1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

info@edgelighting.com

© 2013 Edge Lighting. All Rights Reserved.

TW-S1-1RE-_

904-TW-S1-1RE-02

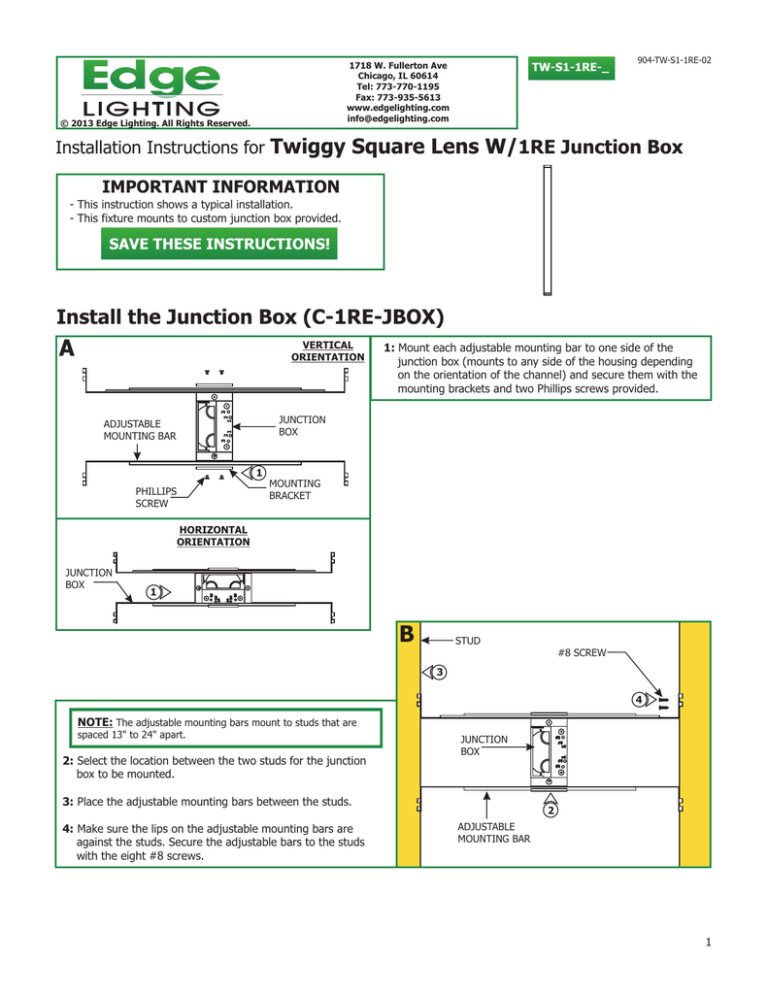

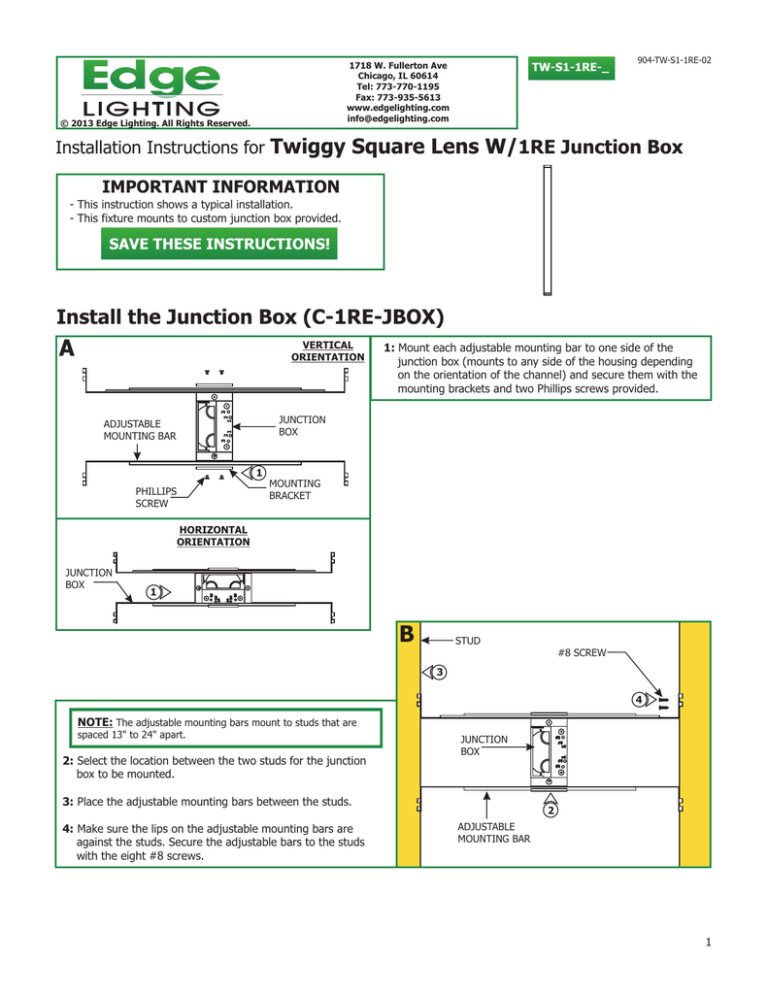

Installation Instructions for Twiggy Square Lens W/1RE Junction Box

IMPORTANT INFORMATION

- This instruction shows a typical installation.

- This fixture mounts to custom junction box provided.

SAVE THESE INSTRUCTIONS!

Install the Junction Box (C-1RE-JBOX)

A

1: Mount each adjustable mounting bar to one side of the

junction box (mounts to any side of the housing depending

on the orientation of the channel) and secure them with the

mounting brackets and two Phillips screws provided.

2

3

VERTICAL

ORIENTATION

1

JUNCTION

BOX

3

2

1

ADJUSTABLE

MOUNTING BAR

1

MOUNTING

BRACKET

PHILLIPS

SCREW

HORIZONTAL

ORIENTATION

JUNCTION

BOX

1

3

2

1

1

2

3

B

STUD

#8 SCREW

3

4

NOTE: The adjustable mounting bars mount to studs that are

3: Place the adjustable mounting bars between the studs.

4: Make sure the lips on the adjustable mounting bars are

against the studs. Secure the adjustable bars to the studs

with the eight #8 screws.

3

2

1

1

2

2: Select the location between the two studs for the junction

box to be mounted.

JUNCTION

BOX

3

spaced 13" to 24" apart.

2

ADJUSTABLE

MOUNTING BAR

1

C

5: Remove a knockout to install the power line conduit.

CONDUIT

6: Install the conduit and run the 120V power wires.

3

2

1

1

2

3

JUNCTION

BOX

5

6

D

STUD

ADJUSTABLE

MOUNTING BARS

CONDUIT

JUNCTION

BOX

NOTE: If necessary junction box opening can be adjusted, in

1

2

3

three positions from position 1 at 0.85", 2 at 0.95" or 3 at 1.05".

Simply loosen screws and tighten to the corresponding position

labeled on junction box.

8

1

9

3

2

7: Connect the white transformer wire to the neutral power

wire with a wire nut.

8: Connect the black transformer wire to the hot power wire

with a wire nut.

7

9: Place the transformer and transformer wires inside the

junction box.

E

RECTANGLE

OPENING

DRYWALL

TRANSFORMER

10: Mark a rectangle shape on drywall where the junction box

opening will be located depending on selected position.

11: Cut out the marked rectangle opening, using a "Dremel

Multi-Max" with the "wood & drywall" cutting bit.

10

DREMEL

MULTI-MAX

11

12: Install & finish drywall.

F

JUNCTION BOX

OPENING EDGE

WOOD & DRYWALL

CUTTING BIT

13

GOOF PLATE

(ONLY USE IF JAGGED

PLASTER EDGE, PAINT

TO MATCH)

13: If necessary: Use the Goof Plate if the junction box

opening has a lot of imperfection/jagged edges. Install the

provided goof plate (paint to match prior) with the two

screws.

SCREW

13

PLASTER THE EDGE OF

THE JUNCTION BOX

2

Install the Fixture

G

MARK LOCATION

JUNCTION BOX

OPENING

CENTER LINE

NOTE: It is recommended more than one person to assist in

this installation.

NOTE: Fixture can be mounted in a horizontal or vertical

position.

NOTE: The junction box does not need to be in middle of the

channel (could be at either end) but needs to be aligned in the

center of the channel.

1: Center the channel to the junction box opening. Make

markings to each end of the channel and also make a center

line from end to end. Also keep in mind on

which side the wires are located to later install the

locking clip to the opposing side.

1

CHANNEL

WALL

H

EXISTING MARK

6 5/8" 7 5/8"

2

MOUNTING

CLIP

LOCKING

CLIP

NOTE: Locking clip must be installed in the opposite direction

of the fixture wire.

NOTE: The junction box could be offset, but needs to be

aligned in center.

2: From the two existing marks, make additional marks by

following drawing B (suggested locations with measurements

for the locking clip) to install the locking & mounting clips

properly. Mounting clips must be installed every 20" from

locking clip.

I

JUNCTION

BOX

20" TYPE

CENTER LINE

MARK

2

2-3/4"

WALL

3-3/4"

EXISTING MARK

NOTE: Steps 3 and 4 are for drywall mounting. Omit these steps

CEILING

if mounting the clips to a wood surface directly.

3: Tap the anchors onto the marked points up to the threaded

portion with a hammer.

3

ANCHOR

4

4: Screw in the threaded portion of the anchors with a Phillips

screwdriver.

ANCHOR MUST

BE FLUSH TO WALL

3

J

5: Secure the locking clip & mounting clip(s) to the marked

surface or anchors by passing the screws through the clip

holes followed by the washers into the marked points or

anchors.

WASHER

LOCKING CLIP

#6 SCREW

MARKED

POINT/ANCHOR

K

FIXTURE

BODY

5

ELECTRICAL BOX

LOCKING CLIP

MOUNTING

CLIP

6

JUNCTION BOX

5

WALL

6: Connect each power supply wire to a fixture body wire with

a wire nut.

7: Place the wires and wire nut connection inside the junction

box.

L

WALL

FIXTURE

BODY

8

LOCKING CLIP

LOCKING CLIP

WALL

8: Carefully snap fixture body onto the locking & mounting

clip(s) then slide into receiving bracket to lock in place.

Make sure not to nick the wires.

NOTE: If the receiving bracket interferes with the electrical box,

then relocate the bracket by loosening the set screws and make

the necessary adjustments.

JUNCTION BOX

8

RECEIVING BRACKET

8

MOUNTING CLIP

LOCKING CLIP

BACK VIEW

GENERAL WIRING DIAGRAM

TWIGGY S1

INPUT

120VAC

WHITE (NEUTRAL)

WHITE (NEUTRAL)

RED (24VAC)

LED TRANSFORMER

BLACK (HOT)

BLACK (HOT)

RED (24VAC)

YELLOW

ELECTRONIC LOW

VOLTAGE DIMMER

4