2016 Power Sources CAM-7 abstract

advertisement

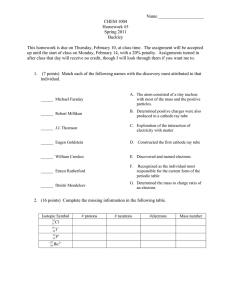

High Energy Li-ion Cells Based on CAM-7 Cathode Material (submitted to Secondary Lithium Batteries/Lithium-Ion Batteries session of 47th Power Sources Conference for oral presentation) Jane Rempel, David Ofer, Adrian Pullen, Daniel Kaplan, Brian Barnett, and Suresh Sriramulu CAMX Power, 35 Hartwell Avenue, Lexington, MA 02421 e-mail: suresh@camxpower.com, phone: (781)879-1240 Li-ion batteries are attractive for many DoD applications owing to their excellent combination of energy and life. However, Commercial-Off-The-Shelf (COTS) Li-ion cells still do not offer high enough energy density (both volumetric – Wh/L and gravimetric – Wh/kg) to enable the mission profiles and durations desired for many current and anticipated DoD applications. To a large extent, the cathode material in a Li-ion cell limits the achievable energy density. LiCoO2 cathode material is predominantly used in COTS high energy density Li-ion cells. The past two decades have seen a steady increase in the energy density of Li-ion cells with LiCoO2 cathode material through a combination of improved cell engineering, cathode morphology, and even cathode charge voltage. However, cell manufacturers have exhausted the cell energy increases possible with LiCoO2; further increases can come only from new cathode materials. Although COTS cells with LiNi(1-x-y)MnxCoyO2 (NMC) or LiNi0.80Co0.15Al0.05O2 (NCA) cathode materials are available, these cells typically have lower energy density than cells with LiCoO2-based cathodes. Recognizing this need for cathode materials that can enable higher energy density cells, CAMX Power has been developing a "stabilized" LiNiO2-based cathode material, CAM-7, that combines high capacity and high average discharge voltage with excellent high rate capability and long life. In a materials development effort spanning more than 10 years, CAMX Power has resolved the challenges historically associated with high-nickel LiNiO2 materials such as synthesis reproducibility, electrode slurry stability, high-temperature cycle life, and thermal stability. CAM-7 is now being commercialized for several civilian applications worldwide. Production of this material is being scaled up to 50 metric tons per year in our pilot plant located in Rowley, MA, and we are collaborating with scale-up partners to produce this material at much larger scale. CAM-7 enables very high energy density as demonstrated by the data in Figures 1 and 2. Figure 1 shows the performance of 18650 cells fabricated at CAMX Power combining CAM-7 with graphite and a low-temperature electrolyte to provide excellent energy density, both at room temperature and lower temperatures. These 18650 cells were also independently evaluated at the Army Research Laboratory as part of a Phase II SBIR program [1]. Figure 2 shows the performance of a 1 Ah stacked-electrode pouch cell also fabricated at CAMX Power, combining CAM-7 with a silicon-based anode and a tailored electrolyte. This cell can provide > 300 Wh/kg at C/5 rate while also supplying ~ 270 Wh/kg at 5 C rate. In this presentation, we will discuss the key performance attributes of CAM-7 relative to commercial cathode materials, with a particular emphasis on the attractiveness of CAM-7 for DoD applications. We will highlight the energy density improvement that can be achieved over COTS Li-ion cells. We will also show performance data on CAMX Power’s prototype cells showcasing the unique advantages of CAM-7 for DoD applications. 4.3 a 3.9 Voltage (V) 3.7 3.5 3.3 3.1 Specific Energy (Wh/kg) 247 2.9 Energy Density (Wh/L) 610 2.7 Specific Energy, Jelly Roll (Wh/kg) Energy Density, Jelly Roll (Wh/L) 290 710 b 300 Specific Energy (Wh/kg) 4.1 250 200 150 100 50 0 RT 2.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0 -30°C -40°C Operating Temperature Capacity (Ah) Figure 1: (a) Discharge curves for five high energy CAM-7/graphite 18650 cells fabricated at CAMX Power. The inset box shows that the measured specific energy of the jelly roll itself approaches 300 Wh/kg, but the heavy cell hardware limits the 18650 energy. (b) Measured discharge energy density(C/10) at different temperatures shows that these 18650 cells can support discharge even at -40ºC. A COTS cell with comparable room temperature specific energy supported less than 10 Wh/kg at -30ºC and even less at -40ºC. Performance of our cells was independently measured by the Army Research Laboratory [1]. 4.2 4 C/5 3.8 1C Voltage (V) 3.6 5C 3.4 3.2 48 x 30 x 4.7 mm pouch cells 3 2.8 2.6 2.4 2.2 2 0 30 60 90 120 150 180 210 240 270 300 Cell specific energy, Wh/kg Figure 2: C-rate dependence of discharge specific energy for a 1.1 Ah, CAM-7/silicon, stackedelectrode pouch cell fabricated at CAMX Power. The inset shows a photograph of the cell and the cell dimensions. References: [1]. Allen JL, Allen JL, Delp SA, Jow TR. (2014). Evaluation of TIAX High Energy CAM7/Graphite Lithium-Ion Batteries at High & Low Temperatures, U.S. Army Research Laboratory.