Air and vapour control layer (AVCL) products

– Essential to durable, long term performance in buildings

Products can differ considerably, careful selection avoids unwelcome surprises

With the trend towards greater energy efficiency in buildings, as driven by Building Regulations,

air tightness plays a vital role in meeting these standards. While in the past little or no attention

was paid to airtightness, in recent years it has come become clear how much air tightness can

contribute to the energy balance of a building. Air tightness protects the insulation against air

movement and humidity, both of which have a negative impact on thermal performance, and it

has been demonstrated that poor airtightness can be responsible for up to 40% of heat loss from

buildings.1

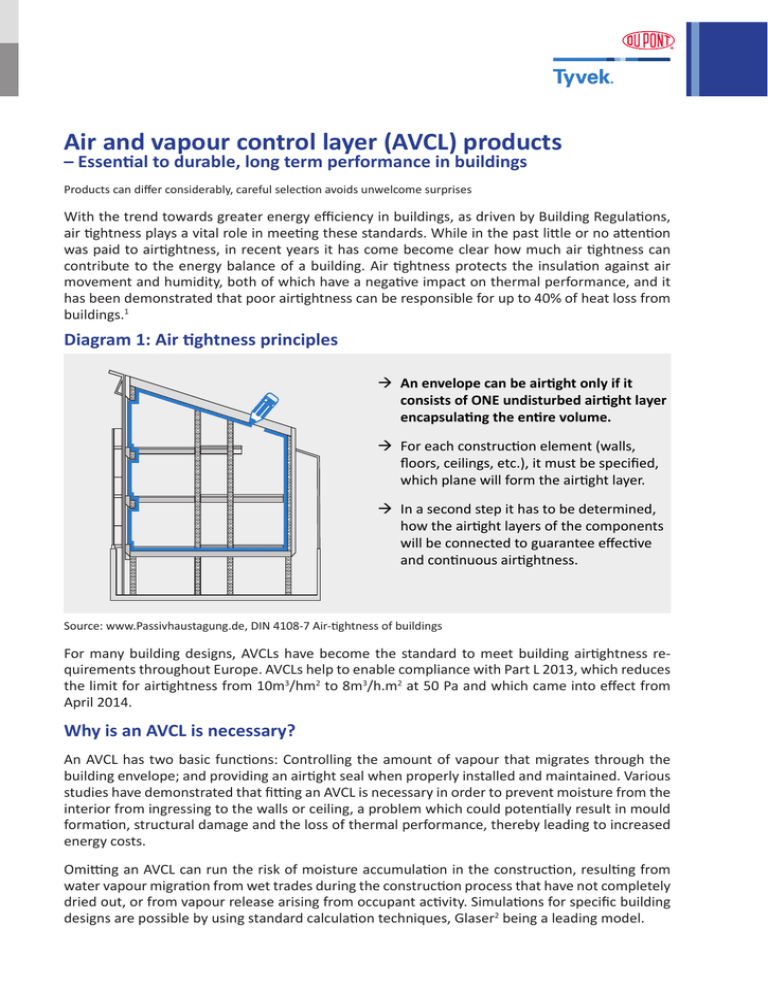

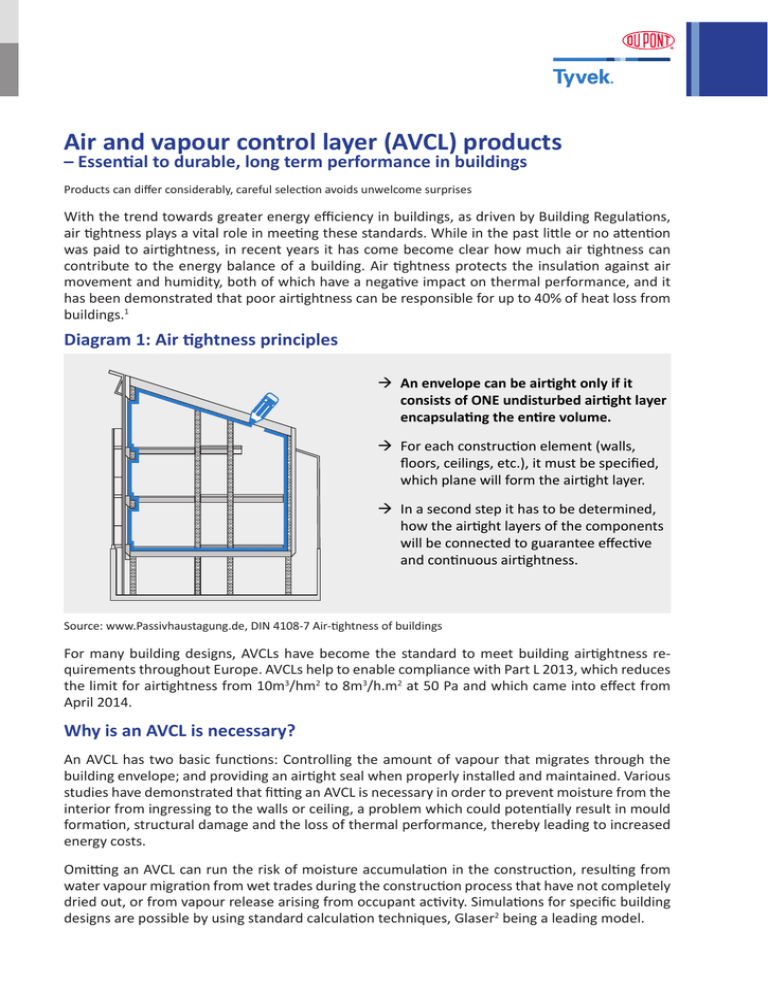

Diagram 1: Air tightness principles

An envelope can be airtight only if it

consists of ONE undisturbed airtight layer

encapsulating the entire volume.

For each construction element (walls,

floors, ceilings, etc.), it must be specified,

which plane will form the airtight layer.

In a second step it has to be determined,

how the airtight layers of the components

will be connected to guarantee effective

and continuous airtightness.

Source: www.Passivhaustagung.de, DIN 4108-7 Air-tightness of buildings

For many building designs, AVCLs have become the standard to meet building airtightness requirements throughout Europe. AVCLs help to enable compliance with Part L 2013, which reduces

the limit for airtightness from 10m3/hm2 to 8m3/h.m2 at 50 Pa and which came into effect from

April 2014.

Why is an AVCL is necessary?

An AVCL has two basic functions: Controlling the amount of vapour that migrates through the

building envelope; and providing an airtight seal when properly installed and maintained. Various

studies have demonstrated that fitting an AVCL is necessary in order to prevent moisture from the

interior from ingressing to the walls or ceiling, a problem which could potentially result in mould

formation, structural damage and the loss of thermal performance, thereby leading to increased

energy costs.

Omitting an AVCL can run the risk of moisture accumulation in the construction, resulting from

water vapour migration from wet trades during the construction process that have not completely

dried out, or from vapour release arising from occupant activity. Simulations for specific building

designs are possible by using standard calculation techniques, Glaser2 being a leading model.

Diagram 2 shows the potential risk of water vapour transmission into the construction if an interruption in the airtight layer occurs.

Diagram 2: Risk of airtightness interruption

10mm

S

-10°C; 80 %

20°C; 50 %

Construcon

layer thickness

100

10Pa

5Pa

3Pa

1Pa

50

0

0,5

1

1,5

Gap width S

2 [mm]

Water vapour transmission

Water vapour transmission

Pressure difference

150

0

20°C; 50 %

[g/mh]

200

[g/mh]

200

-10°C; 80 %

100mm

S

Pressure difference

150

100

50

0

0

0,5

1

1,5

Gap width S

2 [mm]

Source: Gerd Hauser, Anton Maas, Universität Kassel, Germany, published by DBZ (1992, He 1, page 97-100)

Effective sealing of the building envelope requires both good workmanship and the right choice

of AVCL. Water vapour, which can find many ways into the construction, is difficult to control and

could result in risks to both the building and its occupants.

Table 1: Examples of moisture creation in buildings

MOISTURE EXAMPLES3

Water used in construction

Plaster, concrete, masonry require large volumes of water

Precipitation during construction

Rainwater

Snow

Installation quality

Special attention shall be given to penetrations, as for example:

• Loft hatches

• Windows

• Doors

• Partition walls

• Joints

• Etc.

Building in use

Building occupancy generates moisture

People

• Asleep

40g/h.person

• Seated, office work

70g/h.person

• Standing, housework

90g/h.person

• Moderate manual work 300g/h.person

Effective drying out of a building can sometimes be difficult to achieve, especially as the moisture

content of some construction materials is not always obvious. Once the building is in use, diffusion

and convection are the typical methods of moisture migration into the structure. Diffusion takes

place via pressure differences between the interior and the exterior. During winter, diffusion takes

place from the building interior towards the exterior whereas, during the summer, the vapour

drive is from outside to in. How much vapour can pass through the airtightness layer depends on

its resistance to diffusion (MNs/g or sd-value expressed in m). Convection takes place by air flow,

for example through poor joints. A high degree of convective vapour can result in high moisture

accumulation in the insulation layer resulting potentially in a considerable risk of condensation.

Vapour diffusion can be calculated based on the likely environmental conditions and vapour resistance of the airtightness layer. The extent of convective vapour drive, together with built-in moisture, however, is difficult to assess, but can be effectively limited through high quality installation.

AVCLs can differ significantly

Any AVCL should be airtight by definition. The degree of vapour diffusion, however, depends on

the material composition. It can be distinguished by four different product technologies: Monolithic (solid) Polyethylene membranes, typically with high and fixed sd-values; Composite AVCL

membranes with low to medium fixed sd-values; Reflective AVCLs; and AVCLs with variable sd-values by means of humidity concentration.

Table 2: AVCL product technologies

POLYETHYLENE

MEMBRANES

COMPOSITE AVCL

MEMBRANES

VARIABLE AVCL

MEMBRANES

REFLECTIVE AVCLS

Sd-value (m)

>= 20m up to 100Vapour

150m and above

resistance

expressed as

equivalent air

layer thickness

From 2m up to 25m

0.3to 5m*

0.25to 10m**

0.05 to >30m***

The lower

the low value and the

higher the high value

the better

the performance.

>100m for composites

with metallised

surface

>500m for composites

with aluminum foil

Vapour

resistance

(MNs/g)

>=100MNs/g up to

500-750MNs/g and

above

10MNs/g up to

125MNs/g

1.5 to25MNs/g*

1.25 to 50MNs/g**

0.25 to

>150MNs/g***

>500MNs/g for

composites with

metallised surface

>2500MNs/g for

composites with

aluminum foil

Product

technology

examples

Standard Polyethylene Coated spunbond

membranes

polyprop, thermally

bonded polyprop or

polyester nonwovens

Spunbond polyprop/

polyamide laminate*

Spunbond polyprop/

Polyethylene

copolymer**

DuPont™ Airguard®

technology***

Polyethylene,

Polypropylene or

polyester metallised

foils

Spunpond reinforced

layers of aluminum foil

*Isover Vario KM

Duplex

**Proclima Intello®

***DuPont™

Airguard® Smart

Proctor Reflectatherm

Plus

Protect VC Foil Ultra

DuPont™ Airguard®

Reflective

Product

examples

Siga Majpell 5

DAFA DiFoil™

DuPont™ Airguard®

Control

Under normal room humidity levels (40-70%), the water vapour resistance of a variable AVCL will

not only block moisture transmission during the winter months, but also enables drying out of

unwanted humidity during the summer months. In general, the higher the sd-value, the higher

the moisture resistance during winter conditions, but conversely, the lower the drying out potential during summer weather. High vapour tightness reduces the capacity of a membrane to allow

moisture trapped within the construction to dry out easily.

Many roof and wall assemblies are only durable if they can dry-out to the interior side as well4

In many cases moisture damage can be attributed to the fact that a vapour barrier is practically

impermeable in both directions, i.e. it does not permit any drying out.5

Polyethylene membranes are typically offered with sd-values ranging from >=20m up to 100150m (>=100MNs/g up to 500-750 MNs/g and above). Due to their high vapour resistance, they

can quickly become a moisture trap, as drying out of the construction toward the room side is

rarely possible.

AVCLs with a variable sd-value offer excellent protection against condensation risk and potential

damage due to the adaptation of their water vapour resistance by means of humidity concentration. During the winter the sd-value of the membrane increases as the relative humidity within

the building interior increases, thus reducing moisture transfer towards the insulation when vapour control is needed most. The sd-value decreases as the relative humidity drops during the

summer months, allowing the construction to dry out towards the interior.

The broader the sd-value range of a variable AVCL, the higher the humidity protection. The lower

sd-value represents the drying out potential of a variable AVCL during summer months. A difference of 0.2-0.25m may sound small, but this can have a big impact if humidity is trapped within

the construction. The upper sd-value represents the water vapour transmission during winter

months, the higher the value the less moisture will penetrate from the room side towards the

insulation.

DuPont has developed a special laminate technology enabling a lower sd-value of 0.05m

(=25MNs/g) and an upper sd-value of 30m (=150MNs/g) for its adaptable AVCL DuPont™ Airguard® Smart. DuPont™ Airguard® Smart provides outstanding humidity protection compared

to other AVCLs, and helps to accelerate the drying out process of wet construction materials. Its

capacity is approximately 1400-2000 times greater than Polyethylene membranes with an sd-value of 75-100m (375-500 MNs/g) and 5-6 times greater than comparable AVCLs with a variable

sd-value.

Diagram 3: AVCLs with fixed sd-value in comparison

Drying out potenal of AVCLs by sd-value

during summer month (g/m2 24h)

Source: DuPont, moisture diffusion at 1000Pa, calculated according to DIN4108-3

(g/m2 24h)

3.20

0.70

DuPont™ Airguard®

Control, 5m

DuPont™ Airguard®

sd23, 23m

0.16

0.23

Polyethylene

membrane, 100m

Polyethylene

membrane, 70m

0.01

DuPont™ Airguard®

Reflecve, 2000m

Diagram 4: AVCLs with variable sd-value in comparison

Drying out potenal of AVCLs by sd-value

during summer month (g/m2 24h)

Source: DuPont, moisture diffusion at 1000Pa, calculated according to DIN4108-3

320.00

(g/m2 24h)

64.00

DuPont™ Airguard® Smart, 0.05m > 30m

Spunbond polyprop/Polyethylene

copolymer, 0.25m - 10m

53.33

Spunbond polyprop/Polyamid laminate,

0.3m < 5m

Diagram 5: AVCL performance in flat roof construction with plywood

0.021m and mineral wool, 0.35m thick layer, climate London

Total water content kg/m2

Source: DuPont, calculated by WUFI soware program

Plywood water content kg/m2

Source: DuPont, calculated by WUFI soware program

4.00

200

3.50

180

160

3.00

140

2.50

120

2.00

100

1.50

80

60

1.00

40

0.50

20

0.00

1-Jul-12

0

1-Jul-13

1-Jul-14

1-Jul-15

1-Jul-16

1-Jul-17

Polyethylene membrane, sd = 20m

Spunbond polyprop/polyamid laminate, sd = 0.3m < 5m

Spunbond polyprop/Polyethylene copolymer, sd = 0.25m - 10m

DuPont™ AirGuard® Smart, sd = 0.05m > 30m

1-Jul-12

1-Jul-13

1-Jul-14

1-Jul-15

1-Jul-16

1-Jul-17

Polyethylene membrane, sd = 20m

Spunbond polyprop/polyamid laminate, sd = 0.3m < 5m

Spunbond polyprop/Polyethylene copolymer, sd = 0.25m - 10m

DuPont™ AirGuard® Smart, sd = 0.05m > 30m

Diagram 6: Water vapour transmission risk of AVCLs

with adaptable sd-value

Water vapour transmission during winter months (g/m2 24h)

Source: Calculated by DuPont, according to EN 1931

(g/m2 24h)

7.8

3.6

1.1

DuPont™ Airguard® Smart, 0.05m > 30m

Spunbond polyprop/Polyethylene

copolymer, 0.25m - 10m

Spunbond polyprop/Polyamid laminate,

0.3m < 5m

For rooms with extreme humidity levels (>70%), AVCLs with high sd-values are recommended

for installation after the drying out of construction materials. Special care should be given to the

installation method to avoid moisture being trapped in the construction, since the high sd-value

does not allow for drying out during summer months.

DuPont Building Innovations offers a range of AVCL products covering a broad range of applications: DuPont™ Airguard® Control, 25MNs/g, which is suitable for roofs, walls and floors with a

diffusion open outer layer. This is a mechanically strong membrane with less risk of damage during

installation, it is also translucent making it ideal for air-blown insulation applications and can be

easily located for fixing; DuPont™ Airguard® Reflective, 10 000MNs/g: This is a 100% air and vapour tight AVCL. It has a metallised surface with a very low emissivity which significantly improves

its thermal insulation performance, providing an additional 0.58-0.80 m2K/W to the R-value.6 It is

ideal for applications with high humidity that require high vapour resistance; DuPont™ Airguard®

Smart is an exceptional membrane with highly adaptable vapour resistance. It helps to protect

against structural mould damage due to its high drying out potential, furthermore its flexibility

combined with excellent robustness, makes it easy to install and handle.

The selection of an AVCL depends on a number of criteria, as for example room humidity level, the

external sd-value or the diffusion openness of the insulation. DuPont has developed a product selector to help choose from its range of AVCL products. The technical hotline team is also available

to assist you with further information on application specific questions.

Table 3: DuPont Airguard® AVCL product selector

DUPONT™

AIRGUARD®

CONTROL

Normal room humidity, ~40%-70%

High room humidity, >70%

Roof type

Flat

Pitched > 10°

Roof Covering

Metal

Tiles

Single ply/bitumen

Wall

Floor

External Sd-value

Low

High

Insulation

Diffusion open (μ≤10) eg.:

Stone wool, glass wool, wood

fibre, cellulose fibre, etc.

Diffusion closed (μ>10) eg.:

EPS, XPS, PUR/PIR, phenolic

foam, foam glass

Legend: green: recommended, red: not recommended, yellow: case specific

DUPONT™

AIRGUARD®

SD 23

DUPONT™

AIRGUARD®

REFLECTIVE

DUPONT™

AIRGUARD®

SMART

Picture 1: DuPont™ Airguard® Smart

Picture 2: DuPont™ Airguard® Control

Authors:

Nick Williams, Technical Manager UK & Ireland, Du Pont (U.K.) Limited

Norbert Frey, Technical Specialist, DuPont de Nemours S.àr.l., Luxembourg

Tobias Mehlsam, New Business Development Manager Western Europe DuPont de Nemours

(Deutschland) GmbH

Ulrike Koster, Marketing Specialist, DuPont de Nemours S.àr.l., Luxembourg

L-11380 - Copyright © 2014 DuPont. All rights reserved. The DuPont Oval Logo, DuPont™, The miracles of science™, Tyvek®, AirGuard® and all products denoted with ® or ™ are

registered trademarks or trademarks of E. I. du Pont de Nemours and Company or its affiliates. 04/2014

NHBC Foundation, Michael Jaggs and Chris Scivyer, BRE: A practical guide to building airtight dwellings, June 2009

1

DIN 4108-3

2

BSI Starndards Publication: BS 5250:2011 – Code of practice for control of condensation in buildings

3

Fraunhofer Institut für Bauphysik, H. B. Künzel: Adapted vapour control for durable building enclosures, April 2005

4

Fraunhofer Institut für Bauphysik, H. B. Künzel: Adapted vapour control for durable building enclosures, April 2005

5

BBA certificate: Where this faces into an unventilated cavity this corresponds to the following cavity thermal

resistance values. Walls, a cavity > 20 mm thick: 0.67 m2·K/W, Floors, a cavity > 17 mm thick: 0.58 m2·K·W,

Floors, a cavity > 25 mm thick: 0.80 m2·K·W

6