Review of Position Estimation Methods for IPMSM Drives Without a

advertisement

XIX International Conference on Electrical Machines - ICEM 2010, Rome

Review of Position Estimation Methods for

IPMSM Drives Without a Position Sensor

Part I: Nonadaptive Methods

O. Benjak, D. Gerling

Φ

Abstract --This paper presents a review in state of the art

techniques for position sensorless permanent magnet

synchronous motor drives . In particular nonadaptive methods

like estimators using monitored stator voltages or currents, flux

estimators and back-EMF based estimators are described.

Furthermore the authors give an overview for current methods

to the integrator drift problem.

Index Terms—permanent magnet (PM) machines, positions

estimation, sensorless drives, review, flux estimator, back-EMF,

extended back-EMF, integrator drift.

I

I.

INTRODUCTION

n the past few years great efforts have been made in the

field of speed – and/ or shaft position sensorless

controlled drives. These drives are usually referred to as

“sensorless” drives. This expression refers to the speed and

shaft sensors, but there are still other sensors, e.g. current

sensors [1].

Permanent Magnet Synchronous Motors provide an

excellent power density (compactness), a high energy

efficiency and a high torque to inertia ratio. In the last years

the price of rare-earth magnet material decreased

significantly. For this reason PM-Machines are available for

standard drives up to 300 kW [40].

The main drawback of a PM-Machine is the position sensor,

which is vulnerable for electromagnetic noise in hostile

environments and has a limited temperature range. For PM

motors rated up to 10kW the cost of an encoder is below

10% of the motor manufacturing cost, but e.g. for

applications in the automotive industry with the high number

of produced units the elimination of the position sensor is

preferable. Thus the elimination of the electromechanical

sensors reduces the hardware costs, reduces the installation

complexity of the system (because of associated cabling),

decreases the system inertia, increases the robustness and the

reliability and reduces obviously the noise sensitivity of the

electrical drive [2],[3].

PM-Machines can be divided in two categories which are

based on the assembly of the permanent magnets (PM’s).

The PM’s can be mounted on the surface of the rotor

(surface permanent magnet synchronous motor - SPMSM)

or inside of the rotor (interior permanent magnet

synchronous motor - IPMSM). These two configurations

have an influence on the shape of the back electromotive

force (back-EMF) and on the inductance variation.

Subsequent only the IPMSM machine with a sinusoidal

excitation is examined.

The aim of this paper is to provide a review of a position

estimation for IPMSM drives without a position sensor

O. Benjak is with the Institute of Electrical Drives, University of Federal

Defense Munich, 85577 Neubiberg Germany

(e-mail: oliver.benjak@unibw.de).

D. Gerling is the head of the the Institute of Electrical Drives, University of

Federal Defense Munich, 85577 Neubiberg, Germany

(e-mail: dieter.gerling@unibw.de).

978-1-4244-4175-4/10/$25.00 ©2010 IEEE

which is based on nonadaptive methods and presented in

recent publications. The author renounces a regard of special

kinds of rotor construction for the IPMSM.

This paper is organized as follows:

• First, a classification for the strategies of position

estimation for interior PM synchronous machines is

given.

• Second, the motor equations for the PMSM in

different coordinates are illustrated.

• Third, the nonadaptive methods are described.

II.

STRATEGIES FOR POSTION ESTIMATION OF IPMSM

In general there are three strategies for position estimation of

IPMSM [2], [4]:

1. Fundamental Excitations

a. Nonadaptive Methods,

b. Adaptive Methods,

2. Saliency and Signal Injection,

3. Artificial Intelligence.

a) Nonadaptive Methods: will described in Section III,

are divided in the following three categories [2], [4] :

1. Techniques using the measured DC-Link,

2. Estimators using monitored stator voltages, or

currents,

3. Flux based position estimators

4. Position estimators based on back-EMF.

b) Adaptive Methods: are divided in four categories [4] :

1. Estimator based on Model Reference Adaptive

System (MRAS).

2. Observer-based estimators.

3. Kalman estimator.

4. Estimator which use the minimum error square.

c) Saliency and Signal Injection: In many ac machines,

the position dependence is a feature of the rotor. In the

case of the interior PMSM there is a measurably spatial

variation of inductances or resistances (saliencies) in the

dq direction due to geometrical and saturation effects,

which can be used for the estimation of rotor position [2],

[25], [27].

Another method to estimate the rotor position is to add a

high frequency stator voltage (current) component and

evaluate the effects of the machine anisotropy on the

amplitude of the correspondent stator voltage (current)

component [20].

d) Artificial Intelligence: Artificial intelligence describe

neural network, fuzzy logic based systems and fuzzy

neural networks. These kind of methods do not require a

mathematical model of the drive, exhibit good noise

rejection properties, can easily be extended and modified,

can be robust to parameter variations and are

dq-voltages can be rewritten as:

computationally less intensive [2]

III. MATHEMATICAL MODEL OF IPMSM

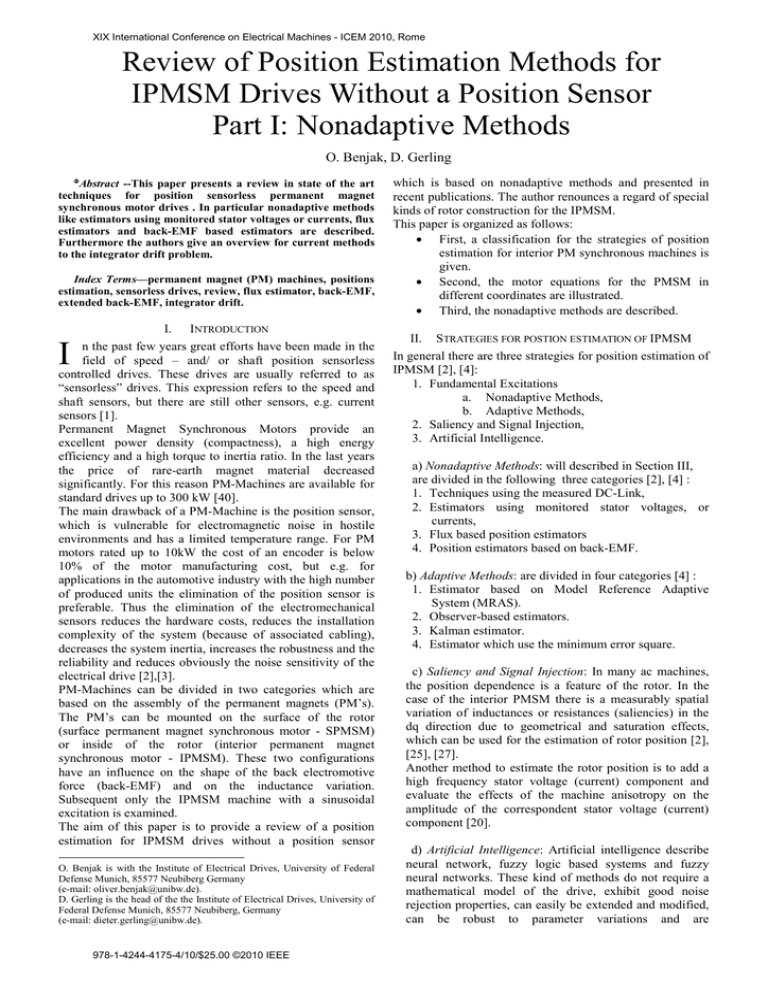

Coordinates, used in this paper, are defined in Fig. 1, which

shows the model of a IPMSM.

⎡ud⎤ ⎡Rs +Ldhp−ωrLqd −ωrLq +Ldqhp ⎤ ⎡id⎤ ⎡ 0 ⎤

⎥⎢ ⎥+⎢

⎢ ⎥=⎢

⎥ . (7)

Rs +Lqhp−ωrLdq ⎦⎥ ⎣⎢iq⎦⎥ ⎣ωrψm ⎦

⎣⎢uq⎦⎥ ⎣⎢ ωrLd +Lqdhp

Subsequently only (4) is examined. In a position sensorless

drive system the d-q-model can not be utilized because the

rotor position is not detected and the real rotating coordinate

is unknown. A d-q-coordinate is the rotating coordinate. A γδ-coordinate is the estimating rotating coordinate having the

Δθ difference from the d-q-coordinate.

Because of the saliency the transformed equation of a

IPMSM based on the mathematical motor model becomes

very complicated. The transformation matrix is defined by:

⎡cos(Δθ) −sin(Δθ)⎤ .

Tdq−γδ =

(8)

⎢ sin(Δθ) cos(Δθ) ⎥

⎣

Fig. 1. Model of an IPMSM with definition of the used coordinates [41]

The 3-phase voltages of an IPMSM are given by [50]:

⎡ dψu ⎤

⎢

⎥

⎡ uu ⎤ ⎡Rs 0 0 ⎤ ⎡ iu ⎤ ⎢ dt ⎥

⎢ ⎥ ⎢

⎥ ⎢ ⎥ ⎢ dψv ⎥

⎢ uv ⎥ = ⎢ 0 Rs 0 ⎥ ⎢ iv ⎥ + ⎢

⎥ .

⎢u ⎥ ⎢ 0 0 R ⎥ ⎢i ⎥ ⎢ dt ⎥

s⎦ ⎣ w⎦ ⎢ dψ ⎥

⎣ w⎦ ⎣

w

⎢ dt ⎥

⎣

⎦

⎡uγ ⎤ ⎡Rs +pLd −ωrLq ⎤ ⎡iγ ⎤

⎡−sin Δθ⎤

⎥⎢ ⎥ +ω ψ ⎢

⎢ ⎥=⎢

⎥ +"

r

m

⎢⎣uδ⎥⎦ ⎢⎣ ωrLd Rs +pLq ⎥⎦ ⎣⎢iδ⎦⎥

⎣ cos Δθ ⎦

(1)

Where:

⎡

⎤

−(Ld −Lq )sin2 (Δθ) ⎥

⎢−(Ld −Lq )sin(Δθ)cos(Δθ)

Lb = ⎢

⎥,

2

(Ld −Lq )sin(Δθ)cos(Δθ)⎥⎦

⎢⎣ −(Ld −Lq )sin (Δθ)

⎡ dψd

⎤

⎡ud⎤ ⎡Rs 0 ⎤ ⎡id⎤ ⎢ dt −ωrψq⎥

⎥.

⎢ ⎥=⎢

⎥⎢ ⎥+⎢

⎢

⎥

⎣⎢uq⎦⎥ ⎣⎢ 0 Rs⎦⎥ ⎣⎢iq⎦⎥ ⎢ dψq +

ωrψd⎥

⎣ dt

⎦

(2)

Where ud, uq, id, iq, ψd and ψq are the dq-axis-voltages,

currents and flux linkages, respectively. ωr is the rotor

electrical angular velocity. ψd and ψq can be written as [4],

[50]:

(3)

Where Ld, Lq, are the self-inductance and ψm the flux linkage

due to permanent-magnets. Apply (3) into (2) the d-q

voltages can be rewritten as:

⎡ud⎤ ⎡Rs +pLd −ωrLq ⎤ ⎡id⎤ ⎡ 0 ⎤

⎥⎢ ⎥+⎢

⎢ ⎥=⎢

⎥.

⎣⎢uq⎦⎥ ⎣⎢ ωrLd Rs +pLq ⎦⎥ ⎣⎢iq⎦⎥ ⎣ωrψm⎦

(4)

Where p is the differential operator d/dt.

[33], [44], [45] and [46] proposed a modified two axis

model, which contains the non-linearity ψd, ψq, dψd/dt and

dψq/dt due to the influence of magnetic saturation. With this

assumption (3) can be written as:

ψd=Ldid+Ldqiq+ψm ,

ψq=Lqiq+Lqdid .

(5)

Where Ldq and Lqd are the mutual-inductances. The

differentiation of ψd and ψq can be described as [50]:

dψd ∂ψd did ∂ψd diq

=

+

=L ⋅pi +L ⋅pi ,

dt ∂id dt ∂iq dt dh d dqh q

dψq ∂ψq diq ∂ψq di

d =L ⋅pi +L ⋅pi .

=

+

dt ∂iq dt ∂id dt qh q qdh d

(6)

Where Ldh, Lqh, Ldqh and Lqhd the incremental self- and

mutual-inductance. Apply (5) and (6) into (2) the modified

(9)

⎡iγ ⎤

" + ⎣⎡Lap+ωr Lb +( Δωr −ωr )Lc ⎦⎤ ⎢ ⎥ .

⎢⎣iδ⎥⎦

⎡

⎤

2

(Ld −Lq )sin(Δθ)cos(Δθ)⎥

⎢ −(Ld −Lq )sin (Δθ)

La = ⎢

⎥,

(Ld −Lq )sin2 (Δθ) ⎥⎦

⎢⎣(Ld −Lq )sin(Δθ)cos(Δθ)

Where uu, uv, uw, iu, iv, iw, ψu, ψv and ψw are the phase

voltages, currents and flux linkages respectively and Rs the

phase resistance. (1) can be transformed into the rotor

reference dq-frame [50]:

ψd=Ldid+ψm ,

ψq=Lqiq .

⎦

Transforming (4) into the γ-δ frame the model is obtained as

follows [35]:

⎡

⎤

2

2

⎢ (Ld −Lq )sin(Δθ)cos(Δθ) −Ld sin (Δθ)−Lq cos (Δθ)⎥

Lc = ⎢

⎥.

2

2

⎢⎣Ld sin (Δθ)+Lq cos (Δθ) −(Ld −Lq )sin(Δθ)cos(Δθ) ⎥⎦

Some authors prefer to transform the d-q- coordinates in α-β

coordinates directly, which gives the rotor angle θ instantly.

The transform matrix is with Δθ=θ similar to (8). The

equation (4) can be written in α-β frame as [29] ,[32]:

⎡uα⎤ ⎡Rs +pLα −ωrLαβ ⎤ ⎡iα⎤

⎡−sin θ⎤

⎥⎢ ⎥ +ω ψ ⎢

⎢ ⎥=⎢

r m cos θ ⎥ .

⎢⎣ uβ⎥⎦ ⎢⎣ ωrLαβ Rs +pLβ⎥⎦ ⎢⎣iβ⎥⎦

⎣

⎦

Where,

(

)

L0 = Ld + Lq / 2,

(

(10)

)

L1 = Ld − Lq / 2,

Lα = L0 + L1 cos2θ, Lβ = L0 − L1 cos2θ,

Lαβ = L1 sin 2θ .

IV. NONADAPTIVE METHODS

In this section common nonadaptive methods, which use

measured currents and voltages as well as fundamental

machine equations of the IPMSM, are presented.

A. Techniques using the measured DC-Link

The Method of measuring the DC-Link is one of the oldest

in order to get adequate signal for feedback. It is an easy and

low-cost process.

In [10] the authors presented two energy optimizing

techniques, which are based on measuring the DC-link

current and a voltage/ frequency (V/f) control method. The

assumption of these methods is that the machine is working

in a stationary operating point, hence the load torque and the

rotor speed is constant at each frequency.

The first technique is the “minimum input power method”,

which minimize the average DC-link current at a considered

fixed DC-link voltage. For the method the current is filtered

and put in a control algorithm, which adjust the reference

voltage. Problematical is the low frequency instability in the

class of synchronous motor drives. The damping of the local

oscillation can be improved by an dc-link current feedback

for the frequency modulation, which made it nearly

independent of the applied frequency.

The second technique is the “power factor method”, which is

based on the contour of the non-filtered DC-link current. The

power factor (PF) is for sinusoidal stator currents and

voltages is defined as PF = cos(θ) , where θ is defined as the

angle from the stator current phasor to the stator voltage

phasor. To get the optimum PF, the DC-link current contour

should has the form of Fig. 2.

⎛ u v −u w −R s ( i v −i w )− Ld p( i v −i w )− 3ωr ( L q −L d )i u ⎞

⎟⎟

⎜

3( u u − R s i u − L d pi u )+ωr ( Lq − Ld )( i v −i w )

⎝

⎠

(13)

The required speed ωr can be calculated as follows:

θ = arctan ⎜

ωr =

1

2

(u u R s pi u ) 2 + ⎡⎣ u v − u w − R s ( i v −i w )− Ld p( i v −i w ) ⎤⎦

3

ψm

(14)

The initial position of the rotor at t=0 can be determined by

substitution ωr=0 in (14).

[12] proposes a voltage-model and current-model based

control which works in the γ-δ reference frame with the

assumption that Ld=Lq=L. Furthermore it is supposed that

Δθ=0 and ωM=ωr. (4) can be transformed and rearranged in:

⎡uγ ⎤ ⎡R +pL −ω L ⎤ ⎡iγ ⎤ ⎡ 0 ⎤

r ⎢ ⎥+

⎢ ⎥=⎢ s

⎥

⎢

⎥

⎢⎣uδ⎥⎦ ⎣ ωrL Rs +pL⎦ ⎣⎢iδ⎦⎥ ⎣ωrψm ⎦

(15)

The estimated speed ωe can be obtain as follows:

u −(R s + pL)iδ

ωe = δ

Li γ +ψ m

Fig. 2. DC-link current when the stator current is in phase with the stator

voltage [10]

The PF is calculated from variation of the current, which is

controlled by a feedback system. Voltage is controlled by

using a PI-controller [13].

Rotor position oscillations in currents arise due to small load

change. To minimize this stability problem, the authors in

[10] applied a control input, which uses the measurement of

the DC-link current. This stability control increase the

reference angular velocity when the filtered DC-link current

decreases and vice versa. After Stabilization the current

pulsation stopped and stable current waveforms were

obtained.

The methods, which are using the DC-link as input gives

nearly the same efficiencies at different loads and speeds

(appr. 10-100% of the rated speed in without and appr. 5100% with current feedback). Disadvantageous is the low

dynamic performance and accuracy, compared with torquecontrolled PM drives [5].

B. Estimator using monitored stator voltages or currents

For estimating the rotor angle θ using monitored stator

voltages and currents different authors follow different

approaches regarding to the used reference frame. This

section shows examples for the perspective in three-axis and

γ-δ coordinates.

[8], [17] and [24] propose the approach with the three axis

model. Firstly transformation from the d-q coordinates to the

α-β coordinates have to be done. The transformation matrix

is based on (8):

⎡cos( θ) − sin(θ) ⎤

Tdq −αβ = ⎢

⎥

⎣ sin(θ) cos(θ) ⎦

(11)

The transformation matrix from the α-β coordinates to the

three-axis model is illustrate in (12).

⎡

⎢1

⎢

2⎢

T23 = ⎢ 0

3

⎢

⎢1

⎢2

⎣

1

2

3

−

2

1

2

−

1⎤

− ⎥

2

⎥

3⎥

2 ⎥

⎥

1 ⎥

2 ⎥⎦

The currents are detected by a current sensor and the

voltages are obtained by calculation which using information

on PWM-pattern, dc-voltage and dead time.

The speed estimation for the current-model is sample based

and can be obtained as:

n en +1

θn +1 −θM

K

ωnM+1 = M

= M T + E Δinγ

ψM

T

T

The final equation for the rotor position angle can be found

as:

(17)

With T and KE as sampling period and estimation gain

respectively. The current model-based sensorless control

algorithm does not need voltage information, that means the

control is free from inaccuracy of the voltage caused by the

inverter.

The estimated speed is compared to the speed reference and

the speed error is processed in the PI-speed control.

C.

Flux estimators

A PMSM drive normally uses a Y connection line and

has no neutral one. The advantage of the flux calculation

method is, that the line voltages can be used [24].

The phase-voltage equation of the stator can be written in the

following form [2], [4]:

G

d G

G

(18)

u s = R s i s + Ψs

dt

G

There is uG s the input voltage, is the current, R s the

resistance and

G

ψ

s

the flux linkage of the stator. With

knowing the initial position, the machine parameters and the

relationship of the flux linkage to the rotor position, the

estimated stator flux is used to calculate the 3-phase stator

currents [24], [39]. The performance depends on the quality

and accuracy of the estimated flux linkage and measured

values of voltages and currents [39].

Change (18) to the stator flux space vector ψG s :

G

G

G

G

G

Ψs = ∫ es = ∫ (us−Rs i s)dt + Ψs0

where is e the induced back-EMF and

(12)

(16)

G

ψ

s0

(19)

the initial

position for the stator flux [2], [4], [34], [39], [59], [60]. (19)

written in α-β-coordinates depends on the terminal voltage

and the stator current. Equation (3) only needs the stator

current of the two phase d-q-reference frame [39], [59].

For determining the rotor position many ways are proposed,

which depend on the used reference frame. Using the α-βframe the equation for the rotor angle can be written as

follows [60]:

⎛ Ψ −Li ⎞

α ⎟.

θ=arctan ⎜ α

⎜ Ψβ − Lβ ⎟

⎝

⎠

(20)

Where L is the winding inductance.

The actual rotor angle using the d-q frame can be calculated

with [2], [4], [9], [39], [59], [60]:

⎛Ψ ⎞

θ=arctan ⎜ d ⎟.

⎜ Ψq ⎟

⎝

⎠

(21)

The estimation of the rotor position from the flux has the

difficulty of the pure integrator in (19). In [18], [22], [34],

[57] solutions for this major problem are presented.

Because of the noise, in the last decade a pure investigation

of the rotor position has gained less attention. Solutions with

adaptive or observer methods are more common [20], [31],

[42], [43].

D.

Position estimation based on back EMF

In PM machines , the movement of magnets relative to

the armature winding causes a motional EMF. The EMF is a

function of rotor position relative to winding, information

about position is contained in the EMF-waveform [43].

Back-EMF based sensorless methods were first developed to

estimate the rotor position of PMSM having a surface

mounted PM-rotor without rotor magnetic saliency [50].

[16] proposes to detect the rotor angle with a back-EMF

measurement which is preformed by adding MCDI

(Maximum Current Decaying Interval) test cycle to the

current control algorithm (cf. fig. 3).

system and improves its reliability. Instead of the measured

voltages reference voltages are used. The back-EMF is not

calculated by the integration of the total flux linkage of the

stator phase circuits because of the integrator drift problem.

The estimation of the rotor position is given by the

difference of the arguments of the back-EMF in the α-β

reference frame and the arguments of the same one in the

rotating d-q frame:

⎛ψ

⎛ eβ ⎞

M

θ=arctan ⎜

⎟ −arctan ⎜⎜

e

⎝ α⎠

⎝ Lq i q

⎞

⎟

⎟

⎠

(25)

(25) shows, that there is only a quadrature current

dependency of the rotor position. Furthermore the back-EMF

in subject to the reference voltage in α-β- coordinates can be

described as following function:

⎛ uβ − Riβ ⎞

ƒ (u α , u β ) = arctan ⎜⎜

⎟⎟

⎝ u α − Riα ⎠

(26)

The relationship between the actual motor voltages and the

reference ones is:

*

u α = u α + δu α

*

u β = u β + δu β

(27)

After substituting (27) in (26) we get:

(

) (

)

∂ƒ

∂ƒ

ƒ u*α ,u*β = ƒ u α ,uβ +

δu +

δu

∂u α α ∂uβ β

⎛ u* −Ri ⎞ V

β

β⎟

= arctan ⎜

− ωT

⎜ u* −Ri ⎟ E r

α⎠

⎝ α

(28)

The second term in (28) is the dependent of the back EMF

on the rotor speed. V, E and T are the RMS voltages, the

back-EMF and the lag time introduced by the inverter

respectively. Thus we get for the “estimated” position θ*:

⎛ u* −Ri ⎞

⎛ψ ⎞

β

β ⎟ V

θ*=arctan ⎜

− ω T −arctan ⎜ M ⎟.

⎜ Lq iq ⎟

⎜ u* −Ri ⎟ E r

⎝

⎠

α⎠

⎝ α

Fig. 3. MCDI test cycle [16]

From the measured back-EMF, the actual rotor angle can be

achieved as follows [16], [39]:

− Ed K eωr sin( θ) sin(θ)

=

=

= tan ( θ )

Eq K eωr cos( θ) cos( θ)

⎛ −E

θ = arctan ⎜ d

⎜ Eq

⎝

⎞

⎟

⎟

⎠

(22)

(23)

The experimental results shows an acceptable accuracy in

the low speed range (10~100rpm). The rotor speed quantities

is fluctuating but can be decreased by a higher bandwidth

for the speed controller.

[33] proposes to estimate the rotor position with an approach

measure the current ripple under a conventional PWM

modulation to derive the back-EMF. Under a PWM

modulation the phase currents always present large ripple. If

this current ripple is measured, the rotor position dependent

inductance and back-EMF can be solved using the PMSM

machine model with the known voltage vectors applied.

The machine model in the α-β reference frame will be

discretized. Thus the rotor position can be expressed as :

⎛ e (n) ⎞ π

θ=arctan ⎜ α

⎟ −

⎜ eβ (n) ⎟ 2

⎝

⎠

(24)

[61] propagates the determination of the back-EMF without

the aid of voltage probes which reduces the cost of the

(29)

The proposed estimation in [61] appears to be very robust

against parameter variation. Furthermore the electrical drive

has a good dynamic performance. Disadvantageous is that

after torque application the error increase but stay never

exceeded 35 r/min during transient operation.

Because of the saliency the transformed equation of an

IPMSM based on the mathematical motor model (10)

becomes very complicated [32], [35], [40]. There are two

trigonometric functions of 2θ, which result from changing

stator inductance. A reason why in (10) 2θ terms appear is

that the impedance matrix is asymmetrical. The desired

matrix should have the following form:

G ⎡ R s + pLd

A=⎢

⎢⎣ ωr Lq

−ωr Lq ⎤

⎥

R s + pLd ⎥⎦

(30)

To eliminate this problem the following easy mathematical

method have to be applied for the desired voltage uq on (4):

uq = A21 + Rsiq + A22 +ωrψm +ωrLdiq + pLqiq − A21 − A22 (31)

with

A 21 = ωr Lq i d , A 22 = pL d i q

Substitute (30) in (4) we get:

⎡ud⎤ ⎡Rs +pLd −ωrLq ⎤ ⎡id⎤ ⎡

⎤

0

⎥⎢ ⎥+⎢

⎢ ⎥=⎢

⎥

⎢⎣uq⎥⎦ ⎢⎣ ωrLd Rs +pLq ⎥⎦ ⎣⎢iq⎦⎥ ⎢⎣(Lq −Ld )(ωrid −piq )+ωrψm ⎥⎦

Transforming (32) in the α-β frame can be written as:

(32)

Books:

⎡uα⎤ ⎡ Rs +pLd

ωr (Ld −Lq )⎤ ⎡iα⎤

⎥ ⎢ ⎥ +"

⎢ ⎥=⎢

⎣⎢ uβ ⎦⎥ ⎣⎢−ωr (Ld −Lq ) Rs +pLd ⎦⎥ ⎢⎣ iβ ⎥⎦

{

(33)

}

⎡−sin θ⎤

" + (Lq − Ld )(ωrid − piq ) +ωr ψm ⎢

⎥

⎣ cos θ ⎦

{

}

⎡−sin θ⎤

(Lq − Ld )(ωrid − piq ) +ωrψm ⎢

⎥

⎣ cos θ ⎦

⎡ u −(R +pL )i −ω (L −L )i ⎤

⎡−e ⎤

θ = arctan ⎢ e α ⎥ = arctan ⎢− α s d α r d q β ⎥

⎢⎣ uβ −(Rs +pLd )iβ +ωr (Ld −Lq )iα ⎥⎦

⎣⎢ β ⎦⎥

[4]

Papers from Conference Proceedings (Published):

[5]

[6]

[7]

[8]

(35)

[9]

[10]

(36)

For the calculation of the necessary speed a PI-controller is

used in [31], [35].

[40], [54] propose a discrete calculation of the EEMF, which

is based on the approximation of the current in γ-δ-frame.

It has to be note, that the arctan calculation is sensitive to

the signal-noise-ratio. In the direct calculation it has no lag,

but suffers from a large position estimate error due to the

noise. This problem can be mitigate by using a state filter,

but the estimate then has lagging properties. The estimation

accuracy of the EEMF based state filter is determined by the

bandwidth of the state filter and the errors in parameter

estimation an reference voltage [34].

Further positon estimation techniques of EMF in conjunction

with flux estimation are [34], [58].

Just in section “flux estimators” the problem of noise is also

presented for back-EMF-methods. To overcome this

difficulty several authors uses observer and adaptive

methods [17], [29], [32], [35], [38], [41], [42], [48], [55],

[56], [62].

V.

[3]

(34)

In conventional estimation methods a phase-locked loop

(PLL) control for making the position error Δθ=0 is applied

[31], [32], [41],[51].

⎡ u −(R +pL )iδ−ωrLqiγ ⎤

⎥

Δθ = arctan ⎢− γ s d

⎢⎣ uδ −(Rs +pLd )iγ+ωrLqiδ ⎥⎦

K. Rajashekara, A. Kawamura, K. Matsuse, Sensorless control of AC

motor drives: speed and position sensorless operation, IEEE Press,

1996.

Vas, P., Sensorless Vector and Direct Torque Control, Oxford

University Press (UK), 1998.

Jacek F. Gieras, Mitchell Wing, Permanent Magnet Motor

Technology, 2nd ed., Marcel Dekker, Inc, 2002.

D. Schröder, Elektrische Antriebe - Regelung von Antriebssystemen.

3th edn., Berlin Heidelberg New York: Springer-Verlag, 2008 (in

German)

[2]

The second term on the right side of (33) is defined as the

extended EMF (EEMF). The physical meaning can be

explained as follows. The first term represent the induced

voltage by the rotating flux excited by the d-axis current.

The second term means an induced voltage by changing qaxis current. This differential term of iq is responsible that,

even when the motor’s velocity is near zero, the EEMF is

not zero when the q-axis current iq is changing. This property

can be use for standstill and low speed-drives. The last term

depict the EMF induced by the rotating permanent magnet.

Generally the position estimation calculated from the EEMF

[28], [32], [47]:

⎡eα⎤

⎢ ⎥=

⎢⎣ eβ ⎥⎦

[1]

CONCLUSION

IPMSM drives without mechanical sensors for motor

position or speed have the attraction of lower cost and higher

reliability. Algorithms which can be implemented in

standard microcontroller hardware, are of increasing interest

for industrial application.

A review of prior work in the field of non-adaptive methods,

especially techniques using the DC-link, stator voltages or

currents and flux- or back-EMF based position estimators

has been presented in this paper.

A review of adaptive methods will be given in a subsequent

publication.

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

R.S. Colby, D.W. Novotny, An Efficiency-Optimizing PermanentMagnet Synchronous Motor Drive, IEEE Trans. On Industry

Applications, vol. 4, no. 3, pp. 462-469, 1988

K. Wu, G. Slemon A Permanent Motor Drive without a Shaft Sensor,

IEEE Transaction on Industry Applications, Vol 27, pp. 1005-1011,

1990.

J. Holtz, Speed estimation and sensorless control of AC drives, IEEE

International Conference Industrial Electronic, Control and

Automation, IECON, pp. 649-654, 1993.

M.A. Hoque, M.A. Rahaman, Speed and Position Sensorless

Permanent Magnet Synchronous Motor Drives, IEEE Anadien

Conference on Electrical and Computer engineering, CCECE, pp.

689-692, 1994.

N. Ertugrul, P. P. Acarnley, A New Algorithm for Sensorless

Operation of Permanent Magnet Motors, IEEE Transaction on

Industry Application, No. 1, pp. 126-133, 1994.

P.S. Frederiksen, J. Birk, F. Blaabjerg, Comparison of Two Energy

Optimizing Techniques for PM-machines, 20th. International Conf. on

Industrial Electronics, Control and Instrumentation for PM-Machines,

IECON, pp. 32-37 vol. 1, 1994.

K. J. Talbot, C. E. Kleinhans, G. Diana, and R. G. Harley: Speed

sensorless field oriented control of a csi-fed induction motor by a

transputer based digital controller, IEEE Power Electronics

Specialists Conference, PESC, pp. 785-791, 1995.

T. Kondo, A. Takahashi, T. Nishida, Armature Current Locus Based

Estimation Method of Rotor Position of Permanent Magnet

Synchronous Motor without Mechanical Sensor, Conference Record

of the Industrial Applications Society, IAS, pp.55-60, 1995.

Y. Nakamura, T. Kudo, F. Ishibashi, S. Hibino, High-Efficiency Drive

Due to Power Factor Control of a Permanent Magnet Synchronous

Motor, IEEE Trans. on Power Electronics, Vol. 10, Issue 2, pp. 247 253, 1995.

N. Matsui, Sensorless PM Brushless DC Motor Drives, IEEE Trans.

on Industrial Electronics, Vol. 43, pp. 300-308, 1996.

J. Solsona, M. I. Valla, C. Muravchik, A Nonlinear Reduced Order

Observer for Permanent Magnet Synchronous Motor, IEEE

Transaction on Industrial Electronics., pp.492-497, 1996.

J.-S. Kim and S.-K. Sul, New approach for the low-speed operation of

pmsm drives without rotational position sensors, IEEE Transactions

on Power Electronics, Vol. 11, no. 3, pp. 512-519, 1996.

M.A. Jabbar, M.A. Hoque, M.A. Rahman: Sensorless Permanent

Magnet Synchronous Motor Drives, Canadian Conference on

Electrical and Computer Engineering, CCECE, pp. 878-883, 1997.

M. N. Marwali, A. Keyhani, A Comparative Study of Rotor Flux based

MRAS and Back EMF based MRAS Spedd Estimators Vector Control

of Induction Machines, IEEE Conference Record of Industry

Applications Conference, IAS, pp. 160-166, 1997.

J. Hu, B. Wu: Field Oriented Control CSI Synchronous Motor Drive

Without Shaft Sensors, International Conference on Power Electronics

and Drive Systems, PEDS, pp. 798-803, 1997.

G.M Asher, Sensorless estimation for vector controlled induction

motor drives, Colloquium on Vector Controlled Revisited pp. 6/1-6/5,

1998.

T. Nogachi, K. Yamada, S. Kondo and I. Takahashi, “Initial rotor

position estimation method of sensorless PM synchronous motor with

no sensitivity to armature resistance,” IEEE Trans. Industrial

Electronics, vol.45, no.1, pp.118-125, 1998.

J. Hu, B. Wu, New Integration Algorithms for Estimating Motor Flux

over a Wide Speed Range, Power Electronics Specialist Conference,

PESC’97, pp. 1075-1081, 1998.

A. Consoli, G. Scarcella, A. Testa, Sensorless control of AC motors at

zero speed, Proc. IEEE International Symposium on Industrial

Electronics, ISIE, Vol. 1, pp. 373-379, 1999.

J. P. Johnson, M. Ehsani and Y. Guzelgunler, Review of sensorless

methods for Brushless DC, IEEE Industry Applications Conference,

IAS, Vol. 1, pp. 143 – 150, 1999.

[25] A. Takashi, A. Toba, T. Yanase, A. Mashimo, K. Endo, Sensorless

Torque Control of Salient-Pole Synchronous at Zero Speed Operation,

IEEE Transaction on Power Electronics, pp. 202-208 1999.

[26] D. Yousfi, M. Azizi, A. Saldi, Position and Speed Estimation with

improved Integrator for Synchronous Motor, IEEE Conference of

Industrial Electronics Society, ICEON’99, pp. 1097-1102, 1999.

[27] Gerg. M. Asher, Sensorless Induction Motor Drives, Advances in

Induction Motor Control (Ref. No 2000/072), IEE Seminar, 1999.

[28] L. Harnefors and H.-P. Nee, A General Algorithm for Speed and

Position Estimation of AC Motors, IEEE Transaction on Industrial

Electronics, pp. 77–83, 2000.

[29] Z. Chen, M. Tomita, S. Ichikawa, S. Doki, and S. Okuma, Sensorless

Control of Interior Permanent Magnet Synchronous Motor by

Estimation of an Extended Electromotive Force, Industry Applications

Conference, IACON, pp. 1814-1819, 2000.

[30] F. Briz, M.W. Degner, A. Diez, R.D. Lorenz, Measuring, Modeling,

And Decoupling Of Saturation Induced Saliencies In Carrier Signal

Injection Based Sensorless Ac Drives, IEEE Transaction on Industrial

Applications, pp 1356-1364, 2001.

[31] K. Sakamoto, Y. Iwaji, T. Endo, T. Takakura, Position and Speed

Sensorless Control for PMSM Drive Using Direct Position Error

Estimation, Industrial Electronics Society, 2001. IECON '01. pp 1680

– 1685, 2001.

[32] S. Ichikawa, Z. Chen, M Tomita, S. Doki, S.Okuma, Sensorless

Control of an Interior Permanent Magnet Synchronous Motor on the

Rotating Coordinate Using an Extended Electromotive Force,

Industrial Electronic Society, ICEON ’01, pp. 1667 – 1672, 2001

[33] C. Wang, L. Xu, A Novel Approach for Sensorless Control of PM

Machines Down to Zero Speed Without Signal Injection or Special

PWM Technique, IEEE Transaction on Power Electronics, pp. 857864; 2001.

[34] J.X. Shen, Z.Q. Zhu, & D. Howe, Improved Speed Estimation in

Sensorless PM Srushless AC Drives, IEEE Transactions on Industry

Applications, Vol. 38; pp. 1072-1080; 2002.

[35] S. Morimoto, K. Kawamoto, M. Sanada and Y. Takeda, Sensorless

Control Strategy for Salient-Pole PMSM Based on Extended EMF in

Rotating Reference Frame,” IEEE Transaction on Industry

Applications, Vol. 38, no. 4, pp. 1054-1061, 2002.

[36] B. Stumberger, G. Stumberger, D. Dolinar, A. Hamler, M. Trlep,

Evaluation of Saturation and Cross-Magnetization Effects in Interior

Permanent-Magnet Synchronous Motor. Transactions on Industry

Applications, pp 1264 – 1271, 2003.

[37] Hyunbae K.; Harke, M.; Lorenz, R.; Sensorless Control of Interior

Permanent-Magnet Machine Drives with Zero-Phase Lag Position

Estimation” Industry Applications, IEEE Transactions on , Volume:

39 , pp:1726 — 1733, 2003.

[38] Z. Chen, M. Tomita, S. Doki and S. Okuma, An Extended

Electromotive Force Model for Sensorless Control of Interior

Permanent-Magnet Synchronous Motors, IEEE Trans. on Industrial

Electronics, Vol. 50, No, pp.288-295, 2003.

[39] C. DeAngelo, G. Bossio, J. Solsona, G. Garcia, M. Valla, Sensorless

Speed Control of Permanent Magnet Motors Driving an Unknown

Load, IEEE International Symposium on Industrial Electronics, pp.

617-620, Vol.1, 2003.

[40] D. Montesinos, S. Galceran, A. Sudria, O. Gomis, Low Cost

Sensorless Control of Permanent Magnet Motors. An Overview and

Evaluation, IEEE International Conference on Electric Machines and

Drives, pp. 1681-1688, 2005.

[41] H Obana, Y.Ota, I. Miki, A Position Sensorless Control Method of

Interior Permanent Magnet Synchronous Motor, ICEMS Conference

on Electrical Machines and Systems, pp. 215 – 220, 2005.

[42] H. Rasmussen, P. Vadstrup, A Novel Back EMF Observer for

Sensorless Control of Interior Permanent Magnet Synchronous

Motors, IEEE Conference of Industrial Electronics Society, pp. 15281531, 2005.

[43] M. Tursini, R. Petrella, A. Scafati, Speed and Position Estimation for

PM Synchronous Motor with Back-EMF Observer, IEEE Conference

Record of Industry Applications, pp. 2083 – 2090, 2005.

[44] P. P. Acarnley, J. F. Watson, Review of Position-Sensorless Operation

of Brushless Permanent-Magnet Machines, IEEE Transactions on

Industrial Electronics, pp. 352-362, April 2006.

[45] G. Dajaku, D. Gerling,, The correct analytical expression for the

phase inductance of salient pole machines, IEEE International Electric

Machines and Drives Conference, IEMDC ’07, pp. 992-996, 2007

[46] M. Rashed, P.F.A. MacConnell, A.F. Stronach, P. Acarnley,

Sensorless Indirect-Rotor-Field-Orientation Speed Control of a

Permanent-Magnet Synchronous Motor With Stator-Resistance

Estimation,. IEEE Transactions on Industrial Electronics, TIE, pp.

1664 – 1675, 2007.

[47] T. Halkosaari, Speed Sensorless Vector Control of a Redundant

Permanent Magnet Wind Power Generator, Symposium on Industrial

Electronics, ISIE 2007, pp. 2595 - 2600 2007.

[48] B. Nahid-Mobarakeh, F. Meibody-Tabar, F.M. Sargos, Back EMF

Estimation-Based Sensorless Control of PMSM: Robustness With

Respect to Measurement Errors and Inverter Irregularities, IEEE

Transaction on Industry Applications, Vol. 43, pp. 485-494, 2007.

[49] L. Chretien, I. Husain, Position Sensorless Control of Non-Salient

PMSM from Very Low Speed to High Speed for Low Cost

Applications, Conference Record of Industrial Applications, IAS, pp

289-296, 2007.

[50] Y. Li, Z.Q. Zhu, D. Howe, C.M. Bingham, Improved Rotor Position

Estimation in Extended Back-EMF Based Sensorless PM Brushless

AC Drives with Magnetic Saliency. IEEE International Electric

Machines & Drives conference, IEMDC’07, pp. 214-219, 2007

[51] H. Hida, Y. Tomigashi, K. Kishimoto, Novel sensorless control for pm

synchronous motors based on maximum torque control frame, IEEE

Conference on Power Electronics and Applications, EPE, pp. 1-10,

2007.

Position

[52] V.C. Ilioudis, N.I. Margaris, Sensorless Speed and

Estimation of PMSM Using Sliding Mode observers in γ-δ Reference

Frame, International Conference on Control and Automation, pp. 641646, 2008.

[53] F. Wu; S. Wan; S. Huang, Unity Power Factor Control for PMSM

Position Sensorless Drive, International Conference on Electrical

Machines and Systems, 2008. ICEMS 2008. pp. 1618 – 1620, 2008.

[54] J. Lee; T. Kong; W. Lee; C. Won; J. Yu, A New Hybrid Sensorless

Method using a Back EMF Estimator and a Current Model of

Permanent Magnet Synchronous Motor. Power Electronic Specialists

Conference, PESC, pp.4256 – 4262, 2008.

[55] I. Vasilios, M. Nikolaos, PMSM Sliding Mode Observer for Speed and

Position Estimation Using Modified Back EMF, Power Electronics

and Motion Control Conference, EPE-PEMC, pp. 1105-1110, 2008.

[56] X. Wang, Q. Ge, Speed Sensorless Control of a Linear Synchronous

Motor using State Observer on d-q Reference Frame, International

Conference on Electrical Machines and Systems, ICEMS 2008, pp.

1553-1557, 2008.

[57] H. Lu, M. Li, Y. Xu: Sensorless Position and Speed Estimation with

Improved Integrator for PMLSM, International Conference on

Information and Automation, ICIA’09, pp.380-384, 2009.

[58] D. Yousfi, A. Halelfadl, M. El Kard, Review and evaluation of some

position and speed estimation methods for PMSM sensorless drives,

International Conference on Multimedia Computing and Systems,

ICMCS’2009, pp.409-414, 2009.

[59] W.D. Drury, D. Holliday, D. Drury, P.H. Mellor, An Adaptive

Structure Based Sensorless Position Estimator for Permanent Magnet

Machines in Aerospace Applications. International Electric Machines

and Drives Conference, IEMDC '09, pp. 1264-1269, 2009

[60] D. Yousfi, A. Halefadl, M. El Kard, Sensorless control of Permanent

Magnet Synchronous Motor. International Conference on Multimedia

Computing Systems, ICMCS ’09, 2009.

[61] R. Miceli, F. Genduso, C. Rando, G. Ricco Galluzzo, Back-EMF

Sensorless Control Algorithm for High Dynamics Performances

PMSM, IEEE Transaction on Industrial Electronics, 2009

[62] G.B. Lee, J.S. Park, S.H. Lee; Y.A. Kwon, High-performance

Sensorless Control of PMSM Using Back-EMF and Reactive Power,

ICCAS-SICE, 2009.

VI. BIOGRAPHIES

Oliver Benjak was born in Hennigsdorf in German Democratic

Republic, on April 28th, 1978. He graduated from the German Polytechnic

School, Hennigsdorf, Germany and studied Electrical Engineering at the

Technical University of Berlin, Germany where he received his diploma

degree in 2009. He joined the Institute for Electrical Drives of the

University of Federal Defense Munich in 2009 as research assistance.

Dieter Gerling, born 1961, got his diploma and Ph.D. degrees in

Electrical Engineering from the Technical University of Aachen, Germany

in 1986, 1992 respectively. From 1986 to 1999 he was with Phillips

Research Laborites in Aachen, Germany as Research Scientist and later as

Senior Scientist. In 1999 Dr. Gerling joined Robert Bosch GmbH in Bühl,

Germany as Director. Since 2001 he is a Full Professor and Head of the

Institute of Electrical Drives at the University of Federal Defense Munich,

Germany.