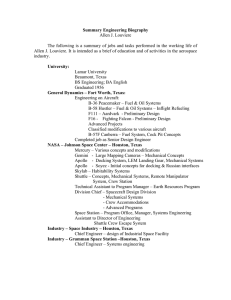

Statement of Qualifications

advertisement