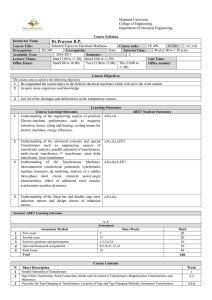

MIDEL eN Natural Ester Transformer Fluid

advertisement

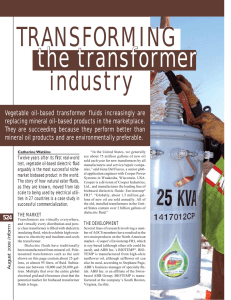

MIDEL eN Natural Ester Transformer Fluid Product Guide Experience: The Difference MIDEL eN – Reducing Risk MIDEL eN MIDEL eN is our natural ester-based dielectric fluid which is suitable for sealed electrical equipment or equipment fitted with a bagged conservator. In particular it is ideal for installations in temperate locations or indoors. Natural esters or vegetable oils as they can also be known, are a group of materials which are directly derived from renewable plant sources. In the case of MIDEL eN the source material is rapeseed oil. Since their introduction in the 1990’s natural esters have primarily been used in distribution transformers. Nowadays natural esters are successfully being applied to large power transformers. MIDEL eN is an excellent dielectric fluid because it has a high fire point making it far more fire safe than mineral oil. It is also one of the most environmentally friendly dielectric fluids available. Not only is MIDEL eN manufactured using renewable vegetable oil, it is also non-toxic and readily biodegradable. In addition, MIDEL eN offers superior moisture tolerance and it has the potential to increase the lifetime of cellulose based solid insulation, which in turn can extend the life of the transformer. M&I Materials Ltd Our multilingual sales and customer service personnel and internationally recognised team of highly experienced engineers and chemists are always ready to offer their expert guidance and ongoing support. MIDEL eN Experience: Safety M&I Materials Ltd is the driving force behind the success of Midel fluids. Our Midel team specialise in transformer fluids and have many years experience in manufacturing synthetic and natural esters. Our Midel plant is dedicated exclusively to the production of esters for the electrical industry and we are very proud of our reputation. Our experienced engineers and chemists have built close working relationships with the major transformer manufacturers. They are also respected leaders of CIGRÉ and IEC working groups and regularly undertake extensive projects with prestigious research organisations. We believe our breadth of experience allows us to provide an unrivalled standard of expert technical guidance. M&I Materials Experience: The Difference Midel is the world’s leading brand of ester-based dielectric fluids primarily because of its excellent track record and ability to minimise risk. However, we also maintain this position because of our commitment to supporting our customers both technically and commercially. Distribution Increased Fire Safety 100% fire safety record High fire point (>300°C) K-class classification Suitable for indoor and outdoor installation FM Global® and UL® listed transformer fluid Established resistance to ignition Reduced protection costs Potentially lower insurance premiums High Performance and Low Maintenance Suitable for use in hybrid and aramid designs Allows for compact transformer design Excellent lubrication properties Self healing Lower no-load losses than cast resin transformers No corrosive sulphur No sludge formation Greater Environmental Protection Renewable vegetable oil Lower carbon footprint than mineral oil Readily / fully biodegradable Non-water hazardous Non-toxic and not harmful to aquatic life Will not evaporate into the environment Not detrimental to degradation of activated sludge in biological treatment plants RoHS compliant Power Superior Moisture Tolerance Absorbs large amounts of moisture with no reduction of breakdown voltage (up to 300ppm) Allows moisture to migrate from cellulose into the fluid Very high saturation limit making precipitation of free water virtually impossible Reduces the risk of bubble formation Asset Life Extension Slower rate of cellulose ageing than mineral oil Longer lifetime at standard temperatures Option to run at a higher temperature, for a standard lifetime Provides a higher power output, without the need for high temperature insulation Has the potential to offer smaller, lighter transformers with cellulose Today in modern distribution and transmission networks there is a focus on total life management. The new ISO 55 000 suite of standards for asset management brings with it a need to get the most from equipment. As part of a whole life strategy for transformers MIDEL eN offers an effective solution to reduce installation costs due to its fire and environmental properties. It also offers extended lifetime for transformers, which can substantially reduce overall lifetime costs. Alternatively there is the potential to produce smaller transformers which use far less raw materials than mineral oil. MIDEL eN is manufactured using renewable vegetable oil and is readily biodegradable making it the most environmentally friendly dielectric fluid on the market. www.midel.com Distribution Power Comparison of Transformer Fluids Fire Safety Class MIDEL eN Mineral Oil Silicone Liquid K2 O K3 X X Readily / Fully Biodegradable Water Hazard Classification nwg 1 1 Breakdown Voltage kV >75 >70 50 1100 55 220 37 12 39 0.92 0.88 0.96 0.00074 0.00075 0.00104 Permittivity 3.1 2.2 2.7 Pour Point °C -31 <-50 -50 Good Poor Excellent Moisture Saturation ppm at Amb Temperature Kinematic Viscosity at 40°C Density at 20°C Expansion Coefficient High Temperature Data quoted above are typical values, may be altered without notice and do not constitute a specification Detailed technical data is available on request, via scanning the QR code or from our website Contact our team today to discuss your project requirements Tel: +44 (0)161 864 5422 E-mail: midelsales@mimaterials.com www.midel.com MIDEL eN - Asset Life Extension Midel fluids can have a beneficial influence on paper ageing, this gives As part of the new standards a unit life vs. temperature chart has been produced for both kraft paper and thermally upgraded paper. This summarises the findings of a large number of studies conducted with natural ester fluids and indicates that at an operating temperature of 95°C the lifetime for kraft paper could be as much as 5 times longer than in mineral oil. Alternatively to get more power from the transformer, without additional loss of life, the ester unit life chart indicates that kraft paper can be run 16°C hotter. Longer life for cellulose insulation at standard temperatures The option to run transformers at a higher temperature for standard lifetime The benefit of a higher power output or a smaller footprint by running transformers hotter. Researchers around the world have determined that immersion in natural ester based transformer fluids offers longer lifetime for cellulose insulating paper than mineral oil. Following years of painstaking investigations this research has been summarised within IEC 60076-14:20131 and IEEE C57 154:20122, with information provided on the potential life extension. In the case of thermally upgraded paper the lifetime extension can be as much as 7 times, or alternatively the running temperature can be increased by 20°C if ester is used in place of mineral oil. Whichever type of insulating paper is chosen this gives asset managers more flexibility and could substantially cut lifetime costs. 1. IEC 60076-14 ed1.0 (September 2013) Power transformers - Part 14: Liquid-immersed power transformers using high-temperature insulation materials 2. IEEE C57.154 (October 2012) Standard for the Design, Testing, and Application of Liquid-Immersed Distribution, Power,and Regulating Transformer Image Page 5 © Siemens AG UL® is a registered trademark of Underwriters Laboratories FM ® is a registered trademark of Factory Mutual Insurance Company Any recommendation or suggestion relating to the use, storage, handling or properties of the products supplied by M&I Materials Ltd either in sales and technical literature or in response to a specific enquiry or otherwise is given in good faith, but it is for the customer to satisfy itself of the suitability of the product for its own particular purposes. © M&I Materials Ltd. October 2014 Products of M&I Materials Ltd ® M&I Materials Ltd Hibernia Way Trafford Park Manchester M32 0ZD United Kingdom Tungsten alloys Silicon carbide surge protection T: +44 (0) 161 864 5422 F: +44 (0) 161 864 5444 E: midelsales@mimaterials.com W: www.mimaterials.com www.wolfmet.com www.metrosil.com Vacuum sealants and lubricants www.midel.com www.apiezon.com