Estimation and validation of maxwell stress of planar dielectric

advertisement

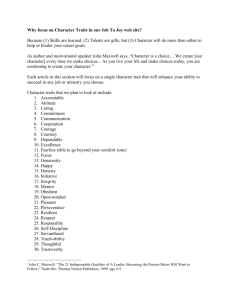

Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 www.springerlink.com/content/1738-494x(Print)/1976-3824(Online) DOI 10.1007/s12206-015-1247-y Estimation and validation of maxwell stress of planar dielectric elastomer actuators† Raj Kumar Sahu1, Abhishek Saini2, Dilshad Ahmad2, Karali Patra2,*and Jerzy Szpunar3 1 Department of Mechanical Engineering, National Institute of Technology Raipur, Raipur-492010, India 2 Department of Mechanical Engineering, Indian Institute of Technology Patna, Patna-800013, India 3 Department of Mechanical Engineering, University of Saskatchewan, Saskatoon SK S7N 5A9, Canada (Manuscript Received October 9, 2014; Revised July 11, 2015; Accepted September 16, 2015) ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Abstract In this paper, Maxwell stress of circular planar actuator at different applied voltages was estimated and then validated with the uniaxial compression test of three different dielectric elastomers (VHB, silicone and natural rubber). Pelrine’s equation was revisited to estimate Maxwell stress which causes the actuation in the planar direction. More precise and accurate estimation of Maxwell stress could be made in this work by considering variation of dielectric constant with respect to frequency and pre-strain. Estimated Maxwell stress was validated through (i) out-of-plane strain or thickness strain obtained from measured area strain considering constant volume deformation, and (ii) out-of-plane mechanical compressive test results. The estimated Maxwell stress agrees well with the corresponding experimental compressive stress values for different pre-straining cases considered in this work. Keywords: Uniaxial compression test; Dielectric elastomers; Maxwell stress; Pre-strain; Planar actuator ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- 1. Introduction Dielectric elastomer (DE) is a smart material which produces large strain with the application of voltage. Due to its tunable mechanical properties, robust and reliable performance, high net energy efficiency and high power density, it can be used to design lightweight and compact actuators [1]. DE actuator can be appealing alternative to conventional actuators for numerous applications, including robotics, adaptive optics, Braille displays, micro-fluidics, prosthetics, biomedical, etc [2, 3, 27]. Description of mechanical forces generated by the electric field, i.e., electromechanical coupling is considered as one of the key steps for the design and optimization of the DE actuators [4]. Electromechanical coupling is commonly described by the Maxwell stress proposed by Pelrine et al. [5]. Maxwell stress which is shown in the Eq. (1) has been derived for free boundary conditions and is generally accepted as a representation of electromechanical coupling in any DE actuator system [5, 6]. æV ö p = e re 0 E 2 = e re 0 ç ÷ èt ø * 2 Corresponding author. Tel.: +91 612 2552012, Fax.: +91 612 2277384 E-mail address: kpatra@iitp.ac.in † Recommended by Associate Editor Gang-Won Jang © KSME & Springer 2016 (1) Fig. 1. Sketch of the considered electromechanical system showing DE film thickness and active actuation area. where, p is the Maxwell stress, E is the electric field, e r is the relative permittivity, e 0 is the permittivity of free space (8.85x10-12 F/m), V is the applied voltage, and t is the polymer thickness. Due to the Maxwell stress, the elastomer film contracts in the thickness direction and expands in the film’s planar directions. The direction of Maxwell stress which acts in perpendicular to the DE film and the mechanical stress in radial direction (σr) during planar actuation are shown in Fig. 1. Ideally, the coated electrodes are to be compliant in order to minimize the resistance to the deformation, and the dielectric elastomers are pre-stretched in their in-plane directions, in order to improve their performance [6]. Maxwell stress (Eq. (1)) has been coupled with mechanical stresses acting on the elastomeric film to predict the actuation strain in different 430 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 actuators so far [6-13]. With reference to the circular planar actuator as shown in Fig. 1, the electromechanical coupling stress-stretch relation described earlier [12] can be modified as s r + e 0e r E 2 = lr ¶Ws (lr , lt ) ¶lr (2) (a) where, Ws (lr , lt ) is the Helmholtz free energy associated with stretching the elastomer [12]. lr , lt are the stretch ratio in radial and thickness direction, respectively. All these works on electromechanical coupling have considered a constant value of relative permittivity even though these actuators are tested in different operating conditions. However, recent investigations on the dielectric constant/relative permittivity show that its value varies with prestraining, temperature, frequency and applied complied electrodes [14-16]. Hence, it is important to consider the variation of relative permittivity/dielectric constant with operating conditions for more accurate estimation of the Maxwell stress. Earlier, some attempts were made to validate the Pelrine equation (Eq. (1)) for Maxwell stress by indirect measurement [17] and numerical simulation technique [18]. Kofod et al. [17] developed a constant strain experimental setup to measure the blocking force which was related to Maxwell stress by finite elasticity theory. Wissler and Mazza [18] validated the same equation through Comsol multiphysics simulation of circular actuator with energy balance consideration. In these electromechanical coupling works, Maxwell stress is considered as compression stress acting perpendicular to the insulating elastomer film. So it is imperative to understand the constitutive behaviour of elastomers under the influence of compressive loading for prediction of actuation strain of dielectric elastomer actuators. Tagarielli et al. [19] determined both axial strain (Thickness direction strain) and transverse strain of a dielectric elastomer under uniaxial compression load. Material response was modelled by a neo-Hookean constitutive model. However, several difficulties such as premature specimen failure by buckling, specimen barreling due to multiaxial stress state because of friction at the interface between specimen surface and compression plate are involved in the uniaxial compression test [20, 21]. To avoid buckling of the sample, generally short specimen (length to diameter ratio is less than 1.5) were applied. However, barreling effect could be observed in such cases [21]. Attempts were also made to reduce barreling effect by applying compliant tape and using cone compression set-up [20]. In this work, an actuation test setup was developed and actuation area strains of planar dielectric elastomer circular actuators were measured at different pre-straining values and applied voltage conditions. Dielectric constant values of the elastomer were estimated from measurements of capacitance values of the pre-strained samples coated with the same compliant electrode (here it is carbon grease) applied in the actuators. Maxwell stress and thickness strains were next estimated (b) Fig. 2. Biaxial pre-straining of VHB 4910 with (a) marked circular area (radius of 10 mm) before straining; (b) deformed marked area after straining. from dielectric constant and area strain values, respectively, for different applied voltages on pre-strained actuators. Finally, a new approach to validate Maxwell stress was attempted using uniaxial mechanical compression test under free boundary condition. The main advantage of this direct method to relate compression stress of a mechanical test with Maxwell stress of an actuator is that actuation strain can be directly predicted from applied voltage or vice versa from the stressstrain values of the mechanical test. 2. Experimental protocol 2.1 Materials The primary actuator material used in this work for investigating Maxwell stress phenomenon and its analogy with mechanical compressive stress is VHB 4910 (3M, USA). This material is characterized by low mass density of 960 kg/m3 and operating temperature range -10oC to 90oC [3]. To prove the effectiveness of this present investigation, experiments are also performed on other two commercially available dielectric elastomers i.e., silicone and natural rubber. 2.2 Pre-straining of dielectric elastomer Pre-straining of dielectric elastomer samples may be done in one direction or in both directions. In this work, bidirectional straining method is used for pre-straining. Dielectric elastomer films can be pre-strained onto an adjustable frame to provide equal amount of pre-strain in both directions. Figs. 2(a) and (b) show biaxial pre-straining of a VHB tape. A circle of specified radius is marked that increases with the increase of the distance between four moving arms. The marked deformed area in Fig. 2(b) can be approximated as axially symmetric. The samples for actuation tests are prepared from this marked region for having homogeneous thickness value. The accuracy of the equi-biaxial straining of the fixture is verified from the measured strain in X and Y direction as shown in Fig. 3. Measured strain values in Y direction agree well with the same in X direction. The maximum deviation of strain measurement was found to be within 5%. Hence, equi-biaxial straining of the sample is assumed here to estimate the pre-strained film thickness. Final thicknesses at different biaxial pre-strain values were esti- 431 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 (a) (b) Fig. 3. Variation of strain in X and Y directions. (c) (d) Fig. 5. Actuation tests of circular planar VHB 4910 DE actuator: (a) before actuation; (b) after actuation; (c) close-up view of un-actuated active area; (d) close-up view of actuated active area sample at 8.4 kV. Fig. 4. Layout diagram of experimental setup for actuation experiment. mated from initial thickness, initial area and deformed final area assuming incompressible deformation of the material, i.e., constant volume deformation. The estimated thickness values used for estimating Maxwell stress of planar actuator are described later. 2.3 Planar Actuator test setup Fig. 4 shows the test setup for planar circular actuators. In this setup, high voltage was applied on pre-strained dielectric elastomeric sample coated with carbon grease electrode. The high voltage was generated by a DC to high voltage DC convertor (Model no. Q101-5, made by Emco, Austria) which was used to scale the input voltage of 0-5 V to output voltage of 0-10 kV. The positive output side of the DC converter was connected with one end of the pre-strained dielectric elastomeric sample through wire and copper tape. The other end of the sample on opposite surface was fixed with negative output side. The output voltage was measured in digital multimeter through high voltage testing probe (Model No. HV40T, made by APLAB Ltd, India). A camera fixed to a tripod was used for capturing the images of the planar actuator under actuation. The digital camera (Sony DSC-W620 made by Sony Corporation, Japan) used for the experiment was having resolution of 4320 X 3240 and color representation of sRGB. The images were captured for different applied voltages and for different pre-strain values of the DE film. Increase of actu- ated area of the active region (coated area) can be observed at high applied voltage as shown in Figs. 5(a) and (b). Close up views of the active area are shown in Figs. 5(c) and (d) for unactuated and actuated state, respectively. Image processing technique in MATLAB tool box has been used to process the actuation images of different samples. The basic idea in calculating the strain is to find the area of the DE film in terms of number of pixels and then to multiply it with area of a pixel. For calculating the actuated area from the image processing tool box in MATLAB, first we have set the camera at a definite position and the pixel size is calibrated with known active area. Next, the images of different prestrained samples with different input voltages are captured. RGB image was converted to gray-scale image. Now grayscale image was further converted to binary image by setting the threshold value in order to find a region of interest i.e., a portion of the image that was of interest for further processing. Area of the ‘region of interest’ or ‘active region’ was calculated from number of pixels in it. Finally area strain (εA) due to actuation was calculated from the following equation [22]. eA = A - A0 . A0 (3) Where, A = actuated active area and A0 = un-actuated active area. Considering DE as incompressible material it can be assumed that the volume remains constant in the actuation process. The procedure for determining thickness strain from area strain of a planar actuator has been described in Sec. 3.2. Similar planar actuation test setups for natural rubber and silicone elastomer were also developed in this work and shown in Figs. 6 and 7, respectively. For natural rubber, the increase of actuated area (coated area) can be observed at high applied voltage as shown in Figs. 6(a) and (b). Close up views of the active area are shown in Figs. 6(c) and (d) for unactuated and actuated state, respectively. 432 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 (a) (b) Fig. 8. LCR meter with sample. termined from capacitance measurement using the following Eq. (4). (c) (d) Fig. 6. Actuation tests of circular planar natural rubber DE actuator: (a) before actuation; (b) after actuation; (c) close-up view of un-actuated active area; (d) close-up view of actuated active area sample at 8.4 kV. (a) (c) (b) (d) Fig. 7. Actuation tests of circular planar silicone DE actuator: (a) before actuation; (b) after actuation; (c) close-up view of un-actuated active area; (d) close-up view of actuated active area sample at 6.4 kV. Similarly, for silicone based rubber, the increase of actuated area (coated area) can also be observed at high applied voltage as shown in Figs. 7(a) and (b). Close up views of the active area of this planar actuator are shown in Figs. 7(c) and (d) for un-actuated and actuated state, respectively. 2.4 Experimental procedure for relative permittivity measurement Estimation of permittivity under different operating conditions is important to calculate Maxwell stress for actuator [5] or sensor applications [23]. Relative permittivity can be de- er = Ct Ae 0 (4) where, e r is the relative permittivity of the material, e 0 is the dielectric permittivity of free space (8.854 x 10-12 F/m), C is the capacitance of the material, A is the electrode area and t is the film thickness. For VHB 4910, capacitance measurements were carried out in the frequency range of 25 Hz to 1 MHz by using a properly calibrated LCR Meter (GWINSTEK LCR-8101G, made by Good will Instrument Co. Ltd., Taiwan) at room temperature (27 OC). The two ends of conductive electrode were connected with the LCR meter through crocodile probes as shown in Fig. 8. The VHB 4910 has the ability to change in thickness with the application of very high voltage. To avoid the change in thickness during experiment, small voltage alternating signal (sinusoidal signal of 2 V) has been applied on the sample. Average value of the three readings was taken under the same conditions to minimize inaccuracies (random error) in the measurement. Similarly, capacitance measurements for natural rubber and silicon were carried out in the frequency range of 1Hz to 1 MHz by using LCR meter (PSM1735, made by Newtons4th Ltd) at room temperature of (27oC). Procedure of calculation of dielectric constant of these materials was same as that of VHB 4910. 2.5 Sample preparation and uniaxial compression test set-up In order to prepare specimens for the uniaxial compression test, two monolithic plates of thickness 3 mm each were produced first by stacking three layers of VHB 4910 film of 1 mm thickness. Due to good self adhesive nature of the film it is impossible to separate the layers and the original interfaces between the layers are not visible. Then circular cylindrical specimens of diameter d of 6.5 mm were cut from these monolithic plates with sharp circular punches, lubricated with vaseline, which were pressed with low speed to avoid the straining of the material during the punching process. The punched samples were again stacked to get the desired length l 433 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 Table 1. Estimated Maxwell stress, thickness strain and corresponding compression test results of VHB 4910 (for 150% x 150% pre-strained planar actuator). Input voltage (kV) Area strain (%) Thickness strain Relative permittivity at 25Hz (for carbon grease) Film thickness (mm) Fig. 9. Uniaxial compression testing. of 6 mm. The aspect ratio l/d considered in this study is less than 1 for avoiding buckling and shear failure during uniaxial compression test [20]. Specimens were placed between two flat steel platens and were compressed in transverse direction using universal testing machine (Instron model no. 3366) as shown in Fig. 9. Compressive force applied on the specimen was measured by a 500 N load cell and specimen deformation was determined by a strain sensor attached with the cross-head. Cross-head movement of the machine was fixed at very slow compressive rate of 2 mm/min. During compression test barreling effect was avoided by coating compression plates with silicone based lubricant in order to limit friction between them and the samples. The Maxwell stress values of different pre-strained planar actuators at different applied voltages are estimated with the following assumptions: (i) electrostrictive effects are negligible for VHB 4910 elastomer, (ii) carbon grease electrode is ideally compliant (it does not constraint the elastomer mechanically) and (iii) the elastomer is incompressible. In the estimation of Maxwell stress using Pelrine equation, the relative permittivity e r is considered as a variable which varies with the applied frequency, pre-straining of the DE film and type of compliant electrode. Experimentally obtained dielectric constant values of VHB 4910 at different biaxial pre-straining using carbon grease electrode are shown in Fig. 10. These dielectric constant values and DE film thicknesses corresponding to the different pre-strained planar actuators were used to calculate the Maxwell stress for different applied voltages. Estimated Maxwell stress against different applied voltages for three different pre-strained planar actuators are shown in Tables 1-3. Maximum applied voltage in a prestrained planar actuator depends on the dielectric breakdown strength and thickness of the elastomer film [24, 25]. Even though dielectric strength increases with the increase in prestrain value, reduction of film thickness with pre-straining may affect the maximum applied voltage values. In this actuation test, breakdown voltage was 8.4, 6.4 and 6.4 kV for 150% x 150%, 200% x 200%, and 250% x 250% planar circular actuator, respectively. Compression stress (MPa) 0 0 0 5 0.2 0 0 1.4 1.57 -0.0155 5 0.2 0.0022 0.0023 2.4 2.24 -0.0219 5 0.2 0.0064 0.0037 3.4 7.27 -0.0678 5 0.2 0.0128 0.0121 4.4 11.13 -0.1002 5 0.2 0.0214 0.0190 5.4 14.84 -0.1292 5 0.2 0.0323 0.0257 6.4 21.7 -0.1783 5 0.2 0.0453 0.0384 7.4 32.91 -0.2476 5 0.2 0.0606 0.0598 8.4 41.41 -0.2928 5 0.2 0.0781 0.0760 Table 2. Estimated Maxwell stress, thickness strain and corresponding compression test results of VHB 4910 (for 200% x 200% pre-strained planar actuator). Thickness strain Relative permittivity at 25Hz (for carbon grease) Film thickness (mm) 3. Results and discussion 3.1 Estimation of maxwell stress from planar actuator experiments Maxwell stress (MPa) Input voltage (kV) Area strain (%) Maxwell stress (MPa) Compression stress (MPa) 0 0 0 4.66 0.14 0 0 1.4 2.26 -0.0221 4.66 0.14 0.0041 0.0039 2.4 4.77 -0.0455 4.66 0.14 0.0121 0.0078 3.4 13.68 -0.1203 4.66 0.14 0.0243 0.0234 4.4 18.48 -0.1560 4.66 0.14 0.0407 0.0325 5.4 33.64 -0.2517 4.66 0.14 0.0614 0.0607 6.4 66.31 -0.3987 4.66 0.14 0.0862 0.1028 Fig. 10. Relative permittivity v/s frequency at different biaxial prestrain for VHB 4910. 434 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 Table 3. Estimated Maxwell stress, thickness strain and corresponding compression test results of VHB 4910 (for 250% x 250% pre-strained planar actuator). Input voltage (kV) Area strain (%) Thickness strain Relative permittivity at 25Hz (for carbon grease) Film thickness (mm) Maxwell stress (MPa) Compression stress (MPa) 0 0 0 4.19 0.11 0 0 1.4 4.27 -0.0410 4.19 0.11 0.0060 0.0035 2.4 6.62 -0.0621 4.19 0.11 0.0177 0.0165 3.4 15.18 -0.1318 4.19 0.11 0.0354 0.0378 4.4 29.98 -0.2307 4.19 0.11 0.0593 0.0575 5.4 61.51 -0.3808 4.19 0.11 0.0894 0.0973 6 102.25 -0.5056 4.19 0.11 0.1103 0.1309 6.4 113.85 -0.5324 4.19 0.11 0.1255 0.1483 Fig. 11. Engineering stress v/s strain. eA = A - A0 p r 2 - p r02 = = lr2 - 1 . A0 p r02 (9) From Eqs. (8) and (9), e t and e A can be related by Eq. (10) 3.2 Estimation of thickness strain from planar actuator experiments Assuming constant volume actuation process, thickness strain values of the actuator were determined from the actuated area strain. Referring to Fig. 1 and constant volume assumption, one can write (5) A0t0 = At et = 1 -1 . 1+ eA (10) Area strain values for different pre-strained cases and for different applied voltages were estimated as shown in previous section. Thickness strain values were calculated from these area strain values using the Eq. (10). These thickness strain values for different pre-strained actuators were also shown in Tables 1-3. where, A0 is area of the active region before actuation. A is area of the active region after actuation. t0 is initial thickness of DE film. t is final thickness of the DE film. For the circular actuator Eq. (5) can be written as p r02t0 = p r 2t . 3.3 Uniaxial compression tests (6) From Eq. (6), one can get lt = t p r02 1 = = t0 p r 2 lr2 (7) where, lt is compression ratio in the thickness direction. lr is stretch ratio in radial direction. The above expression can also be expressed in terms of thickness strain ( e t ) æ 1 et = ç 2 è lr ö - 1÷ . ø Again, area strain ( e A ) can be written as, Uniaxial compression tests on VHB 4910 were performed to determine the required compressive stress corresponding to the estimated thickness strain values in Sec. 3.2. The specimen was compressed upto a strain value of 0.6 as the thickness strain values in all actuation tests are within this range. The material response to uniaxial compressive stress is shown in Fig. 11. Compression test results were compared with the earlier reported results given by Tagarielli et al. [19] and found to be in good agreement as shown in Fig. 11. (8) 4. Validation of maxwell stress with uniaxial compression test results 4.1 Validation of maxwell stress of VHB 4910 planar actuator From uniaxial compression test results of VHB 4910, compressive stress values corresponding to the calculated thickness strains were identified and shown in Tables 1-3. Estimated Maxwell stress and corresponding compressive stress were plotted against applied voltage at different pre-straining values and shown in Fig. 12. It can be observed that Maxwell stress increases with the increase in pre-strain value at a particular applied voltage. This may be due to the reduction in R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 435 Fig. 14. Maxwell stress v/s applied voltage for silicone. Fig. 12. Maxwell stress v/s applied voltage for VHB. The estimated Maxwell stress values of natural rubber and silicone planar actuators also agree well to the corresponding compressive stress values for different applied voltages and pre-straining conditions. 5. Conclusions Fig. 13. Maxwell stress v/s applied voltage for natural rubber. thickness for pre-straining of DE film. The effect of thickness reduction on Maxwell stress is more significant than that of reduction of dielectric constant value for a pre-strained sample. With the increase of Maxwell stress, thickness strain also increases. It leads to selection of compressive stress to a higher value for higher pre-strained sample. The estimated Maxwell stress agrees well with the corresponding experimental compressive stress values for all three different pre-straining cases. 4.2 Validation of maxwell stress of natural rubber and silicone planar actuators Applying similar procedure, Maxwell stress and thickness strain for different pre-strained (70% x 70%, 150% x 150% and 200% x 200%) silicone and natural rubber based planar actuators were estimated applying similar procedures used for VHB 4910 planar actuator. However, mechanical compressive stress data corresponding to different thickness strain values of natural rubber and silicone elastomers were extracted from uniaxial compression test results given by Daniela et al. [26] and Meunier et al. [27], respectively. Estimated Maxwell stress and corresponding compressive stress for natural rubber and silicon are plotted against applied voltage at different prestraining values and shown in Figs. 13 and 14, respectively. The trends of Maxwell stress with respect to applied voltage and pre-strained values are similar to those of VHB 4910. This work reported the estimation of Maxwell stress of three different dielectric elastomers (VHB, silicone and natural rubber) planar circular actuator at different levels of operating voltage and pre-strain values. Pre-straining was shown to improve the actuation performance because of the significant reduction of thickness and increase of dielectric strength. Estimation of Maxwell stress could be more precise and accurate by considering variation of dielectric constant with respect to applied frequency and pre-straining of elastomer film. This work proposed a novel method to re-validate the Pelrine’s equation for Maxwell stress using mechanical compression test analogy. These results may have important consequences in designing and fabrication of dielectric elastomer actuator for real practical applications. References [1] R. E. Pelrine, R. D. Kornbluh and J. P. Joseph, Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation, Sensors and Actuators A, 64 (1998) 77-85. [2] R. Shankar, T. K. Ghosh and R. J. Spontak, Dielectric elastomers as next-generation polymeric actuators, Soft Matter., 3 (2007)1116-1129. [3] F. Carpi, D. D. Rossi, R. Kornbluh, R. Pelrine and P. S. Larsen, Dielectric elastomers as electromechanical transducers, First Ed., Elsevier, Oxford UK (2008). [4] M. Wissler, Modeling dielectric elastomer actuators, Ph.D. Thesis, Swiss Federal Institute of Technology (2007). [5] R. E. Pelrine, R. D. Kornbluh, Q. Pei and J. Joseph, Highspeed electrically actuated elastomers with strain greater than 100%, Science, 287 (2000) 836-839. [6] G. Kofod, The static actuation of dielectric elastomer actuators- how does pre-stretch improve actuation?, J. Phys. D.Appl. Phys. 41 (2008) 215405. [7] M. Wissler and E. Mazza, Modeling of a pre-strained circu- 436 R. K. Sahu et al. / Journal of Mechanical Science and Technology 30 (1) (2016) 429~436 lar actuator made of dielectric elastomers, Sensors and Actuators A, 120 (2005) 184-192. [8] J. S. Plante, Dielectric elastomer actuators for binary robotics mechatronics, Ph.D Thesis, Massachusetts Institute of Technology (2006). [9] G. Kovacs P. Lochmatter and M. Wissler, An arm wrestling robot driven by dielectric elastomer actuators, Smart Mater. Struct., 16 (2) (2007) S306-S317. [10] P. Brochu and Q. Pei, Advances in dielectric elastomers for actuators and artificial muscles, Macromol. Rapid Commun., 31 (1) (2010) 10. [11] Z. Gao, A. Tuncer and A. M. Cuitino, Modeling and simulation of the coupled mechanical-electrical response of soft solids, International Journal of Plasticity, 27 (2011) 1459-1470. [12] T. Q. Lu and Z. G. Suo, Large conversion of energy in dielectric elastomers by electromechanical phase transition, Acta Mechanica Sinica, 28 (4) (2011) 1106-1114. [13] S. Akbari, S. Rosset and H. R. Shea, Improved electromechanical behavior in castable dielectric elastomer actuators, Applied Physics Letters, 102 (2013) 071906. [14] C. J. Mistral, A. Sylvestre, S. Basrour and J.-J. Chaillout, Dielectric properties of polyacrylate thick lms used in sensors and actuators, Smart Mater. Struct., 19 (7) (2010) 075019. [15] J. Qiang, H. Chen and B. Li, Experimental study on the dielectric properties of polyacrylate dielectric elastomer, Smart Mater. Struct., 21 (2) (2012) 025006. [16] R. K. Sahu, B. Pramanik, K. Patra, S. Bhaumik, A. K. Pandey and D. K. Setua, Dissipation Factor of Acrylic Dielectric Elastomer - An Experimental Study, Journal of Nanoscience and Nanotechnology, 14 (10) (2014) 7439-7444. [17] G. Kofod, P. Sommer-Larsen, R. Kornbluh and R. Pelrine, Actuation response of polyacrylate dielectric elastomers, Journal of Intelligent Material Systems and Structures, 14 (2003) 787-793. [18] M. Wissler and E. Mazza, Electromechanical coupling of dielectric elastomer actuators, Sensors and Actuators A, 138 (2007) 384-393. [19] V. L. Tagarielli, R. Hildick-Smith and J. E. Huber, Electromechanical properties and electrostriction response of a rubbery polymer for EAP applications, Int. Journal of Solids and Structures, 49 (2012) 3409-3415. [20] M. Jerabek, Z. Major and R. W. Lang, Uniaxial compression testing of polymeric materials, Polymer Testing, 29 (2010) 302-309. [21] S. Z. Qamar, M. Akhtar, T. Pervez and M. S. M. AlKharusi, Mechanical and structural behavior of a swelling elastomer under compressive loading, Materials and Design, 45 (2013) 487-496. [22] R. K. Sahu, K. Sudharshan, K. Patra and S. Bhaumik, Evaluation of area strain response of dielectric elastomer actuator using image processing technique, Proc. of SPIE, 9056 (2014) 90562C-1. [23] K. Junga, K. J. Kima and H. R. Choi, A self-sensing dielectric elastomer actuator, Sensors and Actuators A, 143 (2008) 343-351. [24] A. Barnes, Q. Liu, G. Young and T. F. Lu, Evaluation of selected Dielectric Elastomer for use in an Artificial Muscle Actuator, Proceedings of the Australasian Conference on Robotics and Automation (2007) 1-9. [25] C. J. Mistral, S. Basrour, J. J. Chaillout and A. Bonvilain, A complete study of electroactive polymers for energy scavenging: modelling and experiments, Design, Test, Integration and Packaging of MEMS/ MOEMS Symposium (2007). [26] O. F. Daniela, B. Mihai, F. Vlad and V. Vasile, Compression modulus of elastomers, Buletinul institutului politehnic DIN IAŞI, Tomul LIX (LXIII), Fasc.2 (2013) 157-166. [27] L. Meunier, G. Chagnon, D. Favier, L. Orge and P. Vacher, Mechanical experimental characterisation and numerical modelling of an unfilled silicone rubber, Polymer Testing, 27 (2008) 765-777. Raj Kumar Sahu received his B. Tech. Degree from MIT Purnea in 2008 (Bihar, India), and his M. Tech. degree from National Institute of Technology Jamshedpur in 2010 (Jharkhand, India), and his Ph.D. degree from Indian Institute of Technology Patna in 2014 (Bihar, India). All degrees are in mechanical engineering. He is currently an assistant professor at Department of Mechanical Engineering, National Institute of Technology Raipur, India (Chhattisgarh, India). His research interests are focused on smart materials, materials characterization using modern techniques, material development, etc. Karali Patra is an Assistant Professor in the Department of Mechanical Engineering, Indian Institute of Technology Patna (IIT Patna), Patna, India. He did his BTech, MTech and Ph.D. from BE College, Shibpur (IIEST, Shibpur), IIT Guwahati and IIT Kharagpur in 1997, 2003 and 2008, respectively. He worked as research associate at Robotics Research Center, Nanyang Technological University in 2007-2008 and as Reader in Manipal Institute of Technology, Manipal, India before joining IIT Patna in 2008. His current research interests are actuators and energy harvesting applications of electroactive polymers, bio-robotics and micro-manufacturing processes.