 1995 as more attractive options for CH-TRU waste repackaging were considered to be available. 1995 – Independent Feasibility Study DOE had originally planned to construct a new facility for the on-site processing and final disposal of TRU waste. However, when the projected life-cycle costs were to exceed $1 billion, DOE began to evaluate other alternatives. In 1995, DOE directed the M&O contractor to charter an independent study on the feasibility of using existing facilities to process TRU wastes at ORNL. The feasibility study was conducted to determine a cost-effective approach to comply with federal hazardous waste requirements and with commitments made to the TDEC and the EPA in the ORNL Site Treatment Plan. The independent study involved an extensive investigation of alternatives to a new facility, including WM’01 Conference, February 25-March 1, 2001, Tucson, AZ analyzing over 20 waste processing technologies, as well as modifications to five existing ORNL facilities to prepare ORNL TRU wastes for disposition at the WIPP. 1. 2. 3. 4. 5. Building 3517, the Fission Product Development Laboratory; Building 3525, the Irradiated-Fuel Evaluation Laboratory; Building 7860, the New Hydrofracture Facility; Building 7930, the Thorium-Uranium Recycle Facility; and Building 7877, the Low-Level Waste Solidification Facility. Building 7877 was included to allow for the evaluation of an in-liner cementation process for TRU sludge waste. All of the facilities were good candidates for processing TRU waste. Each facility was evaluated to determine the extent and nature of the modifications required to process RH- TRU sludges and CH- and RH-TRU solids. The evaluations included reviews of design documents, drawings, previous technical evaluations and the support infrastructure (e.g., roads, utilities, etc.) for each building, and interviews with engineers and operations personnel familiar with these facilities. The independent study recommended upgrading the two existing ORNL facilities; one to process TRU sludges and supernatants, and another to process TRU solids. Although the cost estimates to modify the various facilities were minimally different, the study concluded that Buildings 7860 and 7930 in Melton Valley were the “most feasible” facilities for processing TRU waste at ORNL. The lowest life-cycle cost estimate for the facility upgrades, operations, and D&D of the facilities was $692 million, over $500 million less than the cost estimate for the WHPP. The study also suggested that competitive contracting for a new facility, the reduction of redundant regulatory oversight, and an expedited schedule could provide up to an additional 50% savings over the lowest cost alternative. The recommendation for competitive contracting became the general foundation for a privatization initiative with an estimated of $370 million. 1996 to 1998 – Privatization Initiative The purpose of the DOE “privatization initiative” was to minimize the cost and schedule of conducting DOE Environmental Management (EM) projects by allowing the commercial sector to compete for projects that were typically within the scope of a DOE M&O contractor. In addition, “Privatization” allows DOE to avoid a delay from “lack of sufficient funds” to cover a huge capital investment such as the ORNL TRU Waste Treatment Facility, since a selected contractor would be required to front the capital investment and receive payment based on completed contract milestones and the number of treated and certified waste containers (for the designated disposal facilities WAC). The privatization contracting approach led DOE to develop and issue a draft invitation for bid in 1996 for the construction and operations of an on-site TRU waste treatment facility at ORNL. Due to the expressed interest in the project, DOE generated a request for proposal for the design, permitting, construction, operations and D&D of the ORNL TRU Waste Treatment Facility. DOE received bids from three companies, and after a detailed and strenuous review process, DOE awarded a contract to Foster Wheeler in August 1998. The project’s proposed cost was $195 million, almost $500 million less than the lowest cost estimate for the modification of the facilities identified in the independent feasibility study. The contract awarded to Foster Wheeler was contingent on the completion of the WM’01 Conference, February 25-March 1, 2001, Tucson, AZ National Environmental Policy Act (NEPA) process for the proposed facility. An Environmental Impact Statement (EIS) was prepared for the proposed facility, which was conducted in tandem with the proposed facility design and permitting process. DOE issued a Record of Decision in July 2000 selecting the facility and treatment processes proposed by Foster Wheeler over other alternatives presented and reviewed in the EIS. THE ORNL TRU WASTE TREATMENT FACILITY PROJECT (1, 2) Project Scope The scope of the TRU Waste Treatment Project includes the design, permitting and construction, operation, and D&D of a TRU Waste Treatment Facility in the Melton Valley area of ORNL. The goal of the ORNL TRU Waste Treatment Project is to successfully process the designated waste for final off-site disposal in a manner that is safe and efficient, and which provides the best value to the American taxpayer. Foster Wheeler must treat and package the waste to meet the WAC of the appropriate disposal facility (WIPP or NTS) Fig. 4. Artist’s rendering of the ORNL TRU Waste before they receive payment. Treatment Facility, which will be located adjacent and west Payment will be based on the of the MVSTs. number of WAC certified containers. DOE will lease the MVSTs and five acres of land adjacent and west of the MVSTs to Foster Wheeler for the construction of the treatment facility. The close proximity to the MVSTs improves Foster Wheeler’s ability to mobilize and transfer sludge and associated LLLW to the waste treatment facility. The ORNL TRU Waste Treatment Facility will be fenced and have its own private access to isolate it from other ORNL facilities. This separation reduces the potential for interface issues with the facility contractor and other ORNL major contractors. The waste that will be treated and packaged at the ORNL TRU Waste Treatment Facility is previously summarized and included in Tables I, II and III. Much of the waste displays RCRA characteristics, and therefore may be classified as mixed waste. Beta/gamma radiation levels as high as 5 R/hr have been recorded in and around the MVSTs, which indicated a need for remote waste retrieval capabilities. All of the sludge and associated LLLW will be treated via remote handling and treatment processes. Remote retrieval of TRU waste was successfully demonstrated in three of the BVESTs, which have physical characteristics identical to the MVSTs. Waste retrieval operations using pulsed jet mixing were successful in removing more than 95 percent of the waste from these three active waste storage tanks, which minimizes the risk, to both DOE and the contractor, for the waste retrieval scope of the ORNL TRU Waste Treatment Project. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ Regulatory Requirements The ORNL TRU Waste Treatment Project responds to a 1995 order by the TDEC Commissioner resulting from the RCRA Site Treatment Plan. In September 1995, the TDEC Commissioner issued an order that requires DOE to make the first shipment of treated TRU waste sludge for disposal at the WIPP by the end of January 2003. The TDEC has publicly stated that the processing and disposal of the ORNL TRU waste is their number one priority. DOE likewise places a high priority on addressing this problem, and thus complying with the order. The TDEC order includes interim milestones, such as the date for awarding the TRU Waste Treatment Project contract. These milestones were included to ensure progress toward the ultimate goal of processing the ORNL TRU waste for disposal at the WIPP. The ORNL TRU Waste Treatment Project also addresses the treatment and disposal of waste from two Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) remediation projects conducted at ORNL. The Interim Record of Decision for eight of the Gunite and Associated Tanks, and the Action Memorandum for the five Old Hydrofracture Facility Tanks require the tank waste to be processed in the TRU Waste Treatment Facility and disposed of at the WIPP or the NTS, further increasing the regulatory emphasis of this project. Sludge and most of the associate LLLW from the eight largest gunite tanks located in ORNL’s North and South Tank Farms in Bethel Valley have been successfully retrieved and consolidated in the MVSTs. The remaining LLLW currently stored in these tanks will be consolidated in the MVSTs as capacity becomes available. The sludge and associated LLLW from the five steel Old Hydrofracture Facility tanks in Melton Valley were consolidated into the MVSTs in 1998. Many of the existing containers used to store CH- and RHTRU solid waste will require repackaging before disposal certification in order to comply with U.S. Department of Transportation regulations. Waste Treatment Foster Wheeler has proposed an evaporating and drying process for the RH-TRU sludges and associated LLLW. The process is flexible enough to cover a wide range of waste properties. The lowtemperature process will substantially reduce the waste volume, generate minimal amounts of secondary waste, and will meet the WAC of the designated disposal facility. LLLW will be pumped from the MVSTs through a double-contained above ground pipeline to the waste treatment facility. Foster Wheeler will perform evaporation operations, followed by lowtemperature vacuum drying. Condensate and recycled LLLW may be used during sluicing operations in the MVSTs to retrieve the RH-TRU sludge. Treated LLLW will be loaded directly into a disposal container that is preloaded into a transportation cask. Foster Wheeler proposed to dry the LLLW for final disposal at the NTS, which will result in a significant life-cycle cost avoidance when compared to disposal costs at the WIPP. RH-TRU sludge will be retrieved from the MVSTs by sluicing. The resulting waste slurry will be pumped through a double-contained above ground pipeline to collection/decant tanks in the TRU Waste Treatment Facility. Concentrated sludge will be dried by low-temperature vacuum drying and packaged directly into the WIPP TRU canisters. DOE will certify the packaged RH-TRU sludge waste for disposal at the WIPP. In the event that the WIPP does not accept RH-TRU waste in time to meet WM’01 Conference, February 25-March 1, 2001, Tucson, AZ the TDEC Commissioner’s Order milestone for off-site disposal of treated RH-TRU sludge, Foster Wheeler has proposed applying additives that reduce solubility of the RCRA metals in the waste and form stable compounds that will no longer exhibit RCRA characteristics and pass the Toxic Characteristic Leaching Procedure. Becthel Jacobs Company LLC, DOE Oak Ridge Operation’s Management and Integrating contractor for environmental management activities, will retrieve solid TRU waste from SWSA 5N from January 2004 until June 2005 and deliver it to the ORNL TRU Waste Treatment Facility. They will also be responsible for delivering the other TRU solid waste from their existing storage facilities to the waste treatment facility at the rate specified in the Foster Wheeler proposal. The on-site untreated TRU solid waste delivery will be accomplished by loading the existing waste containers onto a flatbed truck, and hauling them less than five miles on roads within the ORNL boundary to the ORNL TRU Waste Treatment Facility. The solid wastes will be processed inside gloveboxes or hotcells depending on the radiation levels of the waste. The solid waste will be better characterized during the repackaging efforts to ensure that the final waste form meets the WAC of the WIPP or the NTS. Solid waste will be emptied onto a sorting table, and the mixed waste items will be identified and set aside for treatment. Solid waste contaminated with RCRA-regulated constituents and classified as mixed waste will be isolated for macroencapsulation or another RCRA-approved treatment technique to comply with the RCRA LDRs. This will ensure that the alpha low-level waste streams will meet the NTS WAC, but will also comply with RCRA LDRs if interim on-site storage is required for the RH-TRU solid waste. Foster Wheeler will not treat the bulk of the TRU solid waste that is not considered mixed waste under RCRA. Foster Wheeler will compact and repackage this waste resulting in a 50% volume reduction. Depending on the activity and waste type, the compacted waste will be packaged to meet the appropriate WAC of the designated DOE disposal facilities. Foster Wheeler is responsible for the disposal of all secondary waste, including the original waste containers. The waste processing proposed by Foster Wheeler results in a minimal amount of waste requiring disposal, contributing to the life-cycle cost savings associated with the project. Project Schedule The ORNL TRU Waste Treatment Project consists of four phases shown in Table IV. DOE will perform regulatory oversight of this project for the occupational safety and health and radiological protection during all phases of the project. TDEC will oversee the environmental compliance of the project. Table IV. ORNL TRU Waste Treatment Project High Level Schedule and pricing structure. PHASES ACTIONS SCHEDULE PRICING Phase I Licensing and Permitting August 1998 – November 2000 Fixed Price Phase II Construction and PreOperational Testing December 2000 – January 2004 No Payment Phase III Treatment and Packaging December 2002 until September 2007 Fixed Unit Price Phase IV D&D September 2007 until September 2009 Fixed Price WM’01 Conference, February 25-March 1, 2001, Tucson, AZ PHASE I DOE completed the NEPA process concurrent with the contractor’s Phase I permitting. Foster Wheeler obtained RCRA Part A and B permits, air quality permits, and storm water permits during Phase I of the project. They also completed the facility design, the Safety Management System (SMS) plan, and provided DOE with information to support the NEPA EIS. The ORNL TRU Waste Treatment Project EIS used the existing analyses performed on the DOE Environmental Management Waste Management Programmatic EIS and the WIPP Supplemental EIS, plus additional analyses that evaluated five alternatives, including a “No Action” alternative. Based on the analysis presented in the final EIS for Treating TRU/Alpha Low-Level Waste at ORNL, the DOE issued a Record of Decision selecting the facility and waste treatment processes proposed by Foster Wheeler. Phase I of the contract also allowed the DOE and Foster Wheeler to identify other potential (including off-site) waste streams for processing at the proposed treatment facility. Approximately 15 m3 of TRU waste from the Paducah, Kentucky Gaseous Diffusion Plant was identified for processing at the ORNL TRU Waste Treatment Facility and was included in the project’s EIS. Any additional off-site waste identified for processing at this facility will be analyzed in a separate NEPA review. PHASE II Phase II, construction of the ORNL TRU Waste Treatment Facility, will began in March 2001. Foster Wheeler is solely responsible for financing and construction of the facility. Phase II will last for four years. The facility construction will initially focus on completing and testing the required components for treating and packaging the RH-TRU sludge and associated LLLW. Once Foster Wheeler indicates this part of the facility construction is complete and ready for operations, DOE will perform a detailed operational readiness review to assure that the facility can process the RH-TRU sludge and associated LLLW in a safe and compliant manner. Once Foster Wheeler passes the operational readiness review, Phase III will be authorized and sludge waste retrieval processing will begin in compliance with applicable DOE orders, while the construction and of the facility components for treating RH-TRU solids and operational testing will continue through January 2004. PHASE III Phase III consists of waste treatment operations. Foster Wheeler will receive payment for treated TRU waste when the transportation contractor picks up the waste at the ORNL TRU Waste Treatment Facility for final off-site disposal at the WIPP. Payments for the primary low-level waste streams will be made after receipt of the waste at NTS. Foster Wheeler accelerated the waste treatment schedule and will process the base quantities of waste three years ahead of the schedule allowed in the RFP, resulting in reduced project costs. Foster Wheeler plans to initially process only the RH-TRU sludge and associated LLLW. TRU solid waste processing will begin after the facility is completed in 2004. The ORNL TRU Waste Treatment Facility will be operational until September 2007. TRU solid waste treatment will take approximately 3 years. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ PHASE IV After the waste treatment operations are completed, and DOE has determined that no further use of the facility is warranted, DOE will authorize Phase IV (D&D) of the ORNL TRU Waste Treatment Facility. Foster Wheeler is required to D&D the facility, and the contract requires that the construction site be returned to its original condition. D&D of the facility and site should be conducted from September 2007 until September 2009. CONCLUSIONS The DOE has evaluated many alternatives in order to provide safe and cost-effective treatment and disposal of TRU/alpha low-level waste at ORNL. Through cost consciousness and a privatization contract strategy, DOE developed a request for proposal for the design, permitting, construction, operation, and D&D of the ORNL TRU Waste Treatment Facility. DOE awarded a fixed price contract to Foster Wheeler in August 1998 to complete the project at a cost of $195 million. The use of the privatization contracting strategy resulted in a cost avoidance of over $1 billion from the original baseline cost estimate for construction, operations and D&D of a similar facility designed and proposed the ORNL M&O contractor in the early 1990’s. Waste treatment at the ORNL TRU Waste Treatment Facility should be completed by 2007, expediting the proposed DOE schedule delay by eighteen years, and satisfying the milestone of the TDEC Commissioner’s Order that the first shipment of treated RH-TRU sludge be made to the WIPP by the end of January 2003. The D&D of the facility is expected to be completed by 2009. REFERENCES DOE, June 2000, Final Environmental Impact Statement For Treating Transuranic (TRU)/Alpha LowLevel Waste at the Oak Ridge National Laboratory – Volume 1, DOE/EIS-0305-F, US DOE Oak Ridge Operations ORNL, July 1998, ORNL TRU Waste Treatment Project Report to Congress, US DOE Oak Ridge Operations. DePaoli, S. M., and Walker, A. D. 1998. Current and Projected Liquid Low-Level Waste Generation for ORNL, ORNL/TM-13513, Oak Ridge National Laboratory, Oak Ridge, TN. Kuhaida, A. J., Jr., and Parker, A. F. 1997. Site Descriptions of Environmental Restoration Units at Oak Ridge National Laboratory, Oak Ridge, Tennessee, ORNL/ER-391, Oak Ridge National Laboratory, Oak Ridge, TN. Trabalka, J. R. 1997. Buried Transuranic Wastes at ORNL: Review of Past Estimates and Reconciliation with Current Data, ORNL/TM-13487, Oak Ridge National Laboratory, Oak Ridge, TN. ORNL, July 1995, A Facility Design for Repackaging ORNL CH-TRU Legacy Waste in Building 3525, ORNL/TM-13034, Oak Ridge National Laboratory, Oak Ridge, TN. WM’01 Conference, February 25-March 1, 2001, Tucson, AZ ORNL, September 1995, Feasibility Study for Processing ORNL Transuranic Waste in Existing and Modified Facilities, ONRL/M-4693, Parallax, Inc., Oak Ridge National Laboratory, Oak Ridge, TN. IFDP (Isotopes Facilities Deactivation Project). 1995. Work Plan for the Isotopes Facilities Deactivation Project at Oak Ridge National Laboratory, ORNL/ER-249/R1, Oak Ridge National Laboratory, Oak Ridge, TN. Carver, M., and Slater, M. 1994. Architectural/Historical Assessment of the Oak Ridge National Laboratory, Oak Ridge Reservation, Anderson and Roane Counties, Tennessee, ORNL/M-3244, Oak Ridge National Laboratory, Oak Ridge, TN. Jolley, R. L., Genung, R. K., McNeese, L. E., and Mrochek, J. E. 1994. The ORNL Chemical Technology Division 1950-1994, ORNL/M-2733/R1, Oak Ridge National Laboratory, Oak Ridge, TN. Johnson, L., and D. Schaffer. 1992. “ORNL: The First 50 Years (1942-1992),” ORNL Review 25 (Nos. 3 & 4), 1–282. ORNL, April 1989, Conceptual Design Report for the Waste Handling and Packaging Plant , XOE-453, Engineering Division, ORNL, Martin Marietta Energy Systems, Inc., Oak Ridge, TN. Coobs, J. H., and Gissel, J. R. 1986. History of Disposal of Radioactive Wastes into the Ground at Oak Ridge National Laboratory, ORNL/TM-10269, Oak Ridge National Laboratory, Oak Ridge, TN. NAS (National Academy of Sciences). 1985. The Management of Radioactive Waste at the Oak Ridge National Laboratory: A Technical Review, DOE/DP/48010-T1, National Academy Press, Washington, D.C. Thompson, W. E. 1963. History of the Oak Ridge National Laboratory 1943-1963, ORNL/CF-638-75, August 23, 1963, Oak Ridge National Laboratory, Oak Ridge, TN. [Also see Thompson, W. E. 1973. “Clinton Laboratories–the War Years,” ORNL Review 6 (No. 2), 16-22.]