Design of a novel ZVT soft-switching chopper

advertisement

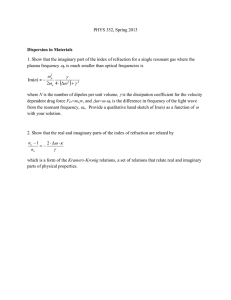

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 17, NO. 1, JANUARY 2002 101 Design of a Novel ZVT Soft-Switching Chopper Huijie Yu, Member, IEEE, Byeong-Mun Song, Member, IEEE, and Jih-Sheng (Jason) Lai, Senior Member, IEEE Abstract—This paper presents a simple soft-switching chopper scheme with fixed timing control. A near-zero-voltage transition (near-ZVT) switching condition is realized by adding one auxiliary resonant snubber branch to a full-bridge two-quadrant chopper. The turn-off loss is reduced by lossless snubber capacitors in parallel with the main switches. The proposed design approach is to realize true ZVT at the rated load and near-ZVT under all other load current conditions. Computer simulation and hardware experiments have been implemented to verify the proposed concept, and the resulting voltage and current waveforms are shown from 30% to 150% load conditions in this paper. Under near-ZVT switching, the switching loss and of the power device can be significantly reduced, and the reverse recovery problem of main switches can be avoided as compared to the hard-switching case. The design criteria for the resonant components are described with a practical example that has been used in a commercial magnetic levitation system. Under different load current conditions, the proposed design methodology has been fully verified with simulation and experimental results. Index Terms—Chopper, resonant, soft-switching, snubber, zero voltage transition. I. INTRODUCTION S OFT switching techniques, especially the zero-voltage transition (ZVT) have become more and more popular in the power electronics industry. The goal of soft switching is to achieve less switching losses and noises than that of the traditional hard switching. There are numerous examples of soft-switching techniques [1]–[4]. Some are quite promising in some particular applications, but may not be suitable for inverter applications. One major issue is to adapt to load current change and to achieve ZVT conditions at all load conditions. Variable timing control needs to be used to make soft switching more efficient than hard switching, especially for insulated-gate bipolar transistor (IGBT) based inverter applications. However, the control of variable timing is very complicated, and the implementation requires numerous iterations and tunings. Fixed timing is preferred to variable timing for control simplification, but how to achieve ZVT with fixed timing under all load condition is quite challenging. The objective of this paper is to present the design criteria of a novel fixed-timing soft-switching chopper using the auxiliary resonant snubber to replace a conventional RCD-snubber based hard-switching Manuscript received July 20, 1999; revised January 15, 2000. Recommended by Associate Editor J. H. R. Enslin. H. Yu and J.-S. Lai are with the Center for Power Electronics Systems, The Bradley Department of Electrical and Computer Engineering, Virginia Polytechnic Institute and State University, Blacksburg, VA 24061-0111 USA (e-mail: huyu@vt.edu). B.-M. Song is with the Center for Power Electronics Systems, The Bradley Department of Electrical and Computer Engineering, Virginia Polytechnic Institute and State University, Blacksburg, VA 24061-0111 USA and also with the General Atomics, San Diego, CA 92186-9784 USA (e-mail: songb@gat.com). Publisher Item Identifier S 0885-8993(02)02165-8. chopper. The tested chopper is being used in a magnetic driver for a commercial magnetic levitation (MAGLEV) system. and loss reduction, turn-on The new design achieves current spike and noise reduction, and finally the improvement of efficiency and associated heat sink size reduction. Because the load current of the chopper is only in one direction, only one auxiliary branch is needed and the control is relatively simple. The basic cell topology is similar to that of a family of auxiliary resonant snubber presented in [5]. Main features of the proposed circuit are 1) main switch turns on at near zero-voltage condition; 2) auxiliary switch turns on and off under zero-current condition; 3) main switch turn-off loss is reduced by lossless snubber capacitors; 4) near zero-voltage turn-on condition is created by a current injection from the auxiliary branch that contains a resonant inductor, an auxiliary switch, and snubber capacitors. These features are similar to those of the resonant snubber inverters described in [5], except that the main switch operation is near ZVT in the proposed circuit because its initial inductor current is not controllable, and the capacitor voltage at the end of resonance cannot reach true zero due to the effect of the dissipative components in the resonant branch. The loss due to near-ZVT is related to the design methodology. This paper emphasizes the design methodology that allows a two-quadrant chopper to have an efficient near-ZVT operation for a wide-range load conditions. Using the proposed design criteria, a 10-kW hard-switched commercial chopper that was used in a magnetic levitation (MAGLEV) system was retrofitted with the proposed resonant circuit and fully executed with conceptual design, computer simulation, and hardware implementation for near-ZVT operation. Simulation and experimental results prove that the proposed design methodology is effective, and the proposed soft-switching circuit is well suited for two-quadrant chopper applications. II. OPERATION PRINCIPLE Fig. 1 shows the proposed soft-switching chopper circuit with auxiliary resonant snubber for a two-quadrant chopper. The chopper bridge consists of two synchronously switching - . The diodes provide a pairs, switches - and diodes freewheeling current path and a reverse voltage across the load for two-quadrant operation. The lossless snubber capacitors are added across main devices, and the auxiliary branch is added in between two phase-legs. The auxiliary branch consists of one auxiliary switch, one fast reverse recovery diode, and one resonant inductor. Since the load current flows in uni-direction, only one auxiliary branch is needed to achieve soft switching. 0885–8993/02$17.00 © 2002 IEEE Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. 102 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 17, NO. 1, JANUARY 2002 Fig. 1. Proposed soft-switching chopper circuit. Fig. 2 illustrates the operation modes for the proposed softswitching scheme. The basic control is to turn on the auxiliary , before turning on the main switch, and . The switch, auxiliary branch takes over the current from the freewheeling diode and resonates with capacitors in parallel with the main switch. The main switch is turned on while the voltage across the main switch drops nearly to zero after resonance. Although only near-zero-voltage switching can be achieved with the proposed fixed timing control, the diode reverse recovery and problems of the chopper circuit are effectively solved. The circuit operation modes are described in Fig. 3(a)–(f). Initially at time , all switches are off, and the load current is and as shown in Fig. 3(a). Operation freewheeling through modes for a complete cycle are described in detail as follows. Fig. 2. Key waveforms of the proposed scheme. itor voltage drops to zero without proper sensing, the main switch can thus be turned on at a nearzero-voltage condition. This near zero-voltage is created by the auxiliary resonant circuit for a short period, which can be considered as “near zero-voltage transition” or near-ZVT. After the main switches turn on, the inductor current decreases linearly due to reverse voltage polarity. Mode e Mode a : Assume that load current is positive when and are conducting the load current, and the and are off. main switches : Following the pulse-width-modulation (PWM) turns on at command, the auxiliary switch , the current in increases linearly and the and decreases linearly. current in diodes The auxiliary branch diverts the current from the freewheeling diode gradually. : After the resonant current decreases to zero at , the auxiliary switch gate signal can be turned off at . The main switches then conduct the load current, and the auxiliary switch is turned off under zero-current condition. : Main switches turn off with lossless snubber and are capacitors. Once the capacitors , and and are discharged charged to to 0, the load current is transferred to diodes and , and the circuit operation returns to Mode a. Mode b Mode c : After the auxiliary branch current is larger than and turn off the load current at , diodes naturally. Then all four snubber capacitors resonate with the auxiliary inductor. The capacitor across the switch discharges with a finite rate to allow the switch voltage drop to zero. Mode d : At the end of the resonant stage, the snubber capacitors are discharged to zero voltage at . At this moment, the main switch can be turned on at zero-voltage condition. In reality, the dissipative components in the resonant branch may prevent the voltage from swinging down to true zero but close enough. However, even if the voltage can swing to true zero, it is difficult to turn on the main switch at the exact moment that the capac- Mode f III. DESIGN CRITERIA A. Design Analysis , the voltage across At the end of the resonant stage the main switch should be fully discharged so that the main switches can be turned on under zero voltage. The key design point is how to catch the zero-voltage instant and turn on the main switches exactly at or as close as possible to . The following design analysis will focus on this particular resonant stage to ensure a proper resonant operation. Once the resonant stage is well designed, the component value and control timing can be determined. As long as the resonant inductor current begins to resonate with the careaches the load current at pacitors. The equivalent circuit during the resonant period can be shown in Fig. 4. Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. YU et al.: DESIGN OF A NOVEL ZVT SOFT-SWITCHING CHOPPER 103 (a) (b) (c) (d) (e) (f) Fig. 3. Operation stages of ZVT chopper. 2) The duration of the resonant stage is fixed at half of the natural resonant cycle of resonant tank . The resonant capacitor voltage and inductor current can be expressed as (2) (3) where Fig. 4. Equivalent circuit of resonant stage. (4) To simplify the circuit, is flipped down, and is flipped up. The initial condition (IC) of the resonant tank is given in Fig. 5. Finally, a very simple circuit can be drawn as shown in and are the equivalent resonant Fig. 5(c). In this figure, capacitor and inductor during the resonant stage, i.e., (1) , we have . In the case of The final equivalent circuit is a very simple LC resonant tank with zero initial condition. Here we notice two important points. 1) The resonant stage is independent of load current condition. The current stress on the auxiliary branch can be obtained as (5) , is the interval The auxiliary switch pre-turn-on time, to , which is the sum of inductor charging time from and the resonant stage duration, . A quality factor is to , as shown in defined here as the ratio of (6) (7) Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. 104 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 17, NO. 1, JANUARY 2002 (a) (b) (c) Fig. 5. Simplification of resonant stage circuit. Note that if and can be chosen such that is sufficiently large with a fixed pre-turn-on time, , where is the charging time under normal load condition, the near-ZVT can then be is much larger than , even if the main obtained. Since switch is turned on a little earlier or later due to the load current variation, the voltage will only swing back to a finite amplitude, but close enough to zero-voltage condition. To reduce the peak resonant current so as to reduce the cirand small . culating energy, it is desirable to have large However, for a wide range of near-ZVT operation, it is desirand a small so that conable to have a large dition is satisfied. Since a typical MOS gated device can withstand a high peak over-current in a short period, a larger and a smaller may cause a high peak current but not cause a problem of finding an economical device to handle it. In other words, a small tank impedance is desirable in the most cases, and thus the tank impedance becomes an important design factor. The capacitor value can be selected based on the requirement and turn-off loss test. The resonant inductor value can be calculated with the predetermined , and the pre-turn-on time of the auxiliary switch is optimized at the rated load conequals under the rated load dition. That is to let condition. As a result, the worst case happens under no-load and heavily overload conditions. or . Fig. 6. Ratio of T to T with respect to normalized impedance Z B. Design Procedure Example Fig. 7. Normalized resonant branch peak current I . as a function of Z If the main switch is turned on precisely with delay after the auxiliary switch, and the circuit components are lossless, the exact ZVT condition can be achieved. It should be noted is load current dependent, it is necesthat according to (6), sary to adjust the pre-turn-on time of the auxiliary switch to meet different load current condition if an exact ZVT is desired. To implement this it is necessary to use variable timing control to according to the load current condition. However, change such a variable timing control requires current sensing and additional complicated control circuitry. It is desirable to look for a simple solution with fixed-timing control but not losing ZVT. The proposed approach is described as follows. In a commercial MAGLEV chopper application, the nominal is 25 A, and the dc bus voltage is 300 V. load current The design procedure can be described as follows. Step 1) Decide resonant tank impedance so that the quality is large enough to satisfy near-ZVT factor condition with fixed timing control. However, the must be limited to avoid peak resonant current excessive loss in the auxiliary branch. To facilitate the comprehensive of the design under different condition, the tank impedance and resonant peak current is normalized as follows: (8) Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. YU et al.: DESIGN OF A NOVEL ZVT SOFT-SWITCHING CHOPPER Fig. 8. 105 Turn-off energy as a function of C under different load conditions. (0.25, 0.4, 0.542, 0.8). Fig. 9. Variation of T as a function of C and Z Thus (5) and (7) can be rewritten as (9) (10) As shown in Fig. 6, is chosen as 0.542 which value of 6.0. In this case, corresponds to a a the estimated normalized peak resonant current is 2.845 as indicated in Fig. 7. The selection process can also start with limiting the peak current first, and to allow a wide range near-ZVT check with condition. and so the requirement can be Step 2) Select is proper for acsatisfied, and the resonant cycle tual implementation. Since the main switch turn-off loss can only be reduced by snubber capacitors, it is necessary to perform device test to determine a proper value for . Fig. 8 shows the test results of turn-off energy under different snubber capacitance value so and load current conditions. Select a will not significantly that further increments of further reduce turn-off loss. In the meantime, it is necessary to let resonant cycle, , be a reasonable value so that it is not too small for practical implementation and not too large to avoid loss of duty cycles. Fig. 9 shows the changes of resonant cycle, , under different and values. Based on the above criteria, a value of 0.1 F was chosen for . The resonant inductor value is then calculated by H, and the tank resonant cycle is around 4 s. Step 3) Determine the pre-turn-on time of the auxiliary , and the turn-on duration of the auxilswitch, . is the sum of the pre-charging iary switch, and resonant period . is load current time dependent and can be chosen under static load is much larger than current condition. Since , the variation of will not affect much of the near zero-voltage condition. In this example Fig. 10. Simulated key waveforms of near-ZVT chopper scheme. is chosen as 2.3 s. is the turn-on duration of is not critical because the auxiliary switch. the auxiliary switch can be turned off after the should be larger current reduces to zero. So , and the selection in this case is than s. Step 4) Summarize the design parameters and select proper auxiliary switch and passive components. Up to this point, the major design has been completed. The remaining jobs such as switch selection and magnetic design can be left to practicing engineers. The complete design summary is listed as follows: V, A, F, H, s, s, s, A, . IV. SIMULATION RESULTS The effectiveness of the proposed control scheme can be simulation with the above design paramproved by eters. Actual commercial IGBT SPICE models are used, but parasitic parameters and dissipative components like capacitor ESR and ESL are not included in the simulation. Fig. 10 shows the key waveforms of the chopper operation. , and current, , Fig. 10(a) shows the main switch voltage, Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. 106 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 17, NO. 1, JANUARY 2002 Fig. 11. Resonant current I under incorrect timing. (A) and switch voltage V (a) (c) Fig. 12. Waveforms of resonant current I under different load current conditions. (V) waveforms Fig. 13. Experimental waveforms of the ZVT chopper scheme. Fig. 14. Switch voltage waveform under incorrect timing. (b) (d) (A) and switch voltage V (V) waveforms. It can be seen that the main switches operate well is in near zero-voltage turn-on condition. The turn-on and the turn-off controlled by the resonant time constant, is proportional to the load current but is limited by the added snubber capacitors. The main switch diode reverse recovery problem is eliminated, and thus there is no current spike during main switch turn-on. Fig. 10(b) shows that the auxiliary , is around 70 A, as expected in the branch peak current, previous design section. Fig. 10(c) shows the main switch gate , and auxiliary switch gate signal, . drive signal, It is possible that near zero-voltage turn-on condition may be lost if the timing is not controlled properly. Fig. 11 indicates that the main switch is turned on while the switch voltage swings up to a certain value with the situation that the pre-turn-on time is longer than the designed value. Fig. 12(a)–(b) show the simulated waveforms of the voltage across the main switch and the resonant current during turn-on process with designed control timing under different load currents: (a) 7.5 A, (b) 17 A, (c) 28 A, and (d) 37 A. It can be seen that near-ZVT turn-on of the main switch is satisfied for all load current conditions. In this simulation, the load current is considered as a constant current source during the switching period with a value corresponding to the actual experimental load current as described in the next section for the comparison purpose. V. EXPERIMENTAL RESULTS The above-designed soft-switching chopper has been fully tested with the same parameters that were used in the simulation. Fig. 13 shows experimental key waveforms of load cur, resonant current, , switch voltage, , and dc rent, input current, . The measurement of dc input current is for the purpose of loss calculation. To verify loss of ZVT with inappropriate timing, an experiment was conducted under the condition addressed in Fig. 11. Fig. 14 shows the corresponding test results of losing ZVT condition. As can be seen from Fig. 14 that an oscillation occurs when the switch turns on after the voltage has been swung back to a relatively high voltage level. Fig. 15(a)–(d) shows experimental waveforms of the load cur, the resonant current, and the voltage across the rent, Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. YU et al.: DESIGN OF A NOVEL ZVT SOFT-SWITCHING CHOPPER 107 TABLE I COMPARISON OF CALCULATED, SIMULATED, AND EXPERIMENTAL RESULTS (a) (b) (c) (d) Fig. 15. Waveforms of resonant current and switch voltage under different load current condition. experimental results match well with the designed value in all different load conditions. VI. CONCLUSION Fig. 16. Loss comparison between hard- and soft-switching choppers. switch, , under different load current conditions that are corresponding to Fig. 12(a)–(d) conditions. The timing design is to ensure that the main switch turns on at near zero voltage under the nominal operation condition (25 A for the example chopper case). Waveforms indicate that even at extreme conditions such as 30% (lightly loaded) in Fig. 15(a) and 150% (overloaded) in Fig. 15(d), the switching waveform is clean, and the near-ZVT condition is well satisfied. Loss evaluation results indicated that the total loss reduction was 31% at the nominal load condition, as indicated in Fig. 16. Table I compares the calculated, simulated and experimental , and its conducresults for resonant branch peak current, , under different load current, , condition time, tions. Although there are some minor differences due to negligence of parasitics and dissipative components, simulation and In this paper, the design criteria of a novel near-ZVT softswitching chopper are presented with verification of both simulation and experimental results. The resonant tank impedance was found to be the most critical parameter for ZVT design and should be selected properly. A step-by-step design procedure was described with a practical example. The proposed simple fixed-timing control scheme is proven to be effective to achieve near-ZVT for a wide range of load conditions. The example soft-switching chopper also performs significantly better than its hard-switching counterpart [6] in switching loss and reduction. REFERENCES [1] B. Serge et al., “Chopper and PWM inverter using GTO’S in dual thyristor operation,” in Proc. EPE Conf., 1987, pp. 383–389. [2] R. W. DeDoncker and J. P. Lyons, “The auxiliary resonant commutated pole converter,” in Proc. IEEE IAS Ann. Meeting, 1990, pp. 1228–1235. [3] W. McMurray, “Resonant snubbers with auxiliary switches,” IEEE Trans. Ind. Applicat., vol. 29, pp. 355–362, Mar./Apr. 1993. [4] J. S. Lai et al., “A delta configured auxiliary resonant snubber inverter,” IEEE Trans. Ind. Applicat., vol. 32, pp. 518–523, May/June 1996. [5] J. S. Lai, “Fundamentals of a new family of auxiliary resonant snubber inverter,” in Proc. IEEE IECON Conf., Nov. 1997, pp. 645–650. [6] B. M. Song, J. S. Lai, D. Qu, H. Yu, and H. K. Sung, “A novel softswitching chopper using auxiliary resonant snubbers for a MAGLEV system,” in Proc. 16th VPEC Sem., Blacksburg, VA, Sept. 1998, pp. 279–284. Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply. 108 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 17, NO. 1, JANUARY 2002 Huijie Yu (M’99) was born in Hunan, China in 1972. He received the B.S. and M.S. degrees in electrical engineering from Tsinghua University, Beijing, China, in 1994 and 1997, respectively, and is currently pursuing the Ph.D. degree at the Virginia Polytechnic Institute and State University (Virginia Tech), Blacksburg. In 1997, he joined the Center for Power Electronics System, Virginia Tech. His research interests include soft switching power converters, modeling and control of inverter motor drive systems, and high temperature power converters. Byeong-Mun Song (M’90) received the B.S. and M.S. degrees in electrical engineering from the Chungnam National University, Taejon, Korea, in 1986 and 1988, respectively, and is currently pursuing the Ph.D. degree at the Virginia Polytechnic Institute and State University, Blacksburg. From 1988 to 1994, he was a Senior Research Engineer of the Power Electronics Division, Korea Electrotechnology Research Institute (KERI), Changwon, Korea. In 1991, he was a Visiting Research Engineer at the Technical University of Braunschweig, Germany, where he worked for developing the magnetic levitation (Maglev) system. Since August 2000, he has been with General Atomics, San Diego, CA, as a Staff Engineer. He is working on advanced Maglev projects and leads for power electronics systems. His research interests are soft-switching inverters, motor drives, multilevel converters, and active power filters. Mr. Song received three awards including an IPEC-2000 Paper Award in 2000, one award from the Korea Ministry of Science and Technology in 1993, and one award from KERI in 1992. Jih-Sheng (Jason) Lai (SM’90) received the M.S. and Ph.D. degrees in electrical engineering from the University of Tennessee, Knoxville, in 1985 and 1989, respectively. From 1980 to 1983, he was the Head of the Electrical Engineering Department, Ming-Chi Institute of Technology, Taipei, Taiwan, R.O.C., where he initiated a power electronics program and received a grant from his college and a fellowship from the National Science Council to study abroad. In 1986, he became a Staff Member at the University of Tennessee, where he taught control systems and energy conversion courses. In 1989, he joined the Electric Power Research Institute (EPRI), Power Electronics Applications Center (PEAC), where he managed EPRI-sponsored power electronics research projects. In 1993, he worked with the Oak Ridge National Laboratory as the Power Electronics Lead Scientist, where he initiated a high power electronics program and developed several novel high power converters including multilevel converters and auxiliary resonant snubber based soft-switching inverters. Since August 1996, he has been with the Virginia Polytechnic Institute and State University as an Associate Professor. His main research areas are in high power electronics converter topologies, motor drives, and utility power electronics interface and application issues. He has published more than 105 technical papers and two books. He received eight U.S. patents in the area of high power electronics and their applications. Dr. Lai received several distinctive awards including a Technical Achievement Award in Lockheed Martin Award Night, two IEEE IAS Conference Paper Awards from Industrial Power Converter Committee, one IEEE IECON Best Paper Award, and an Advanced Technology Award from Inventors Clubs of America. He is a member of Phi Kappa Phi and Eta Kappa Nu. He is the Chair of the IEEE Power Electronics Society Standards Committee. He chaired a Technical Committee for the 2001 DOE Future Energy Challenge and IEEE COMPEL-2000 Workshop. Authorized licensed use limited to: ULAKBIM UASL - YILDIZ TEKNIK UNIVERSITESI. Downloaded on August 04,2010 at 09:47:56 UTC from IEEE Xplore. Restrictions apply.