Complex Environment Devices

advertisement

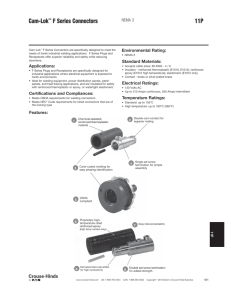

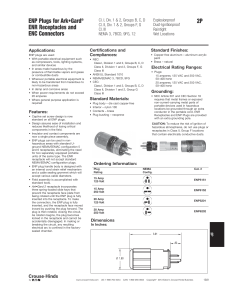

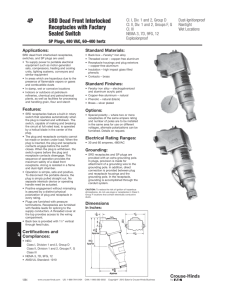

Complex Environment Devices Watertight, Severe Duty Insulated and Corrosion Resistant devices for harsh industrial environments Watertight, Severe Duty Insulated & Corrosion Resistant Devices Arrow Hart® delivers superior performance in the harshest environments Our family of complex environment devices excel where standard wiring devices are most susceptible to failure: physically abusive areas containing a host of contaminants that attack device integrity like oils, chemicals, water and moisture, UV exposure, ozone and corrosive airborne contaminants. Table of Contents Watertight Devices . . . . . . . . . . . . . . . . 4 Severe Duty Insulated Devices . . . . . 11 Corrosion Resistant Devices. . . . . . . 16 Complex Environment Protection Accessories. . . . . . . . . . . . . . . . . . . . . 19 Arrow Hart offers a complete range of solutions for use in complex environments. • Watertight devices provide safe and reliable watertight connections, ideal for use in wet locations and hose-down areas • Severe Duty Insulated devices offer superior resistance to UV exposure, ozone and a wide variety of damaging fluids typically found in industrial applications • Corrosion Resistant devices are engineered to perform where moisture and humidity create corrosive environments • A full line of accessories are available, designed to compliment the unique performance characteristics of our industrial devices 2 • Food Processing Watertight Device Applications: • Petrochem Production • Marinas/ Shipbuilding A complete line of devices designed for complex environments Select from a complete offering of straight blade and locking devices intended for use in complex and harsh environments, including a wide range of plugs, connectors, receptacles and accessories. • Industrial Manufacturing Severe Duty Insulated Device Applications: • Mining & Agriculture • Warehousing & Refrigeration • Chemical Processing Corrosion Resistant Device Applications: • Temporary Power • Machine Shops/ Millworks 3 Watertight Device Applications The most complete offering of watertight wiring devices Application Watertight devices have been designed for industrial applications in which electrical connections are exposed to liquid splashing and hose-down. Watertight devices are ideal for industrial manufacturing, food and beverage processing, agriculture applications, chemical production, shipyards and marinas plus wastewater treatment facilities. These products have excellent resistance to physical abuse, hosedirected water, oils, chemicals, corrosive liquids, airborne particulates and contaminants, UV exposure and ozone attack. Properly mated plugs and connectors, plugs and receptacles and closed receptacles form a multi-point watertight seal that resists 1,000 psi water spray. 4 Arrow Hart® has the broadest line of industrial locking and straight blade watertight devices. Select from the most extensive offering of plugs, connectors, receptacles and accessories – all providing superior watertight protection. Watertight Device Features & Benefits Innovative design and rugged materials make our watertight devices your best solution 1 These versatile products are ideal for food processing plants, oil refineries or chemical processing plants — anywhere that moisture, dirt or corrosive elements may be a factor. Spring-loaded selfclosing flip lid cover ensures a watertight seal when the receptacle is not in use – even in water spray at 1,000 psi 5 2 3 Nickel-plated power contacts and terminal assemblies Glass-filled nylon cover and exterior shell provide impact resistance in abusive environments 6 Quick-drive stainless steel assembly screws provide corrosion resistance and fast assembly Nickel-plated power 7 contacts, blades Watertight Receptacles Stainless steel mounting and assembly screws provide corrosion resistance and terminal screws provide corrosion resistance Neoprene 11 grommet Watertight Plugs & Connectors ensures a watertight seal 4 The flip lid cover in the closed position facilitates OSHA lockout/tagout requirements 8 Tapered individual wire pockets guide stranded wire into contact area for ease of installation 10 Santoprene™ 9 11 Sealing system provides multipoint watertight seal Glass reinforced nylon interior and elastomeric exterior molded together for watertight seal and rugged support thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone Related Products A full range of complimentary products designed specifically for wet and hose-down environments are available. Closure Caps Watertight Wire Mesh Grips Weather Protective Boots For Plugs or Connectors Industrial Cable Strain Relief For Plugs or Connectors 5 Watertight Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Straight Blade Receptacles, Plugs & Connectors 3.10" (78.7mm) 2-Pole, 3-Wire Grounding 15A; 125, 250V/AC 20A; 125, 250V/AC Industrial Specification Grade Straight Blade Devices 1.88" (47.8mm) 4.60" (116.8mm) 3.25" (82.6mm) 60W33 FEATURES • Thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone attack. • Mated plug and connector or plug and receptacle form a watertight seal that meets NEMA and IEC IP ratings (see specification sheet for details) and withstands water spray test at 1000 psi. • High visibility safety yellow for identification. • Power contacts, blades and terminal screws nickel-plated for corrosion resistance. • Quick-drive stainless steel assembly screws for corrosion resistance and fast installation. • Color coded neoprene grommets for a watertight seal on a wide range of cord sizes. • Receptacles have self-closing spring loaded flip lid covers. 3.62" (91.9mm) Straight Blade Receptacles – 2-Pole, 3-Wire 1.88" (47.8mm) 4.63" (117.6mm) 3.25" (82.6mm) 60W48DPLX Rating A V/AC 15 125 NEMA 5-15 15 250 6-15 20 125 5-20 20 250 6-20 C R US Catalog No. Cord Diameter 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) Single ■ 60W47 Duplex ■ 60W47DPLX ■ 60W49 ■ 60W49DPLX ■ 60W33 ■ 60W33DPLX ■ 60W48 ■ 60W48DPLX 1.81" (46.0mm) Straight Blade Plugs & Connectors – 2-Pole, 3-Wire 3.44" (87.3mm) 2.56" (65.1mm) Rating A V/AC 15 125 NEMA 5-15 15 250 6-15 20 125 5-20 20 250 6-20 14W47 4.00" (101.6mm) C R US Catalog No. Cord Diameter 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) Plug ■ 14W47 Connector ■ 15W47 ■ 14W49 ■ 15W49 ■ 14W33 ■ 15W33 ■ 14W48 ■ 15W48 For all-black devices, add color code BK after catalog number. 14W47BK and 15W47BK are available for immediate shipment. All other all-black items are available for quick-shipment within 10 days. For quantities over 100, consult factory for lead times. 1.59" (40.5mm) 15W47 G G W 5-15R G G W 6-15R 5-20R 6-20R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • cUL Certified to CAN/CSA C22.2 no. 42-99 (receptacles) or C22.2, no. 182.2 (plugs & connectors) • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 6 Watertight Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Locking Receptacles, Plugs & Connectors 2-Pole, 3-Wire Grounding 15A; 125, 250, 277V/AC 20A; 125, 250, 277, 480V/AC 30A; 125, 250, 277, 480V/AC 3.10" (78.7mm) Industrial Specification Grade Hart-Lock® Devices 1.88" (47.8mm) FEATURES • Thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone attack. • Mated plug and connector or plug and receptacle form a watertight seal that meets NEMA and IEC IP ratings (see specification sheet for details) and withstands water spray test at 1000 psi. • High visibility safety yellow for identification. • Power contacts, blades and terminal screws nickel-plated for corrosion resistance. • Quick-drive stainless steel assembly screws for corrosion resistance and fast installation. • Color coded neoprene grommets for a watertight seal on a wide range of cord sizes. • Receptacles have self-closing spring loaded flip lid covers. 4.60" (116.8mm) 3.25" (82.6mm) L530RW 3.62" (91.9mm) Locking Devices – 2-Pole, 3-Wire Rating A V/AC NEMA 15 125 L5-15 C R Cord Diameter 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) 0.30"-0.65" (7.6mm-16.5mm) Catalog No. Plug Connector ■ 24W47 ■ 25W47 Receptacle Single Duplex ■ 65W47 ■ 65W47DPLX ■ 24W49 ■ 25W49 ■ 65W49 ■ 65W49DPLX ■ 24W34 ■ 25W34 ■ 65W34 ■ 65W34DPLX 15 250 L6-15 15 277 L7-15 20 125 L5-20 0.36"-0.84" (9.1mm-21.3mm) ■ L520PW ■ L520CW ■ L520RW – 20 250 L6-20 0.36"-0.84" (9.1mm-21.3mm) ■ L620PW ■ L620CW ■ L620RW – 20 277 L7-20 0.36"-0.84" (9.1mm-21.3mm) ■ L720PW ■ L720CW ■ L720RW – 20 480 L8-20 0.36"-0.84" (9.1mm-21.3mm) ■ L820PW ■ L820CW ■ L820RW – 30 125 L5-30 0.43"-1.15" (10.9mm-29.2mm) ■ L530PW ■ L530CW ■ L530RW – 30 250 L6-30 0.43"-1.15" (10.9mm-29.2mm) ■ L630PW ■ L630CW ■ L630RW – 30 277 L7-30 0.43"-1.15" (10.9mm-29.2mm) ■ L730PW ■ L730CW ■ L730RW – 30 480 L8-30 0.43"-1.15" (10.9mm-29.2mm) ■ L830PW ■ L830CW ■ L830RW – 1.88" (47.8mm) US 4.63" (117.6mm) 3.25" (82.6mm) 65W47DPLX 1.81" (46.0mm) 3.44" (87.4mm) 2.56" (65.0mm) 24W47 1.59" (40.4mm) For all-black devices, add color code BK after catalog number. All-black items are available for quick-shipment within 10 days. For quantities over 100, consult factory for lead times. 4.00" (101.6mm) 25W47 X W G L5-15R G W W Y L6-15R G L7-15R G L5-20R W X G Y L6-20R G L7-20R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • cUL Certified to CAN/CSA C22.2 no. 42-99 (receptacles) or C22.2, no. 182.2 (plugs & connectors) • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) X G X W Y L8-20R G L5-30R G Y L6-30R X W G L7-30R G Y L8-30R 7 Watertight Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Locking Receptacles, Plugs & Connectors 3.10" (78.7mm) 3-Pole, 3-Wire Non-Grounding 3-Pole, 4-Wire Grounding 20A; 125/250, 3Ø 250, 3Ø 480V/AC 30A; 125/250, 3Ø 250, 3Ø 480, 3Ø 600V/AC Industrial Specification Grade Hart-Lock® Devices 1.88" (47.8mm) FEATURES • Thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone attack. • Mated plug and connector or plug and receptacle form a watertight seal that meets NEMA and IEC IP ratings (see specification sheet for details) and withstands water spray test at 1000 psi. 4.60" (116.8mm) 3.25" (82.6mm) L1620RW • High visibility safety yellow for identification. • Power contacts, blades and terminal screws nickel-plated for corrosion resistance. • Quick-drive stainless steel assembly screws for corrosion resistance and fast installation. • Color coded neoprene grommets for a watertight seal on a wide range of cord sizes. • Receptacles have self-closing spring loaded flip lid covers. Locking Devices – 3-Pole, 3-Wire Rating A V/AC 20 125/250 2.49" (63.2mm) 3.66" (93.0mm) L1020PW 20 125/250 NEMA NonNEMA L10-20 20 3Ø 250 L11-20 30 125/250 L10-30 30 125/250 NonNEMA L11-30 30 3Ø 250 2.49" (44.2mm) Rating A V/AC 20 125/250 NEMA L14-20 20 3Ø 250 L15-20 20 3Ø 480 L16-20 30 125/250 L14-30 30 3Ø 250 L15-30 30 3Ø 480 L16-30 30 3Ø 600 L17-30 L1420CW 3-pole, 3-wire, nonegrounding locking devices rated 20 A, 125V/250 V RECEPTACLE NON-NEMA 30A 125/250V REC PLUG US ■ 9965PW Single Receptacle ■ 7314RW ■ L1020PW ■ L1020CW ■ L1020RW ■ L1120PW ■ L1120CW ■ L1120RW ■ L1030PW ■ L1030CW ■ L1030RW ■ 3331PW ■ 3333CW ■ 3333RW ■ L1130PW ■ L1130CW ■ L1130RW Plug ■ L1420PW Catalog No. Connector ■ L1420CW Single Receptacle ■ L1420RW ■ L1520PW ■ L1520CW ■ L1520RW ■ L1620PW ■ L1620CW ■ L1620RW ■ L1430PW ■ L1430CW ■ L1430RW ■ L1530PW ■ L1530CW ■ L1530RW ■ L1630PW ■ L1630CW ■ L1630RW ■ L1730PW ■ L1730CW ■ L1730RW Plug C Cord Diameter 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) R Catalog No. Connector ■ 7314CW Locking Devices – 3-Pole, 4-Wire 5.42" (137.7mm) RECEPTACLE NON-NEMA 20A 125V/250V C Cord Diameter 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) R US For all-black devices, add color code BK after catalog number. All-black items are available for quick-shipment within 10 days. For quantities over 100, consult factory for lead times. Y X Y L10-20R X Z L11-20R Y L10-30R W G Z L11-30R Y G X X X X Y X W X W Y G X X W G Y G X Y G Y G Y Z Z Y Z Z Z L14-20R L15-20R L16-20R L14-30R L15-30R L16-30R L17-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • cUL Certified to CAN/CSA C22.2 no. 42-99 (receptacles) or C22.2, no. 182.2 (plugs & connectors) • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 8 Watertight Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Locking Receptacles, Plugs & Connectors 4-Pole, 4-Wire Non-Grounding 20A; 3ØY 120/208, 3ØY 277/480, 3ØY 347/600V/AC 30A; 3ØY 120/208, 3ØY 277/480, 3ØY 347/600V/AC 3.10" (78.7mm) Industrial Specification Grade Hart-Lock® Devices FEATURES • Thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone attack. • Mated plug and connector or plug and receptacle form a watertight seal that meets NEMA and IEC IP ratings (see specification sheet for details) and withstands water spray test at 1000 psi. 1.88" (47.8mm) • High visibility safety yellow for identification. • Power contacts, blades and terminal screws nickel-plated for corrosion resistance. • Quick-drive stainless steel assembly screws for corrosion resistance and fast installation. • Color coded neoprene grommets for a watertight seal on a wide range of cord sizes. • Receptacles have self-closing spring loaded flip lid covers. Locking Devices – 4-Pole, 4-Wire Rating A V/AC 20 3ØY 120/208 20 3ØY 120/208 20 3ØY 277/480 20 3ØY 347/600 30 3ØY 120/208 30 3ØY 120/208 30 3ØY 277/480 30 3ØY 347/600 NEMA NonNEMA L18-20 L19-20 L20-20 NonNEMA L18-30 L19-30 L20-30 Cord Diameter 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) C 4.60" (116.8mm) 3.25" (82.6mm) L2030RW US R Plug ■ 7411PW Catalog No. Connector ■ 7413CW Single Receptacle ■ 7413RW ■ L1820PW ■ L1820CW ■ L1820RW ■ L1920PW ■ L1920CW ■ L1920RW ■ L2020PW ■ L2020CW ■ L2020RW ■ 3431PW ■ 3433CW ■ 3433RW ■ L1830PW ■ L1830CW ■ L1830RW ■ L1930PW ■ L1930CW ■ L1930RW ■ L2030PW ■ L2030CW ■ L2030RW 2.49" (63.2mm) 3.66" (93.0mm) L1820PW 5.42" (137.7mm) For all-black devices, add color code BK after catalog number. All-black items are available for quick-shipment within 10 days. For quantities over 100, consult factory for lead times. 2.49" (44.2mm) L1820CW RECEPTACLE RECEPTACLE NON-NEMA NON-NEMA 20A 3ØY 120/208V 20A 3ØY 120/208V X W X G Y W G X Y W G X Y W X X G Y W G Y W G Y Z Z Z Z Z Z L21-20R L22-20R L23-20R L21-30R L22-30R L23-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • cUL Certified to CAN/CSA C22.2 no. 42-99 (receptacles) or C22.2, no. 182.2 (plugs & connectors) • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 9 Watertight Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Locking Receptacles, Plugs & Connectors 3.10" (78.7mm) 4-Pole, 5-Wire Grounding 20A; 3ØY 120/208, 3ØY 277/480, 3ØY 347/600V/AC 30A; 3ØY 120/208, 3ØY 277/480, 3ØY 347/600V/AC Industrial Specification Grade Hart-Lock® Devices 1.88" (47.8mm) FEATURES • Thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, and the effects of UV exposure and ozone attack. • Mated plug and connector or plug and receptacle form a watertight seal that meets NEMA and IEC IP ratings (see specification sheet for details) and withstands water spray test at 1000 psi. 4.60" (116.8mm) 3.25" (82.6mm) L2330RW • High visibility safety yellow for identification. • Power contacts, blades and terminal screws nickel-plated for corrosion resistance. • Quick-drive stainless steel assembly screws for corrosion resistance and fast installation. • Color coded neoprene grommets for a watertight seal on a wide range of cord sizes. • Receptacles have self-closing spring loaded flip lid covers. Locking Devices – 4-Pole, 5-Wire 2.49" (63.2mm) Rating A V/AC 20 3ØY 120/208 20 3ØY 277/480 20 3ØY 347/600 30 3ØY 120/208 30 3ØY 277/480 30 3ØY 347/600 3.66" (93.0mm) L2120PW NEMA L21-20 L22-20 L23-20 L21-30 L22-30 L23-30 Cord Diameter 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.36"-0.84" (9.1mm-21.3mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) 0.43"-1.15" (10.9mm-29.2mm) C ■ L2120PW Single Receptacle ■ L2120RW ■ L2220PW ■ L2220CW ■ L2220RW ■ L2320PW ■ L2320CW ■ L2320RW ■ L2130PW ■ L2130CW ■ L2130RW ■ L2230PW ■ L2230CW ■ L2230RW ■ L2330PW ■ L2330CW ■ L2330RW Plug 2.49" (44.2mm) L2120CW X X G Y W G X Y W G X Y W X X G Y W G Y W G Y Z Z Z Z Z Z L21-20R L22-20R L23-20R L21-30R L22-30R L23-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • cUL Certified to CAN/CSA C22.2 no. 42-99 (receptacles) or C22.2, no. 182.2 (plugs & connectors) • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 10 US Catalog No. Connector ■ L2120CW For all-black devices, add color code BK after catalog number. All-black items are available for quick-shipment within 10 days. For quantities over 100, consult factory for lead times. 5.42" (137.7mm) W R Severe Duty Insulated Device Applications Choose from an extensive line of rugged industrial devices Where typical devices fail, Arrow Hart's® Industrial Severe Duty Insulated Devices exceed expectations. Select from a complete line of locking or straight blade plugs and connectors for your industrial application. Application Severe Duty Insulated Devices have been designed specifically for industrial applications where electrical connections are exposed to dust, dirt, corrosive elements and physical abuse. Insulated devices are ideal for industrial manufacturing, agriculture applications, construction, warehousing and chemical processing environments. These products have excellent resistance to physical abuse, metal chips, foreign particulates, corrosion, airborne contaminants, UV exposure and ozone attack. Superior materials and design provide excellent insulation and durability properties in complex industrial environments. Our Santoprene™ Thermoplastic Elastomer devices easily outperform rubber construction plugs and connectors under any conditions. 11 Severe Duty Insulated Device Features & Benefits Solid construction to meet your rigorous demands Ideal for manufacturing locations, industrial plants and agricultural applications, our insulated devices are designed to resist dust, dirt, chemicals, corrosion and physical abuse. 6 Heavy gauge Stainless steel assembly screws 1 Santoprene™ thermoplastic elastomeric exterior outperforms rubber when exposed to moisture, chemicals, oils, UV exposure and ozone attack 4 nickel-plated plug blades for excellent electrical performance 5 High visibility safety yellow color provides easy identification 7 Rugged nylon interior protects and insulates terminals Exterior jacket seals 8 cord entrance 2 3 Thermoplastic elastomeric withstands temperature extremes from -81°F (-62°C) to 275°F (135°C) Cord grip accommodates broad cable range and relieves strain Related Products A full range of complimentary products designed specifically for industrial environments are available. 12 Closure Cap Wire Mesh Grips Weather Protective Boots For Plugs or Connectors Industrial Cable Strain Relief For Plugs or Connectors Severe Duty Insulated Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Straight Blade & Locking Plugs & Connectors 2-Pole, 3-Wire Grounding 15A; 125, 250, 277V/AC 20A; 125, 250, 277, 480V/AC 30A; 125, 250, 277, 480V/AC 1.69" (42.9mm) Industrial Specification Grade Straight Blade & Hart-Lock® Devices FEATURES • Thermoplastic elastomeric exterior outperforms rubber in harsh environments. • Connector and plug exteriors can be reversed to shroud plug blades. • Available closure cap can be used on plug or connector to protect from contamination. • High visibility safety yellow for identification. • Power contacts, blades and terminal screws are nickel-plated for corrosion resistance. • Stainless steel assembly and cord grip screws provide corrosion resistance. 2.09" (53.1mm) 1447 Straight Blade Plugs & Connectors – 2-Pole, 3-Wire Rating A V/AC 15 125 15 C US R NEMA Cord Diameter Plug Connector 5-15 0.375"-1.000" (19.05mm-25.4mm) ■ 1447 ■ 1547 250 6-15 0.375"-1.000" (19.05mm-25.4mm) ■ 1449 ■ 1549 20 125 5-20 0.375"-1.000" (19.05mm-25.4mm) ■ 1433 ■ 1533 20 250 6-20 0.375"-1.000" (19.05mm-25.4mm) ■ 1448 ■ 1548 1.69" (42.9mm) Catalog No. 2.78" (70.6mm) 1547 Locking Plugs & Connectors – 2-Pole, 3-Wire C 2.39" (60.7mm) US R Rating A V/AC NEMA Cord Diameter Plug Catalog No. Connector 15 125 L5-15 0.375"-1.000" (19.05mm-25.4mm) ■ 2447 ■ 2547 15 250 L6-15 0.375"-1.000" (19.05mm-25.4mm) ■ 2449 ■ 2549 15 277 L7-15 0.375"-1.000" (19.05mm-25.4mm) ■ 2434 ■ 2534 20 125 L5-20 0.375"-1.000" (19.05mm-25.4mm) ■ L520PY ■ L520CY 20 250 L6-20 0.375"-1.000" (19.05mm-25.4mm) ■ L620PY ■ L620CY 20 277 L7-20 0.375"-1.000" (19.05mm-25.4mm) ■ L720PY ■ L720CY 20 480 L8-20 0.375"-1.000" (19.05mm-25.4mm) ■ L820PY ■ L820CY 30 125 L5-30 0.375"-1.000" (19.05mm-25.4mm) ■ L530PY ■ L530CY 30 250 L6-30 0.375"-1.000" (19.05mm-25.4mm) ■ L630PY ■ L630CY 30 277 L7-30 0.375"-1.000" (19.05mm-25.4mm) ■ L730PY ■ L730CY 30 480 L8-30 0.375"-1.000" (19.05mm-25.4mm) ■ L830PY ■ L830CY 2.86" (72.6mm) L520PY 2.39" (60.7mm) 3.86" (98.0mm) L520CY W 5-15R X W G L5-15R G W W Y L6-15R G L7-15R G L5-20R W X G Y L6-20R G L7-20R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E3663 • cUL Certified to C22.2, no. 182.2 • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) X G W 6-15R L8-20R G L5-30R G Y L6-30R 6-20R 5-20R X W Y G G G G X W G L7-30R G Y L8-30R 13 Severe Duty Insulated Devices Locking Plugs & Connectors Project Name: Prepared By: Project Number: Date: Catalog Number: Type: 3-Pole, 3-Wire Non-Grounding 3-Pole, 4-Wire Grounding 20A; 125/250, 3Ø 250, 3Ø 480V/AC 30A; 125/250, 3Ø 250, 3Ø 480, 3Ø 600V/AC Industrial Specification Grade Hart-Lock® Devices 2.39" (60.7mm) FEATURES • Thermoplastic elastomeric exterior outperforms rubber in harsh environments. • Connector and plug exteriors can be reversed to shroud plug blades. • Available closure cap can be used on plug or connector to protect from contamination. 2.86" (72.6mm) L1020PY • High visibility safety yellow for identification. • Power contacts, blades and terminal screws are nickel-plated for corrosion resistance. • Stainless steel assembly and cord grip screws provide corrosion resistance. Locking Plugs & Connectors – 3-Pole, 3-Wire 2.39" (60.7mm) 3.86" (98.0mm) L1020CY Rating A V/AC 20 125/250 20 Plug 0.375"-1.000" (19.05mm-25.40mm) ■ 9965PY ■ 7314CY 125/250 L10-20 0.375"-1.000" (19.05mm-25.40mm) ■ L1020PY ■ L1020CY 20 3Ø 250 L11-20 0.375"-1.000" (19.05mm-25.40mm) ■ L1120PY ■ L1120CY 30 125/250 L10-30 0.375"-1.000" (19.05mm-25.40mm) ■ L1030PY ■ L1030CY 30 125/250 Non-NEMA 0.375"-1.000" (19.05mm-25.40mm) ■ 3331PY ■ 3333CY 30 3Ø 250 L11-30 0.375"-1.000" (19.05mm-25.40mm) ■ L1130PY ■ L1130CY Rating A V/AC 20 125/250 20 Y L10-20R X Z L11-20R Y L10-30R Z L11-30R L14-20 0.625"-1.156" (15.90mm-29.36mm) ■ L1420PY ■ L1420CY 3Ø 250 L15-20 0.625"-1.156" (15.90mm-29.36mm) ■ L1520PY ■ L1520CY 20 3Ø 480 L16-20 0.625"-1.156" (15.90mm-29.36mm) ■ L1620PY ■ L1620CY 30 125/250 L14-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1430PY ■ L1430CY 30 3Ø 250 L15-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1530PY ■ L1530CY 30 3Ø 480 L16-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1630PY ■ L1630CY 30 3Ø 600 L17-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1730PY ■ L1730CY X X X Y G Y G X X W G Y G X Y G Y G Y Z Z Y Z Z Z L14-20R L15-20R L16-20R L14-30R L15-30R L16-30R L17-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E3663 • cUL Certified to C22.2, no. 182.2 • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 14 US NEMA W G R Catalog No. Plug Connector X Y X W C Cord Diameter PLUG X Catalog No. Connector Locking Plugs & Connectors – 3-Pole, 4-Wire Y X W US Non-NEMA RECEPTACLE NON-NEMA 30A 125/250V REC R NEMA 3-pole, 3-wire, nonegrounding locking devices rated 20 A, 125V/250 V RECEPTACLE NON-NEMA 20A 125V/250V C Cord Diameter Severe Duty Insulated Devices Locking Plugs & Connectors Project Name: Prepared By: Project Number: Date: Catalog Number: Type: 4-Pole, 4-Wire Non-Grounding 4-Pole, 5-Wire Grounding 20A; 3ØY 120/208, 3ØY 277/480, 3ØY 347/600V/AC 30A; 3ØY 125/208, 3ØY 277/480, 3ØY 347/600V/AC Industrial Specification Grade Hart-Lock® Devices FEATURES • Thermoplastic elastomeric exterior outperforms rubber in harsh environments. • Connector and plug exteriors can be reversed to shroud plug blades. • Available closure cap can be used on plug or connector to protect from contamination. 2.39" (60.7mm) • High visibility safety yellow for identification. • Power contacts, blades and terminal screws are nickel-plated for corrosion resistance. • Stainless steel assembly and cord grip screws provide corrosion resistance. Locking Plugs & Connectors – 4-Pole, 4-Wire C 2.86" (72.6mm) L1820PY US R Rating A V/AC NEMA Cord Diameter Catalog No. Plug Connector 20 3ØY 120/208 Non-NEMA 0.625"-1.156" (15.90mm-29.36mm) ■ 7411PY ■ 7413CY 20 3ØY 120/208 L18-20 0.625"-1.156" (15.90mm-29.36mm) ■ L1820PY ■ L1820CY 20 3ØY 277/480 L19-20 0.625"-1.156" (15.90mm-29.36mm) ■ L1920PY ■ L1920CY 20 3ØY 347/600 L20-20 0.625"-1.156" (15.90mm-29.36mm) ■ L2020PY ■ L2020CY 30 3ØY 120/208 Non-NEMA 0.625"-1.156" (15.90mm-29.36mm) ■ 3431PY ■ 3433CY 30 3ØY 120/208 L18-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1830PY ■ L1830CY 30 3ØY 277/480 L19-30 0.625"-1.156" (15.90mm-29.36mm) ■ L1930PY ■ L1930CY 30 3ØY 347/600 L20-30 0.625"-1.156" (15.90mm-29.36mm) ■ L2030PY ■ L2030CY 2.39" (60.7mm) 3.86" (98.0mm) L1820CY Locking Plugs & Connectors – 4-Pole, 5-Wire Rating A V/AC 20 20 C US R NEMA Cord Diameter Catalog No. Plug Connector 3ØY 120/208 L21-20 0.625-1.156" (15.90-29.36mm) ■ L2120PY ■ L2120CY 3ØY 277/480 L22-20 0.625-1.156" (15.90-29.36mm) ■ L2220PY ■ L2220CY 20 3ØY 347/600 L23-20 0.625-1.156" (15.90-29.36mm) ■ L2320PY ■ L2320CY 30 3ØY 120/208 L21-30 0.625-1.156" (15.90-29.36mm) ■ L2130PY ■ L2130CY 30 3ØY 277/480 L22-30 0.625-1.156" (15.90-29.36mm) ■ L2230PY ■ L2230CY 30 3ØY 347/600 L23-30 0.625-1.156" (15.90-29.36mm) ■ L2330PY ■ L2330CY RECEPTACLE RECEPTACLE NON-NEMA NON-NEMA 20A 3ØY 120/208V 30A 3ØY 120/208V X X Y W X X Y W Y W X Y W X Y W X Y W W X G Y W G X Y W G X Y W X X G Y W G Y W G Y Z Z Z Z Z Z Z Z Z Z Z Z L18-20R L19-20R L20-20R L18-30R L19-30R L20-30R L21-20R L22-20R L23-20R L21-30R L22-30R L23-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E3663 • cUL Certified to C22.2, no. 182.2 • Environmental: Flammability meets UL 94 requirements; V2 rated • Temperature Rating: -40ºC to 75ºC (-40°F to 167°F) 15 Corrosion Resistant Device Applications The right device for moist and humid applications Application Corrosion Resistant devices have been designed specifically for environments where moisture and humidity create problems for electrical connections. Corrosion Resistant devices are ideal for industrial manufacturing, food processing, agriculture applications, and washdown environments. These products have excellent resistance to physical abuse and corrosive elements plus airborne particulates and contaminants, providing dependable performance where typical devices fail. Nickel-plated power contacts, terminals, blades and straps deliver enhanced corrosion resistance with excellent electrical performance. 16 Select from a wide range of truly unique locking and straight blade plugs, connectors and receptacles designed for use in corrosive environments. Corrosion Resistant Device Features & Benefits Designed specifically for longevity in harsh, corrosive environments Perfect for industrial or commercial applications, corrosion resistant devices are engineered to deliver long, dependable performance in moisture, humidity, and airborne contaminantladen corrosive environments. Nickel-plated 1 strap, power contacts and terminals for corrosion resistance 3 Single-piece nickelplated 5-leaf brass power contacts provide superior performance and minimum heat rise 4 High impact, arc 2 and moisture resistant nylon construction Screw terminal guards provide insulation from conductive surfaces (straight blade receptacles only) 5 Blades nickel-plated for corrosion resistance 7 Combination-head screws standard 6 Neoprene gasket seals cord grip opening, keeping contaminants out Related Products A full range of complimentary products designed specifically to protect the electrical infrastructure in corrosive environments are available. Wet Location Covers Corrosion Resistant Back Boxes Weather Protective Boots For FS/FD Boxes With Receptacles In Non-metallic & Metal Versions For Plugs & Connectors 17 Corrosion Resistant Devices Project Name: Prepared By: Project Number: Date: Catalog Number: Type: Straight Blade & Locking Receptacles, Plugs & Connectors 1.30" (33.0mm) Industrial Specification Grade Straight Blade & Hart-Lock® Devices FEATURES • Nickel-plated straps, blades, power contacts and terminals provide corrosion resistance. • All-nylon construction for high impact- and chemical-resistance. • Back wire terminal clamps for fast, easy and secure wiring. • Combination head screws standard. 3.28" (83.31mm) 4.19" (106.43mm) 0.88" (22.35mm) 5262CR 1.12" (28.5mm) Rating A V/AC 15 125 15 125 20 125 20 125 20 250 20 125/250 20 3Ø 250 30 125 30 250 30 125/250 2.63" (66.80mm) 1.56" (39.62mm) 1.63" (41.40mm) CRL1430R 1.37" (34.8mm) NEMA 5-15 L5-15 5-20 L5-20 L6-20 L14-20 L15-20 L5-30 L6-30 L14-30 Rating A V/AC NEMA 15 125 5-15 1.51" (38.4 mm) 5266NCR 2.00" (50.8mm) 1.31" (33.3mm) 3.44" (87.4mm) Description Straight Blade Duplex Receptacle Locking Duplex Receptacle Straight Blade Duplex Receptacle Locking Single Receptacle Locking Single Receptacle Locking Single Receptacle Locking Single Receptacle Locking Single Receptacle Locking Single Receptacle Locking Single Receptacle 20 125 5-20 20 125 L5-20 20 250 L6-20 30 125 L5-30 30 250 L6-30 W G 5-20R R S 426 Catalog No. ■ 5262CR ■ CR4700 ■ 5362CR ■ CRL520R ■ CRL620R ■ CRL1420R ■ CRL1520R ■ CRL530R ■ CRL630R ■ CRL1430R C R US F R S Catalog No. Plug ■ 5266NCR ■ 5269NCR Connector ■ 5366NCR ■ 5369NCR ■ CRL520P ■ CRL520C ■ CRL620P ■ CRL620C ■ CRL530P ■ CRL530C ■ CRL630P ■ CRL630C Additional configurations available, visit www.cooperwiringdevices.com for more information. CRL520C W Cord Diameter 0.250"-0.656" (6.40mm-16.70mm) 0.250"-0.656" (6.40mm-16.70mm) 0.375"-1.000" (19.05mm-25.40mm) 0.375"-1.000" (19.05mm-25.40mm) 0.375"-1.000" (19.05mm-25.40mm) 0.375"-1.000" (19.05mm-25.40mm) Description Straight Blade Straight Body Straight Blade Straight Body Locking Straight Body Locking Straight Body Locking Straight Body Locking Straight Body 2.12" (50.8mm) 5-15R F Popular Straight Blade & Locking Plugs & Connectors 1.83" (46.5mm) W • Receptacles feature one-piece nickel-plated brass power contacts to provide superior performance and minimum heat rise. • Plugs and connectors have a cord hole neoprene gasket to seal out dust and debris. • Plugs and connectors feature individual wiring compartments with tapered channels for easy insertion of wires. Popular Straight Blade & Locking Receptacles 3.28" (83.31mm) G 2-Pole, 3-Wire Grounding; 3-Pole, 4-Wire Grounding 15A; 125V/AC 20A; 125, 250, 125/250, 3Ø 250V/AC 30A; 125, 250, 125/250V/AC G L5-15R X W G L5-20R G L6-20R G L5-30R G Y L6-30R W G X X X X W Y Y G W G Y Z Y L14-20R L15-20R L14-30R TESTING & CODE COMPLIANCE MATERIAL CHARACTERISTICS • Listed to UL 498, file no. E2369 (receptacles) or E3663 (plugs & connectors) • UL verified to Federal Spec. WC-596F • CSA certified to C22.2, no. 42, file no. 6914 (6233-01) (receptacles) or cUL Certified to C22.2, no. 42 (plugs & connectors) • NOM certified (straight blade receptacles only) • Environmental: Flammability: meets UL 94 requirements; V2 rated • Temperature Rating: -20ºC to 70ºC (-4°F to 158°F), except straight blade plugs & connectors: -20ºC to 75ºC (-4°F to 167°F) and locking plugs & connectors: -40ºC to 75ºC (-40°F to 167°F) 18 Complex Environment Accessories Choose from a variety of rugged, dependable devices for complex environments Cooper Wiring Devices has the products and accessories you need to protect your wiring devices from corrosion, wet locations, environmental exposure and hose-down applications. Wet Location Covers Rugged metal deluxe wet location covers feature self-closing spring door covers and quality diecast aluminum with EDMP gasket material to withstand the harshest of environments. Heavy duty nylon covers are also available, and provide excellent protection with corrosion resistance. Available in a variety of configurations for 15A, 20A, 30A and 50A devices. Deluxe Wet Location Cover WLRS1 Nylon Wet Location Cover 7788CR While-In Use Covers Metal While-In-Use covers feature diecast metal construction and superior gasketing to provide a NEMA 3R enclosure rating. Innovative design is lockable to prevent accidental disconnects and meets NEC requirements for receptacles in damp or wet locations. Available in horizontal or vertical configurations with a variety of inserts for 15 & 20A devices. Weather Box™ Metal Cover WIUMV-1 & WIUMH-1 Back Boxes Available in cast aluminum and impact-resistant plastic, these boxes are designed to resist corrosion and mate with either our wet location covers, stainless steel wallplates or watertight pin & sleeve receptacles and inlets. Cast Aluminum Back Box CDBB1 FS Non-Metallic Back Box 6080 Other Complex Environment Products Weather Protective Boot BS1 Stainless Steel Wallplate 93971 We also offer a wide variety of other corrosion resistant products that are necessary when creating safe and dependable electrical connection points in harsh environments. Choose from stainless steel wallplates, stainless steel wire mesh grips, corrosion resistant weather protective boots and closure caps for plugs and connectors in 15A, 20A, 30A and 50A versions. For more information: www.cooperwiringdevices.com Popular Complex Environment Accessories Description Catalog No. Deluxe aluminum wet location cover for duplex receptacle, horizontal WLRD1 Aluminum wet location cover with yellow corrosion resistant finish for single receptacle, vertical 7420CR Aluminum wet location cover for duplex receptacle, 2 self-closing lids, horizontal S989 WeatherBox aluminum while-in-use 1-gang cover, vertical WIUMV Weather protective yellow closure cap for 20A plugs & connectors 20PW Non-metallic FS back box, single gang, horizontal or vertical mount 6080 Single gang stainless steel toggle opening mid-sized wallplate 93971 Stainless steel deluxe wire mesh cord grip with male thread end fitting DC100500 19 Cooper Wiring Devices United States 203 Cooper Circle Peachtree City, GA 30269 P: 866-853-4293 F: 800-329-3055 Canada 5925 McLaughlin Road Mississauga, Ontario, L5R 1B8 P: 800-267-1042 F: 800-761-5748 www.cooperwiringdevices.com email: custserv@cooperwiringdevices.com • cwdmarketing@cooperindustries.com Cooper Wiring Devices, Arrow Hart, Hart-Lock and WeatherBox are valuable trademarks of Cooper Industries in the U.S. and other countries. You are not permitted to use the Cooper Trademarks without the prior written consent of Cooper Industries. ©2009 Cooper Industries, Ltd. Your Authorized Cooper Wiring Devices Distributor is: Cooper Industries, Ltd. 600 Travis, Ste. 5600 Houston, TX 77002-1001 P: 713-209-8400 www.cooperindustries.com 9-YGOODSBRO-09 Mexico Carr. Tlalnepantla – Cuautitlan Km 17.8 s/n Col. Villa Jardin esq. Cerrada 8 de Mayo Cuautitlan, Mexico CP 54800 P: +525558999190 F: +525526207116 www.cooperwiringdevices.com.mx