Polyvinylidene Fluoride

Automotive Applications

Automotive Applications

Kynar®, Kynar Flex® and Kynar 500® polyvinylidene fluoride (PVDF) resins exhibit high chemical and abrasion

resistance, excellent thermal stability, are unaffected by UV radiation, and are resistant to creep under

mechanical stress and load. Kynar® PVDF resins can be used for molded parts, for extruded profiles, or as

protective coatings.

WIRING HARNESSES

Kynar ® PVDF is a thermoplastic fluoropolymer with a high melting point and excellent

mechanical properties, including cold flow and abrasion resistance. Kynar ® resin also

has exceptional chemical resistance, is unaffected by UV radiation and is resistant to

electrical arc tracking. Because of its unique chemical structure, Kynar ® PVDF produces

almost no smoke when exposed directly to flame and does not propagate fire like

polyolefins and PVC. Kynar ® fluoropolymer can be extruded as primary insulation

for wiring or used as a protective cover. Its excellent chemical resistance and high

melting point make Kynar ® PVDF well suited for applications “under the hood.”

Kynar ® PVDF insulated wire is commonly cross-linked by electron-beam radiation

to further increase its toughness, cut-through resistance and continuous-service

use temperature. If specifically formulated and processed, the cross-linked polymer

makes light-weight, flame-retardant wire insulation that offers a temperature rating up

to 175°C (347°F). Kynar ® PVDF is resistant to most solvents, fuels, lubricants and other

hydrocarbon fluids. Cross-linked Kynar ® PVDF insulation is commonly used in automotive T4

wire (150°C, 3000 hrs). This Kynar ® PVDF-based insulation has become a construction standard for major original

equipment manufacturers (OEMs) in the world. Originally developed for aerospace and military requirements as

Mil Spec 81044 wire, cross-linked Kynar ® PVDF insulation is widely used where environmental conditions demand

high performance in commercial and military electronics, satellites, ships, trains, automobiles and in aerospace

applications.

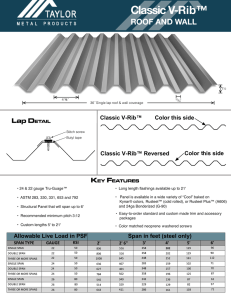

DECORATIVE FILMS

Kynar ® PVDF decorative films for automotive accessories

are both aesthetically pleasing and highly resistant to

corrosion and weathering. These films are used on a

variety of parts, such as rocker panels, roofing strips,

tail lamp housings, bodyside moldings, front and

rear bumpers, mirror housings and pillars. The films

can be processed with standard plastics equipment

and general polymer knowledge, thus requiring little

capital investment. Durable Kynar ® PVDF films are

applied to metal, PVC, PC, TPO and ABS, and can be

supplied with a heat-activated adhesive for bonding to

polyolefins. The films can be thermoformed to a shape,

trimmed and then placed into a mold. They can also

be laminated to flat stock sheets, then thermoformed

into the required shape. Films are also available with

pressure-sensitive adhesives for lamination under ambient

conditions. Kynar ® films are available in virtually any

color, including solid, metallic, pearlescent, chrome and

brushed aluminum.

Kynar® fluoropolymer films provide an attractive,

corrosion-resistant alternative to paint.

The strength, durability and versatility of Kynar® PVDF makes it suitable for automobile wiring harnesses,

fuel lines and fuel line coatings, decals, decorative films, coatings, electrochromic applications and plastic

optical fibers (POF). Conductive Kynar® 340 and Kynar® 3312C, can be injection molded and extruded and is

commonly used for handling aggressive, hot fuel mixtures.

FUEL LINES

Kynar ® polyvinylidene fluoride resin provides a barrier layer in low-permeation automotive fuel lines. The tubing

is a multilayer construction consisting of three or five layers in combination with Arkema’s Rilsan ® polyamide 11

or 12. The Kynar ® PVDF layer resists oxidative by-products and alcohol permeation in fuels and

helps carmakers meet strict EPA guidelines for hydrocarbon emissions. ADHEFLON ® tie resin

is used to bond the Kynar ® PVDF barrier to the RILSAN ® polyamide layers, resulting in

durable, flexible, low-permeation tubing.

In addition to being easily processed on conventional co-extrusion equipment, this

innovative fuel line construction exhibits excellent cold temperature impact strength

(-40°C), chemical resistance and dimensional stability. It is also compatible with a

wide range of fuel-alcohol blends and is available in a conductive version.

Kynar ® PVDF can also be used as a protective coating over carbon steel fuel and brake

fluid lines, and in under-chassis applications. Kynar ® PVDF can be applied in very thin

layers and maintains durability and corrosion resistance. It can also be applied as a liquid

coating, as a powder coating, or by cross-head extrusion.

Flex® 2850 PC FUNCTIONAL POWDER COATING

Kynar Flex ® 2850 PC functional powder coating is a tough and weather resistant coating. This fluoropolymer

coating resists gasoline, road salt, oils, lubricants, brake fluid, transmission fluid, windshield washer fluid,

coolants, and battery acid. Kynar Flex ® 2850 PC powder coating may be used to coat carbon steel parts as a

low-cost alternative to stainless steel. This powder coating is durable and may be applied in very thick coatings

up to 100 mils (2.5mm).

Kynar Flex ® resin is corrosion resistant and unaffected by UV radiation, making it especially suitable for exterior

applications. Excellent chemical, physical, and mechanical properties allow Kynar Flex ® powder coating to be

used in chemical processing applications such as tank linings, valve and flange coatings, and pipe coatings

(exterior or interior). The powder is currently supplied in a natural, unpigmented form, though pigmented versions

can be prepared. Kynar Flex ® 2850 PC is typically applied by electrostatic spray over Kynar Flex ® 2850 PC

Primer.

Kynar® ADX Resin

Rilsan® PA

Kynar ® ADX resin and other Arkema developed tie layers are

designed to bond to nylons, polyolefins and metals. Kynar ® ADX

melt processible resin bonds to various substrates, allowing cost

effecient engineering solutions and maintains nearly all of the

performance properties offered by Kynar ® PVDF. Kynar ® ADX

can be a protective barrier against fuel chemistry on the inside

or outside layer depending on the structure.

Kynar® ADX PVDF

Kynar® PVDF

Kynar® ADX PVDF

Rilsan® PA

For more information on Kynar® PVDF

Phone: 1-800-Kynar-50 (1- 800-596-2750)

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the product and of the information referred to

herein are beyond our control, ARKEMA expressly disclaims any and all liability as to any results obtained or arising from any use of the product or reliance on such information; NO WARRANTY OF FITNESS FOR ANY

PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN.

The information provided herein relates only to the specific product designated and may not be applicable when such product is used in combination with other materials or in any process. The user should thoroughly test any application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent and the user

is advised to take appropriate steps to be sure that any proposed use of the product will not result in patent infringement. See SDS for Health & Safety Considerations. Arkema has implemented a Medical Policy regarding the use of Arkema products in Medical Devices applications that are in contact with the body or circulating bodily fluids: (http://www.arkema.com/en/social-responsibility/responsible-product-management/

medical-device-policy/index.html).

Arkema has designated Medical grades to be used for such Medical Device applications. Products that have not been designated as Medical grades are not authorized by Arkema for use in Medical Device applications

that are in contact with the body or circulating bodily fluids. In addition, Arkema strictly prohibits the use of any Arkema products in Medical Device applications that are implanted in the body or in contact with bodily

fluids or tissues for greater than 30 days. The Arkema trademarks and the Arkema name shall not be used in conjunction with customers’ medical devices, including without limitation, permanent or temporary implantable

devices, and customers shall not represent to anyone else, that Arkema allows, endorses or permits the use of Arkema products in such medical devices. It is the sole responsibility of the manufacturer of the medical device

to determine the suitability (including biocompatibility) of all raw materials, products and components, including any medical grade Arkema products, in order to ensure that the final end-use product is safe for its end use;

performs or functions as intended; and complies with all applicable legal and regulatory requirements (FDA or other national drug agencies) It is the sole responsibility of the manufacturer of the medical device to conduct all

necessary tests and inspections and to evaluate the medical device under actual end-use requirements and to adequately advise and warn purchasers, users, and/or learned intermediaries (such as physicians) of pertinent

risks and fulfill any postmarket surveillance obligations. Any decision regarding the appropriateness of a particular Arkema material in a particular medical device should be based on the judgment of the manufacturer,

seller, the competent authority, and the treating physician.

© 2015 Arkema Inc. All rights reserved.

Kynar® and Kynar 500® are registered trademarks of Arkema Inc.

Adheflon® is a registered trademark of Arkema

kynar.com

Arkema Inc.

900 First Avenue

King of Prussia, PA 19406

USA

Tel.: +1 610-205-7000

Fax: +1 610-205-7497

arkema-inc.com

Arkema (China) Investment Co. Ltd.

Shanghai Branch

6/F, Block 1, Life Hub@Daning,

1868 Gonghexin Road,

Shanghai 200072, P.R. China.

Tel: +86 (21) 6147 6888 ext. 215

Fax: +86 (21) 6147 6746

arkema.com

Headquarters: Arkema France

420, rue d’Estienne d’Orves

92705 Colombes Cedex – France

Tel.: +33 (0)1 49 00 80 80

Fax: +33 (0)1 49 00 83 96

arkema.com

NA-Marcom - ADV # 2015-004 (BC 8-2015)

Arkema France - A French “société anonyme“, registered in the Nanterre (France) Trade and Companies Register under the number 319 632 790

Fax: 1-610-205-7497