Fuel Resistant Plastics

Mike Braeckel, Dwight Smith, Joseph G. Tajar and John Yourtee

Celanese

8040 Dixie Highway

Florence, KY 41042 USA

(Excerpts appeared in Advanced Materials & Processes - August 2000 - pages 37ff )

Limits on emissions and the need to simplify production

have led manufacturers to replace steel with plastic in

many fuel components, from gas caps to fuel rails.

This fuel module is made of Celanese Celcon® acetal

copolymer because of its superior performance in

aggressive fuels.

Without plastics, automakers would have been hard

pressed to develop fuel systems that simultaneously

withstand aggressive fuels, reduce vehicle weight, aid

impact resistance, and enable complex geometries.

Furthermore, given the complexity of fuel systems,

changes in one area often affect other areas. This is the

case when hot fuel from the engine compartment is

returned to the tank. Plastic was introduced for fuel tank

construction to improve chemical resistance and impact,

and to enable tighter auto layouts versus steel tank

designs. However, fuel temperatures rose sharply higher

in the plastic tanks, because plastic is a good insulator,

and because tighter layouts reduce the air flow that

dissipates heat. As a result, fuel temperatures in tanks may

reach 65°C (150°F) in plastic tanks, versus about 40°C

(105°F) in steel tanks, and can rise to 120°C (250°F) or

more in the engine compartment. The higher temperatures also make fuel more reactive and require more

stable plastics.

Environmental laws have also made fuel more reactive.

The Clean Air Act of 1990 called for reformulated gasoline,

which led to the addition of the oxygenate methyl tertiary

butyl ether (MTBE). Because this chemical can cause

plastics to swell, automakers either adjusted tolerances to

compensate for expansion, or found MTBEstable plastic

grades. However, recent MTBE health and groundwater-contamination concerns make it likely MTBE may be

replaced by other oxygenated materials such as ethanol.

Unfortunately, many of these also are aggressive toward

plastics.

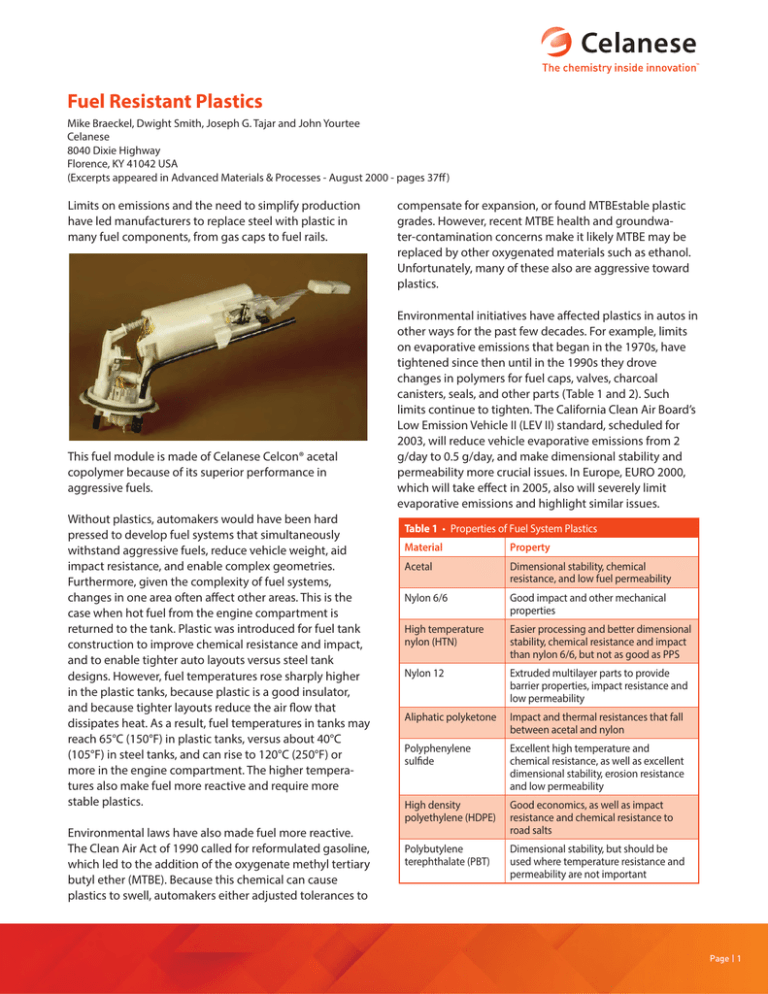

Environmental initiatives have affected plastics in autos in

other ways for the past few decades. For example, limits

on evaporative emissions that began in the 1970s, have

tightened since then until in the 1990s they drove

changes in polymers for fuel caps, valves, charcoal

canisters, seals, and other parts (Table 1 and 2). Such

limits continue to tighten. The California Clean Air Board’s

Low Emission Vehicle II (LEV II) standard, scheduled for

2003, will reduce vehicle evaporative emissions from 2

g/day to 0.5 g/day, and make dimensional stability and

permeability more crucial issues. In Europe, EURO 2000,

which will take effect in 2005, also will severely limit

evaporative emissions and highlight similar issues.

Table 1 • Properties of Fuel System Plastics

Material

Property

Acetal

Dimensional stability, chemical

resistance, and low fuel permeability

Nylon 6/6

Good impact and other mechanical

properties

High temperature

nylon (HTN)

Easier processing and better dimensional

stability, chemical resistance and impact

than nylon 6/6, but not as good as PPS

Nylon 12

Extruded multilayer parts to provide

barrier properties, impact resistance and

low permeability

Aliphatic polyketone

Impact and thermal resistances that fall

between acetal and nylon

Polyphenylene

sulfide

Excellent high temperature and

chemical resistance, as well as excellent

dimensional stability, erosion resistance

and low permeability

High density

polyethylene (HDPE)

Good economics, as well as impact

resistance and chemical resistance to

road salts

Polybutylene

terephthalate (PBT)

Dimensional stability, but should be

used where temperature resistance and

permeability are not important

Page | 1

Fuel Resistant Plastics (continued)

Table 2 • Typical Material Applications

Component

Polymers

Fuel rails

PPS*, nylon 6/6* and HTN*

Fuel lines

Nylon 12

Fuel tanks

HDPE*

Canisters

Nylon 6/6, PBT*

Quick connects

Acetal, nylon 6/6, PPS

Fuel filter housings

Acetal, nylon 6/6

Fuel pump components

Acetal, PPS, and PBT

Fuel sending unit flange

Acetal, PBT

Fuel caps

Acetal, nylon 6/6

Inlet housing (fuel cap receiver)

Acetal

Fuel filler pipes

Nylon 6/6, HDPE

Throttle bodies

PPS, HTN, PBT

Valves: Fuel rollover valves

Acetal, PBT

Fuel fill limit valves

Acetal, PPS

ORVR valves

Acetal, PBT

Inlet check valve filler pipe

Acetal

Properties Needed For Fuel Applications

Plastics in fuel systems must perform at a consistently

high level under demanding conditions for the life of a

car. Several chemical, physical, mechanical and thermal

properties are important for plastics to survive long-term

fuel contact.

Chemical resistance relates to a change in chemical

structure or composition, which generally causes a

loss in performance.

Dimensional stability is an essential property because

many fuel-system parts have tight tolerances. This

factor is also important where different plastics or a

plastic and a metal meet, since their different dimensional stabilities can affect seals.

Mechanical properties include impact, tensile, and

compressive strength, as well as elongation and

strength at break. Parts must be designed to retain

sufficient integrity to do their jobs over the life of a

vehicle.

Coefficient of thermal expansion is one of a number of

temperature-related effects that include chemical

reaction rates and mechanical property changes.

Permeability is now under intensive study in light of

the LEV II standards. The industry is evolving standard

tests and measurements.

Extended Auto Fuel Study

As auto design life reaches 150,000 mi. or 15 years, it is

essential to know how fuel system plastics withstand

prolonged exposure to the new generation of morereac-

Page | 2

tive fuels. Unfortunately, tests on plastics for fuel contact

are typically limited: some are run for just 48 hours, and

others rarely exceed 500 hours (three weeks).

Recognizing the need for more extensive design verification, Celanese tested combinations of nine fuel blends

and seven plastics at two temperatures (65° and 121°C)

for more than 5000 hours each (Table 3). The lower

temperature simulated fuel tank conditions, and the

higher one simulated conditions under the hood. Initial

results from this program, which lasted two years in total,

support the continued use of most plastics now found in

auto fuel applications. The study also indicated that one

material (acetal homopolymer) might not be suitable for

extended life with some aggressive fuels.

Table 3 • Celanese Extended Fuel Study

Test Criteria

Independent Test Lab

EG&G Automotive Research

(now Perkin-Elmer Automotive

Research)

Test protocol

SAE J1748

Temperature

65°C and 121°C

Time

5000 hours

Factors measured

Dimensional stability, Weight

change, Tensile strength and

elongation, Tensile modulus, ISO

notched Charpy

Plastics Tested

65°C Test

121°C Test

Acetal copolymer

Polyphenylene sulfide

Acetal homopolymer

Nylon 6/6

Polybutylene terephthalate

High temperature nylons (two

tested)

Aliphatic polyketone

Fuels tested (65°C)

CMO

Fuel C (50% isooctane and toluene)

CAP

Fuel C + aggressive water + peroxide (sour gas)

CM15A

85% Fuel C + 15% methanol + aggressive water

CM25A

75% Fuel C + 25% methanol + aggressive water

CM85A

15% Fuel C + 85% methanol + aggressive water

CE22A

78% Fuel C + 22% ethanol + aggressive water

CE85A

15% Fuel C + 85% ethanol + aggressive water

TF1

GM TF1 (equivalent to IE10)

TF2

GM TF2 (equivalent to IM5E2)

Fuels Tested (121°C)*

CM15A

85% Fuel C + 15% methanol + aggressive water

CE22A

78% Fuel C + 22% ethanol + aggressive water

CE85A

15% Fuel C + 85% ethanol + aggressive water

TF1

GM TF1 (equivalent to IE10)

* Fuels recipes match those in SAE J1681.

Fuel Resistant Plastics (continued)

The wide range of methanol and ethanol concentrations

evaluated reflects the practice by some gasoline distributors of cutting gasoline with less-expensive alcohol. The

effects of this can vary. For example, fuel blends with

methanol are most aggressive in the 20% range.

Although the study began well before the July 1999

release date for SAE J1681, which sets standard fuels for

screening plastics and elastomers, it anticipated many of

the recipes contained in J1681. The study also followed

SAE J1748 protocols for testing and evaluating components in fuel tests, and evaluated mechanical and physical

properties. Dimensional stability results showed that the

resins tested generally swelled by about 1% to 3% during

the first seven to 21 days of exposure, and changed

relatively little after that.

One exception to this pattern was acetal homopolymer

(Figure 1), which swelled during the first seven days of

exposure to CM15A (85% Fuel C and 15% aggressive

methanol), held almost steady for the next 35 days, and

then shrank steadily over the next 182 days until the

study ended. The slope of the curve implies that shrinkage would continue unabated after this. The weight

change data (Figure 2) followed the same pattern,

suggesting that the fuel reacted with the homopolymer

and altered its composition. The study also found that

acetal copolymer had significantly less swelling and

weight change than aliphatic polyketone in oxygenated

and peroxidecontaining fuels.

3.0

Dimensional Change (%)

The study also looked at many current and potential

future fuel blends. Nine fuels were tested: three methanol

blends; three ethanol blends, including TF1; TF2, an

ethanol/ methanol blend; and C and CAP fuels with

aggressive water (i.e., water that contains highly reactive

ions such as chloride) and peroxide. (Fuel that contains

peroxide, a refining impurity that makes fuel more

reactive, is often called sour gas.)

Figure 1 • Dimensional Change During Exposure to

CM15A Fuel at 65°C

Polyketone

2.5

Acetal homopolymer

2.0

Celcon acetal copolymer

1.5

1.0

0.5

0.0

0

1000

2000

3000

4000

5000

6000

Time (Hours)

Figure 2 • Weight Change During Exposure to CM15A

Fuel at 65°C

6

Polyketone

5

Weight Change (%)

Celanese began the study by asking its auto OEM and Tier

I fuel system customers what fuels and plastics they

wanted to see studied. They chose seven plastics: acetal

copolymer, acetal homopolymer, PPS, PBT, aliphatic

polyketone, nylon 6/6, and high-temperature nylon (HTN).

4

Celcon acetal copolymer

3

2

1

0

Acetal homopolymer

-1

-2

0

1000

2000

3000

4000

5000

6000

Time (Hours)

PPS had the best overall performance of the polymers

studied in the 121°C (250°F) high temperature soaking

test. It exhibited the lowest weight gain, the least dimensional change, and the highest retention of tensile

strength over the range of fuels evaluated, with the

differences accentuated with the more aggressive fuel

blends. For example, in fuel CM15A, weight change

(Figure 3) and dimensional change (Figure 4) were

significantly lower for the PPS than for the HTNs and

nylon 66. All the nylons showed continual reduction in

retained tensile strength with increased exposure time,

whereas the PPS remained much more consistent (Figure

5).

Page | 3

Fuel Resistant Plastics (continued)

Figure 3 • Weight Change in CM15A at 121°C

Weight (% of Original)

109

25% Glass Reinforced Nylon 6/6

107

35% Glass Reinforced HTN

105

45% Glass Reinforced PPA

103

40% Glass Reinforced PPS

101

99

0

1000

2000

3000

4000

5000

Time (Hours)

Figure 4 • Length Change in CM15A at 121°C

102

25% Glass Reinforced Nylon 6/6

Length (% of Original)

45% Glass Reinforced PPA

101

35% Glass Reinforced HTN

99

0

1000

2000

3000

4000

5000

Time (Hours)

Figure 5 • Tensile Strength Change in CM15A at 121°C

100

Tensile Strength (% of Original)

Evaluating new fuel formulations will clearly be an

ongoing task as fuel oxygenate content changes. MTBE is

due to be phased out by 2003 and replaced by other

blending components, possibly TAME (tertiary amyl

methyl ether), ETBE (ethyl tertiary butyl ether), and/or

ethanol. Similar issues also apply to trucks. A commitment

to bio-diesel fuels in Europe has led to the introduction of

rapeseed oil (a.k.a., canola oil), commonly called “rape

seed methyl ester,” or RSME. This makes fuel more acidic

and aggressive to plastics at high temperatures.

40% Glass Reinforced PPS

100

98

40% Glass Reinforced PPS

80

25% Glass Reinforced Nylon 6/6

60

Plastic manufacturers are improving their products to

cope with the new fuels. They are lowering permeability

while enhancing dimensional stability, chemical

resistance, thermal capability and more. A good example

of this is Celanese Hostaform C13031 XF acetal copolymer, which is designed to be stable during prolonged

exposure to RSME-containing diesel fuels at relatively

high system temperatures.

In meeting future auto fuel system needs, especially on a

global basis, plastic suppliers must account for a wide

variety of more aggressive fuels, longer vehicle life and

higher temperatures. This will mean higher-performing

plastics able to cope with any fuel under any set of

conditions.

35% Glass Reinforced HTN

40

45% Glass Reinforced PPA

20

0

0

1000

2000

3000

4000

5000

Time (Hours)

The study indicates that no quick answers are available in

understanding how fuels and plastics interact, and that

Page | 4

assumptions about these interactions should be supported by long-term testing. This is especially important for

dimensional stability, because so many of today’s

high-tech emission-control parts depend on tolerances of

0.05 to 0.076 mm (0.002 to 0.003 in.) Even modest

changes in dimension can create problems. For example,

a part 12.7 mm (0.5 in.) in diameter that swells just 2%

would grow 0.25 mm (0.01 in.) and may exceed tolerances

set for it. Swelling also can affect permeability and create

microleaks.

Existing resins can be reformulated to enhance their

properties. Or automakers can move up the performance

chain, switching from acetal copolymer to PPS to more

than double thermal capabilities. In terms of this example,

acetal has a long history in fuel system applications for

emission control valves mounted on or within fuel tanks

where temperatures are moderate. At higher underhood

temperatures, PPS would be a more appropriate valve

material. Other options are new grades of plastics with

advanced performance characteristics.

ENGINEERED MATERIALS

celanese.com/engineered-materials

World -Class Engineered Materials

Contact Information

• Celanex® thermoplastic polyester (PBT)

Americas

8040 Dixie Highway, Florence, KY 41042 USA

• Hostaform® and Celcon® acetal copolymer (POM)

• Celstran, Compel and Factor long fiber

reinforced thermoplastic (LFRT)

®

®

®

• Celstran® continuous fiber reinforced

thermoplastic (CFR-TP)

• Fortron® polyphenylene sulfide (PPS)

• GUR® ultra-high molecular

weight polyethylene (UHMW-PE)

• Impet® thermoplastic polyester (PET)

• Riteflex® thermoplastic polyester elastomer (TPC-ET)

• Thermx® polycyclohexylene-dimethylene

terephthalate (PCT)

• Vandar® thermoplastic polyester alloy (PBT)

• Vectra® and Zenite® liquid crystal polymer (LCP)

Product Information Service

t: +1-800-833-4882

t: +1-859-372-3244

Customer Service

t: +1-800-526-4960

t: +1-859-372-3214

e: info-engineeredmaterials-am@celanese.com

Europe

Am Unisys-Park 1, 65843 Sulzbach, Germany

Product Information Service

t: +(00)-800-86427-531 t: +49-(0)-69-45009-1011

e: info-engineeredmaterials-eu@celanese.com

Asia

4560 Jinke Road, Zhang Jiang Hi Tech Park

Shanghai 201203 PRC

Customer Service

t: +86 21 3861 9266

f: +86 21 3861 9599

e: info-engineeredmaterials-asia@celanese.com

Copyright © 2013 Celanese or its affiliates. All rights reserved.

This publication was printed on 19 September 2013 based on Celanese’s present state of knowledge, and Celanese undertakes no

obligation to update it. Because conditions of product use are outside Celanese’s control, Celanese makes no warranties, express or

implied, and assumes no liability in connection with any use of this information. Nothing herein is intended as a license to operate

under or a recommendation to infringe any patents.

CE-010_CelaneseFuelStudyWP_AM_0913