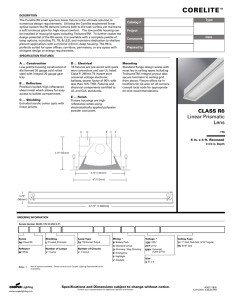

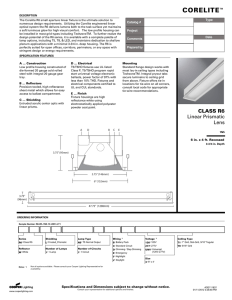

White Optics Overview

advertisement

White97™ Film WhiteOptics™ Metal whiteoptics ™ HIGH DIFFUSE REFLECTANCE FOR HIGH EFFICIENCY LIGHT FIXTURE DESIGN WhiteOptics™ Metal WhiteOptics™ develops and manufactures the patent-pending Coil metal composite Can be roll formed, progressive die stamped, punched Available in cold rolled steel and Aluminum WhiteOptics™ Reflector based on a highly reflective plastic substrate. White97™ Film Insertable reflector, 18 mils thick Available in rolls, custom width Die-cut and thermoformable Available with adhesive backing and release liner The reflector is unique in that it has extremely high diffuse reflectance and has greater than 97% reflectance across the visible spectrum, allowing light fixtures to be designed with more efficient light output while the highly diffuse nature of reflection allows light to be distributed evenly with a low-glare æsthetic. Features Benefits 97% Reflectance Increased light output, Energy efficiency Low glare, uniform reflectance Extended product life Low dirt depreciation (LLD) Easy to clean No color shift or iridescence Highly diffuse UV stable, does not yellow Antistatic Cleanable with common cleaners Color neutral Reflectance vs Incident Angle * Reflectance vs Wavelength 100% 100% 98% White97 ™ WhiteOptics Metal 96% 94% White97™ (film) WhiteOptics™ Metal 96% Reflectance Reflectance 98% 94% 95% Reflective PVD Aluminum 92% 90% 88% 92% High reflectance powder coat 86% 90% 0 20 40 Incident Angle 84% 60 *testingby LTI Optics LLC APPLICATIONS Reduces Lamp Image Reduces hotspots Fluorescent lighting LED lighting Lightboxes/Illuminated signage Daylighting Display backlighting Reduces glare Reflective tiles Diffuses indirect light efficiently 500 600 700 Wavelength (nm) HIGH DIFFUSE REFLECTANCE Mixes LED colors 400 2 whiteoptics ™ Energy Efficiency Why does 5 to 20% fixture efficiency improvement matter? Fixture Manufacturers Fixture efficiency is becoming a strong point of differentiation. Increases of even 2% are significant. High reflectance coil eliminates need for post-forming powder coat paint. Lighting Specifiers Willingness to pay premium for increased efficiency and white, diffuse distribution Building Owners 2-year payback in energy savings is a “no brainer” for investment … value to your customers LED Downlight PERFORMANCE TESTING Fixture: 4” LED Downlight, 14 watt Frosted diffusion lens Factory Reflector: Aluminum back-reflector Powder-coat white trim Third Party Testing Test: Integrating sphere 24C constant ambient Light Output with and without White97 13% efficiency increase over powder coat paint in Direct/Indirect fixture 700 650 with White97 WhiteOptics™ White97 ring inserted Lumens 600 550 500 450 with powder coat trim 400 350 0 15 30 45 60 Time (min) 75 90 16% Light output improvement High Efficiency Architectural Luminaire Fixture: 2X2 recessed with linear prismatic lens Lamps: 2, GE F14WT5-835 ECO Finish: High reflectance white powder coat, ribbed reflector Luminaire “as is” Efficiency = 64.6% Light Output Comparison using WhiteOptics™ Reflector 19.3% increase 15.5% increase 0.026 powder coat side reflectors Luminaire with reflector Efficiency = 77.5% 0.026 WhiteOptics Metal reflector on sides and ballast • Direct Indirect 2’X4’ • PHILIPS F54T5/841/HO/A LTO • 91% reflective powder coat *Lux measured at 5' in integrating cavity Fixture efficiency improvements using the reflector are highly dependant on fixture design, lamp and ballast selection. 3 whiteoptics ™ Why does 97% reflectance matter? Every time a light ray is reflected, a portion will be absorbed by the reflecting surface. Many current fixture designs involve multiple reflections to achieve good aesthetics for indirect lighting or tight cavities. Used in such situations, a high performance reflector will minimize absorbance from multiple bounces and maximize the usable exiting light. A small difference in reflectance can make big difference in lighting efficiency. Why does high diffuse reflection matter? For typical indoor lighting applications, many designers would like to present a uniform, soft lighting experience, avoiding unpleasant glare and uneven “hot spots.” This becomes even more critical with LED light fixtures where diffuse reflectance is needed to hide multiple lamp images and mix color. % Remaining light 100% 90% Reflectance 97% 80% 70% 95% 60% 92% 50% 85% 40% 1 2 3 4 5 # of bounces Enhanced Aluminum vs WhiteOptics VS Existing Commercial “Diffuse” Reflector DIFFUSE WhiteOptics™ White97 Diffused luminance of 40 degree incident light 5 Significantly more uniform look vs specular aluminum at all viewing angles whiteoptics ™ IMPROVING LIGHTING EFFICIENCY AND DESIGN www.whiteoptics.com PHONE: 302.476.2055 EMAIL: INQUIRIES@WHITEOPTICS.COM 18 SHEA WAY, SUITE 106 NEWARK, DELAWARE 19713