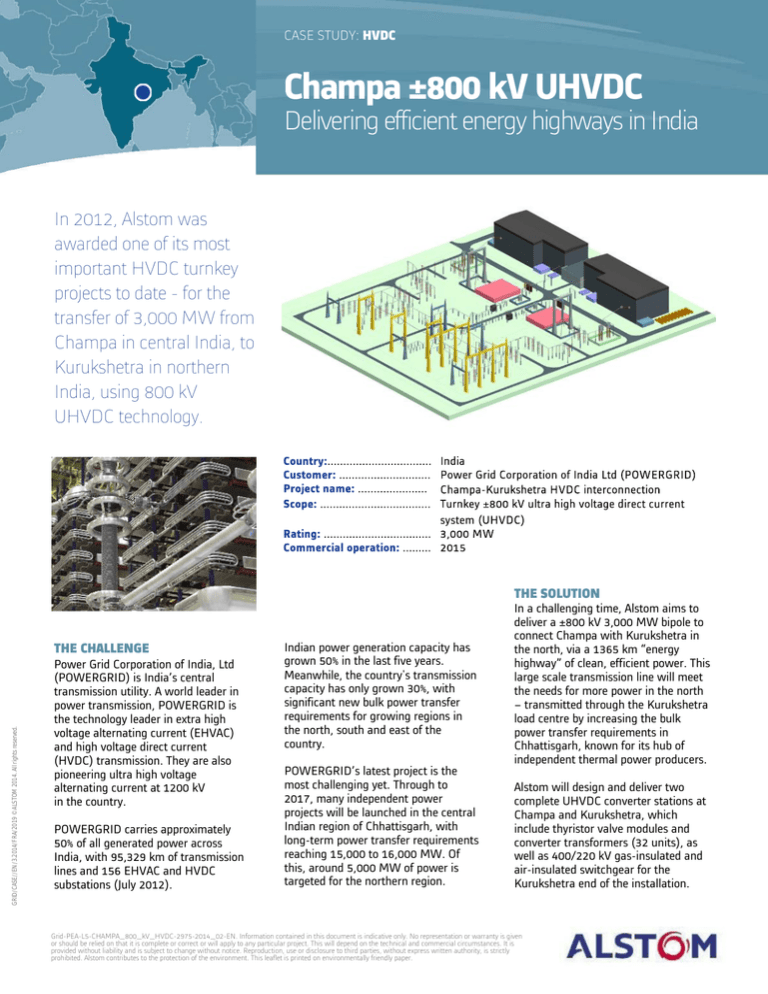

CASE STUDY: HVDC

Champa ±800 kV UHVDC

Delivering efficient energy highways in India

In 2012, Alstom was

awarded one of its most

important HVDC turnkey

projects to date - for the

transfer of 3,000 MW from

Champa in central India, to

Kurukshetra in northern

India, using 800 kV

UHVDC technology.

THE SOLUTION

GRID/CASE//EN/3.2014/FRA/2019 © ALSTOM 2014. All rights reserved.

THE CHALLENGE

Power Grid Corporation of India, Ltd

(POWERGRID) is India’s central

transmission utility. A world leader in

power transmission, POWERGRID is

the technology leader in extra high

voltage alternating current (EHVAC)

and high voltage direct current

(HVDC) transmission. They are also

pioneering ultra high voltage

alternating current at 1200 kV

in the country.

POWERGRID carries approximately

50% of all generated power across

India, with 95,329 km of transmission

lines and 156 EHVAC and HVDC

substations (July 2012).

Indian power generation capacity has

grown 50% in the last five years.

Meanwhile, the country's transmission

capacity has only grown 30%, with

significant new bulk power transfer

requirements for growing regions in

the north, south and east of the

country.

POWERGRID’s latest project is the

most challenging yet. Through to

2017, many independent power

projects will be launched in the central

Indian region of Chhattisgarh, with

long-term power transfer requirements

reaching 15,000 to 16,000 MW. Of

this, around 5,000 MW of power is

targeted for the northern region.

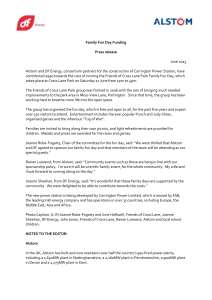

In a challenging time, Alstom aims to

deliver a ±800 kV 3,000 MW bipole to

connect Champa with Kurukshetra in

the north, via a 1365 km “energy

highway” of clean, efficient power. This

large scale transmission line will meet

the needs for more power in the north

– transmitted through the Kurukshetra

load centre by increasing the bulk

power transfer requirements in

Chhattisgarh, known for its hub of

independent thermal power producers.

Alstom will design and deliver two

complete UHVDC converter stations at

Champa and Kurukshetra, which

include thyristor valve modules and

converter transformers (32 units), as

well as 400/220 kV gas-insulated and

air-insulated switchgear for the

Kurukshetra end of the installation.

Grid-PEA-L5-CHAMPA_800_kV_HVDC-2975-2014_02-EN. Information contained in this document is indicative only. No representation or warranty is given

or should be relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is strictly

prohibited. Alstom contributes to the protection of the environment. This leaflet is printed on environmentally friendly paper.

CASE STUDY: HVDC

CHAMPA 800 kV UHVDC

THE SOLUTION - Continued

The scope of supply also includes

substation automation digital control

systems, telecommunications

equipment and a SCADA system.

The aim is to improve the quality and

increase the capacity of the Indian

transmission grid using DC technology,

which is inherently more efficient with

fewer losses. Meeting these

requirements will be complex, given the

highly customised nature of HVDC

projects in general and the challenging

time constraints.

Over the last 15 years, Alstom and

POWERGRID have worked together on

three significant HVDC projects:

Chandrapur (1000 MW

interconnection between western and

southern networks), Visakhapatnam

(500 MW interconnection between

eastern and southern networks) and

Sasaram (500 MW interconnection

between eastern and northern

networks).

HISTORY

Alstom has played a key role in rebuilding and improving existing AC

networks, supporting India’s mission to

move to ever higher voltages. Since

delivering the country’s first 765 kV

extra high voltage (EHV) substation to

the SIPAT power plant in 2007, Alstom

has been selected for more than half of

the 40 planned EHV substations all

over the country.

However, with such large power

transmission requirements, AC is in

many cases no longer the most efficient

or practical option. India has thus taken

significant steps in pioneering HVDC

technology to transport bulk power

over long distances.

POWERGRID is one of the most

knowledgeable utilities in the world

with regards to HVDC transmission

systems and Supergrids.

“We are delighted to work

together with POWERGRID on

this new large scale HVDC

installation, having already

commissioned three back-to-back

HVDC projects in the past,”

said Patrick Plas, Senior Vice

President, Alstom Grid.

“The Supergrid HVDC market is

enjoying one of the highest

growth rates in the energy

transmission sector. The award

of the Champa-Kurukshetra

800 kV HVDC project confirms

Alstom as a major player in the

Supergrid market.”

GRID/CASE//EN/3.2014/FRA/2019 © ALSTOM 2014. All rights reserved.

ALSTOM's SCOPE OF SUPPLY

THE TECHNOLOGY

Power electronics solutions – notably

HVDC – are key elements to enabling

utilities around the world to take

control of their networks and improve

their transmission systems. Strong,

reliable networks rely on power

electronics. Line commutated converter

(LCC) technology is the backbone of

meshed AC-DC grids, or “Supergrids”

and can be used for:

• Back-to-back interconnections up to

500 kV

• Point-to-point long distance transmission (energy highways) up to

800 kV

Regardless of the source (hydro,

thermal or nuclear), UHVDC provides

efficient and cost-effective transmission

of very high levels of remotely generated power over very long distances to

the load centres. Moreover, 800 kV

UHVDC requires four times less “rightof-way” land when compared to

UHVAC transmission, the typical

transmission system in India, reducing

both the ecological and visual impacts.

HVDC solutions are more economical

than HVAC for schemes with transmission distances longer than 700 km.

The technology is asynchronous,

meaning that it can adapt to any rated

voltage or frequency and can be used to

assist the AC network at each end of

the link.

Full turnkey with civil works including:

Thyristor valve modules, control and protection systems

800 kV DC switchgear (switches, isolators, surge arrestors, instrument

transformers)

32 converter transformers

For more information

please contact Alstom Grid:

Alstom Grid Worldwide Contact Centre

www.alstom.com/grid/contactcentre/

400/220 kV gas-insulated and air-insulated switchgear for the Kurukshetra

converter station

Phone: +44 (0) 1785 250 070

Substation automation digital control systems

Telecommunications equipment, SCADA

Grid-PEA-L5-CHAMPA_800_kV_HVDC-2975-2014_02-EN. Information contained in this document is indicative only. No representation or warranty is given

or should be relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is strictly

prohibited. Alstom contributes to the protection of the environment. This leaflet is printed on environmentally friendly paper.

Visit us online: www.alstom.com