Datasheet - Mouser Electronics

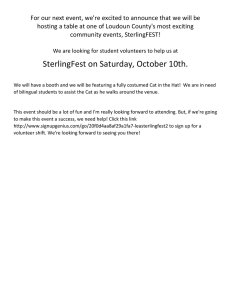

advertisement