Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Fisher™ FIELDVUE™ DVC6200 SIS Digital

Valve Controller for Safety Instrumented

Systems (SIS)

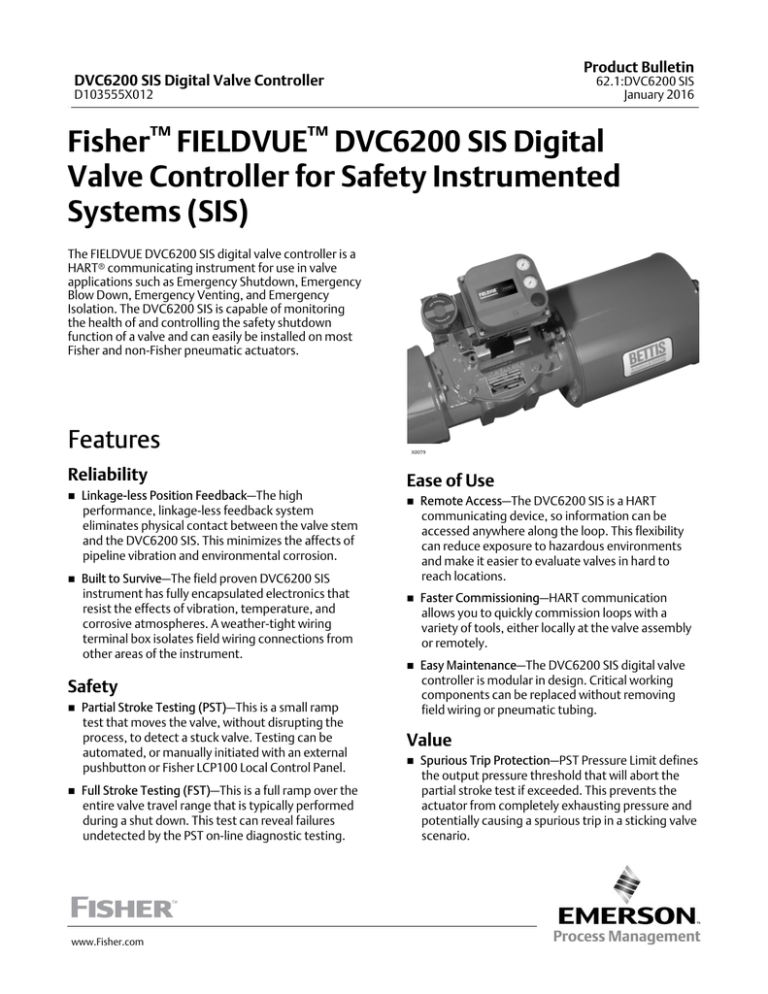

The FIELDVUE DVC6200 SIS digital valve controller is a

HARTr communicating instrument for use in valve

applications such as Emergency Shutdown, Emergency

Blow Down, Emergency Venting, and Emergency

Isolation. The DVC6200 SIS is capable of monitoring

the health of and controlling the safety shutdown

function of a valve and can easily be installed on most

Fisher and non‐Fisher pneumatic actuators.

Features

Reliability

n Linkage‐less Position Feedback—The high

performance, linkage‐less feedback system

eliminates physical contact between the valve stem

and the DVC6200 SIS. This minimizes the affects of

pipeline vibration and environmental corrosion.

n Built to Survive—The field proven DVC6200 SIS

instrument has fully encapsulated electronics that

resist the effects of vibration, temperature, and

corrosive atmospheres. A weather‐tight wiring

terminal box isolates field wiring connections from

other areas of the instrument.

Safety

n Partial Stroke Testing (PST)—This is a small ramp

test that moves the valve, without disrupting the

process, to detect a stuck valve. Testing can be

automated, or manually initiated with an external

pushbutton or Fisher LCP100 Local Control Panel.

n Full Stroke Testing (FST)—This is a full ramp over the

entire valve travel range that is typically performed

during a shut down. This test can reveal failures

undetected by the PST on-line diagnostic testing.

www.Fisher.com

X0079

Ease of Use

n Remote Access—The DVC6200 SIS is a HART

communicating device, so information can be

accessed anywhere along the loop. This flexibility

can reduce exposure to hazardous environments

and make it easier to evaluate valves in hard to

reach locations.

n Faster Commissioning—HART communication

allows you to quickly commission loops with a

variety of tools, either locally at the valve assembly

or remotely.

n Easy Maintenance—The DVC6200 SIS digital valve

controller is modular in design. Critical working

components can be replaced without removing

field wiring or pneumatic tubing.

Value

n Spurious Trip Protection—PST Pressure Limit defines

the output pressure threshold that will abort the

partial stroke test if exceeded. This prevents the

actuator from completely exhausting pressure and

potentially causing a spurious trip in a sticking valve

scenario.

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

n Increased Uptime—The self‐diagnostic capability of

the DVC6200 SIS provides valve availability and

health evaluation without shutting down the

process or pulling the valve assembly from the line.

n Audit Documentation—Using ValveLink™ software,

a time and date stamp on all tests and reports

provides compliance with requirements of statutory

authorities.

D103555X012

Packaged Solutions

LCP100—A local control panel can be connected

directly to the DVC6200 SIS to provide manual control

of the SIS valve, including manual reset. A partial

stroke test can also be initiated with the LCP100

(see figure 1).

Figure 1. Fisher LCP100 Local Control Panel

n Hardware Savings—When installed in an integrated

control system, significant hardware and

installation cost savings can be achieved. Valve

accessories such as limit switches and position

transmitters can be eliminated because this

information is available via the HART

communication protocol. In addition, an integrated

4‐20 mA position transmitter or limit switch option

is available.

n Improved Maintenance Decisions—Digital

communication provides easy access to the

condition of the valve. Sound process and asset

management decisions can be made by analysis of

valve diagnostic information through ValveLink

software, DD's, or DTM's.

X0248

Safety Certification

The functional safety assessment was performed to

the requirements of IEC 61508: ed2, 2010, SIL3.

The DVC6200 SIS digital valve controller, in the

de-energize to trip (DETT) or energize to trip (ETT)

configuration, meets the systematic integrity

requirements of SIL 3.

The DVC6200 SIS position monitor, in the position

transmitter or limit switch configuration, meets the

systematic integrity requirements of SIL 2.

2

Figure 2. exida Certificates

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Valve Diagnostics

The DVC6200 SIS digital valve controller provides a

broad and deep portfolio of valve diagnostic

capabilities. Whether the 475 Field Communicator is

used to check for valve alerts and operational status, or

ValveLink software is used for comprehensive

diagnostic test and analysis, the tools are easy to use.

Valve diagnostic tests enable condition and

performance monitoring of the entire valve assembly not just the digital valve controller. Results are

displayed graphically, with severity indicated by a

red/yellow/green icon. A detailed description of the

identified issue as well as suggestions for

recommended actions are provided.

In the event that the DVC6200 SIS is commanded to

trip, diagnostic data can be gathered automatically to

be used for troubleshooting.

Solenoid Valve Health Monitoring

If a solenoid valve is installed between the DVC6200

SIS pressure output and the actuator, as shown in

figure 3, the final control element assembly can be

configured to verify the operation of the solenoid valve

during online operation. In single-acting actuator

applications, the “unused” output port of the

DVC6200 SIS can be piped such that the pressure

downstream of the of solenoid valve is measured.

When the solenoid valve is pulsed, the DVC6200 SIS

can sense the momentary pressure drop across the

solenoid valve. The solenoid should be pulsed long

enough to detect a pressure drop across the solenoid

valve, but not so long that it affects the travel of the

final control element. This not only increases the

availability of the solenoid valve during a safety

demand, but also enhances the reliability of the SIF

(Safety Instrumented Function) loop.

Figure 3. Solenoid Valve Testing

S

Examples of identifiable issues are:

n Valve Stuck

AS

n Solenoid Stuck

n Low air supply or pressure droop

n Dirty air supply

E1460

n External air leak (actuator diaphragm or tubing)

TRAVEL

SET POINT

n Piston actuator O‐ring failure

TRAVEL

n Excessive valve assembly friction

n Low valve assembly friction

PORT B

PRESSURE

n Broken actuator spring

0.095 sec

n Broken valve/actuator shaft

For additional information on FIELDVUE diagnostics

and ValveLink software refer to Fisher Bulletin

62.1:ValveLink Software (D102227X012).

0.100 sec

E1028

ValveLink Software Screen Image Showing Pressure

Drop Across the Solenoid Valve

3

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Application Examples

Figure 4. De-Energize to Trip (DETT) FIELDVUE DVC6200 SIS and DETT Solenoid Valve

LOGIC SOLVER

OR DCS

LOGIC SOLVER

4-20 mA DETT

OR 0-24 VDC DETT

LOGIC SOLVER

0-24 VDC DETT

0-24 VDC DETT

1

2

FISHER LC340 2

LINE CONDITIONER

LOW POWER

SOLENOID VALVE

S

S

AS

E1455

AS

E1456

Options Available

n LCP100 Local Control Panel or external pushbutton

n Integral 4-20 mA position transmitter or discrete switch

Benefits

n DVC6200 SIS provides diagnostic coverage with PST

n DVC6200 SIS used with solenoid can provide redundant safety function

n DVC6200 SIS can provide additional diagnostic coverage when optional

solenoid pulse recording is utilized

n When powered by 4-20 mA, the DVC6200 SIS is capable of recording the

demand and reset stroke

Operation

n DVC6200 SIS will move to the safety demand state upon signal

de­energization, loss of power, or loss of pneumatic supply

1 An LC340 line conditioner is required for 0-24 VDC DETT

2 LC340 mounting requires standard 35 mm DIN rail; install in marshalling or I/O cabinet, or junction box.

For additional information refer to the LC340 instruction manual (D102797X012), available at

www.FIELDVUE.com or from your Emerson Process Management sales office.

4

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Figure 5. De-Energize to Trip (DETT) FIELDVUE DVC6200 SIS; No Solenoid Valve

LOGIC SOLVER

LOGIC SOLVER

0-24 VDC DETT

4-20 mA DETT

1

LC340

LINE CONDITIONER

AS

AS

E1457

E1458

Options Available

n LCP100 Local Control Panel or external pushbutton

n Integral 4-20 mA position transmitter or discrete switch

Benefits

n DVC6200 SIS provides diagnostic coverage with PST

n Eliminates solenoid valve

n When powered by 4-20 mA, the DVC6200 SIS is capable of

recording the demand and reset stroke

Operation

n DVC6200 SIS will move to the safety demand state upon signal

de­energization, loss of power, or loss of pneumatic supply

1 LC340 mounting requires standard 35 mm DIN rail; install in marshalling or I/O cabinet, or junction box. For

additional information refer to the LC340 instruction manual (D102797X012), available at www.FIELDVUE.com

or from your Emerson Process Management sales office.

5

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Figure 6. FIELDVUE DVC6200 SIS for PST only and DETT Solenoid Valve

LOGIC SOLVER

OR DCS

LOGIC SOLVER

4-20 mA ETT

0-24 VDC DETT

S

AS

SINGLE-ACTING, REVERSE (RELAY B)

4 mA = FULL SUPPLY TO ACTUATOR

E1459

Options Available

n LCP100 Local Control Panel or external pushbutton

n Integral 4-20 mA position transmitter or discrete switch

Benefits

n The energize to trip option provides maximum actuator pressure at

minimum control signal (4 mA). Therefore, loss of the control signal will

not cause the valve to trip.

n Prevents spurious trip on loss of electrical power to DVC6200 SIS

n DVC6200 SIS can provide additional diagnostics coverage when

performing PST

n DVC6200 SIS can provide additional diagnostic coverage when optional

solenoid pulse recording is utilized

Operation

n DVC6200 SIS will move to the safety demand state upon signal

energization or loss of pneumatic supply

n The solenoid valve will move to the safety demand state upon signal

de-energization

6

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Specifications

Electronic Output(2)

Available Mounting

J Integral 4‐20 mA Position Transmitter:

J Sliding‐stem linear applications

J Quarter‐turn rotary applications

J Integral mounting to Fisher rotary actuators

J Integral mounting to the Fisher GX control valve and

4‐20 mA output, isolated

Supply Voltage: 8‐30 VDC

Fault Indication: offrange high or low

Reference Accuracy: 1% of travel span

Safety Accuracy: 5% of travel span

J Integral Limit Switch: One isolated switch,

configurable throughout the calibrated travel range

or actuated from a device alert

Off State: 0 mA (nominal)

On State: up to 1 A

Supply Voltage: 30 VDC maximum

Reference Accuracy: 2% of travel span

Safety Accuracy: 5% of travel span

actuator system

DVC6200 SIS digital valve controllers can also be

mounted on other actuators that comply with

IEC 60534‐6‐1, IEC 60534‐6‐2, VDI/VDE‐3845, and

NAMUR mounting standards

Communication Protocol

J

HART 5 or J HART 7

Steady State Air Consumption(3)(4)

Input Signal

Low Bleed Relay

At 1.4 bar (20 psig) supply pressure:

0.056 normal m3/hr (2.1 scfh), average

At 5.5 bar (80 psig) supply pressure:

0.184 normal m3/hr (6.9 scfh), average

Point‐to‐Point

Analog Input Signal: 4‐20 mA DC, nominal

Minimum Voltage Available at Instrument Terminals

must be 9.5 VDC for analog control, 10 VDC for HART

communication

Minimum Control Current: 4.0 mA

Minimum Current w/o Microprocessor Restart: 3.5 mA

Maximum Voltage: 30 VDC

Overcurrent protected

Reverse Polarity protected

Maximum Output Capacity(3)(4)

At 1.4 bar (20 psig) supply pressure:

10.0 normal m3/hr (375 scfh)

At 5.5 bar (80 psig) supply pressure:

29.5 normal m3/hr (1100 scfh)

Multi‐Drop

Instrument Power: 11 to 30 VDC at 10 mA

Reverse Polarity protected

Operating Ambient Temperature Limits(1)(5)

-52 to 85_C (-62 to 185_F)

Independent Linearity(6)

Supply Pressure(1)

Typical Value: +/-0.50% of output span

Minimum Recommended: 0.3 bar (5 psig) higher than

maximum actuator requirements

Maximum: 10.0 bar (145 psig) or maximum pressure

rating of the actuator, whichever is lower

Electromagnetic Compatibility

Meets EN 61326‐1:2013

Immunity‐Industrial locations per Table 2 of the

EN 61326‐1 standard

Emissions-Class A

ISM equipment rating: Group 1, Class A

Supply Medium

Air or Natural Gas

Vibration Testing Method

Supply medium must be clean, dry, and noncorrosive

and meet the requirements of ISA Standard 7.0.01 or

ISO 8573-1

Tested per ANSI/ISA S75.13.01 Section 5.3.5

Input Load Impedance

Output Signal

An equivalent impedance of 500 ohms may be used.

This value corresponds to 10V @ 20 mA.

Pneumatic Output: up to full supply pressure

Minimum Span: 0.4 bar (6 psig)

Maximum Span: 9.5 bar (140 psig)

Action: Double, Single Direct, or Single Reverse

Humidity Testing Method

Tested per IEC 61514‐2

‐continued‐

7

Product Bulletin

DVC6200 SIS Digital Valve Controller

62.1:DVC6200 SIS

January 2016

D103555X012

Specifications (continued)

Connections

Electrical Classification

Hazardous Area Approvals

CSA— Intrinsically Safe, Explosion-proof, Division 2,

Dust Ignition-proof

FM— Intrinsically Safe, Explosion-proof, Dust

Ignition-proof, Non-Incendive

ATEX— Intrinsically Safe, Flameproof, Type n

IECEx— Intrinsically Safe, Flameproof, Type n

Auxiliary Terminal Contact: Nominal Electrical Rating

5 V, <1 mA; It is recommended that the switch be

sealed or have gold plated contacts to avoid

corrosion

Electrical Housing

CSA— Type 4X, IP66

FM— Type 4X, IP66

ATEX— IP66

IECEx— IP66

Other Classifications/Certifications

CUTR— Customs Union Technical Regulations (Russia,

Kazakhstan, Belarus, and Armenia)

INMETRO— National Institute of Metrology, Quality,

and Technology (Brazil)

KGS— Korea Gas Safety Corporation (South Korea)

NEPSI— National Supervision and Inspection Centre for

Explosion Protection and Safety of Instrumentation

(China)

PESO CCOE— Petroleum and Explosives Safety

Organisation - Chief Controller of Explosives (India)

Contact your Emerson Process Management

sales office for classification/certification

specific information

IEC 61010 Compliance Requirements

Power Source: The loop current must be derived from

a separated extra‐low voltage (SELV) power source

Environmental Conditions: Installation Category I

Supply Pressure: 1/4 NPT internal and integral pad for

mounting Fisher 67CFR regulator

Output Pressure: 1/4 NPT internal

Tubing: 3/8‐inch recommended

Vent: 3/8 NPT internal

Electrical: 1/2 NPT internal or M20(7)

Actuator Compatibility

Stem Travel (Sliding‐Stem Linear)

Minimum: 6.35 mm (0.25 inch)

Maximum: 606 mm (23.875 inches)

Shaft Rotation (Quarter‐Turn Rotary)

Minimum: 45_

Maximum: 90_

Weight

Aluminum: 3.5 kg (7.7 lbs)

Stainless Steel: 8.6 kg (19 lbs)

Construction Materials

Housing, module base, and terminal box:

A03600 low copper aluminum alloy (standard)

Stainless steel (optional)

Cover: Thermoplastic polyester

Elastomers: Fluorosilicone

Options

J Supply and output pressure gauges or tire valves

J Integral mounted filter regulator J Energize to trip

J Standard Bleed Relay J Remote mount(8)(9)

J LCP100 local control panel J LC340 line conditioner

J Stainless steel

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 – Process Instrument Terminology.

1. The pressure/temperature limits in this document and any other applicable code or standard should not be exceeded.

2. The electronic output is available with either the position transmitter or the switch.

3. Normal m3/hour – Normal cubic meters per hour at 0_C and 1.01325 bar, absolute. Scfh – Standard cubic feet per hour at 60_F and 14.7 psia.

4. Values at 1.4 bar (20 psig) based on single‐acting direct relay; values at 5.5 bar (80 psig) based on double‐acting relay.

5. Temperature limits vary based on hazardous area approval.

6. Not applicable for travels less than 19 mm (0.75 inch) or for shaft rotation less than 60 degrees. Also not applicable for digital valve controllers in long-stroke applications over 4-inch.

7. M20 electrical connection only available with ATEX approvals.

8. 4‐conductor shielded cable, 18 to 22 AWG minimum wire size, in rigid or flexible metal conduit, is required for connection between base unit and feedback unit.

9. The position monitor (transmitter or switch) with the remote mount construction is not safety certified.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, FIELDVUE, and ValveLink are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. HART is a registered trademark of

FieldComm Group. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E

8 2012, 2016 Fisher Controls International LLC. All rights reserved.